Development of Electrode Architectures for High Energy ... · Electrochemical Characterization...

Transcript of Development of Electrode Architectures for High Energy ... · Electrochemical Characterization...

-

Development of Electrode Architectures for High Energy Density Electrochemical Capacitors

Bruce Dunn1 and Yury Gogotsi2

1. Department of Materials Science and Engineering

University of California, Los Angeles

2. Department of Materials Science and Engineering

Drexel University, Philadelphia, PA

Research Team at Drexel: Dr. Majid Beidaghi - Postdoctoral scholar Maria Lukatskaya, John Zhang - PhD students Research Team at UCLA: Dr. Ryan Maloney, Dr. Emilie Perre - Postdoctoral scholar Matt Lai – Ph.D. student

ESS Peer Review September 16-19, 2014

-

Electrochemical Energy Storage Batteries Capacitors

“Bulk” Batteries

Nanostructured Batteries

Capacitors EC Double Layer Supercapacitors

Pseudo-capacitors

H2SO4(aq)

Pb

Pb

O2

+ + +

+ + +

- - -

- - -

+ +

+ + + + +

Li+

e- Li+M+n-1

M+n Li+

e-

M+n

Li+M+n-1

Faradaic Charge Storage (High Energy) Non-Faradaic (Low Energy)

Diffusion Controlled Non-Diffusion Controlled (High Power)

• e.g. Lead-Acid • Charge stored in

bulk • Moderate Energy • Low Power • Low Cost

• e.g. Li-ion • Charge stored in

bulk • High Energy • Moderate Power • Moderate Cost

• e.g. RuO2 • Charge stored near

surface (thin films) • Moderate Energy • High Power • High Cost

• Carbon • Charge stored

at surface • Low Energy • High Power • Low Cost

• Metal • Charge stored

at surface • Low Energy • High Power • Low Cost

P. Simon, Y. Gogotsi and B. Dunn, Science 343, 1210 (2014)

-

Pseudo- vs. Supercapacitors

Carbon

• Moderate Energy • High Power • High surface area

• Moderate Energy • High Power • Very thin (nm)

Li+

e-

M+n

Li+M+n-1

Metal Oxide

Pseudocapacitor EC Double Layer Supercapacitor

-

Pseudo/Supercapacitor Composite

Carbon

• Moderate Energy • High Power • High surface area

• Moderate Energy • High Power • Very thin (nm)

• High Energy • High Power

Li+

e-

M+n

Li+M+n-1

Metal Oxide

Metal Oxide / Carbon Composite

Pseudocapacitor EC Double Layer Supercapacitor

-

UCLA - Drexel Collaboration

Carbon

• Carbide-derived Carbon • Coin-cell fabrication • Device characterization

• Metal-oxide deposition • Small-scale testing • Materials characterization

DOE Office of Electricity Energy Storage Systems Program

University Energy Storage Program 100 Wh/kg, 1-10 kW/kg

Project Goals

Capacitors Target

0.01 0.1 1 10 100 10001E-3

0.01

0.1

1

10

100

Sp

ecific

Po

we

r (k

W/k

g)

Specific Energy (Wh/kg)

-

Supercapacitive Carbon

Carbon

-

Supercapacitor: Carbide-Derived Carbon

2 nm

Carbide Chlorination Carbon

Process Features

• Precise control over structure and porosity / pore size / surface area

• Network of open pores • Coatings, free standing monoliths,

fibers, foams or powder • Numerous carbides can be used

Carbide

2 nm

Carbide Porosity = 0%

Carbide-Derived Carbon

Nanoporous Carbon Porosity >50%

O. Hutchins, US Patent, 1271713 (1918) W.A. Mohun, US Patent, 3066099 (1962)

Nillok Chemicals, Great Britain Patent, 971943 (1964) S.K. Gordeev et al., J.Appl. Chem. (USSR) 64, 1178 (1991)

N.F. Fedorov, Russ. Chem. J. 39, 73 (1995) Y. Gogotsi, M. Yoshimura, Nature, 367, p. 628 (1994)

Y. Gogotsi, et al, Nature, 411, p. 283 (2001) J. Leis, et al. Carbon, 39, 2043 (2001)

V. Presser, et al. Advanced Functional Materials, 21, 810 (2011).

[001]

[110]

Halo-

genation

MC(s) + 2Cl2(g) → MCl4(g) + C(s)

-

Supercapacitor: Carbide-Derived Carbon

Chmiola, J.; Yushin, G.; Gogotsi, Y.; Portet, C.; Simon, P.; Taberna, P.-L., Science, 2006, v. 313, 1760

+ + + +

+

+ +

+

+

+ +

+ Anode

CDC

Ion

Solvation shell

CDC

-

Supercapacitor: Carbide-Derived Carbon

Chmiola, J.; Yushin, G.; Gogotsi, Y.; Portet, C.; Simon, P.; Taberna, P.-L., Science, 2006, v. 313, 1760

+ + + +

+

+ +

+

+

+ +

+ Anode

Metal Oxide

Metal Oxide Ion

Solvation shell

-

Pseudocapacitive Metal-oxide

Li+

e-

M+n

Li+M+n-1

Metal Oxide

-

Pseudocapacitor: Nb2O5 10 mV/s

96 %

capacitive

current

10 mV/s

• Highest capacitance observed with most ordered structure: T-Nb2O5, ~ 370 F/g in 12 seconds

• Amorphous capacity is much smaller & slower

• Presence of an ordered structure is important to achieve high capacity

• (Almost) all of the stored charge is from pseudocapacitance

Kim et al., Adv. Energy Mat. 2, 141-148 (2011)

