Zucchini EdM cast resin transformers -...

Transcript of Zucchini EdM cast resin transformers -...

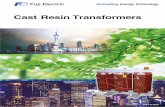

EdM transformers are the high quality solution for many types of applications...

designed and manufactured in accordance with national and international standards.

EdM cast resin transformers are used in a vast range of

applications and, with over 50 years history, are a reliable

answer for distribution systems, energy co-generation,

rectifi cation, traction and other special requirements.

REDUCED ENVIRONMENTAL IMPACT

The absence of infl ammable insulating liquids, the self-

extinguishing materials exempt of toxic gas emissions and

the low noise levels and low electromagnetic emissions all

combine to present a responsible solution to environmental

protection and public security.

Zucchini EdMcast resin transformers

204_205P_D2010.indd 204 09/06/2010 10:48

www.klinkmann.com

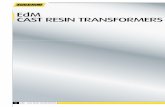

5

7

8

6

1

2

3

10-14

9 -15

11 13 4 12

1. MV windings in aluminium strip coils, cast in resin

under vacuum.

2. Core in three columns in magnetic lamination with

high-permeability oriented crystals, also available

with low losses.

3. LV windings in aluminium plate/sheet and

vacuum-cast impregnated insulation material.

4. LV connections upwards (standard) or downwards

(on request).

5. MV connections upwards (standard) or downwards

(on request).

6. Rubber inserts attenuate the transmission of

vibrations between core and windings and reduce

operating noise generated by the transformer

to a minimum, as well as absorbing the thermal

expansion of the components.

7. Sockets on the MV side can adapt the primary

voltage to the mains when the transformer is

switched off.

8. Structure, armatures and carriage manufactured

from strong painted sheet steel.

9. Carriage with bi-directional castors.

10. The epoxy resin insulation makes the transformer

low maintenance.

11. The operating temperature is checked by Pt100

sensor or PTC in the LV windings.

12. Lifting eyebolts conform to the DIN-580 UNI-2947

standards with safety hooking at 4 points.

13. Optional pre-equipment for connection of the LV

connection to Zucchini busbar trunking system.

14. Class F insulating material, at 155°C, allowing for a

temperature rise of 100°K. (100°C)

15. The carriage allows safe movement and is

pre-equipped for the mounting of IP reinforced

boxes.

QUALITY GUARANTEE

EdM transformers are distinguished by their high quality

production. State-of-the-art manufacturing and attention to

detail throughout the entire production process, including

rigorous fi nal checks, ensure the highest quality products.

204_205P_D2010.indd 205 09/06/2010 10:49

www.klinkmann.com10 / 2011

– 2 –

EdM cast resin transformers medium voltage (11 kV-433 V)12 kV insulation class

Pack Cat. Nos Normal losses series

6% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EE2NADEA 250 750 3700 32601 EF2NADEA 315 850 4600 40501 EG2NADEA 400 1000 5400 49801 EH2NADEA 500 1200 6700 59601 EI2NADEA 630 1450 7600 67501 EJ2NADEA 800 1750 9400 83701 EK2NADEA 1000 2000 10000 89001 EL2NADEA 1250 2300 12700 113001 EM2NADEA 1600 2800 14000 124601 EN2NADEA 2000 3300 18000 162001 EO2NADEA 2500 4300 21000 18900

7% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EP2NADEA 3150 4600 26000 23400

Standards and technology overview (p. 214)Dimensions and technical information (p. 215)Drilling specification and installation information (p. 226)

Cast resin transformers with power ranging from 250 kVA up to 3150 kVAAll EdM transformers are built according to the requirements specified inthe main national and international standards BS EN 60076-1 to 5,BS EN 60076-11 and document CENELEC HD 538.1.51 (1992) All EdM transformers are classified E2-C2-F1 (Certificate of ConformityCESI No. A90323921)

11 kV-433 V transformer – 12 kV insulation class

Zucchini’s specialist team is on hand to help

identify and design the best technical

solutions to meet your needs.

CAPABILITIES :

Rated power up to 17000 kVAPrimary voltage up to 36 kVSecondary voltage on request

TYPICAL APPLICATIONS :

• General industry• Infrastructure• Service sector• Conversion and rectifi cation• Power production (step up)• Marine applications

EdM bespokesolutions

206_213P_D2010 v4.qxd 9/6/10 11:00 Page 206

www.klinkmann.com10 / 2011

– 3 –

Standards and technology overview (p. 214)Dimensions and technical information (p. 216-217)Drilling specification and installation information (p. 226)

Cast resin transformers with power ranging from 100 kVA up to 3150 kVA. All EdM transformers are built according to the requirements specified inthe main national and international standards BS EN 60076-1 to 5, BS EN 60076-11 and document CENELEC HD 538.1.51 (1992) All EdM transformers are classified E2-C2-F1 (Certificate of Conformity CESI No. A90323921)

Pack Cat. Nos Normal losses series

4% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EB2NBCBA 100 440 2000 17601 EC2NBCBA 160 610 2700 23801 ED2NBCBA 200 720 3150 27701 EE2NBCBA 250 820 3500 30801 EF2NBCBA 315 880 4400 38701 EG2NBCBA 400 1150 4900 43601 EH2NBCBA 500 1300 6500 57801 EI2NBCBA 630 1500 7300 6500

6% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EE2NACBA 250 750 3700 32601 EF2NACBA 315 850 4600 40501 EG2NACBA 400 1000 5400 48101 EH2NACBA 500 1200 6700 59601 EI2NACBA 630 1450 7600 67501 EJ2NACBA 800 1750 9400 83701 EK2NACBA 1000 2000 10000 89001 EL2NACBA 1250 2300 12700 113001 EM2NACBA 1600 2800 14000 124601 EN2NACBA 2000 3300 18000 162001 EO2NACBA 2500 4300 21000 18900

7% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EP2NABBA 3150 4600 26000 234001 EP2NACBA 3150 4600 26000 23400

Pack Cat. Nos Reduced losses series

4% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EB2RBCBA 100 320 2000 17601 EC2RBCBA 160 440 2700 23801 ED2RBCBA 200 540 3150 27701 EE2RBCBA 250 600 3500 30801 EF2RBCBA 315 730 4400 38701 EG2RBCBA 400 880 4900 43601 EH2RBCBA 500 1020 6500 57801 EI2RBCBA 630 1150 7300 6500

6% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EE2RACBA 250 580 3700 32601 EF2RACBA 315 700 4600 40501 EG2RACBA 400 790 5400 48101 EH2RACBA 500 920 6700 59601 EI2RACBA 630 1050 7600 67501 EJ2RACBA 800 1350 9400 83701 EK2RACBA 1000 1550 10000 89001 EL2RACBA 1250 1900 12700 113001 EM2RACBA 1600 2200 14000 124601 EN2RACBA 2000 2800 18000 162001 EO2RACBA 2500 3300 21000 18900

7% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EP2RACBA 3150 3950 26000 23400

EdM cast resin transformers medium voltage (11 kV-400 V)12 kV insulation class

11 kV-400 V transformer– 12 kV insulation class

206_213P_D2010 v4.qxd 2/6/10 10:25 Page 207

www.klinkmann.com10 / 2011

– 4 –

Cast resin transformers with power ranging from 250 kVA up to 2500 kVA. All EdM transformers are built according to the requirements specified inthe main national and international standards BS EN 60076-1 to 5, BS EN 60076-11 and document CENELEC HD 538.1.51 (1992) All EdM transformers are classified E2-C2-F1 (Certificate of Conformity CESI No. A90323921)

Pack Cat. Nos. Standard series

6% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EE2SACBA 250 1050 3800 33401 EF2SACBA 315 1320 4600 40501 EG2SACBA 400 1630 5600 50001 EH2SACBA 500 1790 6700 59601 EI2SACBA 630 2100 7800 69401 EJ2SACBA 800 2470 9400 83701 EK2SACBA 1000 2940 11000 98001 EL2SACBA 1250 3520 13400 11800

6·5% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EM2SACBA 1600 3890 16400 14400

7% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EN2SACBA 2000 4830 19000 171001 EO2SACBA 2500 5990 23000 20700

Pack Cat. Nos. Distribution series

6% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EE2DACBA 250 910 3800 33401 EF2DACBA 315 1050 4600 40501 EG2DACBA 400 1320 5600 50001 EH2DACBA 500 1630 6700 59601 EI2DACBA 630 1790 7800 69401 EJ2DACBA 800 2100 9400 83701 EK2DACBA 1000 2470 11000 98001 EL2DACBA 1250 2940 13400 11800

6·5% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EM2DACBA 1600 3520 16400 14400

7% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EN2DACBA 2000 3890 19000 171001 EO2DACBA 2500 5040 23000 20700

EdM cast resin transformers medium voltage (11 kV-400 V) (continued)12 kV insulation class

Standards and technology overview (p. 214)Dimensions and technical information (p. 217-218)Drilling specification and installation information (p. 226)

11 kV-400 V transformer– 12 kV insulation class

206_213P_D2010 v4.qxd 2/6/10 10:26 Page 208

www.klinkmann.com10 / 2011

– 5 –

EdM cast resin transformers medium voltage (15 kV-400 V)17·5 kV insulation class

Pack Cat. Nos. Distribution series

6% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EE3DAFBA 250 910 3800 33401 EF3DAFBA 315 1050 4600 40501 EG3DAFBA 400 1320 5600 50001 EH3DAFBA 500 1630 6700 59601 EI3DAFBA 630 1790 7800 69401 EJ3DAFBA 800 2100 9400 83701 EK3DAFBA 1000 2470 11000 98001 EL3DAFBA 1250 2940 13400 11800

6·5% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EM3DAFBA 1600 3520 16400 14400

7% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EN3DAFBA 2000 3890 19000 171001 EO3DAFBA 2500 5040 23000 20700

