An Economically Feasible Portable Water Purifying Bottle for the Flood Affected Zones

-

Upload

suryaprakash-shanmugam -

Category

Engineering

-

view

269 -

download

1

Transcript of An Economically Feasible Portable Water Purifying Bottle for the Flood Affected Zones

An Economically Feasible Portable Water Purifying Bottle

for the Flood Affected Zones

Department of Mechanical Engineering

College of Engineering, GuindyAnna University, Chennai

STUDENT ARJUN M

ARUN KUMAR P S BIBIN JOE SSURYAPRAKASH S

GUIDE

DR. K. SHANMUGA SUNDARAM ASSOCIATE PROFESSOR

DEPARTMENT OF MECHANICAL ENGINEERINGCOLLEGE OF ENGINEERING, GUINDY, ANNA UNIVERSITY

CO-GUIDES

DR. R. JAYAVEL PROFESSOR & DIRECTOR

CENTRE FOR NANOSCIENCE AND TECHNOLOGY

ANNA UNIVERSITY

DR. D. SANGEETHA ASSISTANT PROFESSOR

DEPARTMENT OF MECHANICAL ENGINEERINGANNA UNIVERSITY

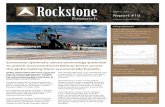

lid

membrane filtered water outlet - holemicro filtration membrane filterinlet – ball operated check valve

contaminated water case

nanofiltration using nanoparticles (Ag) embedded nanocomposites (CA)

activated carbon filtrationpiston with a head

piston handle

Created using Pro-E wildfire 5.0

clean water outlet

hydro sponge

CAD Design

micro filtration membrane filter

• Synthetic microfiltration membranes .

• Can withstand transmembrane pressure given by hands

• Can halt the bacteria in m size𝜇

• Non-toxic and commercially available

• Preferable for short-term applications

Membrane filtration

MF – Micro Filtration; UF – Ultra Filtration; NF – Nano Filtration; RO – Reverse Osmosis

Transmembrane pressure ≈ 2.05 bar (0.7 to 3.4)Force that can be given by an adult human ≈ 550 N (500 N to 600 N) – for safety concern we’re considering 300 N to 700 N

Pressure = ; x = diameter of cylinder = 45 mm

When applying 300 N, Pressure = 1.90 barWhen applying 400 N, Pressure = 2.50 barWhen applying 500 N, Pressure = 3.14 barWhen applying 600 N, Pressure = 3.77 bar

When applying 700 N, Pressure = 4.40 bar

Calculation

Al2O3

H2O

SLURRY

SOLUTION 1 CH3COOH(C6H11O4)n

SOLUTION 1

STIR

CH2(CH2-CHO)2

STIR

REFRIGERATE DRY CA

Prepared nanocomposite is referred as CA which abbreviates to give Chitosan and Alumina

Nano FiltrationPreparation of Chitosan Alumina

nanocomposite

CA

REDISPERSED CA

REDISPERSE IN WATER

AgNO3

Sodium borohydr

ide < 283 K

WASH WITH WATER

Ag-CA

STIR

DRY AT ROOM TEMPERATURE

Ag-CA is the final product which is silver nanoparticles embedded CA nanocomposites

• Non-soluble• High shear stress

Embedding of silver in the chitosan-alumina nanocomposite

• Low price

• Non-toxic

• Abundantly available

• Eco-friendly preparation (by burning the ordinary carbon in no presence of air)

Activated Carbon Filtration

Manufacturing• Separate die must be prepared to make this

product as it contains many cartridges• The piston must be prepared in a high strength

plastic to withstand.• HDPE plastic other polymer materials are

suitable to manufacture the product.• The membranes, activated carbon, raw

materials for nanocomposite synthesis are commercially available and economically feasible.

• Efficient water purification aid in the flood affected areas

• Stranded people will be get benefitted.

• Example: Uttarakhand floods of 2013.

• Instead heavy water cans, military personnel can use this for short-term operations.

• Can be scaled up to meet the demands.

• Can be mass-producible.

Scope

Future Works• The efficiency of Ag-CA will be fine-tuned

using volume vs. mass analysis of water vs. Ag-CA

• More suitable (low cost, high wet resistance, high transportability, less transmembrane pressure) membrane will be chosen and used.

• Other fouling, scaling problems will be addressed and will be attempted to make this as a commercial / long-term water purifier used anywhere.

References1. “A TED Talk by Michael Pritchard” on July 2009 at Oxford, England

and the video content is available on TED.com

2. “Preparation and Application of alumina/chitosan biocomposite” by Rajiv Gandhi, N. Viswnathan, S. Meenakshi of Gandhigram Rural University, Dindigul published by International Journal of Biological Macromolecules May 13, 2010 in vol. 47 and page no. 146 – 154.

3. “Biopolymer-reinforced Synthetic Granular Nanocomposites for Affordable Point-of-use Water Purification” by Mohan Udhaya Sankar, Sahaja Aigal, Shihabudheen M. Maliyekkal, Amrita Chaudary, Ansuhup, Avula Anil Kumar, Kamalesh Chaudhar&Thalappil Pradeep from Unit of Nanoscience, Department of Chemistry, IIT-M, published by PNAS on May 21, 2013 in vol. 110, no. 211 and page no. 8459 – 8464.

4. “Membrane Technologies For Water Applications – Highlights From A Selection Of European Research Projcts” by European Commission.

5. United States PatentPatent No : US 7,824,546 B1 Patent Title : Canteen