-

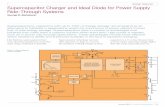

Electrochemical Characterization

Three-step process for developing electrode materials for supercapacitor devices

1. Nanocrystalline electrodes: no carbon or binder; half-cell experiments; Designed to rapidly establish fundamental electrochemical properties

2. Swagelok cells: Practical electrode structure with carbon and binder. Half-cell experiments

3. Coin Cells: Full cell prototype devices; symmetric and asymmetric

-

Ti2AlC powder CDC powder

1. Chlorination for 3 h at 800 °C

2. Hydrogenation for 2 h at 600 °C

CDC powder

C4H4NNbO9 . xH2O

Sonication Hydrothermal treatment for 96 h

at 200 °C Addition of Urea

Nb2O5/ CDC

powder

phenylphosphonic acid (PPA)

Carbide-derived carbon/Nb2O5 hybrid materials

-

Carbon: Metal-oxide: Crystallinity: % oxide: Synthesis:

TAC800 Nb2O5 Amorphous 20% Hydrothermal

Ammonium Niobate Oxalate Hydrate, Water, Carbon, Urea, 200°C, 4 days

Development of Nb2O5/CDC Composite Electrodes

Carbon: Metal-oxide: Crystallinity: % oxide: Synthesis:

TAC800 Nb2O5 Amorphous 20% Hydrothermal

Ammonium Niobate Oxalate Hydrate, Phenylphosphonic Acid, Water, Carbon, Urea 200°C, 4 days

Nanocrystalline electrodes

Without bonding agent

With PPA bonding agent

10 100

0

50

100

150

200

250

300

350

400

450

500

550

600

Ca

pacity (

C/g

)

Scan rate (mV/s)

TAC800

Nb2O5-TAC800

Nb2O5-TAC800, PPA

-

Crystallizing the Nb2O5: heat treatment in CO2

Temperature: 850 °C Time: 1 h CO2 flow rate: 10 sccm

• Nb2O5 crystallizes and increases amount of stored charge

• Only slight oxidation of CDC

Swagelok cells 1.5 mg in weight, 5 mm in diameter, 70 μm thick 8 : 1 : 1 Nb2O5/CDC : PTFE : carbon 7.5 mg/cm2

-

Coin Cell Devices

• Optimization of coin cell design parameters leads to increased specific capacitance

• Nb2O5/CDC-CO2 composites to be substituted for CDC

(1) Spacer: stainless steel (2) CE&RE: Li (3) Separator (4) WE: active material/carbon black/PVdF

First Generation Supercapacitor: CDC electrodes with non-aqueous electrolyte

-

Carbon shell formed by microwave hydrothermal coating of glucose Glucose pyrolysis: 700°C in Ar Partial oxidation: 400°C in Air

1.0 1.5 2.0 2.5 3.0 3.5 4.0

-15

-10

-5

0

5

10

15

Cu

rre

nt (A

/g)

Potential (V vs. Li/Li+)

TAC800

Nb2O5-TAC800, PPA, 600°C CO2

Nb2O5 c/s 400°C Air

10 100

0

100

200

300

400

500

600

Ca

pacity (

C/g

)

Scan rate (mV/s)

TAC800

Nb2O5-TAC800, PPA, 600°C CO2

Nb2O5 c/s 400°C Air

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

Mas

s %

Nb2O5

Oxidized Carbon

Remaining Carbon

T-Nb2O5

Carbon

20 mV/s

Nb2O5

New Directions for Enhanced Charge Storage: Nb2O5 – C Core/Shell

Sol-gel synthesis of Nb2O5 precursor gel; supercritical drying; calcine at 700°C in air; orthorhombic Nb2O5

-

Two-Dimensional Transition Metal Carbides, Oxycarbides and Carbonitrides Composition of Mn+1AXn ; with n =1,2,3; Layered hexagonal structure (P63/mmc)

Examples: Ti2AlC, Ti2AlN, Ti3AlC2,Ti4AlN3 Ta2AlC, Ta4AlC3 Cr2AlC, Cr3AlC2 V2AlC, V3AlC2 Nb2AlC, Nb4AlC3 (>70 phases)

211 312 413

Delamination to Mxene via HF treatment: Ti3AlC2 + 3HF = AlF3 + 3/2H2 + Ti3C2

Ti3C2 + 2H2O = Ti3C2(OH)2 + H2 Ti3C2 + 2HF = Ti3C2F2 + H2

New Directions for Enhanced Charge Storage: Oxidation of Layered Nb2C

M. Naguib, et al., Adv. Mater., 23, 4248 (2011)

-

New Directions for Enhanced Charge Storage: Oxidation of Layered Nb2C

-

New Directions for Enhanced Charge Storage: Nb2O5 – RGO

-

Summary and Ongoing/Future Work

Progress to Date

• Generation I devices based on CDC • Composite electrodes of Nb2O5/CDC-CO2 demonstrate enhanced charge storage • New approaches identified for metal oxide systems with greater storage

Ongoing and Future work

• Fabrication of coin cells incorporating Nb2O5/CDC-CO2 electrode materials (symmetric and asymmetric) • Development of new metal oxide/CDC electrodes - electrode characterization and downselect most attractive candidates - extend electrode studies to aqueous electrolytes and identify most promising materials

Acknowledgements This research was supported by the U.S. Department of Energy, Office of Electricity, Energy Storage Research Program, through Sandia National Laboratory

![ars.els-cdn.com · Web view[2] L. Yang, S. Zhou, W. Yang, Polypyrrole directly bonded to air-plasma activated carbon nanotube as electrode materials for high-performance supercapacitor,](https://static.fdocuments.net/doc/165x107/5faf1e8c53c3691232417491/arsels-cdncom-web-view-2-l-yang-s-zhou-w-yang-polypyrrole-directly-bonded.jpg)