Standard series

6% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EE3SAFBA 250 1050 3800 33401 EF3SAFBA 315 1320 4600 40501 EG3SAFBA 400 1630 5600 50001 EH3SAFBA 500 1790 6700 59601 EI3SAFBA 630 2100 7800 69401 EJ3SAFBA 800 2470 9400 83701 EK3SAFBA 1000 2940 11000 98001 EL3SAFBA 1250 3520 13400 11800

6·5% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EM3SAFBA 1600 3890 16400 14400

7% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EN3SAFBA 2000 4830 19000 171001 EO3SAFBA 2500 5990 23000 20700

Pack Cat. Nos. Reduced losses series

6% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EB3RAFBA 100 380 2050 18001 EC3RAFBA 160 480 2900 25501 ED3RAFBA 200 570 3600 31701 EE3RAFBA 250 670 3800 33401 EF3RAFBA 315 790 4600 40501 EG3RAFBA 400 920 5500 48901 EH3RAFBA 500 1110 6700 59601 EI3RAFBA 630 1290 7800 69401 EJ3RAFBA 800 1520 9400 83701 EK3RAFBA 1000 1800 11000 98001 EL3RAFBA 1250 2000 13000 116001 EM3RAFBA 1600 2420 16000 142401 EN3RAFBA 2000 2920 19000 171001 EO3RAFBA 2500 3650 23000 20700

1 7% Impedance level1 Pk (W)

1 kVA Po (W) 120° 75°

1 EP3RAFBA 3150 3950 27000 24300

Normal losses series

6% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EB3NAFBA 100 430 1900 16701 EC3NAFBA 160 570 2800 24701 ED3NAFBA 200 680 3600 31701 EE3NAFBA 250 750 3650 32101 EF3NAFBA 315 880 4500 39701 EG3NAFBA 400 1000 5200 46301 EH3NAFBA 500 1200 6700 59601 EI3NAFBA 630 1600 7800 69401 EJ3NAFBA 800 1780 9300 82901 EK3NAFBA 1000 2000 10800 96301 EL3NAFBA 1250 2350 12600 112501 EM3NAFBA 1600 2750 15500 138001 EN3NAFBA 2000 3350 18500 166501 EO3NAFBA 2500 4300 21800 19620

7% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EP3NAFBA 3150 4700 26000 23400

Cast resin transformers with power ranging from 100 kVA up to 3150 kVA. All EdM transformers are built according to the requirements specified inthe main national and international standards BS EN 60076-1 to 5, BS EN 60076-11 and document CENELEC HD 538.1.51 (1992) All EdM transformers are classified E2-C2-F1 (Certificate of Conformity CESI No. A90323921)

Standards and technology overview (p. 214)Dimensions and technical information (p. 219-220)Drilling specification and installation information (p. 226)

15 kV-400 V transformer– 17·5 kV insulation class

206_213P_D2010 v4.qxd 1/6/10 20:32 Page 209

www.klinkmann.com10 / 2011

– 6 –

Cast resin transformers with power ranging from 100 kVA up to 3150 kVA. All EdM transformers are built according to the requirements specified inthe main national and international standards BS EN 60076-1 to 5, BS EN 60076-11 and document CENELEC HD 538.1.51 (1992) All EdM transformers are classified E2-C2-F1 (Certificate of Conformity CESI No. A90323921)

Pack Cat. Nos. Normal losses series

4% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EB4NBGBA 100 540 1750 15401 EC4NBGBA 160 750 2500 22001 ED4NBGBA 200 900 2900 25501 EE4NBGBA 250 1000 3450 30401 EF4NBGBA 315 1150 4500 39701 EG4NBGBA 400 1360 4900 43601 EH4NBGBA 500 1580 6400 57001 EI4NBGBA 630 1950 6900 6150

6% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EB4NAGBA 100 480 2000 17601 EC4NAGBA 160 650 2800 24701 ED4NAGBA 200 800 3600 31701 EE4NAGBA 250 850 3700 32601 EF4NAGBA 315 950 4500 39701 EG4NAGBA 400 1150 5400 48101 EH4NAGBA 500 1350 6700 59601 EI4NAGBA 630 1650 7800 69401 EJ4NAGBA 800 1850 9300 82901 EK4NAGBA 1000 2200 10800 96301 EL4NAGBA 1250 2600 12800 114301 EM4NAGBA 1600 2950 15500 138001 EN4NAGBA 2000 3800 18600 167401 EO4NAGBA 2500 4800 22000 19800

1 7% Impedance level1 Pk (W)

kVA Po (W) 120° 75°

1 EP4NAGBA 3150 5100 26000 23400

Pack Cat. Nos. Reduced losses series

4% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EB4RBGBA 100 400 1750 15401 EC4RBGBA 160 580 2500 22001 ED4RBGBA 200 680 2900 25501 EE4RBGBA 250 800 3450 30401 EF4RBGBA 315 920 4500 39701 EG4RBGBA 400 1110 4900 43601 EH4RBGBA 500 1300 6400 57001 EI4RBGBA 630 1600 6900 6150

6% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EB4RAGBA 100 340 2050 18001 EC4RAGBA 160 480 2900 25501 ED4RAGBA 200 550 3600 31701 EE4RAGBA 250 650 3800 33401 EF4RAGBA 315 750 4600 40501 EG4RAGBA 400 940 5500 48901 EH4RAGBA 500 1050 6700 59601 EI4RAGBA 630 1250 7800 69401 EJ4RAGBA 800 1450 9400 83701 EK4RAGBA 1000 1800 11000 98001 EL4RAGBA 1250 2100 13000 116001 EM4RAGBA 1600 2400 16000 142401 EN4RAGBA 2000 2900 19000 171001 EO4RAGBA 2500 3800 23000 20700

7% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EP4RAGBA 3150 4500 26000 23400

EdM cast resin transformers medium voltage (20 kV-400 V)24 kV insulation class

Standards and technology overview (p. 214)Dimensions and technical information (p. 221-222)Drilling specification and installation information (p. 226)

20 kV-400 V transformer– 24 kV insulation class

206_213P_D2010 v4.qxd 2/6/10 11:00 Page 210

www.klinkmann.com10 / 2011

– 7 –

EdM cast resin transformers medium voltage (20 kV-400 V) (continued)24 kV insulation class

Pack Cat. Nos. Standard series

6% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EE4SAGBA 250 1210 3800 33401 EF4SAGBA 315 1470 4600 40501 EG4SAGBA 400 1740 5600 50001 EH4SAGBA 500 2000 6700 59601 EI4SAGBA 630 2420 7800 69401 EJ4SAGBA 800 2730 9400 83701 EK4SAGBA 1000 3260 11000 98001 EL4SAGBA 1250 3730 13400 11800

6·5% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EM4SAGBA 1600 4410 16400 14400

7% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EN4SAGBA 2000 5360 19000 171001 EO4SAGBA 2500 6620 23000 20700

Pack Cat. Nos. Distribution series

6% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EE4DAGBA 250 1050 3800 33401 EF4DAGBA 315 1210 4600 40501 EG4DAGBA 400 1470 5600 50001 EH4DAGBA 500 1740 6700 59601 EI4DAGBA 630 2000 7800 69401 EJ4DAGBA 800 2310 9400 83701 EK4DAGBA 1000 2790 11000 98001 EL4DAGBA 1250 3260 13400 11800

6·5% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EM4DAGBA 1600 3730 16400 14400

7% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EN4DAGBA 2000 4570 19000 171001 EO4DAGBA 2500 5880 23000 20700

Cast resin transformers with power ranging from 250 kVA up to 2500 kVA. All EdM transformers are built according to the requirements specified inthe main national and international standards BS EN 60076-1 to 5, BS EN 60076-11 and document CENELEC HD 538.1.51 (1992) All EdM transformers are classified E2-C2-F1 (Certificate of Conformity CESI No. A90323921)

Standards and technology overview (p. 214)Dimensions and technical information (p. 222-223)Drilling specification and installation information (p. 226)

20 kV-400 V transformer– 24 kV insulation class

206_213P_D2010 v4.qxd 2/6/10 11:00 Page 211

www.klinkmann.com10 / 2011

– 8 –

EdM cast resin transformers medium voltage (25 kV-400 V)36 kV insulation class

Pack Cat. Nos. EnclosuresColour RAL 7032

Degree ofprotection

KVA Walls Base

1 230316 IP211 230353 100 to 200 IP31 IP201 230288 IP23

1 230211 IP211 230263 250 to 315 IP31 IP201 230273 IP23

1 230212 IP211 230234 400 to 500 IP31 IP201 230215 IP23

1 230204 IP211 230222 630 to 800 IP31 IP201 230277 IP23

1 230213 IP211 230223 1000 to 1250 IP31 IP201 230221 IP23

1 230214 IP211 230249 1600 to 2000 IP31 IP201 230267 IP23

1 230287 IP211 230371 2500 to 3150 IP31 IP201 230309 IP23

Pack Cat. Nos. Normal losses series

6% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EE5NAIBA 250 1250 3600 31801 EF5NAIBA 315 1300 4500 39701 EG5NAIBA 400 1500 5800 51001 EH5NAIBA 500 1700 6600 58501 EI5NAIBA 630 2000 7500 66001 EJ5NAIBA 800 2450 9700 8550

7% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EK5NAIBA 1000 2600 11300 9950

8% Impedance levelPk (W)

kVA Po (W) 120° 75°

1 EL5NAIBA 1250 2900 14000 123501 EM5NAIBA 1600 3400 16000 142401 EN5NAIBA 2000 4200 18000 162001 EO5NAIBA 2500 5200 22000 198001 EP5NAIBA 3000 6300 25500 22500

Cast resin transformers with power ranging from 250 kVA up to 3000 kVA.All EdM transformers are built according to the requirements specified inthe main national and international standards BS EN 60076-1 to 5,BS EN 60076-11 and document CENELEC HD 538.1.51 (1992) All EdM transformers are classified E2-C2-F1 (Certificate of ConformityCESI No. A90323921)

