HANDBOOK ON BREAKDOWN MANAGEMENT OF OHE · Handbook on Breakdown Management of OHE January, 2018...

Transcript of HANDBOOK ON BREAKDOWN MANAGEMENT OF OHE · Handbook on Breakdown Management of OHE January, 2018...

CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0

Hkkjr ljdkj GOVERNMENT OF INDIA

jsy ea=ky; MINISTRY OF RAILWAYS

HANDBOOK

ON

BREAKDOWN MANAGEMENT OF OHE

dsoy dk;Zky;hu mi;ksx gsrq

(For Official Use Only)

CAMTECH/E/2017-18/EP-6-OHE-Breakdown/ 1.0

January, 2018

END USER: TRD MAINTENANCE STAFF

HANDBOOK

ON

BREAKDOWN MANAGEMENT OF OHE

QUALITY POLICY

“To develop safe, modern and cost

effective Railway Technology

complying with Statutory and

Regulatory requirements, through

excellence in Research, Designs

and Standards and Continual

improvements in Quality

Management System to cater to

growing demand of passenger and

freight traffic on the railways”.

CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0

CONTENTS

Sr.No. Description Page No.

Contents

Correction Slip

CHAPTER 1 GENERAL DESCRIPTION 01 1.1 KNOWLEDGE OF RULES 01

1.2 TYPES OF BREAKDOWNS 01

1.3 BREAKDOWN GANGS 01

1.4 EMERGENCY STORES AND BREAKDOWN EQUIPMENT 01

1.5 RECORD OF STAFF MOVEMENTS 02

1.6 SUMMONING OF EMERGENCY STAFF 02

CHAPTER 2 OHE BREAKDOWNS 03 2.1 IMPORTANCE OF EXPEDITIOUS REPAIRS 03

2.2 TYPES OF OHE BREAKDOWNS 03

2.3 LOOK-OUT FOR OHE DEFECTS 03

2.4 ACTION TO BE TAKEN BY TPC 04

2.5 PROTECTIVE STEPS 04

2.6 BREAKDOWN STAFF 04

2.7 OFFICERS AND SUPERVISORS TO PROCEED TO SITE 05

2.8 ASSISTANCE TO BE SOUGHT 05

2.9 CONTINUOUS COMMUNICATION WITH TPC 05

2.10 DETAILED ASSESSMENT BY THE FIRST SUPERVISOR/OFFICER

REACHING SITE 05

2.11 PRESERVATION OF EVIDENCE 06

2.12 SAFETY RULES TO BE OBSERVED 06

2.13 TEMPORARY REPAIRS FOR RESTORATION OF TRAFFIC 06

2.14 CLEARANCE OF LINE FOR DIESEL TRACTION 06

2.15 WIRING TRAIN 06

2.16 INTERFERENCE WITH OHE DURING RESTORATION 07

2.17 TEMPORARY DIVERSIONS 07

Sr.No. Description Page No.

2.18 TEMPORARY SPEED RESTRICTIONS 08

2.19 FUNDS REQUIRED FOR DEALING WITH BREAKDOWNS 09

2.20 LOG OF EVENTS AND REPORTING OF BREAK-DOWNS 09

2.21 PROTECTION OF STAFF 10

2.22 USE OF CRANES 10

CHAPTER 3 ROAD VEHICLES 11 3.1 USE OF ROAD VEHICLES DURING EMERGENCIES 11

3.2 DRIVER'S DUTIES. 11

3.3 OPERATION OF ROAD VEHICLES 12

3.4 PRECAUTION WHEN TRANSPORTING HEAVY MATERIALS 13

3.5 TRANSPORTATION OF PERSONNEL 13

3.6 PARKING 14

3.7 MAINTENANCE OF ROAD VEHICLES 14

3.8 PROCEDURE IN TRAFFIC ACCIDENTS 15

CHAPTER 4 ELECTRICAL ACCIDENTS 16 4.1 ELECTRICAL ACCIDENT 16

4.2 ELECTRICAL ACCIDENTS • ACTION TO BE TAKEN 17

4.3 OBSERVANCE OF RULES 17

4.4 ELECTRICAL INSPECTOR TO RAILWAY 18

4.5 REPORTING OF ACCIDENTS 18

4.6 ACCIDENT INQUIRIES 19

4.7 ACCIDENT REGISTERS AND ANNUAL RETURNS 19

4.8 FIRST AID 19

4.9 RESUSCITATION FROM ELECTRICAL SHOCK 21

4.9.1 Instructions to be Displayed 21

4.9.2 Removal from Contact 21

4.9.3 Artificial Respiration 21

4.10 TYPICAL ELECTRICAL ACCIDENTS 23

CHAPTER 5 BREAKDOWN MANAGEMENT 26 5.1 TYPES OF BREAKDOWN 26

5.2 HOW TO HANDLE BREAKDOWNS 26

5.2.1 Pre Breakdown Preparation 26

CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0

Sr.No. Description Page No.

5.2.2 Management and monitoring the restoration 27

5.2.3 Post Breakdown Review 27

5.3 CONCLUSION 28

5.4 MISSION 28

5.5 ESSENTIAL IDEAS OF SUCCESSFUL ACCIDENT MANAGEMENT 28

5.6 CHECK LIST FOR OHE BREAKDOWNS 29

5.7 TOOLS AND PLANTS TO BE AVAILABLE IN TOWER CAR 30

5.8 PANTO ENTANGLEMENTS: ITEMS TO BE CHECKED ON PANTOGRAPH 35

CHAPTER 6 IMPORTANT MAINTENANCE INSTRUCTIONS TO BE FOLLOWED TO AVOID OHE BREAKDOWNS/ ACCIDENTS AND TO KEEP THE OHE HEALTHY 37

ISSUE OF CORRECTION SLIPS

The correction slips to be issued in future for this handbook will be numbered as follows :

CAMTECH/E/2017-18/EP-6- OHE-Breakdown /C.S. # XX date---------

Where ―XX‖ is the serial number of the concerned correction slip (starting from 01

onwards).

CORRECTION SLIPS ISSUED

Sr. No. Date of issue Page no. and Item no.

modified

Remarks

CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0 1

Handbook on Breakdown Management of OHE January, 2018

CHAPTER 1

GENERAL DESCRIPTION

1.1 KNOWLEDGE OF RULES

All Officers and Supervisors of the Traction Branch should be fully conversant with

the "Rules for Reporting Accidents" and other instructions in force for dealing with

accidents and breakdowns. The instructions given in the following paragraphs are to be

treated as supplementary instructions applicable specifically to traction installations; they

should not be taken as nullifying or contradicting the instructions contained in other official

manuals.

1.2 TYPES OF BREAKDOWNS

The types of break-downs pertaining to electric traction can be broadly divided into

the following categories:-

1. Sub-stations and switching stations

2. Remote control equipment and cables

3. OHE feeder lines and transmission lines

1.3 BREAKDOWN GANGS

Accidents and breakdowns involving

traction installations and electric rolling-

stock should normally be attended to by the

maintenance gangs themselves. It is,

however, essential that adequate number of

experienced traction staff should be selected

and housed in railway quarters close to

traction installations, so that their services

can be utilized at short notice for dealing

with breakdowns and accidents whenever

required.

In electrified suburban sections, however, 'breakdown gangs' of adequate strength

may be located at selected points to deal promptly with OHE failures, particularly during the

hours of peak traffic.

1.4 EMERGENCY STORES AND BREAKDOWN EQUIPMENT

1. For each OHE depot/sub-depot, the actual quantity of OHE stores like masts,

conductors, insulators, fittings etc. which should be earmarked especially for use in

breakdowns will be laid down by Sr. DEE (TrD). To start with, all materials required

for 3 kilometers of single line may be kept. Based on experience, the minimum and

maximum quantities may be, revised from time to time. An inventory of such OHE

stores should be maintained by the supervisor-in-charge of the depot/sub-depot and

stocks recouped periodically so as to ensure that the minimum quantity is always

2 CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0

January, 2018 Handbook on Breakdown Management of OHE

available. During periodic inspections by officers, scrutiny of this inventory should

be one of the important items in order that the required stores are always made

available.

2. OHE Inspection Cars, wiring trains,

breakdown lorries and all break-

down tools, tackles, straining screws,

clamps, ladders etc. shall be

maintained in good condition and

kept ready for use at all times.

