Information for customers and staff “Biomass – energy for ...1991 First mobile chipper HEM 30 D....

Transcript of Information for customers and staff “Biomass – energy for ...1991 First mobile chipper HEM 30 D....

Special edition for Open Day / LIGNA

made in Germany

Energy generation from residual forestry wood in Finland

The 2000th JENZ fragmentiser leaving Wegholm

JENZ-Woodcracker

Staff and machines

A K T U E L L

Nr.26, Mai 2007

Information for customers and staff

Technik zur Aufbereitung von Biomasse

“Biomass – energy for the

future”

Layout-16seiter_englisch 09.05.2007 16:29 Uhr Seite 1

Edit

or:

JEN

Z G

mb

H

• R

esp

on

sib

le: U

we

Hem

pen

-Her

mei

er •

Pr

int:

OD

F-D

ruck

, Min

den

The future needs originsThe story of JENZ

1921 Company foundation by master blacksmith Hans Jenz

1930 Village blacksmith works, construction of coaches, trailers and small farming equipment

1947 First gear-rack tipping lorry for the farming industry, prize-awarded by the DLG (German Farmers Association)

1955 Wilhelm Hermeier marries Resi Jenz and enters the company. First change in generation

1955 Patented over-running brake for trucks. The brake is still produced today in similar form.

1957 Production of manure spreaders, trailers, tipping lorries, truck mountings and truck trailers.

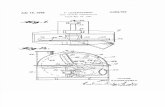

1959 First stationary JENZ wood chipper for a veneer company

1968 Stationary JENZ chipper are running in many veneer companies and sawmills

1976 Licence agreement with the Finnish Algol company for the production and promotion of JENZ chippers in Finland

1977 First mobile JENZ Chipper in cooperation with Algol. Powered by a 220 kW Scania diesel engine

1986 First JENZ waste grinder for composting green waste

1989 First JENZ waste grinder AZ 50. With more than 300 hp the largest waste grinder on the market at that time.

1991 First mobile chipper HEM 30 D. At that time strongest mobile chipper from German production

1992 First mobile JENZ chipper HEM 25 Z. First tractor-driven mobile chipper in Germany, which is loaded by its own loading crane.

1997 New waste grinder AZ 55 replaces the AZ 50.

1999 With the HEM 700 the first mobile chipper of the new generation is presented.

2001 On the Agritechnica JENZ presents the first HEM 560 Z. The machine becomes the most successful mobile chipper so far.

2003 The AZ 660 is presented, the first waste grinder of the new generation.

2005 With the HEM 1000 JENZ produces the largest mobile chipper in Europe at that time.

2006 AZ 960 with 1000 mm feed opening is presented

Layout-16seiter_englisch 09.05.2007 16:29 Uhr Seite 2

Uwe Hempen-Hermeier, Managing Partner

Dear reader,

according to our point ofview, the world changedon the 2nd of February.This was the day on whichthe IPCC (Intergovern-mental Panel on ClimateChange), a committee of500 scientists which isactive on behalf of theUnited Nations, reportedthat it is 90% certain thatthe climatic warming ofthe earth is due to theCO2 emissions caused bymankind. Jacques Chirac, the formerFrench Prime Minister,then commented: "Thetime for half measures haspassed, the day on whichthe climate change will getout of control is gettingnearer." As a result of thisthe EU, under the presi-dency of Angela Merkal,resolved to reduce theCO2 emissions by 20%and to simultaneouslyincrease the proportion of

renewable energies to atleast 20%. The same linewill be followed by theGerman presidency at theG8 summit as well.

Biomasses have an increa-singly important functionwithin the renewable ener-gy concept. Biomasses arestored energy, and in com-parison tosun andwind theyare alwaysavailableand canthereforebe used tocover thebaseloadof energyrequirements.

We have been convincedof the significance bio-mass usage for a longtime. This is not the onlyreason that we decided tocarry out our first OpenDay using the slogan of"Biomass - energy for thefuture". We wanted to

make it quite clear thatthere is no place for "it isthe end of the world"fears. We need new con-cepts for new types ofenergy production, other-wise it will not be possiblefor 9 billion people to liveon this planet in 2050. Wewant to play a part in this

with ourhigh-powe-red, inno-vative ma-chines.