EdM cast resin transformers enclosures

Dimensions and technical information (p. 226)Standards and technology overview (p. 214)Dimensions and technical information (p. 224)Drilling specification and installation information (p. 226)

Class 12 / 17·5 / 24 kVDegree of protection : IP 21 / IP 31 / IP 23

25 kV-400 V transformer– 36 kV insulation class

Transformerenclosure RAL 7032

206_213P_D2010 v4.qxd 6/6/10 08:54 Page 212

www.klinkmann.com10 / 2011

– 9 –

EdM cast resin transformersaccessories

Pack Cat. Nos. Accessories (continued)

Fan control unitTo control the ventilation barsSupplied non-mounted

Type

1 220035 VRT200

Temperature control unitSupplied non-mounted

Type

1 220002 T154 Unit for 4 Pt100 sensors1 220023 MT200 Unit for 4 Pt100 sensors1 220010 T119 DIN Unit for 6 PTC sensors. Set up

for mounting on DIN rail220004 T119 Unit for 6 Pt100 sensors

Anti-vibration pads4 anti-vibration pads for mounting undertransformer casters

RangekVA

1 170019 100 - 1600

1 170020 2000 - 3150

Non-magnetic thermometer1 250662 Thermometer without support bracket, initial

installation or for replacement

1 250005 Thermometer support bracket

Surge arresters kitSupplied mounted on the transformer

VoltageVn kV

1 130054D 111 130055D 151 130056D 20

Fitting of surge arrestors increaseswarranty to 24 months

Pack Cat. Nos. Accessories

Temperature measurement sensorsSupplied mounted on the transformer and wiredto a die-cast aluminium IP 55 junction box.

TemperatureRange threshold

Type kVA °C

3 sensors3 200073 Pt100 up to 2000 -3 200074 Pt100 from 2500 -

3 sensors4 200137 Pt100 up to 2000 -4 200138 Pt100 from 2500 -

3 pairs of PTC sensors. For alarm and release6 CB0012 PTC - 130 - 1406 CB0240 PTC - 110 - 120

Ventilation barsAllow a temporary increase of the rated power(at rated operation conditions) Supplied mounted on the transformer

Range Temporary powerkVA increase %

1 CB02443 100 - 250 + 301 CB02453 315 - 800 + 301 CB02463 1000 - 1250 + 301 CB01413 1600 - 2500 + 301 CB01411 3150 + 301 CB02444 100 - 250 + 401 CB02454 315 - 800 + 401 CB02464 1000 - 1250 + 401 CB01414 1600 - 2500 + 401 CB01412 3150 + 40

EdM transformers are supported by a wide range of accessories, including temperature and ventilation surveillance, plus optional surge arrestersthat extend transformer warranty

Ventilation bars

206_213P_D2010 v4.qxd 1/6/10 20:41 Page 213

www.klinkmann.com10 / 2011

– 10 –

EdM cast resin transformers medium voltagestandards and technology overview

■ Certified quality standardsThe safety and continuity of operation of the specific users dependessentially on the reliability of the transformers installedEdM cast resin transformers have been designed and manufacturedaccording to the provisions laid down by the main national andinternational standards

Reference standardsIEC 60076-11 (2004) :Dry-type power transformers

IEC 60076 Power transformers

HD 538.1 S1 (1992) Dry-type transformers enclosed in resin with insulation up to class 36 KV

Tests and inspectionBefore the cast resin transformers produced by EdM are supplied to thecustomer, they are individually inspected thus eventually passing theacceptance and type-approval tests, if expressly requested whenorderingAt the end of the acceptance tests a specific inspection report isattached to each transformer with all executed checksBoth the ordering company and any final customer can reserve the rightto be present at the inspections in the EdM test room (attendedinspections) and, on prior notification with the productive unit, can makeinspection visits before and during the manufacturing of the order

■ The EdM technology

Medium voltage windingThe medium-voltage winding, made by highly automated windingmachines, is constructed with the continuous disk technique and madein aluminium strip, interleaved with double insulationThis type of working produces uniformity of the internal and externalthickness of the resin and guarantees uniform resistance to thedielectric stresses to which the transformer will be subjected in theinspection phase or during its operation at the place of installation

The primary winding has sockets to adjust the primary voltage equal tothe value ± 2 x 2·5%, made with brass bushes protruding from theresin, copper nuts and bolts and indelible numberingThe insulating materials used belong to class F and the permittedtemperature rises are those specified in Standards IEC 60076-11

Low voltage windingThe low voltage winding, made with special automatic windingmachines, consists of one aluminium strip with an intermediate class For class H insulating sheetThis solution gives the winding a certain compactness capable offorming a one-piece cylinder that can withstand possible axial andradial stresses resulting from short circuit phenomena within the systemand at the downstream side of the transformer

All the welds of the conductor strip with the output bars are made bybutt welding in inert atmosphere and under electronic control, so as toavoid possible damageThis winding is then vacuum-impregnated with epoxy resin so as to giveit the required compactness and uniformity and to avoid the absorptionof humidity throughout the life of the machine, whatever environment itneeds to operate inThis treatment also allows EdM cast resin transformers to comply withthe F1 classification according to the standards and IEC 60076-11

■ The CLE range (certified low electromagnetic emission)CLE transformers (certified low electromagnetic emissions) arespecifically designed and built for reducing electromagnetic emissions.This is the ideal solution for places continuously attended by people or,for example, with particularly sensitive electronic equipment As a result, the EdM CLE range is fully in compliance with the DPCMregulations of 8/7/2003 (electromagnetic emissions lower than 10microTesla), and the EdM quality target” is set to a threshold of 3microTesla EdM provides each CLE cast resin transformer with a specificmeasurement ratio of the electromagnetic emissions

Furthermore, by using a modern semi-anechoic chamber located insidethe EdM laboratory, the CLE transformation systems can also besupplied with a noise measurement ratio based on different emissionbands

Ventilation accessoriesEdM can be equipped at the factory with special ventilation bars These special tangential fans are designed to allow temporary andlimited increase of the power delivered by the transformer, up to + 40%of the rated power

VRT200 Unit : equipment for automatic activation and control of thefans

■ EdM: a system under control - temperature andventilation surveillance

Temperature surveillance toolsEdM gives you the possibility of combining all its transformers of anysize with the best temperature detection tools now available on themarket

Thermal sensors - PT100 : positioned by EdM near the warmest areaof the winding, they can be programmed according to the specificrequirements of any installation

PTC thermistors : positioned by EdM near the warmest area of thewinding, their preset alarm threshold and trip threshold are chosen bythe customer when the order is placed

The wiring of the connections used for the temperature sensors isprotected and screened by a special metal plate conduit andconnected to a terminal board installed inside a strong metallic box

When combined with control sensors, EdM can also supply thefollowing, if required :

T154 Unit or MT200 Unit : equipment used for controlling the PT100thermistors with temperature display, output relay for alarm, optional tripand control of the ventilation bars supplied as a detached part to beinstalled on the electric panel

T119 Unit : equipment used for controlling the PTC thermistors withoutput relay for alarm, optional trip and control of the ventilation barssupplied for being installed on the electric panel

■ The EdM technologyEdM is distinguished by its high-quality production. Using state-of-the-art construction techniques and equipment, and with constant attentionthroughout the production process (ISO 9001 : 2008) and a rigorouscheck in the final phase, guarantees quality throughout the entireprocess

214_227P_D2010 v2.qxd 1/6/10 20:51 Page 214

www.klinkmann.com10 / 2011

– 11 –

EdM cast resin transformers medium voltage (11 kV-433 V)12 kV insulation class – technical data

■ Normal losses series

Class 12

Summary referencevalues. Use theconstruction drawing forthe design

All the data given may bemodified without warningfor reasons of technicalproduction or productimprovement

LVterminals

Standards : BS 14-4 and 14-8 - IEC 60076-11 - CENELEC HD 538.1Power (kVA) : 250 to 3150Frequency (Hz) : 50Primary Voltages (kV) : 11 insulation class 12 kV BIL 60/75 kVSecondary Voltages (V) : 433 insulation class 1·1 kVAdjustment, MV side : ± 2 x 2·5%Vectorial group : Dyn11 (replace the final letter of the item code with ‘B’ for Dyn5 or ‘C’ for Dyn1)Insulating system insulation class : F / FTemperature rise : 100 / 100 KClass : E2-C2-F1 Certified CESI No. A90323921Tolerances : According to BS / IEC

Notes : The values shown refer to the ratio 11/0·433 kV. These values may slightly change when there are different combinations dB = Value measured at a distance of one metre, according to standard BS EN 60076-10Dimensions and weight of integral enclosures (see p. 226)

kVACat. Nos.

