Installing Your f’real FRLB4 Blender · B) Slide Cup Lid up onto blending shaft and screw...

Transcript of Installing Your f’real FRLB4 Blender · B) Slide Cup Lid up onto blending shaft and screw...

Installing Your f’real FRLB4 Blender

Care should be taken to read and fully understand this Installation and

Operation Guide before installing the blender.

Failure to comply risks equipment damage, injury, fire, or shock hazard.

It is the sole responsibility of the buyer and installer to ensure that this

blender is installed in accordance with the “National Electric Code”, “Basic

Plumbing Code of Building Officials”, and/or any other local electrical and

plumbing codes as they apply.

Required Tools

Install Time: 20 minutes

8 Easy Steps

Crescent wrench 7/16” wrench Screwdriver

1 Connect freezer power cable to electrical outlet.

Freezer must be plugged in 1 hour prior to filling. Freezer tem-

perature should be maintaining 0°F to +6°F after 1 hour. If you

experience problems with the freezer, contact f’real Customer

Support Center at 800-483-3218.

2 Install blending components.

A) Open blender door by firmly pressing in square recessed button located near the bottom right side of the door.

B) Slide Cup Lid up onto blending shaft and screw blending assembly clockwise into shaft. Using (2) 7/16” wrenches

(or Crescent Wrench), snug blending assembly to shaft.

(A) Open Front Door

Final View

Blending Components

Cup Lid

TOP VIEW BOTTOM VIEW

Blending Assembly

(DO NOT INSTALL UPSIDE-DOWN)

(B) Install Cup Lid and Blending Assembly

Note: Cup Lid

will tilt when

properly

installed

Rev. G frea l .com • 1 -800 -483 -3218

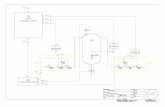

Location Water Line

Supplied Female

Quick-Connect

3 Insert drain line.

Drain Line

The f’real blender is equipped with 10’ of 3/4” ID drain hose. Use the pre-attached

3/4” ID antimicrobial drain hose to route rinse/waste water from blender to a proper

drain, taking care to slope drain line downward all the way to drain to provide for

free flow of rinse water.

Installing Your f’real FRLB4 Blender

4 Connect water line.

Note:

Before continuing with installation,

ensure the water supply line is from a

filtered water source.

A water shut-off valve should also be

installed near the blender.

Connect water supply line into the barbed side of the metal Female Quick-Connect

fitting and connect into Male Quick-Connect fitting located on blender.

Connect blender power cable

to an electrical outlet. 5 6 Note: Blender requires

dedicated 15amp 120 volt circuit.

Freezer and blender should not be

operated on the same circuit.

Turn on blender.

Open front door and turn on

power switch located in upper

right corner of blender.

Note: To open the front door, firmly

press on the square recessed button

located near the bottom right side of

the door.

Power Switch

7 Follow directions on the screen for easy

startup process.

Easy to follow steps:

1. Calibrate touch screen

2. Confirm blender is setup properly

3. Activate blender with the assistance of

f’real Customer Support Center by

calling 800.483.3218, option 4.

4. Please have ready installation location

information: Location name, telephone

number and full address.

5. Initiate steam cleaning cycle.

8 It’s time to make a delicious f’real Frozen Beverage!

Email us at

Have questions? Customer Support Center

1-800-483-3218.

We’re here to help.

frea l .com • 1 -800 -483 -3218

Rev. O All Rights Reserved

f’real Customer Support Center

Phone: 800-483-3218 - Email: [email protected]

(Part Number FR61-0001)

Installation & Operation Manual

Model: FRLB4

Rev. O 2

Table of Contents

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Limited Blender Parts Warranty . . . . . . . . . . . . . . . . . . . . . . . . 4

Freezer Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Tempering & Rotating Stock . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Notice Concerning Proprietary Software . . . . . . . . . . . . . . . . . 7

User Safety Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Blender Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Blender Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

General Blender Care (Daily) . . . . . . . . . . . . . . . . . . . . . . . . . . 13

