LAK Digger and Optimum BH Patterns.pdf

-

Upload

christianenriquezdia -

Category

Documents

-

view

225 -

download

0

Transcript of LAK Digger and Optimum BH Patterns.pdf

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

1/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

1

Optimum BH Patterns,LAK, and DIGGER

for

Ore Control

Isaaks & Co.Nov, 2010

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

2/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

2

Local Anisotropy Kriging (LAK)

“The proper selection of data” for the purposes of estimation is considered by many to be the fundamentalmantra of ore resource estimation. For example, the selection of data for kriging etc. is more often than not

controlled through lithologic and/or alteration models, grade shells or zones, structural domains and so on.Although such models may be appropriate at a macro scale, they are suboptimal at a micro scale. Forexample, experience shows that mineralization may be controlled by lithology combined with structure at amicro scale. Here we define micro scale as order of magnitude changes in grade over distances in theneighborhood of 10 m. These micro scale changes in grade can be seen in blast hole maps. Obviously, it isnot practical to control the selection of data at this scale through either structural or lithologic micromodels. Hence the motivation for a practical solution to data selection at the local or micro scale.

The Concept:

The concept behind LAK is quite simple. When estimating an individual block grade or cross validatingestimates of actual DDH or BH data, the data selection is done through a unique search ellipse (ellipsoid in3D). That is, each search ellipsoid may have its own set of anisotropy ratios and axial orientations. Figure 1

provides a 2D example illustrating an application of locally customized search neighborhoods.

Figure 1: An example of blast holes colored by 6 classes of grade. The red ellipsoid shows the orientation of a global searchneighborhood that would be used for the estimation of every block on the bench. The green ellipsoids show examples of local searchneighborhoods that are customized to fit the local direction of mineral continuity which is identified by the spatial patterns ofidentically colored blast holes. The insert in the lower right hand corner of the figure shows the orientation of elliptical searchneighborhoods centered on individual blocks of the ore control block model. The ellipsoids have been reduced in scale to avoidoverlap and improve clarity.

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

3/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

3

Figure 2: This figure shows a 3D example of the orientation of the local search neighborhoods used to krige an ore control model.The ore control model blocks measured 2x2 m x bench height. You can see from the figure that the search ellipsoids were taken from7 or 8 benches. Each search neighborhood is centered on a 2 x 2 m block, but the ellipsoids have been reduced in size to avoid overlapand improve clarity. The major axis of the ellipsoids tend to follow the local patterns of mineral continuity. Obviously, sub-verticalcontinuity is quite prevalent.

The LAK Algorithm:

The LAK algorithm is a two part algorithm. Part 1 preprocesses the data and identifies the optimum searchellipsoid for each block, or for each composite in the case of cross validation. This information is written tofile for each block. Part 2 does the actual kriging. For part 2, we simply modified an existing kriging

program to read the optimum ellipse parameters from file and orient the search ellipsoid accordingly foreach block.

Part 1 relies on the brute force of the computer to rotate through a number of ellipse orientations andanisotropy ratios to seek out and identify the optimum search ellipsoid for each block. Basically, the idea isto evaluate the captured data within each possible search ellipse using some measure that indicates theappropriateness of the captured data for estimation. The optimum ellipse is the one providing the “best”measure. For example, in the previous example it should be obvious that better estimates are likely to behad by maximizing data selection along the imaginary contours of equal value while minimizing dataselection across the contour lines. One might generalize this concept and conclude that a reasonablemeasure of appropriate data selection is “similarity”. In other words, it seems reasonable to conclude thatone is likely to obtain more accurate estimates using captured data that are reasonably similar to each other.In fact, this is also the motivation behind data selection by rock type models etc. By restricting the selectionof data to specific rock types, one hopes to capture data from a single population or more generally, datathat are reasonably similar to each other, thereby providing more accurate estimates.

