UTILIZATION OF EXHAUST STEAM OF WASTE TO ENERGY (WTE ...

Transcript of UTILIZATION OF EXHAUST STEAM OF WASTE TO ENERGY (WTE ...

UTILIZATION OF EXHAUST STEAM OF WASTE TO

ENERGY (WTE) POWER PLANTS FOR WATER DESALINATION

JingyaWeiAdvisor:ProfessorNickolasJ.Themelis

SubmittedinpartialfulfillmentoftherequirementsforthedegreeofMasterofScienceinEarthResourcesEngineering

DepartmentofEarthandEnvironmentalEngineering

TheFuFoundationSchoolofEngineeringandAppliedScienceColumbiaUniversity

December2015

Researchco-sponsoredby:

2

UTILIZATION OF EXHAUST STEAM OF WASTE TO ENERGY (WTE) POWER PLANT FOR WATER DESALINATION

EXECUTIVESUMMARYThereareoveronethousandwastetoenergy(WTE)plantsoperationalaround

the world to recovery energy and generate electricity from 250 million tons ofmunicipal solid waste (MSW) per year. The most common WTE plants areelectricity-only producers and use the heat of combustion to produce steam thatpowersaturbinegenerator.Tomaximizeelectricityproductivity,theexhauststeamfromturbineissenttoanairorwatercooledcondenser,thenrecycledtotheboiler.ForatypicalWTEplantof10t/hcapacity,thegrosselectricitygeneratingcapacityisabout6MWh/hour,whichintheU.S.representsabout20%oftheenergycontainedintheMSWcombusted.Suchplantsdonotmakeuseoftheenergycontainedintheexhauststeamfromturbine.

ToimprovetheenergyefficiencyofWTEplants,manyEuropeanWTEplantsarecombinedheatandpower(CHP)facilities.Thesefacilitiesselltheextractorexhauststeam from turbine for district heating (DH) system. A CHP WTE plant of 10 t/hcapacityand50%steamextractioncanproduceupto5MWh/hourofelectricityplus 31,000-62,500MJ/hofheat.Although20%ofelectricpowerissacrificed,theoverallefficiency increases from 20% to at least 65% compared to the condensing WTEplants. heat recovery system, the thermal efficiency for these facilities can reach80-90%.

However, the use of theWTE exhaust steam for district heating is limited toclimates with cold winter and also by the cost of DH transmission systemconstruction..This thesisexaminesanotheroption forutilizing the turbineexhauststeamasanenergysourceforthermalwaterdesalination.

Desalinationreferstoprocessesthatremovesaltandothermineralsfromsalinewater to provide freshwater. Almost 16,000 desalination facilities have been builtworldwide, producing over 70 million cubic meters of potable water. Waterdesalination uses either thermal or membrane technologies. Main technologyincludes electricity powered reverse osmosis (RO), steam and electricity poweredmultiple-effect distillation (MED) and multi-stage flash evaporation (MSF). Withlower energy consumptionof 1-7 kWh/m3 anddecreasing cost of 0.1-1.0USD/m3,membrane(RO)desalinationisapreferablechoiceformostdesalinationplantsandrepresents60%oftheinstalledcapacityworldwide.TheMSFdesalinationunitshavea relative high temperature demand, 100-130°C for feed steam and 90-120°C foroperation,resultinginanhigherenergyconsumptionof13.5-25.5kWh/m3electricalequivalent and cost of 0.5-1.75 USD/m3. The MED process can operate with lowpressure(0.3-0.5bar),lowtemperature(70-90°C)steambynearlyvacuumpressurecondition.Withlowerelectricconsumptionof1.5-2.5kWh/m3thanMSF,thetypicalproductioncostofMEDisaround0.7-1USD/m3,competitivetoROtechnology..

Inspired from CHP plants for DH, two power-desalination cogeneration plantswereexamined in this study:TheSt.BarthWTE-desalinationcogenerationplant in

3

theCaribbeanandtheHebeiHuanghuapower-desalinationplantinChina.Withonly1.5t/hMSWcapacity,theSt.BarthWTEplantsells67%ofrecoveredenergytotheMED desalination plant which produces 1350 m3 freshwater per day. The heatconsumption forpotablewaterproduction is8.6MJ/m3 (40.6kWh/m3). Inaddition,about 8.5% of the chemical energy in the MSW is transformed to electricity,sufficient for theelectric consumptionofboth the WTEand theMEDprocess. Inbrief, this plant helps St. Barth to dealwith itsMSWwhile also solving thewatersupplyissueoftheisland.