General Blender Care (Monthly) . . . . . . . . . . . . . . . . . . . . . . . 14

System Operation Descriptions . . . . . . . . . . . . . . . . . . . . . . . . 15

On-Screen Blender Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-19

Rev. O 3

This product is warranted to be free from defects in material

and/or workmanship for a period of one year from date of

installation, not to exceed fifteen months from date of

shipment from our factory. Parts or components which prove

to be faulty in material and/or workmanship within the

warranty period would be eligible for replacement. All labor

for in-market repairs will be furnished by qualified technicians

provided by the customer at customer’s expense, not f’real

foods expense, unless otherwise agreed to in writing at the

time of blender purchase. Major repairs determined by f’real

foods to require removal of product from the market for

repair by a factory authorize representative will be performed

at no cost to customer.

This warranty is subject to the following exceptions and/or

conditions:

Any use of non-genuine f’real spare parts may, at f’real’s

discretion, void this warranty.

, neglect, improper cleaning

or maintenance and/or abuse (e.g., dropping, tampering

or altering parts, shipment damage, fire, flood or act of

God) is not covered under this warranty.

In no event shall f’real foods be liable for any other damages or losses including, but not

limited to: lost sales, lost profits, cost of down time, loss of use of equipment, cost of

substitute equipment, claims of Buyer’s customers, or any other special, incidental or

coincidental damages.

Limited Warranty

Rev. O 4

The Limited Blender Parts Warranty covers any parts found to be defective in materials or workmanship for one year from the date of installation, not to exceed fifteen months from the date of shipment from our factory. The Limited Blender Parts Warranty applies to blender parts only and does not include any labor/service. Please refer to the f’real Warranty Option Selection Agreement for any labor contracts agreed upon at the time of blender purchase. To make a part warranty claim one of the two following claim procedures must be followed:

For Parts Purchased for a Specific Under Warranty Blender Requiring Repair:

a. Contact f’real foods. Orders can be placed by phone at 800-483-3218 option 2 or emailed to [email protected].

b. Provide order information including blender serial number.

c. Warranty information is verified. Once verified, part(s) will be shipped via ground delivery at no charge. If over-

night shipment service is requested, then customer will be invoiced for the difference in shipping charges.

In the event warranty information could not be provided at the time of placing an order the following process must be followed if making a claim after the original purchase.

For Reimbursement of Parts Previously Purchased and Used on a Blender Under Warranty Requiring Repair:

a. Call for an RMA number. All part claims are to be handled directly with f’real foods Customer Support Center.

To request an RMA number, contact our Customer Support Center at 800-483-3218 option 3. To complete the RMA process, the blender serial number, part number(s), and contact information is required. RMA numbers are valid for 30 days from date of issue. Parts received without an RMA number will not be processed.

b. Send the part(s) back to f’real. Write the RMA number provided by f’real on the outside of the box being

returned. Shipping charges for returning parts shall be the responsibility of the customer. Ship part(s) back to:

f’real Customer Support Center Attention: Warranty 2884 NE Independence Ave Lee’s Summit, MO 64064

c. Credit memo issued. A determination will be made within 30 days of receipt of the part whether the claim has

been approved. If the claim is approved, a credit memo with the RMA number referenced will be issued. Credit will be issued for the part and applicable taxes. No credit will be given for shipping charges.

In the event a customer terminates the f’real Program, the customer must notify f’real foods Customer Support Center in writing to receive reimbursement for outstanding credits. Any credits remaining in account will first be applied to outstanding invoices. A check will then be issued for the remaining balance to the customer. Any use of non-genuine f’real Parts may, at f’real’s discretion, void this warranty. Damage caused by carelessness, neglect, improper cleaning or maintenance and/or abuse (e.g., dropping, tampering or altering parts, equipment damaged in shipment, by fire, flood or act of God) is not covered under this warranty. Additional parts purchased for warehouse or truck inventory are sold “as is” with no extended warranties.