We extenda heartywelcometo our cus-t o m e r s ,employe-

es and sup- pliers to our"open day". We have setup almost our whole rangeof mobile waste fragmenti-sers and mobile chippersfor you on our works pre-mises on Wegholmer Stra-ße. The presentation ofour new HEM 1000 XL anda JENZ chipper truck based

on the MAN chassis arevery likely to be the out-standing points of the day.We will, of course, also bedemonstrating all ourother machines in use.Employees will provideyou with information andare available for discussi-ons and to talk shop. Theworks are also open, soyou can get an impressionof our production conditi-ons. Our Open Day isintended to be a pleasantmeeting of specialists froma future-oriented sector.Do come along, we're loo-king forward to meetingyou.

and

ny.

ruck

anies

e lar

bile

obile ane.

erati

he ar.

w

per in

Layout-16seiter_englisch 09.05.2007 16:29 Uhr Seite 3

Mobile chipping machines aredriven using the towing trac-tor power takeoff shaft, orusing a built-on diesel motor.For a while now we have beenreceiving inquiries about fit-ting a chipper to a lorry andusing the lorry motor to drive it.

The reasons for this are:• better utilisation of the lorrymotor because only onemotor is required• higher performance becausethe lorry motor is strongerthan a tractor motor• increased mobility becausethe lorry can travel at 50 mphon the motorway in contrastto a tractor.

Normally, however, lorries arenot fitted out for such tasks. Asuitable side drive, whichtransfers the motor poweronto the chipper, cannot besupplied by the manufactu-rers. This means that up tonow customers have had toconvert the vehicle themsel-ves. This meant that the cus-tomer had to negotiate withthe lorry manufacturer, thecrane manufacturer and thechipper producer. In manycases, a fourth party wasinvolved in fitting the unit.JENZ previously occupied thisposition, but is now able tooffer a complete solution fromunder one roof. The first chip-per truck was presented onOpen Day. It consists of thefollowing main components:- MAN HGV, Type TGA 28.4806X4-4 BL, performance 353kW (480PS), Wheelbase3600mm between 1st and 2ndaxle- Lorry cabin converted to"mowing version", the chip-per is controlled by the rota-ting seat on the passengerside.- EPSILON crane, type E110LPLUS- HEM 561R mobile chipper

The overall vehicle design wascarried out by JENZ in closeconsultation with our custo-mer. The second rear axle issteerable, so that the vehiclehas an extremely small tur-ning circle of 16.6 metreswhich enables it to manoeuv-re very well in small spaces.The overall weight of the HGVis around 20 tonnes. In orderto use the permissible overallweight of 40 tonnes, there isa possibility of carrying addi-tional loads of around 35-40cbm of woodchippings on thevehicle and transporting italong motorways at 50 mph.

The advantages provided bythis concept are clear to see.The remaining question iseconomic efficiency. Theinvestment must be viewed incomparison to other soluti-ons. Here it can quickly beseen that the costs for theHGV concept are not particu-larly higher than those foravailable alternatives. Thenew concept should be serio-usly considered in any plan-ned investment in mobilechipper technology, particular-ly with regard to its logisticadvantages.

JENZ – new technology for the HEM 1000 "Hercules“, "Woodcracker“ and the JENZ Chipper Truck optim

Technical detailsPower: 352kW = 480 HPUndercarriage: MAN, TGA 28.480 6X4-4 BLProduction: up to approx. 150 srm/hFeed opening: 990 x 650 mmMax. material thicknesses: Softwood 560 mm Dimensions: Length: approx. 7.640 mmWidth: approx. 2.550 mmHeight: approx. 3.850 mmCrane: EPSILON, Typ E110L PLUSMachine weight/standard version: approx. 19.500 kg

Layout-16seiter_englisch 09.05.2007 16:30 Uhr Seite 4

the processing of biomassesck optimise performance and logistics for our customers.

Layout-16seiter_englisch 09.05.2007 16:30 Uhr Seite 5

HEM 1000 “Hercules” nowwith longitudinal draw-in. Inthe heavy mobile chipper sec-tor, JENZ re-presented the HEM1000 DQ as a machine withside draw-in and HGV setupback in 2005. This chipper setnew standards in the mobilesector at the time with itschipping drum diameter of1450 mm. However, the HEM1000 DQ can can only showoff its good performance withcertain materials due to its rat-her short side draw-in. Thissolution is not really optimalfor even feeding, especiallywhen dealing with shorterwood pieces.