TheHuanghuapowerplant isacoal-poweredplantwith2,520MWgenerationcapacity, locatedonthePohaiGulfofChina.Anestimated3,200,000-4,400,000m3offreshwaterisconsumedannuallyasfeed-waterfortheboilerunits,aswellasfordesulfurization and other processes. Huanghua solved this massive waterconsumptionthroughseveralcoupledMEDdesalinationunitswhichusetheturbines’exhaust steamas theheat source.TheseMEDunitsproduce57,500m3/dof freshwaterandconsume40%oftheenergyinthecoalinput.Inadditionto meetingitsown needs, the plant also produces up to 10 million tons of freshwater for use(14,000-28,000m3/d)bythePortofHuanghua.Withthiscombinationofelectricityandfreshwaterproduction,90%oftotalenergyinthecoaltotheplantistransferredtovaluableproducts,resultinginanestimatedsavingof500tonsperdayofcoal.

This study showed that the cogeneration of power andwater is an ecologicaland economical solution, both for WTE and fossil fuel-fired power plants.ConsideringthebenefitsandrequirementsofWTE-desalinationcogenerationplants,themostpromisingplacesforthistechniquearethosetropicalislandsorgulfcitieswith little access to land, fuels and waters. Suitable regions include theMediterranean Sea (Cyprus, Crete, etc.), Persian Gulf countries (Kuwait, Bahrain,Oman,etc.),CaribbeanSeaislands,theRedSea,etc.ThecasesofCyprusandUnionTerritoryofLakshadweep(India)wereanalyzed.Thisstudyalsoincludedtheenergyandresourcesidebenefits.However,additionalcost-benefitanalysisisnecessaryforaspecificgeographicarea.

AcknowledgementsFirst, I would like to express my appreciation to my advisor, Professor Nickolas J.Themelis, forhisvaluableandopportuneguidanceuponmythesiscompletion.Hispatience,motivationandabundantexperiencegavemealotofencouragementandinspiration during my work. I also want to show my thanks to my dear LilianaThemelisforallherkindnessandsupportduringmystudyatColumbiaUniversity.

Inaddition, I amgrateful to thankSIDEMandShenhuaGroupe for sharingme thedataof theirdesalinationequipmentandplants. Lastbutnot least, Iwould like tothankmyparentsandfriends.It’stheirsupport,companyandloveencouragingmeovercomethedifficultiesanddisappointmentsthroughoutmyacademiccareer.

4

TableofContents

ExecutiveSummary

Acknowledgements

1.Background............................................................................................7

2.EnergyFlowAnalysisofTypicalExhaustSteamUtilization.................122.1.WithoutExhaustSteamTreatmentandUtilization.....................................12

2.1.1.DescriptionofProcess......................................................................122.1.2.ThermodynamicSimulatedModelofWTEProcess.........................132.1.3.EnergyFlowofSimulatedWTEModel.............................................15

2.2.ExhaustSteamCondensation......................................................................202.2.1.Condensingsteamturbine...............................................................202.2.2.ThermodynamicSimulatedModelofCondensingWTEPlant..........222.2.3.DiscussionofCondensationSimulationModelofWTEProcess......22

2.3.ExhaustSteamforDistrictHeating..............................................................252.3.1.DistrictHeatingandCogenerationWTEPlants................................252.3.2.ThermodynamicSimulationofCHPWTEPlant................................262.3.3.DiscussionofCondensationSimulationModelofWTEProcess......27

3.MainDesalinationTechnologies..........................................................323.1.RODesalinationTechniques........................................................................333.2.ThermalDesalinationTechniques................................................................36

3.2.1.MultipleEffectDistillation(MED).....................................................363.2.2.MED-TVCandMED-MVC..................................................................383.2.3.Multi-StageFlash(MSF)Distillation.................................................40