Limited Blender Parts Warranty

Rev. O 5

Check Freezer Temperature Before Blender Installation

A potential cause of difficulties with the f’real Blender is the display freezer for frozen cups not being within the required 0 to +6°F temperature range. 0 to +6°F is the ideal temperature for frozen f’real cups at time of blending. Without opening the freezer door, check to see that temperature of freezer is near the ideal temperature of 0 to +6ºF.

If freezer is too cold or warm, adjust accordingly, ensuring that temperature stabilizes in desired range. It is best to make an adjustment, and then come back at least 1 hour later to see what the new, stabilized temperature of the freezer is.

Note: If freezer temperature is unexpectedly warm, freezer may be in defrost mode which takes about one half hour to complete. Check again later to see if temperature comes back down to ideal range.

If temperature is not in correct range, continue on with installation but be sure to get temperature corrected or the f’real frozen drinks will not be of optimum quality. If frozen cups are warmer than ideal temperature, the blender may not blend them. Extra cold cups will cause the blender to take longer to blend, and will eventually shorten blender life if left uncorrected.

Note: The 0 to +6°F temperature range applies to the display/serving freezer, not the longer term storage freezer. It is best to store frozen cups at 0°F or colder.

Freezer Temperature

Rev. O 6

Tempering and Rotating Stock

Tempering should be followed when stocking your sales floor freezer from a back-stock freezer

that is kept below 0°F. Immediately blending frozen drinks that are below 0°F can result in

inconsistently blended frozen drinks. Blending drinks that are too cold will also result in

unnecessary wear and tear on your blender. The frozen drinks should be between 0 to 6°F. If

the drinks are stored in a walk-in freezer at a temperature below 0°F, you will need to temper

or stage the product in a walk-in cooler to allow the product to temper to the desired range for

no more than 45 minutes. Once the product passes the “Squeeze Test” covered below, it can

be placed in the display freezer for customers to select and enjoy.

If the back stock freezer is below 0°F, product should be staged in a cooler for no longer

than 45 minutes prior to filling your sales floor freezer.

NOTE: Be sure to check the product every 15 minutes until the product passes the squeeze

test (see below).

Always rotate stock when filling from the back stock freezer to the front display freezer.

This will ensure that the stock that is properly rotated and tempered product will be

blended first.

If product that is below the recommended temperature is blended, there is a chance of

damaging parts inside the blender.

Product that is blended at the correct temperature ensures a consistent freshly blended

drink.

Squeeze Test:

To perform a “Squeeze Test,” take a chocolate milkshake and give it a squeeze in the middle of

the cup. Using your thumb, press on the side of the cup. You should see a small dent in the

side with a little bit of pressure. If you cannot indent the product, it is too cold for immediate

blending.

Tempering Process

Rev. O 7

The product includes software licensed by f’real foods from a third

party. The software, “Firecast OS software,” provides functionality

associated with the product’s graphics capabilities and remote management

of the product.

The customer of the product does not obtain title to the software, but is

obtaining sublicensed rights to use the software solely associated with use of

the product.

The customer may not copy, reverse engineer, modify or transfer rights to

use the software.

Notice Concerning Proprietary Software

Rev. O 8

Carefully read and follow all notices in this manual and on the equipment. All labels on the equipment

should be kept in good condition. Replace any unreadable or damaged labels.

Care should be taken to read and fully understand this Installation and Operation Guide before installing

the blender. Failure to comply risks equipment damage, injury, fire, or shock hazard. All installation and

maintenance work performed on the blender must be performed by a qualified technician.

It is the sole responsibility of the Buyer and Installer to ensure the blender is installed in accordance with

the “National Electric Code”, “Basic Plumbing Code of Building Officials”, and/or any other local electrical

and plumbing codes as they apply.

Specifications

Read the entire Installation and Blender Operation sections of this manual before using this

product.

Requires a dedicated 15A, 120V circuit and includes a 7 foot, three-wire power cord with NEMA

5-15 plug.

Follow all applicable national/local electrical and plumbing codes.

Ensure ground is connected for the blender.

Connect a water supply line filtered to 120 ppm hardness and 150 ppm TDS, to the blender before

connecting to the power source.

Copper levels on location must carry a specification of 0.3ppm, upper limit.