This problem has now beensolved by the new HEM 1000DXL. The machine has beendesigned as a semitrailer withthree axles so that it offerscompletely different operatingconditions due to its dead-weight. Whilst the HEM 1000DQ is limited by the 32 tonneoverall weight limit for HGVs,the semitrailer can be desi-gned for at least 30 tonnesself weight irrespective of thetractor machine. This results inthe possibility of widening thedraw-in width from 1000 mmup to 1200 mm at present. Theupper draw-in roller is moun-ted directly on the rotor shaft,

as in all current JENZ wood-chippers. The lower draw-inconsists of three bottom draw-in rollers downstream of thesteel belt. In a similar mannerto a star screen, sand andsmall stones are separateddownwards in the vicinity ofthe rollers. This protects theblades and increases servicelife. The draw-in rollers andthe front part of the rotor hou-sing are opened upwardshydraulically to change theblades. Tool changing can becarried out in a matter ofminutes comfortably from thedraw-in.

During construction, particularcare was given to changing thescreen baskets. The result isthat the screen basket consistsof a row of individual seg-ments which can be pulled outof the machine sideways. Thesegments can be easily hand-led by the operator and car-ried on the machine afterreplacement. The semitrailer transport king-pin is now positioned directlyunderneath the draw-in beltso that there is a free loadinglength of 5680 mm available.Additional widenings havebeen fitted to both sides ofthe draw-in which can behydraulically folded up for

transport. This results in opti-mal conditions for simple,rapid feed operations. Evenafter a long working day, it isan easy matter for the cranedriver to fill the 5680 mm x3700 mm sized openingquickly and regularly, and the-refore to run at maximumcapacity. The basic philosophy for thedesign of the machine is theunderstanding that the eco-nomics stands and falls oncontinuous high performancelevels. For this reason, thebest conditions possible havebeen achieved with regard tofeed operations. The tried-and-tested OM 502 LA in thehigh-performance versionwith 480 kW = 652 HP hasbeen selected to drive thehuge machine. It offers suffi-cient performance reservesand convinces thanks to itsratio between fuel consumpti-on and performance achieved.

A mobile chipper the size ofthe HEM 1000 DXL can onlybe worked in places wherereally large quantities of chip-pings must be produced sim-ply due to its size. For thisreason, it would make senseto carry out outfeed operati-ons using a conveyor beltinstead of a fan. Conveyor

belts require less power andhave less wear. The standingheap conveyor has a length ofaround 9000 mm, can achievea drop height of up to 7000 mm,and, in addition, can be swi-velled up to 35 degrees toboth sides. This creates thefacility for producing chip-pings heaps of around 100cbm per linear meter. Thismeans that the machine canbe operated for considerably

longer periods in one locationwithout having to be moved. With the HEM 1000 DXL, JENZhas extended its range with amachine which can be usedboth in biomass productionand in the wood-processingindustry. However, since thedesign uses a semitrailer, theheavy machine does not loseany advantages of mobility.

Technical detailsPower: 480kW = 652 HP

Engine: DaimlerChrysler OM502 LA, Euromot3A

Production: up to approx. 280 srm/h

Feed opening: 1.200 x 1.000 mm

Max. material thicknesses: Softwood 1.000 mm

Rotor diameter: 1.450 mm

Dimensions: Length: approx. 16.000 mmWidth: approx. 2.550 mmHeight: approx. 4.000 mm

Machine weight/standard version: approx. 30.000 kg

JENZ – new technology for the HEM 1000 "Hercules“, "Woodcracker“ and the JENZ Chipper Truck optim

Layout-16seiter_englisch 09.05.2007 16:30 Uhr Seite 6

The old task: fragmentisationof hardwoods and roots

The new solution: the JENZWoodcracker - simple, robustand economic in use

Wood is becoming a more amore sought after raw mate-rial due to increases in theprice of fossil energy sour-ces. For the processing com-pany, the important thing isoptimal use of existing mate-rial. In doing so, processingof trunks with oversized dia-meters and tree roots whichdo not fit in the chipper feedis especially problematic.

A new range of technicallyadvanced machines is nowbeing offered on the market.These are not economicallyviable for private contractorsdue to the considerableinvestment required. It isnecessary to fragmentiseoversize wood in order toprocess it. For this reason, JENZ nowhas the Woodcracker woodsplitter in its range. It is awood splitter which is sup-plied as an add-on unit fordiggers, tractors or loadingcranes. The special advan-tage of the JENZ woodcrackeis its well-engineered con-struction with only a fewmoving parts and the use ofextremely durable materials.The result is a unit of extre-mely low weight which is, ofcourse, decisive for rapidhandling. For example, theJENZ W 600 Woodcracker hasa deadweight of only 250 kg.This makes it suitable as atool even for small loadingcranes, and it can thereforesupport a HEM 360 Z in thefragmentisation of hard-woods of more than onemetre trunk diameter.