3.3.ComparisonofPopularDesalinationTechnologies.....................................42

4.CaseStudyofCogenerationDesalinationPlant..................................434.1.St.BarthWTEDesalinationCogenerationPlant..........................................43

4.1.1.BackgroundofSt.Barth....................................................................434.1.2.WasteManagementandWaterProductioninSt.Barth..................444.1.3.WTE-DesalinationPlantEnergyFlowEstimation.............................45

4.2.HebeiHuanghuaPower-DesalinationCogenerationPlant..........................484.2.1.IntroductionofHuanghuaPowerPlant............................................484.2.2Coal-FiredPower-WaterCogenerationEnergyFlowEstimation.......49

5.LocationsforWTE-DesalinationPlantsDevelopment.........................535.1.Cyprus..........................................................................................................545.2.UTofLakshadweep.....................................................................................56

6.Conclusion...........................................................................................61

5

REFERENCES............................................................................................64

ListofFigures

Figure1WTEProcessandApplication.........................................................................7Figure2Cumulativecontractedandcommissioneddesalinationcapacity1965-20119Figure3Totalworldwideinstalledcapacitybyfeedwatercategory............................9Figure4Top10countriesbytotalinstalledcapacitysince1945.................................9Figure5Installedmembraneandthermalcapacity,1980-2010(cumulative)..........10Figure6Top10countriesbytotalinstalledthermalcapacitysince1945.................10Figure7SchematicDescriptionofWTEPlant............................................................13Figure8EnergyFlowofBasicSimulatedModel–WithoutExhaustSteamTreatment

andUtilization(Unit:MJ/h,BasedonMSWincinerationcapacityof10t/h)...17Figure9Water-cooledsurfacecondenser..................................................................21Figure10Air-cooledsurfacecondenser.....................................................................21Figure11ExtractionSteamTurbine...........................................................................26Figure 12 Energy Output for Cogeneration WTE Plants with Different Steam

ExtractionRatio.................................................................................................29Figure13Totalworldwideinstalledcapacitybytechnology.....................................32Figure14MechanismofOsmosisandReverseOsmosis............................................33Figure15RODesalinationPlants...............................................................................34Figure16SpiralWoundROMembrane......................................................................34Figure17AnnualizedSWROCostTrends...................................................................35Figure18SchematicofMEDEvaporatorandSingleEffectUnit.................................37Figure19SchematicofMED-TVCProcess..................................................................39Figure20SchematicofThermocompression.............................................................39Figure21SchematicofMED-MVCProcess................................................................40Figure22MSFDesalinationProcessandMSFCell.....................................................41Figure23MapofSt.Barth.........................................................................................43Figure24WTE-DesalinationPlantofSt.Barth...........................................................44Figure25CombustibleWasteDriedandMoved........................................................44Figure26GuohuaCangdongPowerPlantDesalinationFacility(25,000t/d)..............48Figure27SchematicofShenhuaGuohuaLarge-scaleMEDProcess(12,000t/d).......49Figure28MapofCyprus............................................................................................54Figure29MSWCompositionofCyprus......................................................................55Figure30MapofLakshadweep.................................................................................57Figure31SchematicofLTTDprocessforKaravatti.....................................................59

ListofTables

Table1EnergyFlowResultofBasicSimulationModel..............................................16Table2DesignparametersofsomeWTEplantsandsimulatedmodels....................18Table3EnergyFlowAccountingofWTEPlants(ForChapter2.1)..............................19