Soundpowerlevel

Weight

kg

Pk (W)Prim V Sec VPo (W)

120°VkV 75° dB dB

lo%ØR

Soundpressure

level

6% Impedance level

EE2NADEA 250 11 433 750 3700 3260 1·2 52 65 910 1250 630 1220 520 125 270 330 800

EF2NADEA 315 11 433 850 4600 4050 1·1 53 67 1000 1250 750 1250 670 125 345 405 800

EG2NADEA 400 11 433 1000 5400 4980 1 53 68 1200 1300 750 1320 670 125 345 405 850

EH2NADEA 500 11 433 1200 6700 5960 0·9 54 69 1400 1300 750 1500 670 125 345 405 1000

EI2NADEA 630 11 433 1450 7600 6750 0·8 55 70 1600 1500 850 1590 670 150 395 455 1060

EJ2NADEA 800 11 433 1750 9400 8370 0·8 57 71 1950 1500 850 1740 670 150 395 455 1160

EK2NADEA 1000 11 433 2000 10000 8900 0·7 58 73 2300 1550 1000 1820 820 150 470 530 1270

EL2NADEA 1250 11 433 2300 12700 11300 0·6 59 74 2700 1550 1000 2000 820 150 470 530 1340

EM2NADEA 1600 11 433 2800 14000 12460 0·5 60 76 3300 1650 1000 2180 820 150 470 530 1460

EN2NADEA 2000 11 433 3300 18000 16200 0·5 61 79 4000 1800 1310 2260 1070 200 580 730 1570

EO2NADEA 2500 11 433 4300 21000 18900 0·4 63 81 4800 2050 1310 2390 1070 200 580 730 1650

7% Impedance level

EP2NADEA 3150 11 433 4600 26000 23400 0·4 65 83 5400 2150 1310 2400 1070 200 580 730 1670

A B C D G H N

(mm)(mm) (mm) (mm) (mm) (mm) (mm) (mm)

40 (Ø 125)

60 (Ø 150)

70 (Ø 200)

Detail ofearth terminal

Detail ofterminal MV

M 1

2

G

N

M 1

2

60

HG

DD

A

===ØR

B

■ Technical data

214_227P_D2010 v2.qxd 6/6/10 08:30 Page 215

www.klinkmann.com10 / 2011

– 12 –

EdM cast resin transformers medium voltage (11 kV-400 V)12 kV insulation class - technical data

■ Reduced losses series

Standards : BS 14-4 and 14-8 - IEC 60076-11 - CENELEC HD 538.1Power (kVA) : 100 to 3150Frequency (Hz) : 50Primary Voltages (kV) : 6 - 11 insulation class 12 kV BIL 60/75 kVSecondary Voltages (V) : 400 - 420 insulation class 1·1 kVAdjustment, MV side : ± 2 x 2·5%Vectorial group : Dyn11 (replace the final letter of the item code with ‘B’ for Dyn5 or ‘C’ for Dyn1)Insulating system insulation class : F / FTemperature rise : 100 / 100 KClass : E2-C2-F1 Certified CESI No. A90323921Tolerances : According to BS / IEC

Notes : The values shown refer to the ratio 10/0·4 kV. These values may slightly change when there are different combinationsdB = Value measured at a distance of one metre, according to standard BS EN 60076-10Dimensions and weight of integral enclosures (see p. 226)

kVACat. Nos.

Soundpowerlevel

Weight

kg

Pk (W)Prim V Sec VPo (W)

120°VkV 75° dB dB

lo%ØR

Soundpressure

level

4% Impedance level

EB2RBCBA 100 10 400 320 2000 1760 1·8 40 51 550 1000 600 1100 520 125 270 330 690

EC2RBCBA 160 10 400 440 2700 2380 1·6 43 54 700 1050 600 1140 520 125 270 330 710

ED2RBCBA 200 10 400 540 3150 2770 1·4 45 56 800 1150 620 1190 520 125 270 330 710

EE2RBCBA 250 10 400 600 3500 3080 1·1 46 57 950 1250 630 1270 520 125 270 330 820

EF2RBCBA 315 10 400 730 4400 3870 1 47 59 1050 1200 750 1300 670 125 345 405 830

EG2RBCBA 400 10 400 880 4900 4360 0·9 48 60 1250 1250 750 1370 670 125 345 405 870

EH2RBCBA 500 10 400 1020 6500 5780 0·8 49 61 1450 1250 750 1 550 670 125 345 405 1010

EI2RBCBA 630 10 400 1150 7300 6500 0·7 50 62 1650 1350 850 1600 670 150 395 455 1060

6% Impedance level

EE2RACBA 250 10 400 580 3700 3260 1·1 46 57 910 1250 630 1220 520 125 270 330 800

EF2RACBA 315 10 400 700 4600 4050 1 47 59 1000 1250 750 1250 670 125 345 405 800

EG2RACBA 400 10 400 790 5400 4810 0·9 48 60 1200 1300 750 1320 670 125 345 405 850

EH2RACBA 500 10 400 920 6700 5960 0·8 49 61 1400 1300 750 1500 670 125 345 405 1000

EI2RACBA 630 10 400 1050 7600 6750 0·7 50 62 1600 1500 850 1590 670 150 395 455 1060

EJ2RACBA 800 10 400 1350 9400 8370 0·7 52 64 1950 1500 850 1740 670 150 395 455 1160

EK2RACBA 1000 10 400 1550 10000 8900 0·6 53 65 2300 1550 1000 1820 820 150 470 530 1270

EL2RACBA 1250 10 400 1900 12700 11300 0·5 55 67 2700 1550 1000 2000 820 150 470 530 1340

EM2RACBA 1600 10 400 2200 14000 12460 0·4 56 68 3300 1650 1000 2180 820 150 470 530 1460

EN2RACBA 2000 10 400 2800 18000 16200 0·4 58 70 4000 1800 1310 2260 1070 200 580 730 1570

EO2RACBA 2500 10 400 3300 21000 18900 0·3 59 71 4800 2050 1310 2390 1070 200 580 730 1650

7% Impedance level

EP2RACBA 3150 10 400 3950 26000 23400 0·3 62 74 5400 2150 1310 2400 1070 200 580 730 1670

A B C D G H N

(mm)(mm) (mm) (mm) (mm) (mm) (mm) (mm)

■ Technical data

214_227P_D2010 v2.qxd 6/6/10 08:31 Page 216

www.klinkmann.com10 / 2011

– 13 –

kVACat. Nos.

Soundpowerlevel

Weight

kg

Pk (W)Prim V Sec VPo (W)

120°VkV 75° dB dB

lo%ØR

Soundpressure

level

6% Impedance level

EE2DACBA 250 10 400 910 3800 3340 1·5 55 67 980 1250 640 1300 520 125 270 330 820

EF2DACBA 315 10 400 1050 4600 4050 1·4 56 69 1150 1350 750 1370 670 125 345 405 840

EG2DACBA 400 10 400 1320 5600 5000 1·3 57 70 1200 1350 750 1430 670 125 345 405 920

EH2DACBA 500 10 400 1630 6700 5960 1·2 57 71 1400 1350 750 1540 670 125 345 405 1020

EI2DACBA 630 10 400 1790 7800 6940 1·2 58 72 1650 1500 850 1670 670 150 395 455 1110

EJ2DACBA 800 10 400 2100 9400 8370 1·1 59 73 1900 1500 850 1780 670 150 395 455 1120

EK2DACBA 1000 10 400 2470 11000 9800 1 60 74 2300 1550 1000 1890 820 150 470 530 1280

EL2DACBA 1250 10 400 2940 13400 11800 1 61 75 2700 1550 1000 2030 820 150 470 530 1440

6·5% Impedance level

EM2DACBA 1600 10 400 3520 16400 14400 0·9 63 77 3400 1650 1000 2180 820 150 470 530 1560

7% Impedance level

EN2DACBA 2000 10 400 3890 19000 17100 0·9 65 80 4250 1900 1310 2220 1070 200 580 730 1580

EO2DACBA 2500 10 400 5040 23000 20700 0·8 66 82 4900 2050 1310 2310 1070 200 580 730 1600

A B C D G H N

(mm)(mm) (mm) (mm) (mm) (mm) (mm) (mm)

■ Normal losses series

■ Distribution series

kVACat. Nos.

Soundpowerlevel

Weight

kg

Pk (W)Prim V Sec VPo (W)

120°VkV 75° dB dB

lo%ØR

Soundpressure

level

4% Impedance level

EB2NBCBA 100 10 400 440 2000 1760 1·9 46 59 550 1000 600 1100 520 125 270 330 690

EC2NBCBA 160 10 400 610 2700 2380 1·7 50 62 700 1050 600 1140 520 125 270 330 710

ED2NBCBA 200 10 400 720 3150 2770 1·5 51 63 800 1150 620 1190 520 125 270 330 710

EE2NBCBA 250 10 400 820 3500 3080 1·2 52 65 950 1250 630 1270 520 125 270 330 820

EF2NBCBA 315 10 400 880 4400 3870 1·1 53 67 1050 1200 750 1300 670 125 345 405 830

EG2NBCBA 400 10 400 1150 4900 4360 1 53 68 1250 1250 750 1370 670 125 345 405 870

EH2NBCBA 500 10 400 1300 6500 5780 0·9 54 69 1450 1250 750 1550 670 125 345 405 1010

EI2NBCBA 630 10 400 1500 7300 6500 0·8 55 70 1650 1350 850 1600 670 150 395 455 1060

6% Impedance level

EE2NACBA 250 10 400 750 3700 3260 1·2 52 65 910 1250 630 1220 520 125 270 330 800

EF2NACBA 315 10 400 850 4600 4050 1·1 53 67 1000 1250 750 1250 670 125 345 405 800

EG2NACBA 400 10 400 1000 5400 4810 1 53 68 1200 1300 750 1320 670 125 345 405 850

EH2NACBA 500 10 400 1200 6700 5960 0·9 54 69 1400 1300 750 1500 670 125 345 405 1000

EI2NACBA 630 10 400 1450 7600 6750 0·8 55 70 1600 1500 850 1590 670 150 395 455 1060

EJ2NACBA 800 10 400 1750 9400 8370 0·8 57 71 1950 1500 850 1740 670 150 395 455 1160

EK2NACBA 1000 10 400 2000 10000 8900 0·7 58 73 2300 1550 1000 1820 820 150 470 530 1270

EL2NACBA 1250 10 400 2300 12700 11300 0·6 59 74 2700 1550 1000 2000 820 150 470 530 1340

EM2NACBA 1600 10 400 2800 14000 12460 0·5 60 76 3300 1650 1000 2180 820 150 470 530 1460

EN2NACBA 2000 10 400 3300 18000 16200 0·5 61 79 4000 1800 1310 2260 1070 200 580 730 1570

EO2NACBA 2500 10 400 4300 21000 18900 0·4 63 81 4800 2050 1310 2390 1070 200 580 730 1650

7% Impedance level

EP2NABBA 3150 6 400 4600 26000 23400 0·4 65 83 5400 2150 1310 2400 1070 200 580 730 1670

EP2NACBA 3150 10 400 4600 26000 23400 0·4 65 83 5400 2150 1310 2400 1070 200 580 730 1670

A B C D G H N

(mm)(mm) (mm) (mm) (mm) (mm) (mm) (mm)

214_227P_D2010 v2.qxd 6/6/10 08:32 Page 217

www.klinkmann.com10 / 2011

– 14 –

kVACat. Nos.