NOTE: High copper levels can come from an improperly plumbed store or Reverse Osmosis System.

Water pressure must be maintained between 25 - 65 PSI.

Use only new water supply lines.

Moving components rotate inside the blending chamber during the blending cycle. Never touch

moving components or cup lid when the blender is operating.

The blender is intended for indoor use only. The operating range for the blender is 40 - 90°F and 0

to 100% non-condensing relative humidity.

User Safety Notice

Rev. O 9

Site Requirements: 1. Blender requires a dedicated 15A, 120V circuit.

NOTE: Extension cords are not acceptable and may void warranty due to improper power supply.

2. The freezer unit requires a dedicated 15A, 120V circuit, in compliance with local electrical code. The freezer and

any other equipment should not be operated on the same circuit as the blender.

3. Blender requires a filtered, non-carbonated water supply, regulated to 25 - 65 PSI , with good water flow.

Water should be filtered to 120 ppm hardness and 150 ppm TDS. Additionally, install a shut off valve near the

blender. Use only new water lines. Ensure the water connection complies with local code.

4. The f’real blender requires a drain near where the blender will be placed. The f’real blender is equipped with a

10 foot, 3/4” ID drain line. The drain line must be sloped downward to the drain to provide for free flow of rinse

water.

Install Freezer:

Unpack the freezer from it’s packing carton. Plug-in the display freezer 1 hour before adding frozen product. Place

the freezer in desired location ensuring adequate air flow is maintained on all sides. Freezer will go through a

startup delay of up to 20 minutes before the compressor turns on.

Prepare blender for installation:

Unpack the blender from it’s packing carton. Caution: Use two-person lift, as the blender weighs 155 lbs.

4 Items used in installation are packed with blender:

1. Cup lid Weight - A round cup lid that one slides onto the blend shaft.

2. Blending assembly - To screw onto bottom of blending shaft.

3. Female Quick-Connect fitting with a 1/4” barbed end - For use in water line connection.

4. Clamp – Used to secure braided water line to Female Quick-Connect fitting.

Cup Lid Weight Blending Assembly

Blender Installation

Top Bottom

Water Line Clamp Female Quick-Disconnect

Rev. O 10

Prepare blender for installation - continued:

1. Open the blender front access door by firmly pressing the

square recessed button upward. The button is located near

the bottom right side of the door.

2. Slide the cup lid up onto the blending shaft, directing shaft

down through hole in its center. (See illustration at right)

3. While holding the cup lid up on shaft, thread the lower

spindle and blending assembly into the bottom of the

blending shaft and hand tighten it hard. (See illustration at

right) The metal slider should move freely side-to-side.

4. Close the front access door by pushing on its right side

until it latches.

Note: Do not slam the door shut as this will cause damage

to the interactive LCD screen.

Connecting water supply, drain and electrical:

1. Place the blender in the desired location. Caution: The blender weighs 155 lbs. Use two people to lift

the blender and set into place.

2. Use the pre-attached 3/4” ID anti-microbial drain line to route rinse water from blender to the drain,

taking care to slope the drain line downward all the way to drain to provide for free flow of rinse

water. Ensure the drain connection complies with local code.

3. Connect the location’s water line to the female quick-connect fitting, onto the male fitting on blender.

Be sure to not damage the o-ring. Open the water shut-off to the blender and inspect for leaks.

4. Plug the power cord into a dedicated 120V circuit capable of supplying at least 15A of power.

Caution: Do not plug blender in before connecting the water line.

Note: Do not plug the blender and sales floor freezer in on the same circuit.

Blender Installation - continued

Front of blender with door open

Square recessed button

TOP SIDE

BOTTOM SIDE

NOTE: Do Not Install Upside Down

Rev. O 11

Powering up the Blender:

1. Open the blender front access door by firmly pressing the square recessed button upward. Turn on

blender power using the switch in the upper right corner.

2. Close the front access door by pushing it closed on its right side until it latches.

Note: Do not slam the door shut as this will cause damage to the interactive LCD screen.