6

Table4EnergyFlowResultofCondensingSimulationModel....................................23Table5EnergyFlowAccountingofWTEPlants(ForChapter2.2)..............................24Table6EnergyFlowResultofThreeDHSimulationModel.......................................28Table7ConsumptionandCostofFossilFuelsDH......................................................28Table8EnergyFlowAccountingofWTEPlants(ForChapter2.3)..............................30Table9WaterBoilingPointTable...............................................................................36Table10ComparisonofCharacteristicsofMainDesalinationTechnologies.............42Table11OperationDataofSt.BarthWTEPlant........................................................45Table12ParameterEstimationofSt.BarthWTEPlant..............................................45Table13OperationParameterofSt.BarthDesalinationPlant..................................46Table14EnergyFlowResultofSt.BarthWTE-DesalinationPlant(1hScale).............46Table15EnergyFlowAccountingofSt.BarthWTEPlants.........................................47Table16IntroductionofHuanghuaPowerPlant.......................................................48Table17HuaghuaPowerPlantTurbineOperationData............................................50Table18OperationParameterofHuanghuaDesalinationUnits................................50Table19EnergyFlowResultofHunaghuaPower-DesalinationPlant(1hScale)........51Table20EnergyFlowAccountingofHuanghuaPower-DesalinationsPlants.............52Table 21 Distribution of MSW in Cyprus Can Be Utilized for Energy Recovery per

Region...............................................................................................................55Table22OperationParameterofCyprusDesalinationPlants....................................56

7

1.BackgroundThermalenergycanberecoveredfrommunicipalsolidwaste(MSW)byincinerationbefore it transports to landfilling, typically being output in the form of steam,electricityorhotwater.Simultaneouslythevolumeofwastecanbereducedbyupto80%-90% with a mass reduction of 50%. According to a 2012 market reportpublishedbyGermanenvironmentalconsultancy,ecoprog, thereare2150 thermalwastetoenergy(WTE)plantsoperationalaroundtheworldwithalmost250milliontons waste treatment capacity per year. In addition, 250 new waste to energyfacilitieswith a total capacityof 70million tonsper yearwill be commissionedby2016,mainlyleadingbytheinvestmentofChinaandEurope[1].ThemostprovenanddominantWTEtechnologyismassburning,orgratecombustion,duetoitssimplicityofoperation,highavailabilityandrelativelylowcapitalcost.Ofover800mainWTEplantsintheworld,about600ofthemchoosemassburntechnology.Varioustypesof grate are available depending on the way that the waste is fed on to thecombustion grate, including horizontal grate, forward-moving grate, reverse-actinggrateandrollergrate[2].

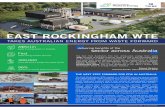

Figure1WTEProcessandApplication

Withsimilartechnologies,theutilizationofenergyrecoveredfromMSWisofseveraldifferenttype.InthemajorityofcountrieslikeUSandChina,themostcommonWTEplantsareelectricity-onlybusiness.Theyusethesteamproducedbycombustiontodrivetheelectricitygenerationturbine,theexhauststeamfromturbineissenttoacondenserforcooling,thenrecycledtoboilerorinjectedintonaturalwatersystem.Itshouldbenotedthatsuchprocessmakesverylittleuseoftheenergycontainedintheexhauststeamfromturbineandlossesover60%oftheenergyreleasedfromthecontrolledcombustionofMSW.TakingUnitedStatesfor instance,62of its84WTE

8

plantsgenerateelectricityastheironlyenergyproduct.Basedonitsshareofmarket,about11millionmegawatthoursof electricity is generated in 2012whileover 20millionmegawatthoursofenergyfromMSWlost[3].Possibleapplicationofthispartof energy, however, is finite due to the relative low pressure and temperaturecharactersofexhauststeam.Toreducetheenergy lossesofelectricityfrompowergeneration, countries like Europe and South Korea uses energy recovered indifferentways.Manyof theirWTEplantsareheat-only facilitiesorcombinedheatandpower(CHP)facilities.Thesefacilitiesprovideheatenergyastheirproductintheformofsteamorhotwaterandsells it fordistrictheatingandcooling(DHC)orforother related industrial production processes. The thermal efficiency for thesefacilities are typically around 80%, much higher than the electric business plants.Besides,tangibleeconomicbenefitscanbeachievedatthesametime.Basedonthesuccess in Europe, DH is a great choice for many places to fully utilize energy inexhauststeam.However,thisapplicationrestrictedbythehighrequestandcostofDHtransmissionsystemconstructionaswellasthesuitableclimateconditionofthearea.Currentlyanewchoiceisposedbytheworldwidefreshwaterscarcity--usingtheexhauststeamasanenergysourceforthermalwaterdesalination.