Manipulation of such heavyand tough wood with smallchassis-mounted cranes is aproblem because the liftingcapacity of the crane is oftennot sufficient. If the log slipsout of the gripper accidental-ly, damage to the fragmenti-ser housing can quicklyresult. The JENZ Woodcrackercan be mounted on the craneand fragmentises the woodsafely on site. After this,there are no problems duringdrawing in and fragmenti-sing.

The JENZ Woodcracker isavailable in four sizes from600 mm up to 1375 mm ope-ning width. All machines areonly fitted with four bearingswhich are permanently lubri-cated. This means that thenew Woodcracker is practi-cally maintenance-free. Anautomatic speed valve, whichleads to quicker openingmovement, is available as anadditional fitting. The newlydeveloped roller systembehind the splitter cutterreduces friction resistanceand makes less power neces-sary.

There is always a suitable fit-ting location on the mobileto the machine for the JENZWoodcracker because it is sosmall and has such a lowweight. For example, farmerand private forest ownerAndreas Lübkemann hasmounted his Woodcracker W600 as a front weight on hisCase 1455 tractor. His chip-per, of type HEM 25 Z, isdesigned for wood of up to40 cm in diameter. Thanks tothe JENZ Woodcracker, he isnow capable of processingall the wood from his privateforest and burning it in hisbiomass heating system.

The new JENZ Woodcrackerrange is the economic soluti-on for processing oversizedwood.

he processing of biomassesck optimise performance and logistics for our customers.

Layout-16seiter_englisch 09.05.2007 16:30 Uhr Seite 7

The JENZ team and its individuEmployees are the most important production factor in any companyThey can be seen from outside by the customers mainly during sales and service activities. The Open Day is an excellent reason to photog

Master and QM groupsHans Ulrich Lange, Heinz Böhlke, DieterBuddenbohm, Werner Schlegel, Wolfgang Dieker, Rene Polivka, ThomasWolf

Final assembly, 1st groupHermann Neumann, Wolfgang Redeker,Victor Neumann, Frank Rüter, HelmutBollhorst, Rainer Fulda, ReinhardNiemeier, Uwe Fiestelmann, MarcoDargel, Sebastian Könemann, H.-H.Jacke, Jürgen Ronnenberg, Karl HeinzMenke

Final assembly, 2nd group Hartwig Rohlfing, August Wischmann,Heinfried Brüggemann, Sven Stegemeier,Klaus Bredemeier, Timm Niermeyer,Wilhelm Kruse, Dirk Westermann, RalfÖtting, Nico Schneiderheinze, ChristianBrase, Holger Hillmann

Motor construction and pre-assemblyMatthias Telkemeier, Heinrich Dick,Waldemar Neumann, Jens Mülken,Michael Buschhorn, Jan Henrik LinzJohann Friesen, Dennis Meyer

Welding and belt constructionAlexius Schick, Jürgen Reinking, JohannGiesbrecht, Thomas Körtner, Ralf DudaMissing: Johann Wall

Mechanical fabricationAndreas Wittemeyer, Christoph Grabowski,Markus Matzke, Frank Böhne, ThomasBredemeyer, Andreas von Minden,Christian Wehking, Benjamin Braasch,Erwin WesemannMissing: Jan Kaatze, Marcus LemkeJens Siedentopf

Electrotechnical Rolf Tiemann, Michael Busse, AndreasBeißner, Sven Schneiderheinze, DirkPfitzner, Maik MöhringMissing: Alexander Epp und Dave Wallis

industrial and commercial apprenticesAusbilder Thomas Wolf, MarlowReckeweg, Simon Rennicke, Peter WallFelix Franke, Sina Buddenbohm, Siegurd Kiel, Anja Schmidt, PhillipBöttcher, Christian Böhlke, HeikoRodenberg, Sebastian Breuer, AusbilderPeter AlvermannMissing: Dennis Gieseking

Technical management, EDP, materialsmanagementGundi Prüßmeyer, Elke Niermeyer, RolfBredemeier, Reiner Büsching, BerndElias, Peter Alvermann, Axel Döpke

Layout-16seiter_englisch 09.05.2007 16:30 Uhr Seite 8

vidual team membersmpany.son to photograph all employees together in their working groups and to show them to you here.