Though it will be the primary

responsibility of the supervisor in-

charge of the OHE depot/sub-depot

to ensure that all breakdown

equipment is in good working order, supervisors and officers at all levels should

specially check their condition during their periodical inspections. A periodic review

should also be made regarding the adequacy of such spares and tools.

3. The SSE (PSI) and SSE (RC) should also have in their custody spares and tools

pertaining to their work as per scale to be laid down by Sr. DEE (TrD) for dealing

with breakdowns and accidents.

1.5 Record of Staff Movements

TPC should, even when everything is normal, keep a continuous record of the

movements of maintenance gangs so that he can contact the gangs immediately whenever

required to attend to any emergency. All senior supervisors and officers of the Traction

Distribution Branch should also keep the TPC informed of their movements. These

instructions also apply to off-duty hours for officers, senior supervisors and key personnel.

1.6 Summoning of Emergency Staff

To enable the TPC to summon staff as

required, a register showing the residential

addresses and mobile/telephone numbers of

specified staff of the Traction Distribution branch,

particularly those residing in railway quarters or

close to railway stations, should be maintained

station-wise by TPC. Normally siren is blown to

call emergency staff during emergencies.

The list of office and residential

mobile/telephone numbers of officers and supervisors should also be kept up-to-date by him

for ready reference.

In view of the importance of communication facilities in an emergency every

telephone should be tested at least once a month.

CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0 3

Handbook on Breakdown Management of OHE January, 2018

CHAPTER 2

OHE BREAKDOWNS

For the purpose of railway working, accident/breakdown is an occurrence in the

course of working of railway which does or may affect the safety of the railway, its engine,

rolling stock, permanent way and works, fixed installations, passengers or servant or which

affect the safety of others or which does or may cause delay to train or loss to railway.

2.1 IMPORTANCE OF EXPEDITIOUS REPAIRS

Every breakdown of OHE, even if minor in nature, should be attended to urgently as

it is generally interferes with traffic. Since electrified lines carry a high density of traffic, the

effect on traffic will be quite severe if restoration is not arranged expeditiously.

2.2 TYPES OF OHE BREAKDOWNS

The common types of OHE breakdowns are as under-

1. Uprooting of or damage to OHE masts on account of cyclone, derailments etc.,

2. Entanglement of pantographs with the OHE,

3. Snapping of OHE- conductors,

4. Flash-over or other damage to insulators,

5. Faults on account of stray wires etc.,

6. Theft of OHE conductors.

2.3 LOOK-OUT FOR OHE DEFECTS

The engine crew of all trains should keep a sharp look-out and report to the TPC

from the nearest station any defects noticed by them in the OHE.

All break-downs or defects in OHE

which are likely to affect the train services,

noticed by any Railway servant, shall be

reported immediately to TPC. If TPC cannot

be contacted, the nearest Station Master or

Cabin Assistant Station Master shall be

advised' The SM/CASM to whom such

breakdowns or defects are reported shall

convey the information immediately to TPC

4 CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0

January, 2018 Handbook on Breakdown Management of OHE

through the control or other available telephone. The person reporting a

breakdown to TPC should give as detailed information as possible on the

nature of the breakdown, its location, if masts have been uprooted or both

lines in a double track section have been affected etc.

The person conveying the information to TPC should not leave

the vicinity of the telephone without TPC's permission, as the latter may

want to contact him again to elicit further information.

2.4 ACTION TO BE TAKEN BY TPC

If required, TPC shall direct the nearest available Electrical Department official to

proceed to site to obtain full details. Simultaneously the TPC should switch off power

supply to the affected lines and inform the Section Controller.

Though initially power may have to be switched off over a whole sub-sector, the

faulty elementary section should be identified and isolated as quickly as possible so that

power supply may be restored to the healthy sections and. normal train operation resumed.

Further, it should be possible in many cases to block the lines for electric locos and

EMUs only, permitting movement of diesel trains. It may also be possible to move electric

locos and EMUs at restricted speed or to coast through the affected section with pantographs

lowered if the damage is only slight. It is for TPC to decide after careful study of

information available from the site and in consultation with traffic officials the extent of

restriction to be imposed on, traffic.

2.5 PROTECTIVE STEPS

1. On receipt of information about OHE break-down, the SM/Section Controller shall

also take such steps as deemed necessary to regulate traffic on the affected lines and

issue caution order where required. Single line working may be introduced, if

feasible.

2. It is the duty of every railway servant who notices hanging OHE conductors to take

immediate preventive steps to ensure that no person comes into contact with them

treating such conductors as live until an authorized person from OHE section arrives

at site and makes the OHE dead and earth it.

2.6 BREAKDOWN STAFF

1. On receipt of the first report about the breakdown, TPC shall direct the nearest OHE

maintenance gang to proceed to site immediately with available breakdown vehicles

for dispatch of staff without waiting for full details of the breakdown.

2. A quick assessment should be made on the basis of information available and where

necessary one or more gangs from both sides of the site may be asked to proceed to

the site. If the accident spot cannot be reached by railway vehicles on account of the

line being blocked by other trains, road vehicles equipped with emergency stores,

tools and staff may be directed to the site. In sub-urban sections with large number of

roads running alongside the track, this method may help in tackling the repairs much

more quickly.

CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0 5

Handbook on Breakdown Management of OHE January, 2018

3. If the OHE Inspection Car or wiring train is required to attend to the break-down, the

Section Controller, on request from TPC shall arrange for quick passage of the OHE

Inspection Car or wiring train to the site of the accident.

2.7 OFFICERS AND SUPERVISORS TO PROCEED TO SITE

On receipt of information about an OHE breakdown the JE/SSE (OHE), DEE/ADEE

(TrD) shall proceed by quickest available means to the scene of accident. The Sr. DEE

(TRD) should also proceed to the site if the circumstances of the case require his personal

supervision and direction. In the event of a major break-down likely to result in interruption

of traffic for more than 12 hrs, CEDE should also proceed to the site for supervising

restoration.

2.8 ASSISTANCE TO BE SOUGHT

1. It should be remembered that restoration of traffic in the event of accident or

breakdown is the responsibility of the Division as a whole. The Electrical

Department Officer in-charge of the restoration work should, wherever required, ask

for assistance from the Engineering, Traffic or other Officers as necessary. He should

also keep the DRM fully posted with arrangements made and the expected time of

restoration.

2. When circumstances warrant, the assistance of OHE gangs of another contiguous

Division may be sought for by contacting ADEE(TRD) or Sr.DEE/DEE(TRD) of the

Division concerned. The Officers who receive such requests from neighboring

divisions should treat the matter as of utmost importance and render all possible

assistance.

2.9 CONTINUOUS COMMUNICATION WITH TPC

The Officer or Supervisor in-charge of supervising repair work should maintain

continuous communication with the TPC from the site of breakdown. For this purpose an

intelligent person should be posted to man the nearest emergency telephone socket

continuously to transmit and receive messages as required. It is very important that the field

staff remains on call all the time until normal service is restored, since no provision exists in

the emergency telephone circuit for the TPC to ring up the emergency telephone stations at

the site.

2.10 DETAILED ASSESSMENT BY THE FIRST SUPERVISOR/OFFICER REACHING

SITE

The first Supervisor or Officer of the Traction Branch reaching the site of the

breakdown should make a quick assessment of the extent of damage and the time required

for restoration. He will ascertain from TPC the details of break-down gangs and equipment

directed to the site and if the circumstances warrant, ask for additional gangs and breakdown

equipment to be sent to the site. On receipt of these details, TPC should arrange for

additional gangs and equipment to be sent to the site expeditiously. In the meanwhile,

isolation and repair works should be started at site.

Further details on the extent of damage and estimated time as obtained from the

Supervisor/Officer at the site from time to time will be passed on from TPC to the Section

Controller to enable him to review the arrangement for regulating the traffic initially made.

6 CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0

January, 2018 Handbook on Breakdown Management of OHE

In the event of major breakdowns affecting main line traffic, Sr. DOM/DOM of the

Division should personally take over regulation of traffic arrangements.

2.11 PRESERVATION OF EVIDENCE

When a pantograph gets entangled with the OHE, it is often very difficult to

establish whether the damage originated from a faulty pantograph or a defect on the OHE.

