Vertical electrostatic coater having vortex effect

Transcript of Vertical electrostatic coater having vortex effect

solution of a base. whose conjugate acid has a pKa in dimethyl sulfoxide of greater than 19, for 1 to 60 set at a temperature in the range from 15 to 190°C; and washing the base-contacted aramid surface with wa- ter until substantially all of the base is removed.

Process for Coating Phosphated Metal Substrates U.S. Pafenf 5,773,090. June 30, 1998 G. Bijner et al., assignors to Herberts GmbH, Wuppertal, Germany

A process for coating a metal substrate comprising phosphating in a solution that contains no nickel; treating the phosphated metal substrate with an aqueous solution after phosphating and before application of a first organic coating; wherein the treating step is performed with an aqueous solution, which contains 5 to 10,000 ppm of dis- sobed bismuth in a form of at least one member selected from the group consisting of inorganic bismuth compounds and or- ganic bismuth compounds and wherein the bismuth is deposited in a total quantity of 5 to 100 mg/m’; and applying one or more organic coatings.

Curtain Coating Device U.S. Patenf .5,773,094. June 30, 1998 H. Krijckel, assignor to KSK lndustrielackierungen GmbH, Geilenkirchen, Germany

A method and apparatus for painting body parts of motor vehicles in series prior to assembly.

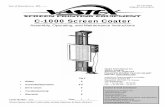

Vertical Electrostatic Coater Having Vortex Effect U.S. Patent 5,773,097. June 30, 1998 J. Rogari, assignor to Nordson Corp., Westlake, Oh/o

A method for electrostatically coating a continuous-length workpiece with a partic- ulate coating material comprising an elec- trostatic fluidized bed system.

Antigraffiti Coating U.S. Patent 5,773,091. June 30, 1998 D. Per/man and R.H. Black, assignors lo Brandeis Universify, Waltham, Mass.

A method of treating surfaces to in- crease resistance to graffiti markings and other soiling and facilitating cleaning of the surfaces comprising applying a coat- ing material to form a barrier coat,

TEE ANSWER TO YOUR WASTEWATER TREATMENT

PROBLEMS.. . No one technology is the correct solution for al applications: Wastewater Treatment, Water Treatmen and Chemical Recovery. That is why we offer man: Werent unit operations and engineer them into ; .reatment solution that is right for your individual needs.

Process Technologies Include:

4 Chemical Treatment 4 Clarification 4 Filtration 4 Ionncxchangc b Media Filtration 4 Microfiltration 4 Ultrafiltration 4 Evaporation 4 Batch Treatment 4 Oil Separation

4 Aqueous Cleaner Recovery

(6

TREATMENT T.P.C. PRODUCTS

u CORPORATION Wastewater Treatment & Recovecv ,!Qstems P.O. Box 444 Thorndale PIL 19372-9998

Phone (610) 384-6279 Fax (610) 384-6239

Circle 114 on reader information card

wherein tlhe coating material includes an effective concentration of at least one wax-protective chemical agent selected from the group consisting of photostable wax-soluble/water-insoluble solar UV light absorbers, wax-soluble/water-insol- uble free-radical and peroxy-radical scavengers, and wax-soluble/water-insol- uble antioxidants.

Resin Composition to be Plated U.S. Patent 5,773,536. June 30, 1998 T Mizoguchl and M. Iwafune, assignors to Cosmo Research Institute and Cosmo Oil Co. Ltd.. Tokyo

A method of forming a structure of a microporous resin bonded to metal com- prising molding a resin composition com- prising a polymer alloy consisting of poly- ether imide and polyphenylene ether and particles of aluminum borate or amorphous silica filler; treating the molded resin com- position uith an aqueous alkaline solution to removje the filler, thereby creating mi- cropores within the resin object; and depos- iting a metal film on a surface of the treated resin ob,ject.

hall-mark \‘hdl-,mArk\ n (Goldsmith’s Ha//, London, England, where gold and silver articles were assayt stamped to indicate orkgin, purity, or genuine----’ 2 : a distinguishing characteristic, trait, or fearure

High Quality Finishing Products

On-site Problem Solving Assistance *A”

2828 Highland Avenue, Cinclnnarl, UH 45212 600.998.8396 l 513.73’1.3400 l 513.731.8113 Fax

Circle 110 on reader information card

124 METAL FINISHING l NOVEMBER 1998