,

ki,

Construction & development Stefan Müller, Waldemar Braun, MarcoKoopmann, Jens Wiehe, RobinFriederichs, Hans Bargen, Ulf BulmahnMario Heller, Uwe Weiße

Warehousing & transport Wilhelm Busse, Thomas Burmester,Reinhard Maisolle, Dieter Ungefroren,Gernot Brian Walker, Werner Hake,Christian Hake, Maik SenneMissing: Ulrich Beutelmann

General administration Thomas Oetting, Marita Knabe, AnnaHermeier, Sylvia Könemann, MaikeBuschhorn, Jessica Kortum, WalterSchubert

Service, parts trading Silvio Patzsch, Jörg Hillmann, BerndWestermann, Wolfgang Benditte, Carolinvon der Ahe

Service workshop Nico Westermann, Axel Wilharm, EugenMiller, Frithjof Meyer, Gregor Giesbrecht,Steffen Hilgendorf

SalesUlf Beier, Hartmut Schneckener, KarinSchwanda, Uwe Hempen-Hermeier,Renate Steinich-Döding, Bernd Ruhe

Service- and parts trading in Petershagen

Layout-16seiter_englisch 09.05.2007 16:31 Uhr Seite 9

Finland's surface area con-sists of up to 60% forest. It is therefore hardly a surpri-se that Finland is top of theleague table of industrialcountries for biomass usage.In 2004, 20.4 % of primaryenergy consumption wascovered by biomass.The wood and paper indu-stries are top of the supplierlist. The potential of residualwood from forestry operati-ons is estimated to be anannual 10 to 16 million cbm,but at present only around 3million cbm is being used forenergy purposes. The fo-rested area has further in-creased over the last fewyears. This market has greatpotential for smaller compa-nies and niche applications. Our customer Reijo Wuorio

had also drawn these conclu-sions when he founded hisbiomass company in 2001.Atthe beginning, he purchaseda HEM 560 D, which wasmounted on a Volvo lorry.Business expanded rapidly inthe following years. Today,the company employs a totalof 26 people directly andindirectly. Four HEM 560 D /HEM 561 D machines formthe core of the machinerypool, all of which are moun-ted on lorries. In addition,two walkingfloor lorries areused for chipping logistics,and a large wheeled loader isused to transport woodchip-pings. The daily productionquantity achieved by the fourmachines is around 1600bulk cubic metres, which isequivalent to the energy

quantity produced by around128.000 litres of oil oraround 1280 MWh.

The youthful company had avery big day in October lastyear. The Finnish PrimeMinister Matti Vanhanen paida personal visit to Wuoriosbioenergy terminal in Askola.In his speech, Vanhanen wasof the opinion that therewould be no conflict betweenmaterial and energy woodusage in Finland in the futureeither. Thermal utilisationcould be increased by a fac-tor of four without furtherado, and would not causeany restrictions on materialusage. The Finnish govern-

ment sees their task in subsi-dising the procurement ofmachines for the treatment ofresidual wood as an invest-ment in the home energymarket. This would also sup-port the national climaticprotection aims, decrease thedependency on oil and simul-taneously promote forestrygrowth.

Entrepreneur Reijo Wuoriotherefore has many reasonsto look positively into thefuture. Shortly before thePrime Minister's visit, heordered the fifth HEM 561 D,and is therefore playing hispart in implementing Fin-land's national aims.

Energy production from residual forest wood in Finland with huge potentialWuorio company receives visit from Finland's premier, Prime Minister Matti Vanhanen

Wuorio’s JENZ mobile chipping machine fleet ready for action

Herr Wuorio explains matters to Finland's Prime MinisterMatti Vanhanen

Fragmentisation of residual forestry wood at the biomass yard

Layout-16seiter_englisch 09.05.2007 16:11 Uhr Seite 10

JENZ has been pro-ducing fragmenti-sing machines since1958. The 2000thmachine was produ-ced last January.This was an AZ 660Duo Cut. The machi-ne was delivered tothe De Beijer Bro-thers contractingcompany in Holland,who are alreadyoperating a HEM 700.