The first Officer or Supervisor of the Electrical Department arriving at site of a

breakdown particularly those involving entanglement of pantographs with the OHE, should

make a very careful note of all relevant details pertaining to the breakdown and also prepare

a sketch indicating the particulars. He will also arranges for preservation of such evidence as

may be useful subsequently for investigating the cause of the breakdown.

2.12 SAFETY RULES TO BE OBSERVED

While speed is the essence of emergency working, rules

prescribed for safe working shall never be infringed. Repair

work may commence only after an emergency power block

has been obtained and all other precaution necessary for

protection of the staff taken. On completion of the repair

work, the power block may be cancelled according to the

prescribed procedure.

2.13 TEMPORARY REPAIRS FOR RESTORATION OF TRAFFIC

In the first instance, repairs to the OHE

should be kept to the barest minimum necessary for

restoration of traffic with least possible delay.

Work must proceed simultaneously at many points.

After effecting temporary repairs, the Officer or

Supervisor in-charge of the work should personally

check the whole area and satisfy himself that the

installations are in order and safe. He may impose

such speed restriction as necessary for movement

of electric and other than electric trains till

permanent repairs are carried out. Permanent

repairs should be arranged and speed restrictions removed and normal operation restored at

the earliest opportunity.

2.14 CLEARANCE OF LINE FOR DIESEL TRACTION

If the breakdown is extensive and restoration of electric traction is unlikely in a short

time even with temporary repairs, the line should be cleared for diesel traction as soon as

possible, so that traffic may be kept moving until repairs to the OHE are completed. After

diesel traction is introduced full precautions should be taken for protection of staff working

at site.

2.15 WIRING TRAIN

If the OHE has suffered extensive damage, the OHE wiring train should be

requisitioned to speed up the work. The wiring train generally consists of a stores-cum-tool

CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0 7

Handbook on Breakdown Management of OHE January, 2018

van, a workshop van, a staff and kitchen van, a reel wagon loaded with one drum of catenary

wire and one drum of contact wire, wagon loaded with materials for temporary diversions, a

BFR loaded with structures, a hand-operated crane to facilitate erection of masts, a power

car with two diesel generator sets for supplying power to the workshop van and for lighting,

two brake vans, an adequate quantity of OHE material and flood-lights with trailing cables.

The vans have platforms with side-railings to facilitate working on the roof.

2.16 INTERFERENCE WITH OHE DURING RESTORATION

In clearing the line for traffic, breakdown staff are forbidden to disturb the OHE

masts or to cut the OHE conductors except under the specific orders of

Sr.DEE(TrD)/DEE(TrD). If it becomes necessary to slew the OHE conductors to facilitate

crane working, this should be arranged to be done by the Electrical Department staff. It

should be borne in mind that indiscriminate cutting of OHE conductors will necessitate

introduction of splices which are not conducive to good current collection. Also introduction

of such splices is liable to delay restoration of normal electric services.

2.17 TEMPORARY DIVERSIONS

Sometimes with derailments and accidents occurring in electrified sections,

temporary diversions have to be laid to clear the traffic with other than electric traction. A

quick means of wiring such diversions so as to resume electric traction without waiting for

the main line to be commissioned is described below.

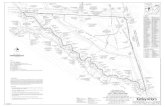

The constructional details of the arrangement for such diversions on BG may be seen

in Fig. below.

8 CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0

January, 2018 Handbook on Breakdown Management of OHE

The portal type structures are made out of 80mm diameter Gl pipes using two right

angled 'T joints. Guys are used in both perpendicular and parallel directions to the track so

as to give extra safety against heavy with load. The contact wire is suspended with the help

of special fittings made of MS flats form the catenary wire stretched between the two

uprights of the structure and insulated by two 9-tonne insulators as shown in the figure. The

80mm diameter Gl pipes are placed in 150mm diameter MS pipes welded on to a 10mm

thick 450mm x 450mm MS base plate which in turn is bolted by 10mm diameter through

bolts to a 4880mm long crossing sleeper put under the rails. The weight of the rails keeps

the crossing sleeper and thereby the structure in possible. The void between the 80mm

diameter and 150mm diameter pipes is wedged by wooden sedges and also filled up with

sand and covered by bituminous compound so as to prevent rusting of the GI pipe due to the

seepage of water through the sand. Since the whole structure is attached to the track as

above, the chances of tilting or sinking of the structure with shrinkage or settlement of the

temporary un-consolidated embankment are eliminated.

The contact wire is anchored at both ends at a height of 6 m on existing masts and

'fly guys' are provided from the anchor mast to the base of the next mast so that no separate

foundation is necessary for anchoring and also the guy can be removed easily at the time of

dismantling.

The advantages of the above type of construction are as under -

1. It is cheap.

2. The structures weigh less than 150 kg and 4 men can easily erect or dismantle them.

3. Since no foundations are required, time is not lost in excavation for foundation and

consequently the structures can be erected quickly.

4. The equipment can be dismantled and erected at new sites quickly.

5. The traffic can move at the speed restriction imposed for the permanent way and no

extra speed restriction on account of OHE is necessary.

6. The materials used for the work are easily obtainable; the new fabrications required

can easily be manufactured in workshops and stocked at depots for quick use in

emergencies.

2.18 TEMPORARY SPEED RESTRICTIONS

The instructions regarding speed restriction in electrified sections are being notified

under GR-17.09. The temporary speed restrictions shall be imposed by Electrical (TRD)

Deptt. as per GR-4.9 wherein a caution order shall be handed over to drivers at the stopping

station immediately short of the place where such precautions are necessary. While

imposing temporary speed restrictions, the following guidelines shall generally be

followed:-

(i) Whenever temporary mast is provided, speed restriction of about 15-40 kmph is

imposed depending upon the site conditions. Then the new mast is provided, the

foundation of which takes about 5/6 days for curing and after that only OHE is

shifted to the new mast. Total time taken in this process is about 10 days from the

date of imposition of speed restriction depending upon the availability of blocks.

(ii) Whenever mast gets bent due to accidents etc. same is straightened using tirfor.

speed restriction of about 30-60 kmph is imposed depending upon the site

conditions/ stagger profile. Bent is removed during next 3-4 days depending upon the

availability of blocks.

CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0 9

Handbook on Breakdown Management of OHE January, 2018

(iii) Whenever there is extensive damages to OHE due to Panto entanglement etc. but not

affecting the masts, OHE is attended by using temporary droppers etc. and speed

restrictions of about 30-60 kmph is imposed depending upon the site conditions and

restoration of sectional speed takes about 4 days depending upon the extent of

damages and block availability.

2.19 FUNDS REQUIRED FOR DEALING WITH BREAKDOWNS

Funds required for dealing with breakdowns may be obtained from station earnings

in accordance with para 714 of the Indian Railways Permanent Way Manual reproduced

below :-

(1) The Divisional/District Engineer or the Assistant Engineer on his behalf may drew

upon the station earnings according to such instructions as prescribed by the

Administration under note to para 1405G, for the following purposes:—

(a) Payment to daily labour employed at the site of breach or accident.

(b) Purchase of tools or materials required in connection with accidents which

cannot be supplied in time by the Stores Department.

(c) To provide food to engineering labour at the site of breach or accident with the

assistance of Station Masters or Inspectors of the Commercial Department.

The supply of food free of charge is permitted in special circumstances at the

discretion of the Administration to facilitate expeditious restoration of traffic.

When food is supplied free at the site of an accident to engineering and other

labour the expenditure per head per day shall not exceed the prescribed limit.

2. The Accounts Officer should be advised immediately by telegram of each sum taken

from station earnings.

In all cases, Engineers obtaining advances from station earnings should, do so

under a clear receipt. On the receipt, the object for which the money has been procured

should be clearly stated.

A complete account should be submitted at the earliest possible date to the

accounts department supported by pay sheets and vouchers.

3. All payments to labour should be witnessed by the Assistant Engineer at site.

2.20 Log of Events and Reporting of Break-downs

1. In all major break-downs TPC, senior officials and Officers concerned shall maintain a

detailed log of events in their diaries noting the time and brief details which may help

in fixing the responsibility for any avoidable delay in restoration.

