Study of WRM FURNACE of Vizag Steel Plant.

-

Upload

lakkireddy-bali-reddy-collage-of-engineering -

Category

Engineering

-

view

125 -

download

5

Transcript of Study of WRM FURNACE of Vizag Steel Plant.

STUDY of FURNACE of

WRM

By

13765A1007

OVERVIEW 1 VSP OVERVIEW

2 WRM OVERVIEW

3 INSTRUMENTS USED IN FURNACE TEMPERATURE CONTROL

4 STUDY OF INSTRUMENTATION AND CONTROL SYSTEM OF WRM FURNACE

5 IMPLEMENTATION

6 CONCLUSION

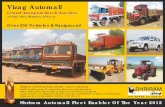

VSP OVERVIEW

Visakhapatnam Steel Plant (VSP) is the most modern, shore-based integrated steel plant in India. It has a capacity to produce 3 million tones of liquid steel per year. A productivity of 230 tones/man year, a steel complex that comprised the tallest of coke over batteries. The largest of Blast furnaces, the most efficient of converter shops and the most trouble free, high speed mills. All designed to work in unison and produce 5.6 lakh tones of pig iron, 2.7 million tones saleable steel and

offering a wide range of long steel products. In the area of pollution control and measures VSP is in the fore front of the Indian industry. The total cost of these measures work out to Rs.4600 million, or nearly 85% of the total cost of the steel plant. To operate the plant at international levels and attain such labor productivity, the total

manning of the organization has been limited to 17300 employees. The plant has a capacity of producing 3.0 MT of liquid steel and 2.656 MT saleable

steel.

MAJOR PLANT FACILITIES:

Visakhapatnam Steel Plant has the following facilities: Three coke oven batteries of 67 ovens Two sinter machines Three blast furnaces Steel melt shop with three I.D. converters (two operating and one standby) Light and Medium Merchant Mill (LMMM) Wire Rod Mill (WRM) Medium Merchant and Structural Mill (MMSM)

WRM OVERVIEW

The mill has 4 zone combination type reheating furnace (walking beam cum walking hearth) of 200t/hr capacity for heating the billets received from the billet mill of LMMM to rolling temperature of 1200°c.

The mill produces rounds in 5.5 – 12.7 mm range and rebar’s in 8, 10&12mm range. The annual capacity of the WRM is 850,000 tones of finished wire rods by 3 shift

operation and specified product mix. The four- strand wire rod mill consists of Four –strand roughing mill with 7 stands Four-strands intermediate mill with 6 stands Four single-strand intermediate blocks with 2 stands 14 and 15 each Four single-strand finishing blocks with 10 stands 16-25 each.

Type of furnace: The furnace is included in a production line of wire and rounds for reinforced concrete. The installation is composed of one mixed type walking beam furnace, with refractory walking beams in the

preheating zones and tabular beams in the heating and soaking zones.

- Preheating : zone 1 - Heating : zone 2 - Top soaking : zone 3 - Bottom soaking : zone 4

Products to be heated: The furnace reheats billets for the Wire Rod Mill. Billets dimensions are the

following: Thickness……………………. 125 mm Width………………………... 125 mm Length……………………….. 10.400+/- 80 mm Weight……………………….. 1.25 tons Steel grade………………… plain carbon steel, Low alloy steel, Medium and high

Carbon steel Maximum deflection Over the billet length…………… 100 mm

Temperature conditions: The billets are charged inside the furnace at an ambient temperature (average 30°c). The billets temperature at the discharge end of the furnace is 1200°c. The temperature variation between the top surface and the bottom surface of the billets is less than 25°c

(equidistance of the beams). The normal working temperatures in the four zones of the furnace are

zone -1 : 750 - 850.

zone- 2 : 850-1000.

zone- 3 : 1100 - 1200.

zone - 4 : 1100-1200.

Furnace output: The nominal production rate of 200 t/h for the furnace is based on the reference

size billet of:

length……………………………..10.400 mm Width…………………………….. 125 mm Thickness…………………………. 125 mm

The furnace is designed and installed with a heating capacity 20% higher than required for the maximum production rate of 210 t/hr. this is considering new skid insulation; 10% excess air and billets length of 10400 mm.

Fuel: The fuel for normal operation of the furnace is a mixed gas (coke oven gas + blast furnace gas + LD gas)

with a net value of 2200 kcal/Nm3 supplied at a pressure higher than 600 mm WG.

Utilities and connected flow:

Mixed gas: Net heat value………………2,200kcal/Nm3

Pressure……………………600 mm WG minimum

Temperature………………..40°C

Connected flow…………….34,650 Nm3/hr

Dust content of LD gas……..10 mgm/Nm3 (max.)

Particle size…………………2 microns (max.)

Industrial water for direct cooling: Pressure………….4 kg/cm2

Temperature………35°c (max.)

Connected flow…..15 m3/hr

Industrial water for indirect cooling:

Pressure…………4.5 kg/cm2 (max.)

Temperature………35°c (max.)

Connected flow……340 m3/hr

use………………...lintels, camera at discharge, Hydraulic station, fixed skids, Movable skids, cooling frame.

Compressed air:

Pressure…………..6 (mini) to 8.5 kg/cm2 (max.)

Flow……………….440 Nm3/hr

Connected flow……400 m3/hr at 0.5 kg/cm2

use………………..cooling of TV cameras, furnace Instruments and door cylinders.

INSTRUMNENTS USED IN FURNACE

Instrumentation and control system: The furnace control & instrumentation is controlled by PLC(Programmable logic controller). The PLC is of

Allen Bradley (Rockwell automation) make, of series Control Logic 5555 controller. The configuration of the PLC is given below.

PLC CPU 1756-L55M23

Digital input module 1794-IB32

Digital output module 1794-OB32

Analog inputs module 1794-IF4I

Analog output module 1794-OF4I

RTD module IR8

Thermocouple module IT8

BLOCK DIAGRAM OF WRM

FINAL PRODUCT OF WRM

CONCLUSION

Instruments used in measuring and controlling process of temperature control in WRM walking beam furnace.

The scope can be further extended to study the implementation of process measurement and control system using PLC. In depth study of PLC architecture and programming is not within the scope of this . The philosophy of this is measurement and control of temperature in walking beam furnace of WRM.