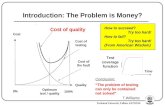

Cost of quality

Transcript of Cost of quality

•Cost of quality: It’s a term that’s widely used and

widely misunderstood., here “cost of quality” isn’t the

price of creating a quality product or service, it’s the

cost of not creating a quality product or service.

Every time work is redone, the cost of quality increases, examples include:

1. The reworking of a manufactured item.2. The retesting of an assembly3. The rebuilding of a tool4. The correction of a bank statement5. The reworking of a service, such as the reprocessing of a loan operation or the replacement of a food order in a restaurant

Today view of quality cost among practitioners seems fall into three categories

Higher quality means higher cost: Quality attributes such as performance and features cost more in terms of labor, material, design, and other costly resources.

The additional benefits from improved quality do not compensate for the additional expenses.

Traditional BA (Waterfall) Agile BA

Requirements are documented in Use

Cases,Business Requirements, Functional

requirements, UI Specifications, Business Rules.

Requirements are documented in Epics, User

Stories and optionally Business (or Essential) Use

cases.

Focuses on completeness of requirement and

spends time in ensuring the requirement is

unambiguous and has all the details.

Focuses on understanding the problem and being

the domain expert so that s/he can answer

questions from the development team swiftly and

decisively.

Focuses on getting a ‘sign off’ on the requirements.

Focuses on ensuring the requirements meet the

currentbusiness needs, even if it requires

updating them.

Often there is a wall between the BA/Business and

the Development team.

Agile BA (Often called as Product Owner) is part of

the team.

Tends to dictate solutions.

Has to remain in the problem domain, leaving the

development team ‘space’ to explore different

solutions.

Long turnaround. Quick turnaround.

Focus on what the requirements document said. In

other words, output (Artifact) is a well written

thorough requirements document.

Focus on the functionality of the developed

software. In other words, output (Artifact) is the

software that meets thebusiness needs.

The cost of improving quality is less than theresultant savings:

Deming promoted this view, which is still widelyaccepted in Japan, the savings result from less rework,scrap, and other direct expenses related to defects,this paved the way of continuous processimprovement among Japanese firms.

Quality costs are those incurred in excess of those that would have been incurred if products were built or service performed exactly right the first time.

This view is held by adherents of the TQM philosophy, costs include not only those that are direct, but also those resulting from lost customers, lost market share, many hidden costs and foregone opportunities not identified by modern cost accounting systems.

Categorization of Quality Costs

The cost of quality is generally classified into four categories:

1.External Failure Cost

2. Internal Failure Cost

3. Inspection (appraisal) Cost

4. Prevention Cost

External Failure Cost: Cost associated with defects found after the customer receives the product or service.

Example: Processing customer complaints, customer returns, warranty claims and product recalls.

Internal Failure Cost: Cost associated with defects found before the customer receives the product or service.Example: Scrap, rework, re-inspection, re-testing, material

review, material downgrades

Inspection (appraisal) Cost: Cost incurred to determine the degree of conformance to quality requirements (measuring, evaluating or auditing).

Example: Inspection, testing, process or service audits, calibration of measuring and test equipment.

Prevention Cost: Cost incurred to prevent (keep failure and appraisal cost to a minimum) poor quality.

Example: New product review, quality planning, supplier surveys, process reviews, quality improvement teams, education and training.

![Cost of Quality[1]](https://static.fdocuments.net/doc/165x107/577d29e71a28ab4e1ea833ef/cost-of-quality1.jpg)