Since commencingproduction of frag-mentisers, JENZ hasalways placed greatvalue on the fact thatthe machine fittings matchthe particular task definitionsand requirements of the cus-tomer - just as in this machine.De Beijer was looking for amachine which could be runusing both a chipper rotorand an impact rotor, because

the purchase of a secondmachine with chipper onlywould not have been econo-mically viable for the company.The AZ 660 machine standswere modified so that therotor could be changed overquickly to meet these requi-

rements. In addition, themachine allows the belt driveto be changed so that thechipper rotor can work withthe required lower rotationspeed for clean chippingoperation. This new versionhas been named the "Duo

Cut". Just as forother "Jubilee machi-nes", we took a pic-ture of our entireworkforce togetherwith this chipper.The dynamics ofdevelopment overthe last 25 years inthe mobile chippertechnology sectorbecomes very obvio-us using JENZ's pic-tures of similar"Jubilee machines".We hope you willenjoy the photos ofour other jubilees.

- Photo of the 500thmachine (Algol hopper chip-per)- Photo of the 600th machine(AZ 30 for Rahden)- Photo of the 1.000th machi-ne (AZ 60 for Schönmackers)- Photo of the 1.500th machi-ne (HEM 560 D for Schaller)

2000th JENZ fragmentiser producedFirma De Beijer erhält AZ 660 Duo Cut

The 500. machine (Regrinder, type funnel chipper for Algol) The 600. machine (AZ 30 for Rahden)

The 1000. machine (AZ 60 for Schönmackers) The 1500. machine (HEM 560 D for Schaller)

The 2000th machine (AZ 660 Duo Cut for the De Beijer brothers)

"Big Mama“: rotors on the 2000th JENZ fragmentiser

Layout-16seiter_englisch 09.05.2007 16:11 Uhr Seite 11

AZ 30 D

Power:Perkins 74,5 kW

Production: up to 60 cbm/hFeed opening: 300 x 790 mm

AZ 460 D

Power:DaimlerChrysler 205 kW

Production: up to 140 cbm/hFeed opening: 460 x 1.200 mm

AZ 660 D

Power:DaimlerChrysler 295 kW, 360 kW, 450 kW

Production: up to 220 cbm/hFeed opening: 660 x 1.500 mm

AZ 660 DXL

Power:DaimlerChrysler ab 295 kW, 360 kW/450kWProduction: up to 260 cbm/hFeed opening: 660 x 1.500 mm

AZ 960 DXL

Power:DaimlerChrysler 450 kW

Production: up to 350 cbm/hFeed opening: 960 x 1.620 mm

HEM 360 Z-ZA

Power:Power take-off up to 180 kW

Production: up to 60 cbm/hFeed opening: 400 x 790 mm

HEM 420 Z

Power:Power take-off up to 180 kW

Production: up to 80 cbm/hFeed opening: 420 x 990 mm

HEM 561 DL Tiger

Power:DaimlerChrysler 360 kW

Production: up to 120 cbm/hFeed opening: 650 x 990 mm

HEM 561 R-Truck

Power:MAN-TGA 350 kW

Production: up to 150 cbm/hFeed opening: 650 x 990 mm

Biomass – energy for the futurIn the future, biomasses will pay an ever increasing part in the implementation of international

We will be presenting our current range of fragmentising machines during our Open Day. The individual machines are presented in brief oYou can find more information in our current product guide and on the Internet at www.jenz.de.

Layout-16seiter_englisch 09.05.2007 16:12 Uhr Seite 12

W

HEM 561 Z

Power:Power take-off up to 235 kW

Production: up to 150 cbm/hFeed opening: 650 x 990 mm

HEM 700 DL

Power:DaimlerChrysler 295 kW, 360 kW, 450 kW

Production: up to 220 cbm/hFeed opening: 700 x 990 mm

HEM 1000 DXL

Power:DaimlerChrysler 480 kW

Production: up to 280 cbm/hFeed opening: 1.000 x 1.200 mm

JENZ-Woodcracker

MU 2000

Power:Perkins 74,5 kW

Production: up to 350 cbm/hFeed opening: 2.000 x 1.000 mm

W 1350 W 1000 W 820 W 600Cracker opening: 1375 mm 1040 mm 820 mm 600 mmSplitting power at 240 bar: 26 t 26 t 26 t 26 tDeadweight: 800 kg 460 kg 330 kg 250 kg

Drum screen T 6 with fine separator

Power: Perkins 90 kW + 5 kW

Production: up to 200 cbm/h

Windshifter W 6

Power: Perkins 42 kW

Production: up to 50 cbm/h

uturernational climatic protection targets. The requirement for this is high-powered machinery.

nted in brief on the following pages.