Waterdesalinationreferstoprocessesthatremovesomeamountofsaltandothermineralsfromsalinewatertoprovidepeoplewithneededfreshwater.Withlimitedfreshwaterresources(1%)andcontinuousgrowingpopulation,thescarcityoffreshwaterandtheneedforadditionalwatersuppliesarealreadyposingmajorproblemsformorethanabillionofpeoplearoundtheworld.Thisissueissignificantlycriticalinmanyaridregionsoftheworldandmanyofthemevendonothavesurfacefreshwaterresourcessuchasriversand lakes,andmanyonlyhave limitedundergroundwaterresources.TheWorldHealthOrganizationpredicts thatbymid-century, fourbillionofus—nearly two-thirdsof theworld’spresentpopulation—will faceseverefresh water shortages. Recent advances in technology have made seawaterdesalinationarealisticandmostpromisingsolutiontosupplyfreshwater.

Inthepast45years,thedesalinationindustryhasgrownfromvirtuallyzero,toover70million cubic meters of treated water per day and almost 16,000 desalinationfacilitieshavebeenbuiltworldwide.Uptill2012,seawaterhasalreadyaccountedforalmosttwo-thirdsofallfeedwater[4].Stimulatedbythethirstofwaterandabundantoilsupply,thedesalinationmarketisledbyMiddleEast,theGulfStates,withashareof 53.4%, followed by North America (17%) and Europe (10%)[5 ]. Technologyadvancement and wide adoption of desalination also causes a significant costcut-downwhichinturnsfurtheracceleratethedevelopmentofdesalinationmarket.Thecostofdesalinatedwaterhasdownedto0.45~1US$/m3 in2013comparedtothe 9 US$/m3 in 1970, nearly compatible to the price of tap water in US (~0.53US$/m3). Consequently, transportation, energy and environmental costs have nowreplacedtechnologyastheprimary impedimentsto large-scaledesalinationandasthemost dominated part, energy cost accounts to 30~45% of the total operativecost[6][7][8].

9

Figure2Cumulativecontractedandcommissioneddesalinationcapacity1965-2011[4]

Figure3Totalworldwideinstalledcapacitybyfeedwatercategory[4]

Figure4Top10countriesbytotalinstalledcapacitysince1945[4]

Water desalination uses either thermal or membrane technologies. Membranetechnologies include reverse osmosis (RO), electrodeionisation (EDI) andelectrodialysis (ED) and generally powered by electricity. Thermal technologiesinclude multiple-effect distillation (MED) and multi-stage flash evaporation (MSF)

10

and are powered by steam together with some electricity. As for sea waterpurification, all of the approaches mentioned is well developed and proved bypractical production. With lower energy consumption and decreasing cost ofmembrane, membrane desalination is a preferable cost-effective choice for mostdesalinationplants. It has grown rapidly since2003,occupied60%of the installeddesalination capacity worldwide. Being more energy-intensive, the comparativelyhigh price of steam is exceptionally believed to be the key blocker of thermaltreatment development. Despite expectations of decline, however, thermaldesalination also continues to grow. It may cause by the development of solarthermal technologies and its new bond to power plants. Saudia Arabia and theUnitedArabEmirateshaveledthethermaldesalinationmarketsincetheGulfStatesaccesstoabundantoilsupplies.

Figure5Installedmembraneandthermalcapacity,1980-2010(cumulative)

Figure6Top10countriesbytotalinstalledthermalcapacitysince1945

Asismentioned,somebig-scalepower-desalinationcogenerationplantshavebeenbuiltrecentyears,mostlyinSaudiArabiaarea,tomakeuseofthewasteenergyfromnearby power plants cut down the energy cost of desalination. Similar to manytraditional power plants, WTE plants also have considerable potential to be an

11

energysuppliertothermaldesalinationfacilities.ThismayhighlyincreasetheenergyefficiencyofWTEplantswhilecreateaccountablefreshwatertomitigatethewaterscarcity.Thisstudyaimsatmakingan initialassessmentofthepossiblebenefitsofusingexhauststeamfromWTEforwaterdesalinationby:

- Analyze and compare the energy flow and efficiency of existing exhaust steamtreatmentorapplication,includingcondensinganddistrictheating;

- Analyzeandcomparetheoperationrequirement,energyconsumptionandcostofmostpopularthermaldesalinationtechniques;

- CasestudyofexistingWTE-desalinationplants;- Basedontheanalysisabove,suggestsomeplacessuitableforthedevelopment

ofwaste-to-watercogeneration.