There are several statistics that can be used to measure “similarity”. For example, variance can be seen as ameasure of similarity with the advantage that it is easily computed. Recall that variance is a measure of thesample variability about the mean. Thus, if the captured samples have a relatively low variance, they arelikely to be more similar to each other than samples with a relatively high variance. One can refine orstandardize the variance to account for a shift in the mean or proportional effect by computing thecoefficient of variation. This is useful when distributions are skewed and the local variance is proportionalto the mean. Other measures of variability include the mean absolute deviation from the median and so on.

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

4/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

4

LAK Variography

LAK variography is slightly different from traditional variography. For example, in traditional geostatistics,the directions of the various separation vectors between pairs of sample locations is always determined withreference to the local coordinate system within a specified domain. However, with LAK the orientation ofthe separation vector between a pair of data locations is always determined with reference to the axes ofthe search ellipsoid. For example, “North” is always parallel to the major axes of the ellipse no matter whatthe actual orientation of the major axis is.

Directional sample variograms are calculated by pairing data points within the same ellipse. Data pointsfrom two different ellipsoids are not paired. However, variogram values with similar separation vectors(same magnitude and direction) from different ellipsoids are averaged together to obtain the ultimatedirectional sample variograms for modeling. For example, recall that “down-the-hole” sample variogramsare calculated by only allowing the pairing of data within the same drill hole. Data from two different drillholes cannot be paired in the calculation of a down-the-hole sample variogram. Thus, the similarity

between “down-the-hole” and LAK variography suggests the term, “down-the-ellipsoid” or better yet,“within-the-ellipsoid” variography.

Figure 3: An example showing how the direction of the separation vector between two samples is referenced to the axes of the searchellipse rather than the axes of the original coordinate system.

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

5/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

5

An Example of Local Anisotropy Kriging (LAK).

Figure 4 shows an example of LAK. The colored circles are blast holes on a nominal 6 to 8 m grid. The orecontrol model is composed of 2x2 m blocks whose grade has been estimated using LAK. Since this is a pdffile, you can zoom this figure to 400% to see the correlation between the blast hole and estimated blockgrade colors. The grade class boundaries were chosen at the grade quantiles, thus each color occupiesapproximately 25% of the total area. Note that smoothing is minimal. For example, there is very littleoverlap of BH and block colors, even where the BH colors indicate skinny or narrow vein-like bands ofsimilar grades (colors). This is due to the local orientation of the search neighborhood and the properselection of BH data for the estimation of each block.

Figure 4: This is a plan view of a LAK ore control model (OCM) and blast holes. The OCM blocks are 2x2 m by bench height. Thecorrespondence between the BH and block grades (color classes) is quite good with minimal smoothing. The LAK kriging plan was

determined by cross validation to insure the block grade estimates are conditionally unbiased.

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

6/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

6

LAK Software

The LAK software consists of two Fortran 90 subroutines callable from MineSight subroutine U99612 (seeFigure 5. LAK may also be run as “stand alone” executables for mining operations using other softwaresuch as Vulcan or Gemcom etc.

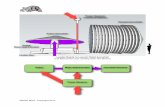

Figure 5: Schematic showing the implemention of LAK through MineSight subroutine U99612.

Program Naybor.

The initial program is known as “Naybor”. The main function of this program is to identify the orientationand anisotropy ratios of an optimum ellipsoidal search neighborhood for the estimation of a single block orcross validation of a single drill hole composite. The search neighborhood is designed to be optimum in thesense that the captured data are characterized by a minimum mixture of data from different statistical

populations. In other words, the purpose of this subroutine is to insure the proper selection of data for blockgrade estimation.

A secondary function of subroutine Naybor is to select, transform, and calculate directional samplevariograms using either composite or blast hole data (see Figure 3). The coordinates of the sample datacaptured within each optimum ellipsoid are referenced to the ellipsoid axes. Directional sample variograms

are calculated and written to an ascii csv file for subsequent fitting of a model using SAGE2001 forexample.

For the MineSight Version, drill hole composite or blast hole data input to the subroutine may be retrievedfrom AcQuire or MineSight as user specified through a data dump in the form of an ascii comma separatedvariables (csv) file.