3. The LCD display will walk you through the Easy Startup Process. Follow the on-screen instructions.

a. Calibrate touch screen.

b. Confirm blender is properly setup.

c. Initiate a self diagnostic test.

d. Activate the blender with the assistance of f’real Customer Support Center. When you’re ready

for this step call the f’real Customer Support Center at 1-800-483-3218 (option 4). Please

have the following information ready: Location name, telephone number and full address.

e. Initiate steam cleaning cycle.

Confirm Normal Blender Operation:

1. Remove the lid and place a f’real frozen product in the cup holder. The blender should recognize the

cup in the cup holder and provide you with thickness choices on the LCD screen and the key pad

membrane.

2. Press the desired thickness to start a blending cycle. The blender will take the cup up into the

blending chamber and mix it for approximately one minute.

3. When the cycle is complete, the cup holder will return to it’s “home” position and you will be able to

remove the cup from blender and enjoy!

Blender Installation - continued

Rev. O 12

f’real Blender Operation:

Operation of the f’real Blender is designed to be entirely self-serve, therefore instructions are provided on

the blender.

The Simple Operating Instructions are:

1. Select one of the frozen cups from the freezer.

2. Remove the lid and place the cup in the blender’s cup holder.

3. Select your preferred thickness either using the touch screen or lower membrane pad. The cup will

automatically go up to blend and will be finished in approximately 1 minute! The blender will run an

automatic rinse inside after each drink is blended.

Potential Mistakes by Customer, and What Happens:

If the customer does not remove the lid, blender will sense this when the blending disc hits the foil lid and

the blender will reverse itself and bring cup back down to the home position.

If the customer uses wrong cup, the blender will reject the cup when it senses an incorrect cup has been

used.

If the customer places a previously blended cup back into the blender, the blender will take the cup up

and begin to blend. However, as soon as blender senses that there is not the expected resistance of

frozen product in the cup, it will stop and reverse itself, bringing the cup back down to the home position.

Blender Operation

Rev. O 13

Wipe down blender screen daily with soft cloth and glass

cleaner. Don’t spray solution directly on screen; spray

on to cloth. Spraying directly on blender screen may

damage screen.

2

3 Wipe down entire outside of blender

daily. Don’t spray solution directly on

blender; spray on to cloth.

Areas requiring daily attention:

4 Raise the Cup Holder for easier cleaning by

pressing: Less Thick + Regular Thickness. Cup

Holder will raise for 60 seconds and return to it’s

home position on its own.

General Blender Care (Daily)

The blender automatically cleans and steam sanitizes on the inside

daily, every 24 hours. 1

For More Information - Please visit f’real University: Press and hold the “Less Thickness” + “OK” buttons - Key in 411 & Enter - Select “Customer Settings” - Select “f’real University”

Rev. O 14

Open the front door of the blending chamber, lift up the flip-up door by pressing upwards on the

flip-up door arm with one hand and clean off any product build up around the Blending Chamber Rim

with a clean damp cloth. Be careful not to damage the Silicone Gasket during this process.

Blending Chamber Rim

Silicone Gasket

Clean the cup sensors that are located underside of blending chamber monthly. 2

Underside of

blending chamber

3 Clean out the water port with de-liming tool monthly. Insert tool shown below into Water Shot Port

as far as possible. Twisting the tool may help to break up any scale deposits.

Water Shot Port

Inside Front Door

General Blender Care (Monthly)

Areas requiring monthly attention:

1

Q-Tip

Rev. O 15

The FRLB4 is comprised of several separate systems that all work together to complete a successful blend.

1. The Linear Motion System is comprised of several components that are responsible for carrying the frozen

drink through its full range of travel. The Position Motor is controlled by the Low Voltage Control Board. The Cup Carriage Assembly is attached to the Position Belt and travels along the Guide Rod as directed by the Position Motor.

2. The Blending System consists of the Mix Motor, the Lower Spindle, and the Blending Components. The Mix Motor is powered by the High Voltage Control Board and the Blending System is controlled by the LVCB. It is responsible for blending the frozen drink.