2. The DRM should submit to CEE and COM a detailed report covering every major

break-down of OHE or other traction installations giving all essential information

including—

10 CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0

January, 2018 Handbook on Breakdown Management of OHE

a. nature of break-downs and lines affected with detailed sketch;

b. chronological account of action taken to effect repairs and restore traffic;

c. repercussions on traffic and rough estimated cost for repairing the damage;

d. cause of break-down and staff responsible, if any;

e. any other special features including an objective analysis of the time taken for

repairs and restoration of traffic with a view to see if these could have been

done more expeditiously and if so measures proposed to improve the

performance in future.

2.21 Protection of Staff

In addition to ensuring that work on OHE is commenced only after obtaining a

power block, the supervisor in-charge shall take all measures for protection of staff and for

exhibition of hand-signals as per GR and SR, particularly when the line under repair and the

adjacent lines are not blocked for other traffic.

2.22 Use of Cranes

Special care is necessary when cranes are used at the site of break-downs. The

movements of the cranes shall be carefully controlled by the person in-charge so as not to

come within 2m of live OHE, in addition to the usual precautions necessary to prevent

infringement of adjacent tracks which have not been blocked for other traffic.

CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0 11

Handbook on Breakdown Management of OHE January, 2018

CHAPTER 3

ROAD VEHICLES

3.1 USE OF ROAD VEHICLES DURING EMERGENCIES

Road vehicles like motor trucks and jeeps available with maintenance officials

should be maintained in proper condition at all times, as they are liable to be called for use

in attending to breakdowns or emergencies. The essential rules for operation of road

vehicles are given in the following paras.

3.2 DRIVER'S DUTIES.

1. No person shall drive a vehicle belonging to the railway unless he has a proper

license and is duly authorized. No vehicle shall be driven on a public road unless the

necessary tax has been paid to the Licensing Authority for the area as prescribed by

the Motor Vehicles Act.

2. Every Driver of a vehicle shall familiarize himself and comply with the traffic laws

prevailing in the area, where he operates. He shall be liable to disciplinary action for

any willful violation thereof.

3. Before operating any vehicle the Driver shall make sure that it is in a proper

operating condition as follows:—

(a) Test brakes, steering gear, clutch, horn and lights.

(b) See that the tyres are in good condition and properly inflated.

(c) Check emergency equipment e.g., first aid kit jack and tools.

(d) Ensure that requisite quantities of petrol, lubricating oil and water are available

in the vehicle.

Drivers shall test the head and the tail lights before undertaking night driving. They

shall not undertake driving until these are in order,

4. If any major defect is noticed during a journey, it shall be reported to the SSE in

charge concerned immediately, and the vehicle shall not be operated until the defect

has been set right.

5. Before filling the petrol tank the engine shall be shut off. The hose nozzle shall be

kept in contact with the tank to avoid static sparks.

While filling petrol tanks of the vehicles, smoking and use of open flames

shall not be permitted near the vehicle.

6. 'Left-hand-drive' vehicles shall have these words written and displayed

conspicuously at the back.

12 CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0

January, 2018 Handbook on Breakdown Management of OHE

7. All loaded trucks, carrying loads projecting beyond the rear end of the body shall

carry red flags of approved type and size when driving during day-time and red lights

placed at extreme ends of the loads or trailers at night.

8. Drivers shall not drive vehicles while in a drunken state.

3.3 OPERATION OF ROAD VEHICLES

1. When loading or unloading vehicles, the emergency parking brakes shall be applied

and the wheels blocked.

2. Equipment, materials and tools carried on vehicles shall be properly secured and

arranged so as not to obstruct the view of the Driver or to interfere with his giving

traffic signals.

3. The vehicle shall be operated within prescribed speed limits. The speed shall be

reasonably reduced, where necessary, due to bad weather, poor visibility, heavy

traffic and the conditions of the road and the Driver.

4. Drivers shall keep at a safe distance from vehicles in front. They shall not attempt to

overtake any vehicle unless they can see far enough to be sure of passing safely and

until the horn signal given for this purpose has been accepted by the Driver of the

vehicle in front.

5. Drivers shall not attempt to pass other vehicles on curves, grades, street intersections

or such other places where the view is not clear.

6. No motor vehicle shall be driven past school buses that are taking in or putting down

children.

7. Drivers shall, at night, dim lights when meeting other vehicles. When blinded by

glaring headlights they shall slow down and, if necessary, stop until the vehicle has

crossed.

8. When fire department vehicles, ambulances or police patrols are heard or observed

approaching from any direction, vehicles shall be stopped at a safe place until these

vehicles have passed,

9. When proceeding down a grade the clutch shall not be disengaged. The engine shall

be throttled.

10. When approaching railway crossings and road intersections, Drivers shall slow down

speed and be prepared to stop.

11. On slippery roads, Drivers, shall operate at a much lower speed and keep a safe

distance from vehicles in front to enable them to make a stop within safe limits,

leaving the vehicle in gear and applying the brakes until speed has been retarded

sufficiently to engage the clutch without danger of skidding.

12. Drivers shall anticipate the intentions of other Drivers and pedestrians and shall

themselves give clear signals of their intentions regarding stopping or turning. They

shall make allowance for lack of skill or improper attitude on the part of other

CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0 13

Handbook on Breakdown Management of OHE January, 2018

Drivers, pedestrians, children and animals. They shall not frighten or annoy them by

hooting too frequently.

13. When moving a vehicle in reverse direction make sure that the rear is clear and free.

Under poor visibility or on hilly or congested roads, driver shall employ a signal-

man.

14. Horns shall be used only when necessary. Use of horn just near the object is

dangerous and shall be avoided.

15. Doors, tall gates, or parts of load of a vehicle shall not be kept dangling when the

vehicle is in motion.

16. The number of persons riding with the Driver shall not exceed the number of seats

actually provided.

3.4 PRECAUTION WHEN TRANSPORTING HEAVY MATERIALS

1. Drivers of trucks carrying heavy structures or long ladders equipped with booms

shall not drive with such equipment in an elevated or partially elevated position.

2. Proper precautions shall be taken at all times to prevent contact with overhead lines,

trees or structures.

3. In transporting material, particular care shall be exercised to see that material will not

shift or fall from the vehicle.

4. Where poles or the long sections of material projecting beyond the vehicle are to be

transported along public roads, a red flag in day-time or a red light at night shall be

fastened to the end of the projection.

3.5 TRANSPORTATION OF PERSONNEL

1. The number of employees carried in vehicles shall not exceed the prescribed limit

and they shall be provided with proper sitting arrangements.

2. Persons who are not employed in the railway shall not be allowed to use the vehicles

unless specifically permitted.

3. A person shall not put any part of his body outside the vehicles and shall not sit or.

stand on the rung-board or other outside projections of the vehicle when in motion to

avoid injury from other vehicles.

4. Employees shall not enter or leave the vehicle when it is in motion.

5. Employees shall not ride on a load of poles or other material carried on vehicles in a

dangerous way.

6. Vehicles fully loaded with personnel shall not be started or stopped suddenly with a

jerk, except under emergency conditions.

14 CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0

January, 2018 Handbook on Breakdown Management of OHE

3.6 PARKING

1. Vehicles should be parked on the correct side close to kerb of the road so as not to

interfere with traffic. Vehicles shall not be parked on bridges, road curves, culverts

and intersections;

2. When parking on a grade, the vehicle shall be in gear, hand-brakes, applied wheels

turned towards the kerb. Bricks or stones shall be placed in the wheel path on the

down grade side so that the vehicle cannot accidentally roll down.

3. When parking along a highway at night, parking lights shall be left on, but dimmed. If

any repair work is to be done, flares shall be set at opposite ends so as to be visible

from a distance of at least 150m to warn other Drivers in advance.

4. When parking on the highway near another vehicle on the opposite side of the road,

sufficient clearance shall be kept between the two vehicles.

5. Before leaving a parked vehicle, Drivers shall take with them the ignition key to

prevent theft or unauthorized starting of the vehicle.

6. Before changing tyres or making any other repairs along a highway, the Drivers shall

pull off the vehicle to the side of the road at a safe distance from the running traffic.

7. When leaving or entering a parked vehicle, kerb side doors alone shall be used. If the

doors open on roadside, look back and make sure that no vehicle is approaching from

the rear.