Grid data in the form of individual I,J,K block coordinates and other block data such as rock type etc. may be provided by the MineSight U99612 subroutine. The U99612 subroutine provided by MineSight, provides read/write functionality between the 612 subroutine and the proprietary binary block model file.

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

7/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

7

Thus, block model data can be extracted, processed and written to the block model through the U99612subroutine.

For the Stand-alone Version, both the drill hole data and block model data must be prepared as ascii commaseparated value (csv) files.

The rotation angles and anisotropy ratios of each search neighborhood output by Naybor are written eitherto the block model stored in the proprietary Minesite binary block model or to an external ascii csv file inthe stand-alone version.

Program control is provided through driver and control files which the user must prepare using Excel andsave as ascii csv files.

Program LAKriger

The second program is known as the local anisotropy kriger or LAK. The primary function of this program

is to estimate block grades using either simple or ordinary kriging. Note that this program also providescross validation functionality.

Input composite or blast hole data is provided from an AcQuire data dump as described above for Nayboror as an external ascii csv file for the stand-alone version.

Grid or block data is provided by U99612 as described above or by an external ascii csv file. Note that the block data may include the rotation angles and anisotropy ratios identified by Naybor and written either tothe block model file by U99612 or to an external ascii csv file for the stand-alone version. LAK mayoptionally use these rotation angles and anisotropy ratios to define the search neighborhood for each blockestimate.

Program control for LAK is also provided through driver and control files which the user must prepare

using Excel and save as ascii csv files.

LAK Features include:o Sample selection optionally constrained by rock type and/or domain, search radius; octants;

number per drill hole; minimum/maximum number per search; etc.o Outlier restriction by search radius and cap valueo Nested variogram modelso Multiple passes in a single runo OK or SKo Local or Global search strategyo Cross validation “dead zone”.o Nine optional output statistics

Copy Protection

Both the stand-alone and MineSight module versions of the LAK executable program are copy protected.In order to execute the LAK program or executable, a pre-configured USB key must be inserted into a USB

port on the host computer. The USB hardware key must be inserted and remain in the computer USB slotwhile LAK is executed. However, the software may be installed on as many machines as required.

The LAK USB key will unlock SAGE2001 as well as LAK.

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

8/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

8

Digger forOptimum Dig-line Design

Do you realize that one 250 ton truck load of ore averaging 1 gram/tonne ausent to the dump results in a loss of approx $10,000.00 USD1 at today’s au

prices?

Here is an actual example of ore sent to the dump bymanually constructed dig lines. The red and green blocksare 5 x 5 ft ore control blocks. Red is ore averaging1g/tonne and green is waste. The circles represent blast holes. The bench height is 30feet. Thus, at 12.4 cubic feet/ton, each block contains approximately 60 tons. The dotted

black line is the manually drawn dig line. Obviously, the grade control engineer wantedto avoid sending green waste blocks to the mill. The minimum mining width is 15 feet, so in order to sendthe green blocks to the dump, he had to include several red ore blocks. Thus, the equivalent of at least 5 ore

blocks (counting partials) or 300 tons of ore grade material was sent to the dump! That’s more than 1 truckload or almost $12,000.00 of potential revenue gone to the dump.

Perhaps the grade control engineer could have reduced the dollar loss by sending some of the green blocksto the mill (dilution) in order to avoid sending ore blocks to the dump? Green blocks sent to the mill do notcontain sufficient metal to pay for the processing costs and so there is a loss there, but maybe this losswould be less than the $12,000.00 lost to the dump. To answer this question, the grade control engineerneeds to know at least the following in order to tediously compute revenues derived from various dig lineoptions:

o Cutoff gradeo The estimated block gradeso The ore recovery functiono Metal price

o

Mill costso Mining costs.o Minimum mining width

.This is a very simple case since there is only one ore type. But what if the ore deposit is complex withmultiple ore types? For example, it is not uncommon for an open pit operation to mine 6 to 15 ore types.With multiple ore types, it becomes impossible for even the best grade control engineer to design optimumdig lines. By optimum, we mean dig lines that minimize the misclassification of ore types, therebymaximizing net revenue.