Soundpowerlevel

Weight

kg

Pk (W)Prim V Sec VPo (W)

120°VkV 75° dB dB

lo%ØR

Soundpressure

level

6% Impedance level

EE2SACBA 250 10 400 1050 3800 3340 1·9 58 70 1050 1250 640 1300 520 125 270 330 820

EF2SACBA 315 10 400 1320 4600 4050 1·8 59 72 1200 1350 750 1370 670 125 345 405 840

EG2SACBA 400 10 400 1630 5600 5000 1·7 60 73 1250 1350 750 1430 670 125 345 405 920

EH2SACBA 500 10 400 1790 6700 5960 1·5 60 74 1500 1350 750 1540 670 125 345 405 1020

EI2SACBA 630 10 400 2100 7800 6940 1·4 61 75 1800 1500 850 1670 670 150 395 455 1110

EJ2SACBA 800 10 400 2470 9400 8370 1·3 62 76 2100 1500 850 1780 670 150 395 455 1120

EK2SACBA 1000 10 400 2940 11000 9800 1·2 63 77 2500 1550 1000 1890 820 150 470 530 1280

EL2SACBA 1250 10 400 3520 13400 11800 1·1 64 78 2900 1550 1000 2030 820 150 470 530 1440

6·5% Impedance level

EM2SACBA 1600 10 400 3890 16400 14400 1 66 80 3750 1650 1000 2180 820 150 470 530 1560

7% Impedance level

EN2SACBA 2000 10 400 4830 19000 17100 0·9 68 83 4550 1900 1310 2220 1070 200 580 730 1580

EO2SACBA 2500 10 400 5990 23000 20700 0·8 69 85 5250 2050 1310 2310 1070 200 580 730 1600

A B C D G H N

(mm)(mm) (mm) (mm) (mm) (mm) (mm) (mm)

■ Standard series

EdM cast resin transformers medium voltage (11 kV-400 V) (continued)12 kV insulation class - technical data

Summary referencevalues. Use theconstruction drawing forthe design

All the data given may bemodified without warningfor reasons of technicalproduction or productimprovement

LVterminals

40 (Ø 125)

60 (Ø 150)

70 (Ø 200)

Detail ofearth terminal

Detail ofterminal MV

M 1

2

G

N

M 1

2

60

HG

DD

A

===ØR

B

214_227P_D2010 v2.qxd 1/6/10 21:03 Page 218

www.klinkmann.com10 / 2011

– 15 –

EdM cast resin transformers medium voltage (15 kV-400 V)17·5 kV insulation class - technical data

■ Reduced losses series

■ Normal losses series

kVACat. Nos.

Soundpowerlevel

Weight

kg

Pk (W)Prim V Sec VPo (W)

120°VkV 75° dB dB

lo%ØR

Soundpressure

level

6% Impedance level

EB3RAFBA 100 15 400 380 2050 1800 1·9 40 51 560 1050 600 1090 520 125 270 330 710

EC3RAFBA 160 15 400 480 2900 2550 1·6 43 54 750 1200 630 1210 520 125 270 330 720

ED3RAFBA 200 15 400 570 3600 3170 1·4 45 56 800 1250 630 1230 520 125 270 330 730

EE3RAFBA 250 15 400 670 3800 3340 1·2 46 57 950 1250 640 1240 520 125 270 330 740

EF3RAFBA 315 15 400 790 4600 4050 1·1 47 59 1050 1250 750 1300 670 125 345 405 840

EG3RAFBA 400 15 400 920 5500 4890 1 48 60 1250 1350 750 1390 670 125 345 405 910

EH3RAFBA 500 15 400 1110 6700 5960 0·9 49 61 1400 1350 750 1520 670 125 345 405 940

EI3RAFBA 630 15 400 1290 7800 6940 0·9 50 62 1700 1500 850 1630 670 150 395 455 1070

EJ3RAFBA 800 15 400 1520 9400 8370 0·8 52 64 2000 1500 850 1780 670 150 395 455 1170

EK3RAFBA 1000 15 400 1800 11000 9800 0·7 53 65 2300 1550 1000 1870 820 150 470 530 1290

EL3RAFBA 1250 15 400 2000 13000 11600 0·6 55 67 2750 1550 1000 2010 820 150 470 530 1350

EM3RAFBA 1600 15 400 2420 16000 14240 0·5 56 68 3300 1650 1000 2190 820 150 470 530 1470

EN3RAFBA 2000 15 400 2920 19000 17100 0·5 58 70 4000 1800 1310 2250 1070 200 580 730 1580

EO3RAFBA 2500 15 400 3650 23000 20700 0·4 59 71 4950 1950 1310 2320 1070 200 580 730 1600

7% Impedance level

EP3RAFBA 3150 15 400 3950 27000 24300 0·3 62 74 5750 2150 1310 2350 1070 200 580 730 1610

A B C D G H N

(mm)(mm) (mm) (mm) (mm) (mm) (mm) (mm)

kVACat. Nos.

Soundpowerlevel

Weight

kg

Pk(W)Prim V Sec VPo (W)

120°VkV 75° dB dB

lo%ØR

Soundpressure

level

6% Impedance level

EB3NAFBA 100 15 400 430 1900 1670 2 45 59 560 1050 600 1090 520 125 270 330 710

EC3NAFBA 160 15 400 570 2800 2470 1·7 49 62 750 1200 630 1210 520 125 270 330 720

ED3NAFBA 200 15 400 680 3600 3170 1·5 51 63 800 1250 630 1230 520 125 270 330 730

EE3NAFBA 250 15 400 750 3650 3210 1·3 52 65 950 1250 640 1240 520 125 270 330 740

EF3NAFBA 315 15 400 880 4500 3970 1·2 54 67 1050 1250 750 1300 670 125 345 405 840

EG3NAFBA 400 15 400 1000 5200 4630 1·1 54 68 1250 1350 750 1390 670 125 345 405 910

EH3NAFBA 500 15 400 1200 6700 5960 1 55 69 1400 1350 750 1520 670 125 345 405 940

EI3NAFBA 630 15 400 1600 7800 6940 1 55 70 1700 1500 850 1630 670 150 395 455 1070

EJ3NAFBA 800 15 400 1780 9300 8290 0·9 57 71 2000 1500 850 1780 670 150 395 455 1170

EK3NAFBA 1000 15 400 2000 10800 9630 0·8 58 73 2300 1550 1000 1870 820 150 470 530 1290

EL3NAFBA 1250 15 400 2350 12600 11250 0·7 59 74 2750 1550 1000 2010 820 150 470 530 1350

EM3NAFBA 1600 15 400 2750 15500 13800 0·6 60 76 3300 1650 1000 2190 820 150 470 530 1470

EN3NAFBA 2000 15 400 3350 18500 16650 0·6 61 79 4000 1800 1310 2250 1070 200 580 730 1580

EO3NAFBA 2500 15 400 4300 21800 19620 0·5 63 81 4950 1950 1310 2320 1070 200 580 730 1600

7% Impedance level

EP3NAFBA 3150 15 400 4700 26000 23400 0·4 66 83 5750 2150 1310 2350 1070 200 580 730 1610

A B C D G H N

(mm)(mm) (mm) (mm) (mm) (mm) (mm) (mm)

Standards : BS 14-4 and 14-8 - IEC 60076-11 - CENELEC HD 538.1Power (kVA) : 100 to 3150Frequency (Hz) : 50Primary Voltages (kV) : 12 - 15 insulation class 17.5 kV BIL 75/95 kVSecondary Voltages (V) : 400 - 420 insulation class 1·1 kVAdjustment, MV side : ± 2 x 2·5%Vectorial group : Dyn11 (replace the final letter of the item code with ‘B’ for Dyn5 or ‘C’ for Dyn1)Insulating system insulation class : F / FTemperature rise : 100 / 100 KClass : E2-C2-F1 Certified CESI No. A90323921Tolerances : According to BS / IEC

Notes : The values shown refer to the ratio 15/0·4 kV. These values may slightly change when there are different combinationsdB = Value measured at a distance of one metre, according to standard BS EN 60076-10Dimensions and weight of integral enclosures (see p. 226)

■ Technical data

214_227P_D2010 v2.qxd 6/6/10 08:33 Page 219

www.klinkmann.com10 / 2011

– 16 –

EdM cast resin transformers medium voltage (15 kV-400 V) (continued)17·5 kV insulation class - technical data

■ Distribution series

■ Standard series

kVACat. Nos.

