Hydraulic Digger Step-by-step assembly instructions (c) 2013 Mechanical Kits Ltd.1.

-

Upload

berenice-henry -

Category

Documents

-

view

219 -

download

2

Transcript of Hydraulic Digger Step-by-step assembly instructions (c) 2013 Mechanical Kits Ltd.1.

(c) 2013 Mechanical Kits Ltd. 1

Hydraulic Digger Step-by-step assembly instructions

(c) 2013 Mechanical Kits Ltd. 2

Contents of Digger Kit

Wooden pieces (⅜” cross-section): 2 X 20 cm (7.87”); 2 X 13cm (5.12”); 2 X 12.5cm (4.92”); 2 X 11cm (4.33”);

2 X 6cm (2.36”); 3 X 4cm (1.58”); 4 X 2.7cm (1.06”); 1 X 2cm (0.79”); 2 X 1cm (0.39”)2 X forks

1 X 3²cm Block (1.81²”); 1 X Block (2 X 3cm (1.18”) + 1 X 1.5cm (0.59”))Syringes, 10cc: 6 (3 have a hole in the plunger)

Plastic Tubing: 3 lengths Wooden dowel, 3/16” diam.: 2 X 12.5cm (4.92”); 6 X 10cm (3.94”); 1 X 8cm

(3.15”); 3 X 5cm (1.97”); 2 X 3cm (1.18”) ; 7/16” diam.: 1 X 7cm (2.76)

Syringe Holders: 3Mini-washers: 30

1 X Base Platform (8” X 4”); 1 X Rotating Platforms (4” X 4”)Large wheels X 3 (1 with 7/16” hole); Medium wheels X 3

1 piece thin cardPlus a small piece of sandpaper

(Use 1cm² thin card to check lengths)

(c) 2013 Mechanical Kits Ltd. 3

(c) 2013 Mechanical Kits Ltd. 4

Cut out the shape from the card and form the bucket as shown below. Keep the extra pieces as some will be used to reinforce

pieces of wood joined together. Each square is 1cm².

(c) 2013 Mechanical Kits Ltd. 5

Using a 10cm dowel connect the pieces as shown below: (left-to-right) mini-washer, 6cm piece, 1 cm spacer block, 12.5cm piece, mini-washer, 2cm spacer, mini-washer, 12.5cm piece, 1cm spacer block, 6cm piece and mini-washer. Use the mini-washers

at each end to hold the pieces firmly together. This is called “SA-1” for later reference.

(c) 2013 Mechanical Kits Ltd. 6

Using a 10cm dowel as a temporary alignment guide, glue the two forks to the 4cm piece – without holes - so that the ends of the 4cm piece flush with the

sides of the forks, as shown below. Cut two 2 X 1 card pieces and glue to reinforce, as shown below.

(c) 2013 Mechanical Kits Ltd. 7

Using two 12.5cm dowels as guides to get the wheel axles perpendicular to the long edge of the base plate, glue the four 2.7cm pieces in place, as shown

below. Ensure the glue is dry before moving on.

(c) 2013 Mechanical Kits Ltd. 8

Using two mini-washers and two 20cm pieces and a 10cm dowel, glue the fork assembly in place so that it is approx. 45° to the 20cm pieces, as shown below. The

10cm dowel will protrude evenly on each side. For later reference this is “SA-2”.

(c) 2013 Mechanical Kits Ltd. 9

Glue the large wheel with the 7/16” hole to the base plate and insert the 7cm dowel (7/16” diam.) into the hole – it is a tight fit. Ensure the dowel is upright. Insert a 3cm dowel into the center hole of a

medium wheel until it is flushed with the top side and place this through the 3/16” hole in the base plate. Place on one side for later.

(c) 2013 Mechanical Kits Ltd. 10

Insert two 5cm dowels through the holes that are closest together in the one of the rotating platforms. They should protrude 3cms on one side and approx. 1.5 cm on the other. Glue the 4cm pieces – with holes – to the 1.5cm lengths of dowel. Use a

dowel to ensure that the holes in the 4cm pieces are aligned, as shown below.

(c) 2013 Mechanical Kits Ltd. 11

Insert the remaining 5cm dowel and the 3cm dowel through the other holes in the platform and glue the two 11cm pieces in place, as shown. Again, use a dowel to align the holes in the same plane as the holes in the 4cm pieces.

(c) 2013 Mechanical Kits Ltd. 12

Cut a 3cm² piece of cardboard and glue it to the 3cm² block. Cut a 3cm X 1.5cm piece of cardboard and glue it to the other block as shown. The dowel

is shown for orientation.

(c) 2013 Mechanical Kits Ltd. 13

Using 4 mini-washers and a 10cm dowel, connect the 3cm² block to the two 11cm upright pieces as shown. The 3cm² block will be in the middle of the

10cm dowel. Using 2 more mini-washers connect 2 X 13cm pieces to the 4cm upright pieces as shown.

(c) 2013 Mechanical Kits Ltd. 14

Connect SA-1 to SA-2. First, using 2 mini-washers connect the 6cm pieces of SA-1 to the 10cm dowel of SA-2 – shown in the bottom portion below. Then, using the 8cm dowel, 4 mini-washers and a 10cc syringe with a hole in its

plunger, connect the 12.5cm pieces of SA-1 to the 20 cm pieces of SA-2. Use the middle holes (of the remaining 3) in the 20cm pieces.

(c) 2013 Mechanical Kits Ltd. 15

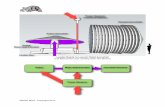

Strip off the protective covering from underneath a syringe holder and place the holder firmly onto the center of the medium wheel – use the side where

the 3cm dowel is flushed with the surface. Place a 10cc syringe, with a hole in its plunger, onto the leg under the rotating platform as shown below.

(c) 2013 Mechanical Kits Ltd. 16

Strip off the protective covering from underneath the other 2 syringe holders and carefully and firmly push then onto the 3cm² block and the other block. Push the rotating platform onto the 7/16” upright dowel in the base plate until approx. ¼”

protrudes and the three legs touch the base plate. Insert 3cm dowel in the medium wheel and push into the base plate and snap the barrel of the syringe into place.

(c) 2013 Mechanical Kits Ltd. 17

Using 2 mini-washers and the last remaining syringe with a hole in its plunger, and a 10cm dowel connect the syringe to the top holes of the 20cm piece of

the SA-1+SA-2 assembly, as shown below

(c) 2013 Mechanical Kits Ltd. 18

Connect the SA-1+SA-2 assembly to the 13cm pieces on the rotating platform using 2 X mini-washers.

(c) 2013 Mechanical Kits Ltd. 19

Insert the two syringe barrels into the syringe holders as shown below without removing the protective cover from the sticky pad inside the holders. Note the position of the syringe barrels in each clip and the orientation of the syringe holders in the diagram and how one plunger is extended. When the syringes are positioned remove them from the holders, then strip off the protective

coverings from inside the holders and replace the syringes.

(c) 2013 Mechanical Kits Ltd. 20

Glue the bucket onto the two forks, and the wheels onto the 12.5cm dowels once the dowels are inserted through their holders on the underside of the

base platform. Connect the 3 other syringes and tubing. Use air in the syringes initially and then, once you have practised a little, use water in them. Use a

very small drop of washing-up liquid with the water as a lubricant.