Digger

Digger is a software product written in C++ for the design of optimum dig lines given a minimum mining

width constraint and multiple ore types. Digger can design optimum dig lines simultaneously for as manyas 15 to 20 ore types. Digger is designed to work with the blocks of an ore control model (OCM). These blocks may be very small, for example as small as 2 x 2 m horizontally. The rule is that the horizontaldimensions of the OCM block should 1/5 of the minimum mining width. For example, if the minimummining width is 10 m, then the OCM blocks should be 2 x 2 m x bench height. The principle behind diggeris simple – minimize dollars lost due to the misclassification of ore types given a minimum mining widthconstraint.

1 1 gram/tonne = 0.0292 oz/short ton. Therefore at $1350/oz, the value of 250 short tons is 1350 $/oz x 250ton x 0.0292 oz / ton or $ 9,855.00 or nearly 10,000 USD.

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

9/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

9

minimize[$loss|constraint] = minimize[(potential revenue - actual revenue)| constraint]

Correctly constructed revenue equations will yield maximum revenue if the material is sent to the correct process. This is the “potential value”. However, if material is sent to the wrong process, correctlyconstructed revenue equations will always yield less revenue than the potential revenue, thus incurring a

dollar loss. Figure 6 illustrates how individual OCM blocks may be sent to the wrong process ordestination.

Figure 6: An example showing an OCM composed of 2x2 m blocks and a 10 m minimum mining width. Given metal prices, OCM block grades, mill and leach pad recoveries, mill and leach pad break even costs, Digger will determine the optimum ore type for thecombined 5 OCM blocks. In other words, Digger will send the 5 blocks to the process that generates the most revenue.

However, sometimes the revenue equations are so complex, that sending material to the wrong processdoes not always incur a dollar loss. For these cases, one can assign a penalty factor within Digger forspecific ore type misclassifications. This enables one to “simulate” optimum dig line designs.

Figure 7: An example of Digger output. Red is mill ore; green leach pad material and blue is waste. The blast holes are also colored by ore type. The OCM blocks are 2x2 m and the minimum mining width is 10 m or 5 OCM blocks. If you examine the figure closely,

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

10/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

10

you will see that the mill feed, leach pad, and waste material can all be mined at the minimum mining width. Many blast holes aremissing because of missing sulfide sulfur (SS) assays which are required for ore typing. Note this Figure contains the same BH datashown in Figure 4.

Digger Input and Output

Digger input consists of an OCM with relevant block data. Digger can be set up to work with subsets of thetotal OCM. Subsets may be identified by blast ID or any other tag as required. Digger also reads inputcontrol parameters from an ascii parameter text file. Input parameters consist of things like input and outputfile names, processing costs, penalty factors etc.

Complex revenue equations may be specified in an auxiliary dll module. The dll module is not copy protected and may be edited by anyone on site. The main program Digger.exe is copy protected and is run by inserting a USB key into the host computer.

Digger outputs two ascii csv files with header records. The first file is a copy of the OCM with additionaloretype data for each OCM block.

The second file contains ore type polygons. These polygons may be imported into client grade controlsoftware such as Minesight, Vulcan, or Gemcom and overlain on the OCM. This provides the grade controlengineer with final editing capability. For example, the digger polygons can be seen as guidelines for thefinal dig line design by the grade control engineer if desired.

Digger runs fairly quickly. For example, it can process 50,000 blocks in a matter of minutes. Thus, it is possible to design dig lines for larger block models such as short term mine planning models. This providesan accurate estimate of the tons and grade that will be recovered at the time of mining given that the OCMgrade estimates are conditionally unbiased.

The current version of Digger is new product which became available to the industry early in 2010.Currently, Digger has been installed at two Newmont Mining mines; 2 Barrick Gold mines, and oneFreeport McMoran mine. Experience shows that Digger can improve net revenue by as much as 4 to 5%.