Layout-16seiter_englisch 09.05.2007 16:12 Uhr Seite 13

The Association for theUtilisation of Organic Wastein the Minden-Lübbeckedistrict (GVoA) and JENZGmbH signed a contract forthe promotion of renewableenergy forestry planting inthe Minden-Lübbecke districtlast April. Both companies assume thatthe potential of existing localforestry in the area will notbe sufficient during times ofincreasing timber demand. They consider the planting ofenergy forestry to be analternative, and are hopingthat set-aside agriculturalland will provide suitablegrowing areas. Planting ofrapid-growing timber typesdoes not prevent the pay-ment of set-aside bonuses. In the context of harvestingmoist woodchippings, theGVoA hopes to provide thefacility for using the wasteheat produced by the fer-menting works on their pre-mises to dry the woodchip-pings. Energy forestry is aparticular challenge for JENZ.The wood harvesting techno-logy in the sector has not yetbeen sufficiently developed.This will provide a new taskfor mobile chipping machinesin the future. With this background, farmerWilhelm Borgmann provided1.08 hectares of land in the

immediate vicinity of theJENZ company premises. Thechoice lay between willow,poplar and miscanthus. Aftera detailed investigation,13,000 cuttings of SwedishTorbis willow were ordered.The crucial factor was thecosts of the plants themsel-ves and the compatibility ofwoodchippings with the JENZbiomass heating works,which has an output of 320kW. It was feared that especi-ally miscanthus woodchip-pings would be unable to beincinerated without pro-blems.

The field was prepared byWilhelm Borgmann in accor-dance with instructions issu-ed by Agrobränsle, theSwedish cutting supplier. Thiswas equivalent to what isrequired for the planting ofmaize. For research reasons,exactly half the area was fer-tilised using Terrahum qualitycompost from the GVoA com-posting works. This is inten-ded to prove whether fertili-sation leads to demonstrablybetter tree growth.The cuttings were planted indouble rows at 13.000 cut-tings per hectare. The cut-tings had a length of 20 cen-timetres and were taken fromone-year-old growth. Theywere delivered in cartons,

and cooled down to a tempe-rature of around 3 degrees ina refrigeration unit beforeplanting.

Planting itself took placeusing a planting machinewhich was operated by twoJENZ apprentices. The plan-ting area is 150x75x150 cm.Spacing within the rows isaround 65 cm. Each hectarerequired around four hours ofplanting work.

Weed control in the first yearis crucial for the success ofthe planting operations. Thisis always emphasised in agri-cultural literature, but theintention was to do withoutchemical weed control as faras possible. The area wasprepared using Roundup and

resprayed shortly after plan-ting the cuttings. After this,no more weed control wascarried out and the area wasleft to itself.The result of this conceptwas unfortunately heavyweed growth, which conside-rately restricted the willowgrowth. For this reason, theJENZ apprentices had toremove the weed by hand inthe autumn. Weed growthwas particularly strong in thearea which had been fertili-sed using compost, so that inthe end composting cannotbe considered to have beena success.Pupils at the Petershagensecondary school, which isconnected to JENZ by aschool sponsoring scheme,carried out a planting sche-

JENZ and GVOA plant the first ePilot project for the promotion of renewable energy forestry in the Minden-Lübbecke district

Werner Hake with the JENZ apprentices in the middle of the 5-mon th-old

24.04.2006: Wilhelm Borgmann and two apprentices plantingthe 13,000 cuttings

Layout-16seiter_englisch 09.05.2007 16:12 Uhr Seite 14

st energy forest in Petershagen

me using homegrown willowson 800 square metres of landto form a comparison with

the Torbis variety. This com-parative planting was inten-ded to show whether the

Swedish willow really was a"turbo willow" variety. Thefact that the Torbis wasobviously growing considera-bly better than the home-grown willows could be seenafter only one year.For reasons of cost, the areawas not fenced off againstwild animal feeding. Sincethe field was only one hecta-re in size, and local deerpopulations were low, thiswas not considered necessa-ry. In addition, Torbis willowleaves are considered totaste very bitter to deer. Theexperience gained after oneyear of growth shows thatwild animal feeding levelshave been very low.

