ADVANCED MECHANICAL DRAFTING LECTURE #10. RUNOUT CIRCULAR RUNOUT TOTAL RUNOUT.

-

Upload

abraham-payne -

Category

Documents

-

view

246 -

download

3

Transcript of ADVANCED MECHANICAL DRAFTING LECTURE #10. RUNOUT CIRCULAR RUNOUT TOTAL RUNOUT.

ADVANCED MECHANICAL DRAFTING

LECTURE #10

RUNOUT

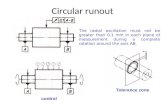

CIRCULAR RUNOUT

TOTAL RUNOUT

RUNOUT feature control frames

RUNOUT FRAMESALWAYS CONTAIN:

• Geometric Characteristic Symbol

• Tolerance zone thickness

• Datum reference

RUNOUT FRAMESNEVER CONTAIN:

• Diameter Symbol

• Material Condition modifier

RUNOUT tolerance zone shapes

RUNOUT

Area between twoconcentric circles

TOTAL RUNOUT

Volume between twoconcentric cylinders

Zone size is thickness of band of tolerance

APPLICATION OF RUNOUT

Rotate Part

.002 tolerance zone over entire surface

DRAWING

DATUM AXIS A

DATUM PLANE B

INTERPRETATION

APPLICATION OF RUNOUT

Rotate Part

DRAWING

DATUM AXIS A

DATUM PLANE B

INTERPRETATION

.005 tolerance zone at each circular element

APPLICATION OF RUNOUT

Rotate Part

DRAWING

DATUM AXIS A

DATUM PLANE B

INTERPRETATION

.005 tolerance zone over entire surface

COMPOUND DATUMS• Allow two different features to act as one

datum

• Both serve as one datum, neither is primary nor secondary with respect to the other

FORGING

• Forging processes– Hammer – swords, horseshoes, etc.– Drop – tools, coins, etc.– Press – same as drop without hard impact– Rolling – plate steel, sheet metal– Upset – fastener heads, spark plug ends, etc.– Extrusion – window frames, wire, etc

Any process which shapes solid metal without cutting

FORGING CONSIDERATIONS

• No tight tolerances• Hot or cold• Mismatch must be controlled• No sharp corners• Draft angles required in deep molds• Phantom lines show chip (areas that

must be machined later)• May require two drawings (forging &

machining)

KNURLING – a forging process• Straight knurl

– Increases effective shaft diameter– Used to create a press fit

Dimensioning the Straight Knurlper ANSI Y14.5

PITCH 96 STRAIGHT KNURL Ø.512 MIN AFTER KNURLING

Ø.50BEFORE KNURLING

.62 FULL KNURL

KNURLING – a forging process• Raised Diamond knurl

– Provides gripping surface– 4 sizes available

• DP 160 – very fine knurl• DP 128 – fine knurl• DP 96 – medium knurl• DP 64 – coarse knurl

– Pitch 96 most common

Dimensioning theRaised Diamond Knurl

per ANSI Y14.5

PITCH 96 RAISED DIAMOND KNURL

Ø.50

.62 FULL KNURL

.25

Application to GSK

GSK DESIGN