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

11/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

11

Designing an Optimum

Blast Hole Pattern andKriging Plan

forGrade Control

Introduction

This report is an actual case study showing the results of a unique method for optimizingthe spacing of blast holes for grade control. The method also enables the identification ofthe optimum blast hole pattern and number of blast holes to use to estimate each selectivemining unit (SMU).

1. The optimum blast hole spacing is one that minimizes the combined costs;a. drilling and assaying the blast holes; b. ore loss (ore blocks misclassified and sent to the waste dump);c. and dilution (blocks sent to mill with insufficient metal to pay for

processing).

2. The optimum kriging plan is one that provides conditionally unbiased estimates by retaining the correct number of blast holes from an optimum pattern for eachSMU estimate.

3. The results of the case study are shown in Figure 1 and Table1. The combinedcosts of drilling, assaying, ore loss, and dilution are minimum for a blast holespacing of 12.5 x 12.5 x 25 ft.

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

12/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

12

Figure 1: Blast hole drilling, assay and misclassification costs per ton versus drill hole pattern. The actualdata values are provided in Table 1.

Table 1: Blast hole drilling, assay and misclassification costs per ton versus drill hole pattern

Method

• A total of approximately 43,000 blast holes were retained for the study.• Figures 2, 3, and 4 show several level maps of the selected blast holes.•

The histogram and univariate statistics of the 43,000 BH grades are provided inFigure 5. Note the high coefficient of variation at 3.87.• Directional sample variograms were calculated and modeled using the 43,000

blast hole assays. The model and sample variogram plots are provided inAppendix 1.

• The 43,000 BH assays were transformed to a normal distribution.1. All Au values including tied values were initially transformed according to

their rank. Tied values were ordered randomly and given unique ranks.

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

13/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

13

2. The average of the normal scores of the tied Au values was calculated foreach group of tied Au values. The calculated average normal scores valuewas then assigned to each tied Au value within each group. This is animportant step because a very large proportion of the 43,000 blast holeassays are tied at 0.001 oz/ton etc. If the nscores transformation is not

done precisely this way, the simulated values will likely be globally biased.• Directional sample variograms were calculated and modeled using the 43,000

normal scores of the blast hole assays. The model and sample variogram plots are provided in Appendix 2.

• For each blast hole pattern from 10x10x25 to 25x25x25 ft.1. Design a blast hole pattern. For this particular deposit, a pattern of 9 holes

on the same bench as the block and 9 holes on the bench above isappropriate because of the strong vertical continuity in grade. This patternof 18 blast holes yielded conditionally unbiased estimates. This must bechecked, as more or less blast holes will yield conditionally biased results.

2.

Compute the ordinary kriging (OK) weights for each blast hole location ofthe current blast hole pattern using the Au gold variogram model.3. Compute the joint un-conditional simulation of blast hole grades at 49

discretization points within the 25x25x25 ft block and at the blast holelocations of the current blast hole pattern using the nscores variogrammodel (see Isaaks 2004).

4. Average the 49 simulated values to obtain a “true” simulated block grade.5. Calculate the OK “estimated” grade of the block using the OK kriging

weights and jointly simulated (18) blast hole values.6. Record the simulated “true” block grade and the “estimated” block grade.7. Repeat steps 2 to 6 --- 500,000 times.

8.

Summarize the misclassified simulated block grades in terms of dollarslost per ton.9. Summarize drilling costs in terms of dollars / ton.

• Identify the optimum drill hole pattern by minimizing the combined blast holedrilling and misclassification costs.

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

14/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

14

Figure 3: Example bench maps of blast hole grades from levels 6935 and 6950 – Red > 0.006 oz/ton.

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

15/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

15

Figure4: Example bench maps of blast hole grades from levels 6985 and 6990 – Red > 0.006 oz/ton.

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

16/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

16

Figure 5: Histogram and univariate statistics of the Blast Hole assays selected for the study.