Questions must naturally beasked about the cost of plan-ting. Costs must, of course,be viewed in relationship tothe yield. Since this is along-term project, a definitivestatement on this matter canonly be made after severalturnovers. The fact of the matter is thatthe price for 1 lcm of willowwoodchippings is certainlycompetitive at current fossilenergy source price levels.Energy forestry should cer-

tainly not be consideredpurely from cost viewpoints.According to an investigationmade by the BavarianRegional forestry office, thebiodiversity in such areas isup to 10 times higher thanthat in adjacent fields. Inaddition, tree growth reducesnitrate concentrations in thesoil.Seventh year pupils inPetershagen secondaryschool measured the lengthof the willow cuttings duringmathematics lessons lastSeptember. In addition, tea-cher Dieter Schäpsmeier divi-ded the overall area into sec-tions. The willow cuttinglength was measured in eachsection. The results showedthat the average length wasas high as 1.73 m after onlyfive months.

The evident advantages ofthe planting scheme havebeen subject to considerableattention in the area. Theefforts made have not beenwithout success. As a resultof this scheme, further con-tracts for the renewable plan-ting of rapid-growing willowson a five hectare area havebeen signed.

5-mon th-old willows

First growth after around 14 days

Layout-16seiter_englisch 09.05.2007 16:12 Uhr Seite 15

JENZ South is optimising itslocation. To do this, the loca-tion is moving from Aichachto 86554 Pöttmes, AichacherStraße No. 11.The new branch office will beopen as of 01.05.2007. Theservice department, spareparts warehouse and salesoffice are all housed in 230mÇ of floor area.At the same time, the tele-phone numbers will changeas follows:Sales: 08253 / 928 283Service: 08253 / 928 284Fax: 08253 / 928 285

Area Sales Manager HelmutKrammer will be supportedby service technicians StefanSchwaiger and ChristianPerkl. Both are trained agri-cultural mechanics with awide range of know-how inthe handling of agriculturaland forestry machinery. Youcan reach our service techni-cians on the following num-bers:Stefan Schwaiger mobile:0170/8613439

Christian Perkl mobile:0170/8613434

JENZ South moving house

Bernd Ruhe takes over the northern sales region as Area Sales ManagerSince May, Bernd Ruhe hasbeen responsible for suppor-ting our existing regular cus-tomers and for the develop-ment of new business relati-onships in this area.Bernd Ruhe has been in thecompany since 1990. Aftercompleting his apprentice-ship as a mechanical engi-neering mechanic, he hasworked in various companydepartments starting withmachine assembly. Duringthis phase, he worked as aservice mechanic dealingwith machines in his currentsales area. His last positionwas Central WorkshopManager in Petershagen, andwas therefore ServiceManager WolfgangBenditte's right-hand man.

Thanks to his previous acti-vities, Bernd Ruhe possessesextensive know-how andwell-based technical know-ledge about our mobile chip-ping machines and wastefragmentisers. This meansthat he is well set up to pro-vide support to our custo-mers and potential purcha-sers in the solution of theoften complicated tasks theyset. He can be reached on0171/6477622, and by e-mail at: [email protected].

The photograph showsBernd Ruhe together withAxel Wilharm, who will beworking as a service mecha-nic for the Northern salesregion in future.

JENZ-Österreich GmbHfounded in Kasten

Bernd Ruhe together with Axel Wilharm, who will be workingas service mechanic for the Northern sales region in future.

The JENZ South team with Helmut Krammer, Christian Perkland Stefan Schwaiger

The trend is clearly towardsdirect operations for salesand service of high-qualityagricultural and forest machi-nery. We have reacted to this, andhave founded JENZ – Öster-reich GmbH as a 100% subsi-diary of JENZ GmbH for theAustrian sales region. Thenew company is also respon-sible for sales of spare parts.JENZ - Österreich GmbH hasits headquarters at Mitterfeld9, 3072 Kasten.General manager Norbert

Goldnagl is supported by hiswife Martina in the accoun-tancy department, RaimundHengenius is active as servicemechanic for JENZ – Öster-reich GmbH. You can reach the new com-pany at:Tel.: 02744 / 7819Mobile: 0664 / 1229800Fax: 02744 / 67066E-mail:[email protected]

Raimund Hengenius:0664 / 1229801

JENZ Austria: General manager Norbert Goldnagl with MartinaGoldnagl and Raimund Hengenius

Layout-16seiter_englisch 09.05.2007 16:12 Uhr Seite 16