8. Before starting a parked vehicle, the Driver shall observe the front and the rear to

ensure that there are no persons or objects in the way.

3.7 MAINTENANCE OF ROAD VEHICLES

1. Road vehicles are costly and should be driven carefully and maintained efficiently.

The SSE-ln-charge shall inspect every vehicle under his control at least once a

fortnight, and arrange to have the defects noticed rectified promptly.

2. Every emergency vehicle shall also be inspected by an AEE once a month and by the

DEE once in six months and the observations made recorded in a register.

3. Each vehicle shall be equipped with an approved set of tools and first aid kit and the

Driver shall be trained in their use.

4. A first aid blanket shall be carried on every truck and the Driver shall be trained to use

it as an improvised stretcher.

5. When vehicles are jacked up for working underneath, sufficient number of wooden

blocks shall be put below to protect men underneath, should the jack fail. Goggles

shall be worn to prevent dust getting into eyes.

CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0 15

Handbook on Breakdown Management of OHE January, 2018

3.8 PROCEDURE IN TRAFFIC ACCIDENTS

1. Accidents which may appear trivial often result in claims for personal injury or

damage to property. A Driver shall, therefore, always be courteous and helpful.

2. Drivers shall not get involved in an argument as to who was responsible for the

accident but endeavour to get all the facts in the case.

3. The following instructions shall be observed by Drivers should an accident occur: -

(a) Stop the vehicle and pull over to the kerb if no other vehicle is involved.

The vehicle should not be disturbed should there be a fatal accident, as

police may make note of the evidence. Protect the rear and front so as to

divert the traffic.

(b) If anyone is injured, render first aid; send for the Doctor and ambulance, if

necessary. Render every assistance.

(c) Do not leave the scene of accident without stopping to identify yourself.

(d) When requested, give your name and address and show your Driver's

License to the other party.

(e) Secure name, address and license number of the other Driver, vehicle

license number and names and addresses of the vehicle owner, witnesses

and the insurance company.

(f) Unless some police officer is available at the scene of accident, notify police

station having Jurisdiction in the territory.

(g) Sketch the location showing position of vehicles or pedestrians involved and

any special condition such as obstructions, parked cars, skid marks.

(h) Try to get the names and addresses of any eye witness and if possible get

their statements.

(i) Record date, time of day, weather and road conditions and any other

information which you may consider useful.

j) Submit a detailed report to the superior.

16 CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0

January, 2018 Handbook on Breakdown Management of OHE

CHAPTER 4

ELECTRICAL ACCIDENTS

4.1 ELECTRICAL ACCIDENT

An electrical accident is caused directly or indirectly due to

electrical causes, that is, it includes any electric shock or electric

burn whether minor, major or fatal and whether suffered by railway

servants or others.

A person may suffer electric shock by coming in contact with:-

1. Live mains, LT or HT:

2. Overhead lines, which although made dead by isolation at both ends still develop high

potentials on account of electro-static or electro-magnetic induction due to parallelism

with other high voltage live lines, or due to lightning discharges during thunderstorms;

3. Parts which have become live due to leakage either because of low insulation

resistance of the electrical windings, high earth resistance or discontinuity of the

earthing lead to the body:

4. Areas which develop a high potential gradient such as near an earth electrode through

which a fault current is flowing, and is insufficient to blow the fuse or cause the circuit

breaker to trip.

In any well-maintained installation, no electrical accidents should occur. Every

accident can in the final analysis, be traced to one or more of the following causes, if

properly probed into:-

a. Disregard or non-observance of the prescribed rules laid down;

b. Ignorance of rules and insufficient training of staff:

c. Carelessness, casual and indifferent methods of working, including improper earthing

d. Indicating inadequate supervision;

e. Faulty protective equipment and poor maintenance;

f. Over-confidence or sheer laziness;

g. Old habits of working on non-electrified lines:

h. Misunderstanding of instructions;

i. Inadvertence.

Every rule prescribed is the result of experience gathered

over the years by several persons, and owes its origin to some electrical accident or damage

to equipment observed in the past. Rules and procedures prescribed should therefore be

taken seriously, and never allowed to fall into disuse.

CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0 17

Handbook on Breakdown Management of OHE January, 2018

4.2 ELECTRICAL ACCIDENTS • ACTION TO BE TAKEN

1. In the event of an electrical accident or the possibility of an accident, the senior most

official present at the site of the accident shall take the following preliminary

precautions immediately :-

(a) If there is a break-down of the overhead lines, he should arrange to cordon off

the area so that no one else may get injured. He shall also warn Drivers of trains.

(b) Arrange to cut off supply to the installation concerned by telephoning to the

Traction Power Controller or the nearest Electrical Department official, and

simultaneously arrange for an Authorized Person to the spot. No one may

attempt to rescue an electrocuted person until power supply has been cut off.

(c) Send for medical assistance. In the meanwhile, after the injured person, if any,

has been separated from the electrified lines, he shall arrange to render first aid;

artificial respiration should be started immediately if the patient is not breathing.

2. Immediately on arrival at site, the Authorized Electrical Department Official (SSE/JE),

shall first check and make sure that the steps mentioned have been correctly taken.

After attending to the injured and clearing the lines, he shall make a detailed note of

all factors relating to the accident, preserve evidence and record the statements of

those who were near the accident spot. He shall also carry out a preliminary

investigation as to the possible cause of accident and get- full particulars of the injury

or damage suffered and advise the Sr. Divisional Electrical Engineer of the details in

writing.

The treatment laid down for resuscitation after electric shock shall be carried

out immediately if applicable. The treatment should be continued for at least two hours

or more as there have been cases where patients, although apparently dead, have

regained consciousness.

3. All electrical accidents occurring within Railway premises shall be reported to the

SSE/JE Electrical in-charge of the area and by him to the Sr. Divisional Electrical

Engineer without delay, however slight the injury may be and even though the injured

man is capable of performing his duties.

4.3 OBSERVANCE OF RULES

All accidents arising out of the use of electricity within the railway premises are

required not only to be dealt with under the provisions of the 'Rules for Reporting Accidents'

of the Zonal Railway but also according to the procedures under the Indian Electricity Act,

1910, Section 33 and Rule 44 A of I.E. Rules, 1967.

Section 33 of I.E. Act 1910 reads as under:-

(1) If any accident occurs in connection with the generation, transmission, supply or use

of energy in or in connection with any part of the electric supply-lines or other works

of any person and the accident results or is likely to have resulted in loss of human or

animal life or in any injury to a human being or an animal, such person shall give

notice of the occurrence and of any such loss or injury actually caused by the

accident, in such form and within such time as may be prescribed, to the Electrical

18 CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0

January, 2018 Handbook on Breakdown Management of OHE

Inspector and to such other authorities as the appropriate Government may by

general or special order, direct.

(2) The appropriate Government may, if it thinks fit, require any Electrical Inspector, or

any other competent person appointed by it on his behalf, to inquire and report:-

(a) as to the cause of any accident affecting the safety of the Public, which may

have been occasioned by or in connection with, the generation, transmission,

supply or use of energy, or

(b) as to the manner in, and extent to, which the provisions of this Act or any

license or rules there under, so far as those provisions affect the safety of any

person, have been complied with.

(3) Every Electrical Inspector or other person holding any inquiry under sub-section (2)

shall have all the powers of a Civil Court under the Code of Civil Procedure 1908,

for the purpose of enforcing the attendance of witnesses and compelling the

production of documents and material objects; and every person required by an

Electrical Inspector or such other person as aforesaid to furnish any information shall

be deemed to be legally bound to do so within the meaning of Section 176 of the

Indian Penal Code.

4.4 ELECTRICAL INSPECTOR TO RAILWAY

The Chief Electrical Engineer of each Railway is appointed to function as Electrical

Inspector to the Central Government for the Railway vide Railway Board's Notification No.

60/Elec./112/6 dated 10th June 1961. All matters in regard to the functions of Electrical

Inspector shall be referred to him.

4.5 REPORTING OF ACCIDENTS

The Electrical SSE/JE shall send in respect of every electrical accident a notice of the

accident in writing to the Electrical Inspector viz.. Chief Electrical Engineer, through

the Sr.DEE/DEE.

In cases where the accident results in or is likely to have resulted in loss of human

being or animal, intimation shall be given within 24 hours of the knowledge of the

occurrence of the accident.