The Simulation Software

The conditional simulation of the block discretization and blast hole grades was doneusing a custom built software program called BP.EXE (for Blasthole Pattern). Figure 6 provides a schematic of the input and output of the software. The following descriptionsdescribe how to use the software.

Figure 6. Schematic of software used to evaluate blast hole patterns.

Figures 7 and 8 provide examples of the blast hole location and input control parameterfiles.

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

17/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

17

Figure 7: The input file (ascii) of blast hole locations for the 15x15x25 ft. grid. Note the center of the

pattern is located at (0,0,0). This is also the exact center of the 25x25x25 ft block.

Figure 8: An example of the input control parameters to BP.EXE

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

18/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

18

Figure 9 provides a small example of the output from program BP.EXE while Figure 10shows the spatial configuration of the simulated blast hole locations, the 25x25x25 ft. block, and the 49 discretization points.

Figure 9: An example of the output from BP.EXE. The column labeled “Au” is the simulated grade of the25x25x25 ft block. The column labeled “Auhat” is the Kriged estimate of the block grade. The columnlabeled “OW” indicates the classification of the block as “O - ore; W- waste; O2W - ore to waste; andW2O -- waste to ore”. The column labeled “Revenue” provides the revenue according to the blockclassification and a revenue formula = Au grade x recovery rate x Au dollar value /oz - break even cost.

Figure 10: This figure shows the spatial configuration of the blast hole locations (red) relative to the 49discretization points (green) of the 25x25x25 ft. block. Nine additional blast holes are located at the same(x, and y) coordinates, but on the bench immediately above the block (see Figure 7). Note the co-located

blast hole and discretization point at the center (0,0,0) of the block.

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

19/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

19

Check the Simulated Values

As can be seen from the control parameters in Figure 8, ---- 500,000 realizations weresimulated for each blast hole pattern. In other words, there are 500,000 simulated blockgrades and 500,000 kriged estimates for each blast hole pattern. These simulated andestimated values should be checked for each blast hole pattern as follows:

• Compute the histogram and univariate statistics of the 500,000 simulated andestimated block grades and compare each mean to the mean of the 43,338composites (Figure 5). Figure 11 shows an example for the 15 ft. blast hole pattern. For example, the mean of the 43,338 composites is 0.00699 oz/ton whilethe mean of the 500,000 simulated block grades is 0.00713 which is close enough.It is interesting to note that the ratio of the block variance (0.0003105) to thecomposite variance (0.000736) is approximately 0.42. In other words, the blockvariance is only 42 % of the composite variance. This is useful information forchecking the grade tonnage curves of the resource model with “HERCO”.

Figure 11: The Histogram and statistics of the 500,000 simulated (Au) and estimated (Auhat) block gradesfor the 15 ft. blast hole pattern.

• Calculate a scatter-plot of the simulated Au versus Auhat values and calculate theregression line. Check that the slope of the regression line is 1.0 and the firstcoefficient near zero. The slope must be equal to 1.0 otherwise the kriged

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

20/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

20

estimates are conditionally biased. Figure 11 shows an example from the 15 ft.grid.

Figure 11: A scatterplot of the 500,000 simulated block values versus the 500,000 estimated block valuesfor the 15 ft. BH grid. Note the slope of the regression line is nearly 1.0.

Calculations and Results

The economic and tonnage factors used for this study are given in Table 2.

Table 2: Study parameters

The following list provides an explanation and calculation formula (where applicable) foreach of the recovery statistics shown in Figure 12.

• OW -- this column indicates the classification of the simulated ore block aseither; ore – O; ore to waste – O2W; waste – W; and waste to ore W2O.

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

21/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

21

• Simulated Realizations – this column provides the number of simulatedrealizations for each classification. The total number of realizations is 500,000.

• Mean (Au) oz/ton -- this is the average gold grade of the simulated block gradesfor each OW class.