3. The Water System is responsible for supplying water to the blender for all rinsing events, blending a frozen drink, and sanitizing the blender system. The water is pushed through the system by the Rotary Pump Head which is powered by the Pump Motor. The Rotary Pump Head forces the water past the Flow Meter which counts the water flow to ensure proper water flow. After passing through the Flow Meter, the water will be directed to the desired location by the Water Manifold. The Manifold channels the water to both water heaters and the rinse nozzles as directed by the Low Voltage Control Board.

4. The Electrical System is a series of several control boards that supply electrical power to various switches, sensors and motors inside the blender. The High Voltage Control Board has 120 volts supplied to it from the outlet. The HVCB then supplies 120 AC volts to the water heaters and voltage to the mix and pump motors. The HVCB also supplies 120 volts to two separate 24vdc power supplies, these power supplies take the incoming 120 volts AC and reduce it to 24 volts DC, which is then directed to the Low Voltage Control Board, Single Board Computer, LCD screen and the Cooling Fan. The LVCB and the SBC use this incoming 24 VDC to operate the Position Motor and many other switches and sensors.

5. The Front Screen System is used to display screen content and as is also used as an input device. The LCD

screen displays information sent to it from the Single Board Computer. The LCD screen also senses touch

commands from the consumer and sends them to the SBC. The SBC then relays these commands to the

Low Voltage Control Board to be turned into mechanical motion for blending a frozen drink. The touch

function of the LCD screen can also be used to navigate through screens that supply information to

customers.

6. The Safety System is a series of switches, sensors and locks designed to ensure the doors remain closed at

the proper times. These sensors and switches are triggered during the blend process and provide the Low

Voltage Control Board with information that is used to lock doors at the correct points of blending. The

Flip-Up Door is also locked during the sanitize cycle and the various rinse cycles during normal operation.

These doors need to be locked during the blend and sanitize process to prevent access to hot or moving

internal parts of the blender.

System Operation Descriptions

Rev. O 16

On-Screen settings and troubleshooting help can be easily accessed by using the touchscreen. Use the

following steps to access the on-screen blender settings:

To access the on-screen settings press and hold ‘Less Thick’ + ‘OK’ for 5 seconds. A keypad will appear. Type in ‘411’, then ‘Enter’. The initial screen will display four buttons (represented in the blue boxes below). Some buttons will have additional options when pressed (represented in the gray boxes below).

Calibrate Touchscreen

Customer Settings

Contact f’real Customer Support Center

Error Help

Health Inspector

Cleaning and Sanitizing Log

If the touchscreen is not responding to touch, run this calibration process following the on-screen instructions.

A variety of settings, information, and troubleshooting can be accessed with this button. Listed below are the options available within Customer Settings.

This button will give you a list of all error codes that can be displayed on the screen. It also gives a description of the error. This code will be useful for troubleshooting the blender.

This area is for the Health Inspector. It will answer questions about the cleaning and sanitizing process along with some other helpful information.

Lists (in chart form) the date, start time, end time, duration of cleaning cycle, maximum temperature achieved, and the status (pass or fail) of each cleaning cycle.

Selecting this will give a detailed description of what the blender is accomplishing during the cleaning & sanitizing cycle.

This will activate the cleaning and sanitizing routine. Once this button is selected, you will be asked to confirm your selection. Once started, this process cannot be stopped.

Activate the Cleaning & Sanitizing Cycle

Activate Cleaning & Sanitizing Cycle

Lists the phone number and hours of operation for the f’real Customer Support Center.

This button provides training video(s) and quiz(zes) to ensure the entire store staff is familiar with the use & maintenance requirements of the blender.

This shows the summary information about the blender, including the Unit ID, Firecast ID, Firmware version, attempted blende, completed blends, original install date and current local time.

This will manually activate a cleaning & sanitizing cycle. When pressed you will be asked to confirm your choice. The blender will initiate the sanitize cycle and be unusable for approximately 12 minutes.

On-Screen Blender Settings

f’real University Quiz Results Log

Provides a log of completed quiz results. Tool to track which of your employees have completed the quiz.