The written report of the accident shall be sent in the form set out at Annexure 'XIII"

of I.E. Rules.

All fatal and grievous hurt accidents shall also be immediately reported to the nearest

Police Station. District Magistrate or Sub-Divisional Officer in-charge of the Civil

Jurisdiction and the body (in case of fatal accidents) shall not be moved until the

Police inquiry is completed.

In the case of electrical accident occurring within workshop premises, the Factory

Rules and Act will apply. In this instance the "Manager" of the workshop will send the

detailed report on the forms prescribed in the Factory Rules to the Factory Inspector,

in addition to CEE. CWE, DRM etc.

CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0 19

Handbook on Breakdown Management of OHE January, 2018

4.6 ACCIDENT INQUIRIES

Every electrical accident shall be inquired into by an officer and a report submitted

to the Chief Electrical Engineer (functioning as the Electrical Inspector for the Railways)

giving complete information within one week of the accident. The report should in particular

cover the following points:-

1. A clear description of the locality and a sketch showing all the relevant details:

2. An analysis of the evidence recorded;

3. Findings as to the exact cause of the accident:

4. Fixing up of responsibility of staff negligence, if any, indicating whether the "Rules

for Safe Working on Electrical Equipment" have been followed or not;

5. Recommendations for preventing such accidents in future: and

6. Any special features peculiar to the case.

Until the official inquiry is conducted all material evidence should be preserved by

the official in-charge to facilitate the inquiry. Where restoration of supply is likely to

obliterate marks on the premises or in any other way destroy evidence which may be of use

in an inquiry, the Senior Electrical Official who first arrives at the site should carefully make

notes and sketches and preserve the evidence as far as possible, for production at the inquiry.

4.7 ACCIDENT REGISTERS AND ANNUAL RETURNS

Every Electrical Official in-charge shall maintain a register showing the particulars

in regard to all electrical accidents taking place under his jurisdiction in the proforma

below:-

Date Time Brief description of

the accident

Date and Time of issue of

accident message

Date accident report

submitted

He will also submit by 15th April of each year a statement of accidents during the

previous financial year to Sr. DEE, who in turn will submit the statement for the entire

division to the CEE for incorporation in the Electrical Inspectors Annual Report to CEA.

4.8 FIRST AID

A box containing first aid equipment shall be kept

in each generating station or each sub-station and electrical

work depot (except where adequate medical facilities exist

for all the 24 hours of the day) close at hand for use when

required. A periodical check shall be made of the contents

and any deficiencies shall be reported to the Medical

Department for replenishment.

Item should be kept in small first aid box. The ones fixed in the station may continue

to be of wooden/ aluminium. The portable ones in train should be of aluminium or metal.

20 CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0

January, 2018 Handbook on Breakdown Management of OHE

Contents:

01. Set of wooden extensible splints (St. John Ambulence type) 1 set

02. Sterile adhesive strip dressing (standard size) 20 Nos.

03. Rubber tourniquet 2 nos

04. Roller bandages (7.5 cm x 4 Mtr) gauze 10 Nos

05. Triangular bandages (130 cm x 90 cm x 90 cm) 4 Nos.

06. Tab Paracetamol 20 in strips

07. Antiseptic cream 25 Gms 1 tube

08. Injury card 1 No

09. Safety pin set of 10 1 set

10. Tab diazepam 10 tab in strip

11. Cotton wool 100 gms 1 packet

As at present, in all big Railway station, the contents should replaced and refilled

from the S.S. these boxes should not be sent to the Health units/ Hospitals for refilling. In

small stations, these may be sent to the Health Units for refilling.

The aluminium boxes should not be bigger than 22 cms x 18 cms x 10 cms and it‘s

weight along with the contents should be about 1.5 Kg and in no case should exceed 2 Kg.

FIRST AID BOX FOR RAJDHANI/ SHATABDI/ SUPER FAST EXPRESS

(Corrected Vide Letter Dt. 4/7/95)

Revised list of contents of First Aid Box for Long Distance Vestibule trains,

Rajdhani Express & Shatabdi Express

S.No. Items Nos.

01. Band aid strip (1.9 x 7.2cms) 50

02. Sterile absorbent gauze pad (7.5 x 7.5) 15

03. Sterilized absorbent cotton (25gms) 10

04. Roller bandage (7.5 cms x 4 m) 20

05. Triangular bandage 5

06. Adhesive plaster (2.5 x 4/5 etres) 2

07. Splints, wooden, extensible set of 6 1 set

08. Pins safety on a card or in a box 20

09. Scissors dressing 1

10. Esmarch tourniquet (IR. Bandage) 1

11. Resuscitator aid bag (Air-viva-type) 1

12. Airway tubes (Medium & small size) 2

13. Tab. Paracetamol 30 tabs in strips

14. Tablets diclofenac sodium 30 tabs in strips

15. Tab. Pheniramine Maleate 5 mg 30 tabs in strips

16. Tab. Stemetil 5 mgm 30 tabs in strips

17. Tab. Dicyclomine HCL 30 tabs in strips

18. Tab. Metronidazole Furazolodone (Dependal-M) 30 tabs in strips

CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0 21

Handbook on Breakdown Management of OHE January, 2018

4.9 RESUSCITATION FROM ELECTRICAL SHOCK

4.9.1 Instructions to be Displayed

Instructions in English and the Regional language regarding the treatment of persons

suffering from electric shock shall be exhibited in all inspection sheds, stabling depots,

repair shops, stations, sub-stations etc. and it is the duty of every authorized official to make

himself thoroughly familiar with such instructions, and to be able to render artificial

respiration when necessary. Electrical shocks are easily received but are as easily avoided if

proper precautions are taken in maintaining and handling electrical equipment.

4.9.2 Removal from Contact

If the person is still in contact with the apparatus that has given him the shock, the

rescuer should, if possible, stand on a dry wooden chair while removing the victim.

Otherwise pull him free by using a dry coat, dry rope, coconut matting or stick, preferably

standing on a rubber mat or any other dry mat handy. Never touch the man's body with bare

hands.

Extinguish any sparks if the patient's clothes are smouldering; ascertain if he is

breathing and send for a Doctor. If apparently not breathing, proceed as described in para

below.

4.9.3 Artificial Respiration

o If there are any burns, avoid, if possible, so placing the patient as to bring pressure on

the burns.

o It is preferable to operate as in the Diagrams A and B, with the face downward. If

badly burnt in front, turn to the second method shown later.

First Method

• First Motion: Observe Diagram A - "Expiration". Kneel over the patient, rest the

hands flat in the small of his back, let your thumbs nearly touch; spread your fingers on

each side over his lower ribs as in the first diagram.

• Now lean firmly but gently forward over the patient, exerting a steady pressure

downwards, still following the first diagram.

22 CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0

January, 2018 Handbook on Breakdown Management of OHE

• Second Motion: Observe Diagram B - "Inspiration". Rock yourself gently backwards,

but do not remove your hands. Merely keep then in position for the next expiration

pressure. Continue these two movements.

• The double movement should be gone through about fifteen times per minute. The

object is to keep expanding and contracting the patient's lungs so as to imitate slow

breathing. If the operator himself breathes slowly, letting the air out as he presses

forward, and drawing it in as he rocks backward, he will naturally arrive at the proper

rate, and will understand the reason for the movements.

• Do not cease operations until natural breathing is re-established. It may take half an

hour or even longer, to produce a desired effect.

Second Method

• Should it be expedient to place the patient on his back, first loosen the clothes around

the chest and stomach. Then place a rolled-up coat, or other improvised pillow, beneath

the shoulders so that the head falls backwards. The tongue should then be drawn

forward.

• First Motion: The operator must kneel in the position shown by Diagram C. Grasp the

patient just below the elbows and draw his arms over his head until horizontal, retaining

them there for about two seconds.

• Second Motion: Next bring the patient's arms down on each side of his chest and

pressing inwards upon his arms so as to compress his chest as in Diagram D.

• Remain thus for two seconds, and then keep repeating the two motions at the same rate.

• The lung-inflating effect in Diagram C is much assisted if the arms be swung outwards

as they are lifted.

• If more than one person is present, the patient's tongue should also be drawn out during

each outward or lung-inflating stroke (Diagram C) and released during each Inward or

lung deflating stroke (Diagram D).