• Mean (Auhat) oz/ton -- this is the average of the kriged or estimated block

grades for each OW class.• Sum(Revenue) --- this is the sum of the revenues calculated for each simulated

block for each OW class. The revenue equations are:o Break even cost (BE)

BE = cutoff grade x recovery rate x $(oz/ton) (1)

o For the O classrevenue Au(oz/ton) x recovery rate x $(oz/ton) - BE= (2)

o For the O2W class revenue 1.0*(Au(oz/ton) * recovery rate * $(oz/ton) - BE)= − (3)

o For the W class revenue = 0.0 (4)

o

For the W2O classrevenue Au(oz/ton) x recovery rate x $(oz/ton) - BE= (5)

• % Dilution

" 2 "

" " " 2 "

.% dilution *100

. .W O

O W O

No realizations

No realizations No realizations=

+

(6)

• % Ore Loss

" 2 "

" " " 2 "

.% dilution *100. .

O W

O O W

No realizations No realizations No realizations

=

+

(7)

• Predicted Ore Grade

" " " " " 2 " " 2 "

" " " 2 "

. * . *

. .O W W O W O

O W O

No realizations Auhat No realizations Auhat Grade

No realizations No realizations

+=

+

(8)

• True Ore Grade

" " " " " 2 " " 2 "

" " " 2 "

. * . *. .

O W W O W O

O W O

No realizations Au No realizations AuGrade No realizations No realizations

+=

+

(9)

• In Situ Value ($)

" " " 2 "

" " " 2 "

Sum Revenue -Sum Revenue($)

. .O O W

O O W

Value No realizations No realizations

=

+

(10)

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

22/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

22

• Recovered Value ($)

" " " 2 "

" " " 2 "

Sum Revenue Sum Revenue($)

. .O W O

O W O

Value No realizations No realizations

+=

+

(11)

• Loss($) / ton

Loss($/ton) Insitu Value($) - Recovered Value($)= (12)

The recovery statistics for all of the grid patterns are given in Figures 12 to17. Note thatthe “Predicted Ore Grade” is nearly equal to the “Recovered Ore Grade” for all tested blast hole patterns. Thus, the kriged estimates are conditionally unbiased which confirmsthe appropriateness of the 18 blast hole pattern.

Figure 12: Recovery statistics for the 10 x 10 x 25 ft. blast hole pattern (18 BH).

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

23/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

23

Figure 13: Recovery statistics for the 12.5 x 12.5 x 25 ft. blast hole pattern (18 BH).

Figure 14: Recovery statistics for the 15 x 15 x 25 ft. blast hole pattern (18BH).

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

24/26

Isaaks & Co

S pecialists in Spatial Statistics

1042 Wilmington Way Emerald Hills CA 94062 Phone [email protected]

24

Figure 25: Recovery statistics for the 17.5 x 17.5 x 25 ft. blast hole pattern (18BH).

Figure 16: Recovery statistics for the 20 x 20 x 25 ft. blast hole pattern (18BH).

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

25/26

-

8/19/2019 LAK Digger and Optimum BH Patterns.pdf

26/26

Isaaks & Co

S pecialists in Spatial Statistics

Au Normal Scores Blast Hole Variogram Model

Reference

Isaaks, E.H. 2004, “The Kriging Oxymoron: conditionally unbiased and accurate prediction ( 2ndEdition)”, in proceedings of the 2004 Geostat Congress, Banff, Alberta. (download fromwww.isaaks.com).

Since this study was done, Isaaks and Co. has upgraded the methodology to multi-variatecapability. For example, suppose the ore types for a particular operation are based ontotal gold, soluble gold, soluble copper, sulfide sulfur, and organic carbon assays. Forsuch a mining operation, the study must be done by jointly simulating all of the inputvariables described above. Isaaks & Co has found that the MAF or the Min/MaxAutocorrelation Factor method provides excellent results.

![[piano patterns]jazz book - john coltrane patterns.pdf](https://static.fdocuments.net/doc/165x107/55cf8679550346484b97fb8b/piano-patternsjazz-book-john-coltrane-patternspdf.jpg)