Soundpowerlevel

Weight

kg

Pk (W)Prim V Sec VPo (W)

120°VkV 75° dB dB

lo%ØR

Soundpressure

level

6% Impedance level

EE3DAFBA 250 15 400 910 3800 3340 1·5 55 67 980 1250 640 1300 520 125 270 330 820

EF3DAFBA 315 15 400 1050 4600 4050 1·4 56 69 1150 1350 750 1370 670 125 345 405 840

EG3DAFBA 400 15 400 1320 5600 5000 1·3 57 70 1200 1350 750 1430 670 125 345 405 920

EH3DAFBA 500 15 400 1630 6700 5960 1·2 57 71 1400 1350 750 1540 670 125 345 405 1020

EI3DAFBA 630 15 400 1790 7800 6940 1·2 58 72 1650 1500 850 1670 670 150 395 455 1110

EJ3DAFBA 800 15 400 2100 9400 8370 1·1 59 73 1900 1500 850 1780 670 150 395 455 1120

EK3DAFBA 1000 15 400 2470 11000 9800 1 60 74 2300 1550 1000 1890 820 150 470 530 1280

EL3DAFBA 1250 15 400 2940 13400 11800 1 61 75 2700 1550 1000 2030 820 150 470 530 1440

6·5% Impedance level

EM3DAFBA 1600 15 400 3520 16400 14400 0·9 63 77 3400 1650 1000 2180 820 150 470 530 1560

7% Impedance level

EN3DAFBA 2000 15 400 3890 19000 17100 0·9 65 80 4250 1900 1310 2220 1070 200 580 730 1580

EO3DAFBA 2500 15 400 5040 23000 20700 0·8 66 82 4900 2050 1310 2310 1070 200 580 730 1600

A B C D G H N

(mm)(mm) (mm) (mm) (mm) (mm) (mm) (mm)

kVACat. Nos.

Soundpowerlevel

Weight

kg

Pk (W)Prim V Sec VPo (W)

120°VkV 75° dB dB

lo%ØR

Soundpressure

level

6% Impedance level

EE3DAFBA 250 15 400 910 3800 3340 1·5 55 67 980 1250 640 1300 520 125 270 330 820

EF3DAFBA 315 15 400 1050 4600 4050 1·4 56 69 1150 1350 750 1370 670 125 345 405 840

EG3DAFBA 400 15 400 1320 5600 5000 1·3 57 70 1200 1350 750 1430 670 125 345 405 920

EH3DAFBA 500 15 400 1630 6700 5960 1·2 57 71 1400 1350 750 1540 670 125 345 405 1020

EI3DAFBA 630 15 400 1790 7800 6940 1·2 58 72 1650 1500 850 1670 670 150 395 455 1110

EJ3DAFBA 800 15 400 2100 9400 8370 1·1 59 73 1900 1500 850 1780 670 150 395 455 1120

EK3DAFBA 1000 15 400 2470 11000 9800 1 60 74 2300 1550 1000 1890 820 150 470 530 1280

EL3DAFBA 1250 15 400 2940 13400 11800 1 61 75 2700 1550 1000 2030 820 150 470 530 1440

6·5% Impedance level

EM3DAFBA 1600 15 400 3520 16400 14400 0·9 63 77 3400 1650 1000 2180 820 150 470 530 1560

7% Impedance level

EN3DAFBA 2000 15 400 3890 19000 17100 0·9 65 80 4250 1900 1310 2220 1070 200 580 730 1580

EO3DAFBA 2500 15 400 5040 23000 20700 0·8 66 82 4900 2050 1310 2310 1070 200 580 730 1600

A B C D G H N

(mm)(mm) (mm) (mm) (mm) (mm) (mm) (mm)

Summary referencevalues. Use theconstruction drawing forthe design

All the data given may bemodified without warningfor reasons of technicalproduction or productimprovement

LVterminals

40 (Ø 125)

60 (Ø 150)

70 (Ø 200)

Detail ofearth terminal

Detail ofterminal MV

M 1

2

G

N

M 1

2

60

HG

DD

A

===ØR

B

214_227P_D2010 v2.qxd 1/6/10 21:05 Page 220

www.klinkmann.com10 / 2011

– 17 –

EdM cast resin transformers medium voltage (20 kV-400 V)24 kV insulation class - technical data

kVACat. Nos.

Soundpowerlevel

Weight

kg

Pk(W)Prim V Sec VPo (W)

120°VkV 75° dB dB

lo%ØR

Soundpressure

level

4% Impedance level

EB4RBGBA 100 20 400 400 1750 1540 2 40 51 630 1200 600 1160 520 125 270 330 730

EC4RBGBA 160 20 400 580 2500 2200 1·7 43 54 900 1250 640 1260 520 125 270 330 740

ED4RBGBA 200 20 400 680 2900 2550 1·5 45 56 1030 1350 640 1320 520 125 270 330 750

EE4RBGBA 250 20 400 800 3450 3040 1·3 46 57 1150 1350 640 1360 520 125 270 330 830

EF4RBGBA 315 20 400 920 4500 3970 1·2 47 59 1350 1350 750 1450 670 125 345 405 880

EG4RBGBA 400 20 400 1110 4900 4360 1·1 48 60 1500 1450 750 1530 670 125 345 405 900

EH4RBGBA 500 20 400 1300 6400 5700 1·1 49 61 1640 1450 750 1610 670 125 345 405 980

EI4RBGBA 630 20 400 1600 6900 6150 1 50 62 2000 1500 850 1690 670 150 395 455 1100

6% Impedance level

EB4RAGBA 100 20 400 340 2050 1800 2 40 51 570 1050 600 1110 520 125 270 330 710

EC4RAGBA 160 20 400 480 2900 2550 1·7 43 54 800 1250 640 1240 520 125 270 330 730

ED4RAGBA 200 20 400 550 3600 3170 1·5 45 56 900 1250 640 1250 520 125 270 330 740

EE4RAGBA 250 20 400 650 3800 3340 1·3 46 57 1000 1350 640 1260 520 125 270 330 750

EF4RAGBA 315 20 400 750 4600 4050 1·2 47 59 1200 1350 750 1350 670 125 345 405 860

EG4RAGBA 400 20 400 940 5500 4890 1·1 48 60 1350 1500 750 1440 670 125 345 405 880

EH4RAGBA 500 20 400 1050 6700 5960 1·1 49 61 1500 1500 750 1560 670 125 345 405 960

EI4RAGBA 630 20 400 1250 7800 6940 1 50 62 1800 1500 850 1650 670 150 395 455 1080

EJ4RAGBA 800 20 400 1450 9400 8370 0·9 52 64 2100 1550 850 1810 670 150 395 455 1200

EK4RAGBA 1000 20 400 1800 11000 9800 0·8 53 65 2500 1650 1000 1890 820 150 470 530 1310

EL4RAGBA 1250 20 400 2100 13000 11600 0·7 55 67 2900 1650 1000 2030 820 150 470 530 1370

EM4RAGBA 1600 20 400 2400 16000 14240 0·6 56 68 3550 1750 1000 2200 820 150 470 530 1480

EN4RAGBA 2000 20 400 2900 19000 17100 0·5 58 70 4300 1900 1310 2270 1070 200 580 730 1590

EO4RAGBA 2500 20 400 3800 23000 20700 0·4 59 71 5250 1950 1310 2350 1070 200 580 730 1610

7% Impedance level

EP4RAGBA 3150 20 400 4500 26000 23400 0·4 62 74 6250 2250 1310 2400 1070 200 580 730 1670

A B C D G H N

(mm)(mm) (mm) (mm) (mm) (mm) (mm) (mm)

■ Reduced losses series

Standards : BS 14-4 and 14-8 - IEC 60076-11 - CENELEC HD 538.1Power (kVA) : 100 to 3150Frequency (Hz) : 50Primary Voltages (kV) : 20-23 insulation class 24 kV BIL 95/125 kVSecondary Voltages (V) : 400 - 420 insulation class 1·1 kVAdjustment, MV side : ± 2 x 2·5%Vectorial group : Dyn11 (replace the final letter of the item code with ‘B’ for Dyn5 or ‘C’ for Dyn1)Insulating system insulation class : F / FTemperature rise : 100 / 100 KClass : E2-C2-F1 Certified CESI No. A90323921Tolerances : According to BS / IEC

Notes : The values shown refer to the ratio 20/0·4 kV. These values may slightly change when there are different combinationsdB = Value measured at a distance of one metre, according to standard BS EN 60076-10Dimensions and weight of integral enclosures (see p. 226)BIL 125 available on request

■ Technical data

214_227P_D2010 v2.qxd 6/6/10 08:35 Page 221

www.klinkmann.com10 / 2011

– 18 –

EdM cast resin transformers medium voltage (20 kV-400 V) (continued)24 kV insulation class - technical data

kVACat. Nos.

Soundpowerlevel

Weight

kg

Pk (W)Prim V Sec VPo (W)