Automated Daily Cleaning & Sanitizing Description

Display Blender Information

f’real University

Rev. O 17

Blender Issue Troubleshooting

Frozen product, before blending, should be approximately

two-thirds full in the cup. If cups are too full contact the

f’real Customer Support Center at 1-800-483-3218.

Product could have been thawed and then refrozen upside

down or at an angle. Choose another product from the

freezer. Inspect for any improperly stored cups and

dispose of them as needed.

Blender gives a “cup too full” message

Troubleshooting Keypad Shortcuts

Purpose Key Combination Pin Code

Calibrate the touchscreen Regular + OK N/A

Access the Customer Setting Screens Less Thick + OK 411

Screen is not working properly Right Arrow + Left Arrow N/A

To reset an error condition on the screen Regular + More Thick N/A

Troubleshooting Guide

Blender front door is not fully latched. Press the middle

right edge of the door firmly until the door latches. You

will hear and feel the door latch.

Blender fails to respond to

thickness selection and displays

“Please close front door”

Troubleshooting Guide

Frozen product has a foil lid that should be removed

before product is blended.

Cup goes up & back down before blending

& error says, “Please remove cup lid”

The blender has encountered high resistance. Make sure

nothing is obstructing the cup holder as it moves up or

down.

Blender displays the “Something’s in the

Way of the Cup Holder” message

Ensure the water supply is turned on and water

connection is secure on the back of the blender. Check the

temperature of the freezer. f’real frozen products should

be stored between 0-6 degrees F.

Blended drinks are not the

Correct consistency

Rev. O 18

Blender Issue Troubleshooting

Troubleshooting Guide - continued

Press the ‘left’ & ‘right’ arrows on the lower keypad for 6

seconds. The screen will go blank and then come back on

with the attract loop.

Perform a reboot of the system. Open the front door and

turn the power off. Wait 15 seconds and turn the power

back on. Screen should come back playing the attract

loop.

LCD touchscreen is not working, blank or

displaying images incorrectly

Press and hold ‘regular’ & ‘more’ blend buttons at the

same time for 5 seconds. The screen should return to the

attract mode. The cup carriage should re-home. There

will be about 10 seconds of water events and then the

blue LED’s will start circling the buttons again.

Cup stuck in blending chamber

Check to make sure the drain line is sloped downward and

is kink-free all the way to the drain.

Rinse water is not draining from chamber

Ensure the power switch is turned on. The switch is black

and is located along the right side with the door open.

Press the top portion of the switch to turn on.

If the blender is on, turn it off and wait 5 seconds, then

turn it back on.

Check to ensure the power cord is plugged in a dedicated

15A, 120V circuit.

Blender does not light up

Check the temperature of the freezer. Product that is too

cold will take longer to blend and will cause unnecessary

wear on the blending system. The temperature range

should be between 0 - 6°F.

Blending takes too long

Rev. O 19

Troubleshooting Guide - continued

Press and hold ‘regular’ & ‘more’ blend buttons on the lower keypad for 5 seconds. The screen should return to attract mode. The cup carriage should re-home if it isn’t there already. There will be about 10 seconds of water events and then the blue LED’s will start circling the buttons again. The blender is ready to be used again.

If the problem continues, please contact the f’real Customer Support Center 1-800-483-3218

Blender has a message on the display

screen, “Blender is Temporarily Out of

Service, Code #”

For additional troubleshooting information,

please review the FRLB4 Service Manual.

You may also contact the f’real Customer

Support Center @ 800.483.3218

Ensure the water supply line is turned on and water inlet

line is properly attached to the back of the blender. Low

or no water flow will cause this issue.

If the water line is connected, disconnect and reconnect

the water line. Then reset the blender.

Reset the blender by pressing and holding the ‘regular’ &

‘more’ blend buttons at the same time for 5 seconds.

Blender is displaying one of

the following error codes:

Error 7D/“Blender Needs Water to

Blend” or Error 81

Blender Issue Troubleshooting

Contact the f’real Customer Support Center at

1-800-483-3218.

Needing or missing a part?