• In both cases, be careful to avoid violent operations, as injury of the internal organs may

result from excessive and sudden pressures. After recovery, burns if serious, should be

treated with a proper oil dressing. Avoid exposing patient to cold. Administer no

restoratives until the Doctor comes. Cold water may be given and smelling salts applied

in moderation.

CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0 23

Handbook on Breakdown Management of OHE January, 2018

• Two methods of treatment for electric shock have been described above. It is the duty of

every railway servant to be familiar with these methods of rendering artificial

respiration.

4.10 TYPICAL ELECTRICAL ACCIDENTS

Brief particulars of a few electrical accidents which have actually occurred are given

below. A study of these particulars will help officers and staff in appreciating the

importance of the various safety rules prescribed.

1. A Khalasi of the Engineering Department, engaged in construction work, sustained

severe burns when handling a long boiler tube under live OHE. The boiler tube

accidentally touched the contact wire. This accident could have been prevented if

proper supervision had been exercised and the Supervisor in-charge of the work had

warned all his staff of the danger of electrocution if the OHE is accidentally

contacted by poles, ladders, pipes or tools. Whenever there is even a remote

possibility of any person coming within the danger zone of live 25 kV

installations at Sub-stations, Switching stations or if any work has to be done

within 2 m of live OHE, the supervisory official in-charge should invariably

obtain permit to work after the lines are made dead and earthed before allowing

staff to start work.

2. An electric fitter working on a locomotive stabled in a loco shed climbed on to the

roof to examine the pantograph which was in the lowered position. The height of the

contact wire on the stabling line was 5.5 m and the height from rail level of the

pantograph in the lowered position was 3.66m. The Fitter was apparently under the

impression that he could conveniently examine the lowered pantograph taking

advantage of the clearance of nearly 2m. Unfortunately, while he was examining the

lowered pantograph, the other pantograph of the locomotive was inadvertently raised

by another employee thus energizing the lowered pantograph also. There was also

danger of the employee getting a shock if he had inadvertently stood up on the roof

in the course of his work. This emphasizes that no one should ever get up on the

locomotive roof when the locomotive is under a live OHE. A shut down should

invariably be effected before climbing on to the roof of stabled locomotives.

3. Two work parties were required to work at an insulated overlap connected together

by an interrupter. Shutdown was effected on both the elementary sections and the

interrupter was also opened. One party earthed the OHE on one side of the insulated

overlap and the supervisor of this party permitted his men to commence work on the

insulated overlap without earthing the other portion of the OHE presuming that the

other portion had been earthed by the other work party. This resulted in some of the

workmen getting electric shock due to contact with the unearthed wires. This

accident emphasizes the importance of the rules that (a) each party should

protect itself by independent earths and (b) when work is to be done at an

insulated overlap either both portions of OHE should be independently earthed

or the electrical continuity between the two portions should be ensured by

keeping isolators/interruptors closed.

24 CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0

January, 2018 Handbook on Breakdown Management of OHE

4. A supervisor took power block for two elementary sections supported on a portal and

overlooked the fact that the same portal supported the wires of a siding.

Consequently a worker sent to work on the portal structure came into- contact with

the live OHE of the siding and sustained shock which resulted in his death. This

serious accident could have been prevented if the supervisor had made himself

thoroughly familiar with the details of OHE supported on the portal and had

ensured that all the wires on the portal structure were made dead and earthed

before permitting his men to commence work on the portal.

5. An Electrical JE (OHE Maintenance) received a fatal shock when he came into

contact with OHE, which had been isolated but not earthed. On completion of work,

he removed the earth and went down into the OHE Inspection Car to check up the

time. Subsequently, he went up the OHE Inspection Car again and came into contact

with OHE, which was not earthed though isolated. A slight drizzle earlier contributed

to the severity of the shock as the JE's feet and the tower wagon platform were wet.

Due to parallelism with the live OHE of an adjacent line, there was an appreciable

induced voltage in the line, though it was isolated. This emphasizes the need for

ensuring that the OHE is earthed in accordance with the rules prescribed before

commencing work and during the whole time the work is in progress.

6. An Assistant Driver of a diesel locomotive of a Steel Works doing shunting work in

an electrified yard close to the Steel Works received a severe shock when he went up

on the roof of the locomotive. The warning notice regarding live OHE was not

painted on the locomotive nor was the Assistant Driver properly instructed on the

hazards of working in close proximity to live OHE. This emphasizes the need for

painting the warning notice not only on the locomotives belonging to the

Railway but also of private parties likely to work in electrified railway yards.

Operating staff of private parties also should be educated in the safety rules

prescribed.

7. A Linesman received a severe shock when working on an isolator. Before

commencing the work one earth had been placed on each side of the isolator.

However, during the course of the work, the isolator was opened when the Linesman

received a shock. The possible cause is that one of the discharge rods was not

making proper contact with the result that the effect of induced voltage on that

portion of the OHE caused the shock. This emphasizes the need for ensuring that

when working on an isolator, either the isolator is kept jumpered or not opened

at all during the course of the work, in addition to the precaution that an earth

should be placed on each side of the isolator.

CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0 25

Handbook on Breakdown Management of OHE January, 2018

8. Supply from an auxiliary transformer had failed. An unskilled Khalasi was sent by

the fitter to check up and renew the high voltage fuses. The Khalasi attempted to do

this without getting a permit to work, accidentally came into contact with live 25 kV

wires and was electrocuted. This accident was a direct result of an unauthorized

person not holding a certificate of competence being deputed to work on live

equipment.

9. An electrical Fitter was electrocuted while carrying out repairs to a jumper

connection to a transformer. He had isolated the transformer and climbed up the pole

to repair the jumper. He had posted a helper near the circuit breaker with instructions

that on receiving a signal from him, the helper should close the circuit breaker. The

helper saw a person at a distance waving his hands and presuming that the signal is

from the Fitter, closed the circuit breaker. This accident was the result of adopting

short circuit methods rather than the prescribed procedure for effecting shut

down and issue of permit to work. Such short circuit methods are not

permissible even if the intention is to speed up the work.

The above cases would illustrate that a heavy responsibility rests with officers and

senior supervisory officials to prevent possibilities of electrical accidents not only by

insisting on strict compliance with rules and procedures laid down for safe working on

electrical equipment, but also by giving wide publicity to the need for utmost precautions on

the part of everyone when working in electrified sections.

A LITTLE CARE MAKES MISHAPS RARE

26 CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0

January, 2018 Handbook on Breakdown Management of OHE

CHAPTER 5

BREAKDOWN MANAGEMENT

5.1 TYPES OF BREAKDOWN

Without Traffic Repercussion

i) In a sub-station,

ii) In a workshop,

iii) In yards.

With Traffic Repercussion

i) Involving single line,

ii) Involving both lines.

Disasters

i) Involving collisions,

ii) Natural calamities,

iii) Lapses,

iv) Fires and

v) Sabotages.

5.2 HOW TO HANDLE BREAKDOWNS

• Pre Breakdown Preparation

• Management and monitoring the restoration

• Post Breakdown Review

5.2.1 Pre Breakdown Preparation

• Attitude to proceed to site if a line is blocked

• Road map of Division in Control Office, with TPC, Depots, Vehicles showing

highways/ roads leading to stations, level crossings etc

• Road sign boards on diversions leading to stations & familiarization to drivers

• Adequacy of communication like working of emergency sockets, mobile phones/

walkie-talkie sets with supervisors & in vehicles and satellite phones in ARTs.

• Reliability of Road vehicles

• Availability of ready, adequate and tested fittings & T&P in Emergency van and

ARTs.

• Training of supervisors and staff along with its evaluation.

• Nomination of staff for specific jobs.

• Rapport with other departments i.e. within and outside Railways.

CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0 27

Handbook on Breakdown Management of OHE January, 2018

5.2.2 Management and monitoring the restoration

• Quick finalization of action plan for restoration

i) Any additional resources required

ii) Assess target of restoration with breakup

iii) Communicate with control/ HQrs/ Rly Bd/ press

iv) Parallel measurements by the joint supervisors‘ team

• Specific directions to supervisors and staff on

i) Sequence of actions

ii) Movement of vehicles

iii) Work distribution to gangs

iv) Specific jobs to officers / supervisors

v) Communication amongst various supervisors

• Monitoring the activities

i) Timely completion of breakup of activities

ii) Any change required in planning

iii) Proper coordination amongst supervisors

iv) Safety being observed in restoration

• Approaching completion

i) Planning clearance of men, material & blocks

ii) Planning clearances of ART, Tower wagons etc.

iii) Planning sequence of traffic resumption

5.2.3 Post Breakdown Review

• Analyse the time taken for each activity

i) Getting first hand information

ii) Readiness of staff and vehicles like ART, Tower wagons & Road vehicles

iii) Reaching the site

iv) Slewing & restoring the OHE

v) Taking and clearing the blocks

• Analyse the type of failure

i) Repeated location, season, fitting

ii) After a particular type of work

iii) Due to under/ over maintenance

• Investigate the failed equipment / fitting

i) Whether under warranty

ii) Whether from approved supplier

iii) Whether overdue maintenance

28 CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0

January, 2018 Handbook on Breakdown Management of OHE

• Identify good / bad T & P items

i) Whether testing schedule followed

• Identify good / bad supervisors / artisans

i) Whether training input required

• Share the experience within & outside division through discussions at all levels

5.3 CONCLUSION

• Proceed to site invariably

• Keep T&P and M&P tested & adequate

• Have reliable communication network

• Spot the heroes and depute them

• Analyze each breakdown with supervisors

• Share the experience with others

5.4 MISSION

• Restore the traffic in the least possible time at barest minimum speed observing safety

of railway personnel and the running trains postponing the final adjustments to the

time when the held up traffic eases out

5.5 ESSENTIAL IDEAS OF SUCCESSFUL ACCIDENT MANAGEMENT

1. All Railway men, whether on duty or otherwise, should involve themselves in rescue

and relief.

2. There should be utmost speed in rushing medical and other relief to the site of

accident.

3. There should be utmost care, consideration and courtesy extended to the passengers

involved in the accident.

4. Adequate and swift arrangements should be made for food, drinking water etc. to the

affected passengers.

5. Employee responsibilities at the site should be clearly defined. This helps prevent

confusion.

6. Quick transmission of information, particularly details of dead and injured, should be

ensured.

7. Ensure proper preservation and care of the dead.

8. Ensure security of passengers‘ luggage.

9. Timely dissemination of information to passengers of evacuation arrangements to

relieve panic and create re-assurance.

10. Ensure proper liaison with Civil Administration and Press.

11. Ensure that clues are preserved and restoration operations are well planned and

swiftly executed.

CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0 29

Handbook on Breakdown Management of OHE January, 2018

5.6 CHECK LIST FOR OHE BREAKDOWNS

All OHE breakdowns whether, major or minor should be treated on top priority as it

generally interferes with traffic. Whenever the field supervisor gets information about any

breakdown, he has to observe the following procedure:

i. Collect all the information about the nature and location of breakdown.

ii. Alert the staff.

iii. If possible send a competent person to breakdown spot who can assess the damage

occurred.

iv. Collect the necessary material, equipment and tools to restore the breakdown.

v. Proceed to the spot with material and staff by quickest available means.

vi. In case he has to move by breakdown vehicle/ lorry, then he must refer the road map

available with him.

vii. After reaching the spot, he should make assessment of the extent of damages, time

required for restoration, the elementary section on which power block is required (after

referring the sectioning diagram) and duration of power block.

viii. If the circumstances warrant, he should ask TPC for additional gangs and breakdown

equipment to be sent to the site.

ix. He should maintain the continuous communication with the TPC.

x. He should also briefly inform to TPC for how he intends to attend the break down

which gives a scope for guidance, if required and an idea to TPC as to plan Power

blocks requirement.

xi. After taking the Power block, provide discharge rods and take necessary safety

precautions. Then only, he should direct the staff for restoration of break down.

xii. Take necessary precautions for other departments also, if involved, such as providing

rail jumpers in case of rail breakage.

xiii. After restoration of breakdown 500 Mts. either side of BD spot to be checked as per

ACTM.

30 CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0

January, 2018 Handbook on Breakdown Management of OHE

5.7 TOOLS AND PLANTS TO BE AVAILABLE IN TOWER CAR

S.No. Description of material 8-wheeler 4-wheeler

Cutting Tools

1 Tree Pruner 02 Nos 02 Nos

2 Axe. 02 Nos. 02 Nos

3 Power Operated grinding cum wire cutter 01 No 01 No.

4 Contact wire cutter 02 No 01 No

5 Dropper wire cutter 02 No 01 No

6 Hacksaw frame Adj. 12" 02 No 02 No

7 Battery operated cutter 02 No 02 No

8 Concrete cutting machine (one per subdivision)

Manila Ropes

1 3/4" manila rope 20m long. 05 Nos. 05 Nos

2 1/2" manila rope 20m long 05 Nos. 05 Nos.

3 1" maila rope 20m long 02 Nos 02 Nos

4 1/2" manila rope 2m long 05 Nos. 05 Nos

Tirfors

1 Tirfor 3 or 5 Ton 02 sets 02 sets

2 Tirfor 1.6 Ton 04 sets 02 sets

3 Tirfor 0.75 Ton 02 sets 01 set

4 Pull-lift 3 Ton 02 sets 02 sets

5 Pull-lift 1.6 Ton 02 sets 02 sets

6 Pull-lift 0.75 Ton 02 sets 01 set

Come- along clamps

1 Contact wire come-along clamp 05 sets 05 sets

2 Cu. Catenary wire come-along clamp 05 sets 05 sets

3 Al. Catenary wire come-along clamp 04 sets 04 sets

4 AC wire come-along clamp 02 sets 02 sets

5 Large span come-along clamp 02 sets 02 sets

6 Al. Feeder type come-along clamp 02 sets 02 sets

Electrical safety items

1 Discharge rods 04 Nos. 04 Nos

2 FRP type Discharge rods 02 Nos. 02 Nos.

3 Rail jumpers 04 Nos. 04 Nos.

CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0 31

Handbook on Breakdown Management of OHE January, 2018

S.No. Description of material 8-wheeler 4-wheeler

Steel Slings

1 Steel slings 01 mtr. (Fibre reinforced) 04 Nos 04 Nos

2 Polyster Webbing slings 01mtr 04 Nos 04 Nos

3 Steel slings 02 mtr. 02 Nos 02 Nos

4 Polyster Webbing slings 02mtr. 02 Nos 02 Nos

5 Steel slings 03 mtr. 02 Nos 02 Nos

6 Steel slings 04 mtr. 02 Nos 02 Nos

7 Steel slings 10 mtr. 02 Nos 01 Nos

D Shackles

1 1" D shackles 08Nos 08Nos

2 3/4" D shackles 05 Nos 05 Nos

3 1/2" D shackles 05 Nos 05 Nos

Pulleys

1 Steel pulleys 6" 06 Nos 06 Nos

2 Steel pulleys 3½" 06 Nos 06 Nos

3 Fibre pulleys 15 Nos 15 Nos

Light fittings

1 Metal Hallide lamp spare bulbs 150W 04 Nos 04 Nos

2 Search lights 02 Nos 02 Nos

3 Light fittings MH 150W 04 sets 04 sets

4 Halogen fittings 500W 02 sets 02sets

5 Halogen bulbs 500W spare 06Nos 06Nos

6 Extension cable full drum 200mtrs 1 drum

7 Torch lights 3 cell 05 Nos 05 Nos

8 Extension board with cable of 20 mtrs 2 No 1 No

9 Portable generator 2/3 KVA 01 no 1no

10 Tri-colour Torch 02 Nos 02 Nos

11 Aska in-flattable lighting tower 01No

12 LED head lamps 10Nos 10Nos

13 LED Torch light 5Nos 5Nos

32 CAMTECH/E/2017-18/EP-06/OHE-Breakdown/1.0

January, 2018 Handbook on Breakdown Management of OHE

S.No. Description of material 8-wheeler 4-wheeler

Communication Devices

1 Walkie-talkie sets with charger 4 Nos. 2 Nos

2 Mege Phone 01 No 01 No

3 Mobile chargers 02 Nos 02 Nos

4 Emergency Control Phone 02 Nos 02 Nos

5 Temporary Mast

6 Sludge hammer 02 No 02 No