120°VkV 75° dB dB

lo%ØR

Soundpressure

level

4% Impedance level

EB4NBGBA 100 20 400 540 1750 1540 2·1 46 59 630 1200 600 1160 520 125 270 330 730

EC4NBGBA 160 20 400 750 2500 2200 1·8 50 62 900 1250 640 1260 520 125 270 330 740

ED4NBGBA 200 20 400 900 2900 2550 1·7 51 63 1030 1350 640 1320 520 125 270 330 750

EE4NBGBA 250 20 400 1000 3450 3040 1·5 53 65 1150 1350 640 1360 520 125 270 330 830

EF4NBGBA 315 20 400 1150 4500 3970 1·4 55 67 1350 1350 750 1450 670 125 345 405 880

EG4NBGBA 400 20 400 1360 4900 4360 1·3 55 68 1500 1450 750 1530 670 125 345 405 900

EH4NBGBA 500 20 400 1580 6400 5700 1·2 56 69 1640 1450 750 1610 670 125 345 405 980

EI4NBGBA 630 20 400 1950 6900 6150 1·1 56 70 2000 1500 850 1690 670 150 395 455 1100

6% Impedance level

EB4NAGBA 100 20 400 480 2000 1760 2·1 46 59 570 1050 600 1110 520 125 270 330 710

EC4NAGBA 160 20 400 650 2800 2470 1·8 50 62 800 1250 640 1240 520 125 270 330 730

ED4NAGBA 200 20 400 800 3600 3170 1·7 51 63 900 1250 640 1250 520 125 270 330 740

EE4NAGBA 250 20 400 850 3700 3260 1·5 53 65 1000 1350 640 1260 520 125 270 330 750

EF4NAGBA 315 20 400 950 4500 3970 1·4 55 67 1200 1350 750 1350 670 125 345 405 860

EG4NAGBA 400 20 400 1150 5400 4810 1·3 55 68 1350 1500 750 1440 670 125 345 405 880

EH4NAGBA 500 20 400 1350 6700 5960 1·2 56 69 1500 1500 750 1560 670 125 345 405 960

EI4NAGBA 630 20 400 1650 7800 6940 1·1 56 70 1800 1500 850 1650 670 150 395 455 1080

EJ4NAGBA 800 20 400 1850 9300 8290 1 58 71 2100 1550 850 1810 670 150 395 455 1200

EK4NAGBA 1000 20 400 2200 10800 9630 0·9 59 73 2500 1650 1000 1890 820 150 470 530 1310

EL4NAGBA 1250 20 400 2600 12800 11430 0·8 60 74 2900 1650 1000 2030 820 150 470 530 1370

EM4NAGBA 1600 20 400 2950 15500 13800 0·7 61 76 3550 1750 1000 2200 820 150 470 530 1480

EN4NAGBA 2000 20 400 3800 18600 16740 0·6 62 79 4300 1900 1310 2270 1070 200 580 730 1590

EO4NAGBA 2500 20 400 4800 22000 19800 0·5 64 81 5250 1950 1310 2350 1070 200 580 730 1610

7% Impedance level

EP4NAGBA 3150 20 400 5100 26000 23400 0·5 67 83 6250 2250 1310 2400 1070 200 580 730 1670

A B C D G H N

(mm)(mm) (mm) (mm) (mm) (mm) (mm) (mm)

■ Normal losses series

kVACat. Nos.

Soundpowerlevel

Weight

kg

Pk (W)Prim V Sec VPo (W)

120°VkV 75° dB dB

lo%ØR

Soundpressure

level

6% Impedance level

EE4DAGBA 250 20 400 1050 3800 3340 1·5 55 67 1050 1350 640 1360 520 125 270 330 850

EF4DAGBA 315 20 400 1210 4600 4050 1·4 56 69 1200 1350 750 1410 670 125 345 405 860

EG4DAGBA 400 20 400 1470 5600 5000 1·3 57 70 1350 1500 750 1510 670 125 345 405 1020

EH4DAGBA 500 20 400 1740 6700 5960 1·2 57 71 1550 1500 750 1570 670 125 345 405 960

EI4DAGBA 630 20 400 2000 7800 6940 1·2 58 72 1800 1500 850 1700 670 150 395 455 1090

EJ4DAGBA 800 20 400 2310 9400 8370 1·1 59 73 2150 1550 850 1850 670 150 395 455 1300

EK4DAGBA 1000 20 400 2790 11000 9800 1 60 74 2550 1650 1000 1930 820 150 470 530 1300

EL4DAGBA 1250 20 400 3260 13400 11800 1 61 75 3000 1650 1000 2070 820 150 470 530 1460

6·5% Impedance level

EM4DAGBA 1600 20 400 3730 16400 14400 0·9 63 77 3600 1800 1000 2250 820 150 470 530 1590

7% Impedance level

EN4DAGBA 2000 20 400 4570 19000 17100 0·9 65 80 4500 1900 1310 2270 1070 200 580 730 1590

EO4DAGBA 2500 20 400 5880 23000 20700 0·8 66 82 5200 2050 1310 2310 1070 200 580 730 1600

A B C D G H N

(mm)(mm) (mm) (mm) (mm) (mm) (mm) (mm)

■ Distribution series

214_227P_D2010 v2.qxd 6/6/10 08:36 Page 222

www.klinkmann.com10 / 2011

– 19 –

kVACat. Nos.

Soundpowerlevel

Weight

kg

Pk (W)Prim V Sec VPo (W)

120°VkV 75° dB dB

lo%ØR

Soundpressure

level

6% Impedance level

EE4SAGBA 250 20 400 1210 3800 3340 1·9 58 70 1150 1350 640 1360 520 125 270 330 850

EF4SAGBA 315 20 400 1470 4600 4050 1·8 59 72 1250 1350 750 1410 670 125 345 405 860

EG4SAGBA 400 20 400 1740 5600 5000 1·7 60 73 1450 1500 750 1510 670 125 345 405 1020

EH4SAGBA 500 20 400 2000 6700 5960 1·5 60 74 1650 1500 750 1570 670 125 345 405 960

EI4SAGBA 630 20 400 2420 7800 6940 1·4 61 75 1950 1500 850 1700 670 150 395 455 1090

EJ4SAGBA 800 20 400 2730 9400 8370 1·3 62 76 2350 1550 850 1850 670 150 395 455 1300

EK4SAGBA 1000 20 400 3260 11000 9800 1·2 63 77 2800 1650 1000 1930 820 150 470 530 1300

EL4SAGBA 1250 20 400 3730 13400 11800 1·1 64 78 3250 1650 1000 2070 820 150 470 530 1460

6·5% Impedance level

EM4SAGBA 1600 20 400 4410 16400 14400 1·1 66 80 3950 1800 1000 2250 820 150 470 530 1590

7% Impedance level

EN4SAGBA 2000 20 400 5360 19000 17100 0·9 68 83 4900 1900 1310 2270 1070 200 580 730 1590

EO4SAGBA 2500 20 400 6620 23 000 20700 0·8 69 85 5650 2050 1310 2310 1070 200 580 730 1600

A B C D G H N

(mm)(mm) (mm) (mm) (mm) (mm) (mm) (mm)

■ Standard series

Summary referencevalues. Use theconstruction drawing forthe design

All the data given may bemodified without warningfor reasons of technicalproduction or productimprovement

LVterminals

40 (Ø 125)

60 (Ø 150)

70 (Ø 200)

Detail ofearth terminal

Detail ofterminal MV

M 1

2

G

N

M 1

2

60

HG

DD

A

===ØR

B

214_227P_D2010 v2.qxd 1/6/10 21:07 Page 223

www.klinkmann.com10 / 2011

– 20 –

EdM cast resin transformers medium voltage (25 kV-400 V)36 kV insulation class - technical data

kVACat. Nos.

Soundpowerlevel

Weight

kg

Pk (W)Prim V Sec VPo (W)

120°VkV 75° dB dB

lo%ØR

Soundpressure

level

4% Impedance level

EE5NAIBA 250 25 400 1250 3600 3180 1.5 55 68 1380 1600 830 1430 670 125 345 485 880

EF5NAIBA 315 25 400 1300 4500 3970 1.4 56 69 1450 1600 830 1510 670 125 345 485 960

EG5NAIBA 400 25 400 1500 5800 5100 1.3 57 70 1650 1600 890 1630 670 150 395 495 1080

EH5NAIBA 500 25 400 1700 6600 5850 1.2 58 71 1900 1650 890 1760 670 150 395 495 1150

EI5NAIBA 630 25 400 2000 7500 6600 1 59 73 2200 1650 890 1770 670 150 395 495 1160

EJ5NAIBA 800 25 400 2450 9700 8550 0.9 60 74 2650 1750 920 1930 670 150 395 525 1290

7% Impedance level

EK5NAIBA 1000 25 400 2600 11300 9950 0.8 61 75 2950 1900 1000 2050 820 150 470 530 1300

8% Impedance level

EL5NAIBA 1250 25 400 2900 14000 12350 0.7 62 76 3450 1950 1020 2190 820 150 470 550 1520

EM5NAIBA 1600 25 400 3400 16000 14240 0.6 64 77 4000 1950 1030 2240 820 150 470 560 1540

EN5NAIBA 2000 25 400 4200 18000 16200 0.5 65 79 4800 2100 1310 2300 1070 200 580 730 1530

EO5NAIBA 2500 25 400 5200 22000 19800 0.5 67 80 5950 2300 1310 2360 1070 200 580 730 1560

EP5NAIBA 3000 25 400 6300 25500 22500 0.4 68 82 7000 2350 1310 2550 1070 200 580 730 1820

A B C D G H N

(mm)(mm) (mm) (mm) (mm) (mm) (mm) (mm)

■ Normal losses series

Summary referencevalues. Use theconstruction drawing forthe design

All the data given may bemodified without warningfor reasons of technicalproduction or productimprovement

LVterminals

40 (Ø 125)

60 (Ø 150)

70 (Ø 200)

Detail ofearth terminal

Detail ofterminal MV

M 1

2

G

N

M 1

2

60

HG

DD

A

===ØR

B

Standards : BS 14-4 and 14-8 - IEC 60076-11 - CENELEC HD 538.1Power (kVA) : 250 to 3000Frequency (Hz) : 50Primary Voltages (kV) : 25-33 insulation class 36 kV BIL 145/170 kVSecondary Voltages (V) : 400 - 420 insulation class 1·1 kVAdjustment, MV side : ± 2 x 2·5% 33kV: +2 / -3 x 1.5kV (36 – 34.5 – 33 – 31.5 – 30 – 28.5kV)Vectorial group : Dyn11 (replace the final letter of the item code with ‘B’ for Dyn5 or ‘C’ for Dyn1)Insulating system insulation class : F / FTemperature rise : 100 / 100 KClass : E2-C2-F1 Certified CESI No. A90323921Tolerances : According to BS / IEC

Notes : The values shown refer to the ratio 25/0·4 kV. These values may slightly change when there are different combinationsdB = Value measured at a distance of one metre, according to standard BS EN 60076-10Integral enclosure available on requestBIL 170 available on request

