GDT Runout Tolerance

-

Upload

firdhaus-sakaff -

Category

Design

-

view

221 -

download

3

Transcript of GDT Runout Tolerance

• In GD&T, runout tolerance is used to control the location of a circular part feature relative to its axis.

• Runout tolerances can be state by two tolerance zone. These are circular or total runout.

• Runout tolerances are three-dimensional and apply only to cylindrical parts, especially parts that rotate.

• A part must be rotated to inspect runout.

• Both circular and total runout reference a cylindrical feature to a center datum-axis.

• The material condition applied to the feature being controlled and the datum feature or features is always RFS because 360° rotation is required to conduct the inspection.

DEFINITION

APPLICABILITY OF MMC, LMC, RFS TO DATUMS

TOLERANCE ZONE

REFERENCE TO DATUMS

APPLICABILITY OF MMC, LMC, RFS TO FEATURE

TYPICAL USE

Runout is a composite tolerance used to control the functional relationship of one or more features of a part to a datum axis.

Each considered feature must be within its runout tolerance when the part is rotated about the datum axis.

One or more datum features. Relation to more than one datum feature is specified to stabilize the tolerance zone in more then one direction.

The specified tolerance can only apply on an RFS basis.

The specified datum can only apply on an RFS basis.

Typically used to control circularity and concentricity simultaneously.

• In the top figure the runout symbol is applied to the angled surface.

• The boxed symbols can be read "each circular element of this surface must have full indicator movement (FIM) of less than 0.1 relative to datum A".

• The bottom figure shows a sample measurement taken at one cross section, but multiple measurements are required to verify runout.

• The indicator is applied perpendicular to the measured surface, and that this tolerance controls only individual circular elements at one time.

• Three ways to establish a datum axis for a runout specification:

1. A single diameter sufficient length.

2. Two coaxial diameter a sufficient distance apart to create a single datum axis.

3. A surface and a diameter angles.

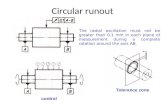

• Circular Runout zone is limited in the measuring plane perpendicular to the axis by two concentric circles, the common centre of which lies on the datum axis.

• Also it is can be defined as two-dimensional geometric tolerance that controls the form, orientation, and location of multiple cross sections of a cylindrical part as it rotates.

• For circular runout, the tolerance zone for each circular element on a surface constructed at right angle to the datum axis.

• The circular element through a surface point conforms to the circular runout tolerance for a given mating surface if all points of the circular element lie down within some circular runouttolerance zone.

• Circular run out controls the cumulative variation of circularity (roundness) around a datum axis and circular elements of a surface constructed an angle not parallel to the datum axis.

• Figure : CIRCULAR RUNOUT applies to each cross section individually.

• The worst circular runout occurs at the slice with the greatest variation (0.03 mm in this case).

• Total runout is the difference between the highest and lowest readings found over the entire feature. (0.11 mm in this case).

• Total runout involves tolerance control along the entire length of, and between, two imaginary cylinders, not just at cross sections.

• Total run out controls the entire surface simultaneously hence it controls cumulative variations in circularity, coaxiality, straightness, taper, angularity, and profile of a surface.

• Total runout tolerance for a surface constructed at right angles to the datum axis specifies that all points of the surface must lie in a zone bounded by two parallel plains perpendicular to the datum axis.

• It is separated by specified tolerance, a total runout tolerance.

• Total runout is a composite control; it limits the cylindricity, orentation, and axis offset of a diameter.

• When total runout is applied to a diameter, it affect the worst case boundry of the diameter.

• When a diameter is controlled by total runout, its maximum possible axis offset from the datum axis is equal to one half the runout tolerance value.

• 3 separate check should be made: the size of the diameter, the Rule #1 boundary, and the runout of the diameter.