■ Technical data

214_227P_D2010 v2.qxd 6/6/10 08:37 Page 224

www.klinkmann.com10 / 2011

– 21 –

EdM cast resin transformerscompatibility with Zucchini SCP busbar

■ Compatibility with Zucchini SCP busbar

Transformer Busbar (copper)Insulation 433 V

kVA class current IK 6 % Connection(kVA) (kV) (A) (kA) Family component

630 841 14·10 SCP 1000 A 65281011P

800 1067 17·80 SCP 1250 A 65281013P

1000 1334 22·30 SCP 1600 A 65281015P

1250 1667 27·80 SCP 2000 A 65281016P

1600 2134 35·60 SCP 2500 A 65391018P

2000 2667 44·50 SCP 3200 A 65391015P

2500 3334 55·60 SCP 4000 A 65391016P

3150 4201 60·10(1) SCP 5000 A 65391018P

12, 17·5,

24, 36

Transformer Busbar (copper)Insulation 417 V

kVA class current IK 6 % Connection(kVA) (kV) (A) (kA) Family component

630 873 14·60 SCP 1000 A 65281011P

800 1108 18·50 SCP 1250 A 65281013P

1000 1385 23·10 SCP 1600 A 65281015P

1250 1731 28·90 SCP 2000 A 65281016P

1600 2216 37·00 SCP 2500 A 65391018P

2000 2770 46·20 SCP 3200 A 65391015P

2500 3462 57·70 SCP 4000 A 65391016P

3150 4362 62·40(1) SCP 5000 A 65391018P

12, 17·5,

24, 36Transformer Busbar (copper)Insulation 400 V

kVA class current IK 6 % Connection(kVA) (kV) (A) (kA) Family component

630 910 15·20 SCP 1000 A 65281011P

800 1 155 19·30 SCP 1250 A 65281013P

1000 1 444 24·10 SCP 1600 A 65281015P

1250 1 805 30·10 SCP 2000 A 65281016P

1600 2 310 38·50 SCP 2500 A 65391018P

2000 2 887 48·20 SCP 3200 A 65391015P

2500 3 609 60·20 SCP 4000 A 65391016P

3150 4 547 65·00(1) SCP 5000 A 65391018P

12, 17·5,

24, 36

Transformer Busbar (aluminium)Insulation 400 V

kVA class current IK 6 % Connection(kVA) (kV) (A) (kA) Family component

630 910 15·20 SCP 1000 A 60281012P

800 1 155 19·30 SCP 1250 A 60281014P

1000 1 444 24·10 SCP 1600 A 60281016P

1250 1 805 30·10 SCP 2000 A 60281017P

1600 2 310 38·50 SCP 2500 A 60391014P

2000 2 887 48·20 SCP 3200 A 60391016P

2500 3 609 60·20 SCP 4000 A 60391017P

12, 17·5,

24, 36

Transformer Busbar (aluminium)Insulation 433 V

kVA class current IK 6 % Connection(kVA) (kV) (A) (kA) Family component

630 841 14·10 SCP 1000 A 60281012P

800 1067 17·80 SCP 1250 A 60281014P

1000 1334 22·30 SCP 1600 A 60281016P

1250 1667 27·80 SCP 2000 A 60281017P

1600 2134 35·60 SCP 2500 A 60391014P

2000 2667 44·50 SCP 3200 A 60391016P

2500 3334 55·60 SCP 4000 A 60391017P

12, 17·5,

24, 36

Transformer Busbar (aluminium)Insulation 417 V

kVA class current IK 6 % Connection(kVA) (kV) (A) (kA) Family component

630 873 14·60 SCP 1000 A 60281012P

800 1108 18·50 SCP 1250 A 60281014P

1000 1385 23·10 SCP 1600 A 60281016P

1250 1731 28·90 SCP 2000 A 60281017P

1600 2216 37·00 SCP 2500 A 60391014P

2000 2770 46·20 SCP 3200 A 60391016P

2500 3462 57·70 SCP 4000 A 60391017P

12, 17·5,

24, 36

(1) 7% impedance

The Zucchini SCP busbar trunking system and EdM cast resintransformers have been designed in perfect synergy for a directconnectionThe versions shown below represent just a few of the standardisedsolutions

400 V secondary voltage

417 V secondary voltage

433 V secondary voltage

Transformer to busbar connection

214_227P_D2010 v2.qxd 6/6/10 08:38 Page 225

www.klinkmann.com10 / 2011

– 22 –

EdM cast resin transformers enclosures

■ Enclosures

A

C

S

B

Degree ofA B C S Weight protection

kVA [mm] [mm] [mm] [mm] [kg] Walls Base

230316 IP 21230353 100 1600 900 1470 500 120 IP 31 IP 20230288 IP 23

230316 IP 21230353 160 1600 900 1470 500 120 IP 31 IP 20230288 IP 23

230316 IP 21230353 200 1600 900 1470 500 120 IP 31 IP 20230288 IP 23

230211 IP 21230263 250 1700 950 1580 405 140 IP 31 IP 20230273 IP 23

230211 IP 21230263 315 1700 950 1580 405 140 IP 31 IP 20230273 IP 23

230212 IP 21230234 400 1800 1000 1680 405 160 IP 31 IP 20230215 IP 23

230212 IP 21230234 500 1800 1000 1680 405 160 IP 31 IP 20230215 IP 23

230204 IP 21230222 630 1900 1050 1950 575 180 IP 31 IP 20230277 IP 23

230204 IP 21230222 800 1900 1050 1950 575 180 IP 31 IP 20230277 IP 23

230213 IP 21230223 1000 2050 1100 2200 600 210 IP 31 IP 20230221 IP 23

230213 IP 21230223 1250 2050 1100 2200 600 210 IP 31 IP 20230221 IP 23

230214 IP 21230249 1600 2300 1310 2500 730 280 IP 31 IP 20230267 IP 23

230214 IP 21230249 2000 2300 1310 2500 730 280 IP 31 IP 20230267 IP 23

230287 IP 21230371 2500 2500 1310 2700 730 300 IP 31 IP 20230309 IP 23

230287 IP 21230371 3150 2500 1310 2700 730 300 IP 31 IP 20230309 IP 23

EdM cast resin transformersdrilling specifications

40

40

D= =

4xØ13

20

80

32

32

C= =

2xØ13

14

60

50

50

E= =

4xØ15

25

100

50

25

B= =

Ø15

60

60

F= =

4xØ18

30

120

40

20

A= =

Ø13

■ Standard drilling details

LV connection terminals are manufactured from aluminiumSpecial CUPAL bimetallic plates can be supplied for the connection ofcopper cables

All the data given can be modified without warning for reasons oftechnical production or product improvement

Range Thickness Width No. of Ø holesDrawing kVA [mm] [mm] holes [mm]

A 100 4 40 1 13160 4 40 1 13

B 200 5 50 1 15400 5 50 1 15

C 500 6 60 2 13630 6 60 2 13800 8 60 2 13

D 1000 8 80 4 13

E 1250 8 100 4 15

F 1600 10 120 4 182000 12 120 4 182500 16 120 4 183150 20 120 4 18

214_227P_D2010 v2.qxd 1/6/10 21:14 Page 226

www.klinkmann.com10 / 2011

– 23 –

EdM cast resin transformers installation information

■ Installing an EdM transformer EdM cast resin transformers can be installed quickly and easilySince no additional construction or building activities are necessary, safe installation can be ensured by following a few simple steps :

• Standard execution – indoor installation, in dry / clean environments, protected from direct sunlight, with no possibility of water ingress

• Altitude no higher than 1 000 m above sea level (for higher installations, contact us on +44 (0) 845 600 6266)

• Room temperature with transformer in operation (for higher values, contact us on +44 (0) 845 600 6266) :•T minimum – 25°C•T maximum + 40°C

• With a standard execution, the transformers are designed in accordance with the IEC Standards 60076-11 for the following room air temperatures :• 40°C at peak times• 30°C as a monthly average in the warmest month• 20°C as a yearly average

• In order to protect the transformers from external environment impacts and people from the risk of having direct contacts, a set of standardboxes is available with different degrees of protection : IP 21 / IP 31 / IP 23

5

7

8

6

1

2

3

10 - 14

9 - 15

11 13 4 12

1 MV windings in aluminium strip coils, cast in resin under vacuum

2 Core in three columns in magnetic lamination with high-permeabilityoriented crystals, also available with low losses

3 LV windings in aluminium plate/sheet and vacuum-cast impregnatedinsulation material

4 LV connections upwards (standard) or downwards version (onrequest)

5 MV connections upwards (standard) or downwards version (onrequest)

6 Rubber inserts attenuate the transmission of vibrations between core and windings, and reduce operating noise generated by thetransformer to a minimum, as well as absorbing the thermal expansionof the components

7 Sockets on the MV side to adapt the primary voltage to the mains,which can be set with transformer switched OFF

8 Structure, armatures and carriage, manufactured from strong paintedsheet steel

9 Carriage with bi-directional castors

10 The epoxy resin insulation makes the transformer low maintenance

11 The operating temperature is checked by Pt100 sensor or PTC in the LV windings

12 Lifting eyebolts conform to the DIN-580 UNI-2947 standards withsafety hooking at 4 points

13 Optional pre-equipment for connection of the LV connection toZucchini busbar trunking system

14 Class F insulating material, at 155°C, allowing for a temperature riseof 100°K. (100°C)

15 The carriage allows safe movement and is pre-equipped formounting IP reinforced boxes

214_227P_D2010 v2.qxd 6/6/10 08:41 Page 227

Yekaterinburgtel. +7 343 376 [email protected]

St. Petersburgtel. +7 812 327 [email protected]

Moscowtel. +7 495 641 [email protected]

Кievtel. +38 044 495 33 [email protected]

Helsinkitel. +358 9 540 [email protected]

Vilniustel. +370 5 215 [email protected]

Rigatel. +371 6738 [email protected]

Мinsktel. +375 17 200 [email protected]

Tallinntel. +372 668 [email protected]

Samaratel. +7 846 273 95 [email protected]

www.klinkmann.com

Legrand_Industry_Zucchini_EdMcast_resin_transformers_en_0811.pdf