12

2.EnergyFlowAnalysisofTypicalExhaustSteamUtilization

2.1.WithoutExhaustSteamTreatmentandUtilization

2.1.1.DescriptionofProcess

WTE plant is designed to combust unrecyclable MSW and simultaneouslyrecuperates the energy and cleans the gases generated from combustion[9]. Bydefinition,wasteincinerationiscarriedoutwithsurplusofair.Thisprocessreleasesenergy and produces solid residues as well as a flue gas emitted into theatmosphere[10].

AschematicdescriptionofgeneralincinerationprocessisrepresentedasFigure7.Asdepicted,MSWisfirstdischargedintoandthenextractedfromawastebunkerbyanoverheadclawcrane,thenloadedintoafeedhopperofWTEfurnaceandprocessedon a moving grate in order to achieve a correct combustion in combustionchamber[11].

Thehigh temperatureoxidation in thechamber reduces largeparticleMSWtoashand discharged at the lower end of the grate. Some of the ash is transported forlandfillingwhilesomecanbereusedinapplicationssuchasfillinginthebuildingandconstructionindustries.Toguaranteethehighperformanceofcombustion,theairistypically fed into thecombustion twice.Theprimaryair is injected frombottomofthegrate,dryingtheMSWwhileprovideoxygenforcombustion;thesecondaryairisinjectedfromtopofthechamber,providingacirculateconditionwithinthechamberas well as providing extra oxygen for unburned residuals. Additional fuelsmay beneededtoensurethecombustiondependingonthecompositionandheatvalueofMSW.Thecombustionproduct,calledfluegases,thenexchangesitsenergywiththeboiler. The water in tubes within the boiler becomes superheated steam (highpressure) as heat transferred, and is sent to drive the turbine that generateselectricity. Low pressure steam from the generator then exhausted for furthertreatmentoruse.

Intermsofthesteamturbine,itcanberoughlydividedintocondensingturbineandnon-condensing (back pressure) turbine. For a condensing steam turbine, it isoperatedwithanexhaustpressure lessthanatmospherictomaximizethepressuredrop through the turbine, thus greater the energy extracted from steam input(approx.30-40%efficiency).ThetechnologywithcondensingturbinewillfurtherbeexplainedandanalyzedinChapter2.2.Thenon-condensingturbine,onthecontrary,isoperatedwithanexhauststeamequaltoorinexcessofatmosphericpressureandismostwidelyusedforprocesssteamapplications(refineries,districtheatingunits,paper plants, and desalination facilities). The exhaust steam pressure can be

13

controlledbyregulatingvalvetosuittheneedsoftheprocesses.

The flue gas cleaning system, or air pollution control (APC) system, ensurescontrolled emissions fromWTE plants. A certain percentage of pollutant particles,however,willstillbeemittedintotheatmosphereaftertreatment,dependingonthecompositionofMSWandthetypeofAPCsystemchose.ThecommonpollutantsareCO2,N2O,NOx,SOxandNH3.

Figure7SchematicDescriptionofWTEPlant

2.1.2.ThermodynamicSimulatedModelofWTEProcess

To assess the energy efficiency of the WTE processes mentioned above, athermodynamicmodelisneeded.Accordingtothefirstlawofthermodynamics,foranisolatedsystemthetotalamountofenergyisconstant,that istosaytheenergyinputequals to theenergyoutputandenergy losses. For this study,wedefine theWTEplantandtheelectricitygeneratorunitasourstudysystemandourmaintargetis the flowof energy generated andused from theMSW. In this case, despite theextra fuels added tohelp the combustionandenergy forpreheating,otherenergylike electricity consumed by equipment operation will not be included in thecalculation.Thisisbecauseinmostcasestheelectricityconsumedissuppliedbytheplantsthemselvesbydetouringpartofpowergeneratedforself-usebeforeinjecttogrid.Andtobetteranalysistheenergytransformationofthissystem,wedividethematerialflowintothreeparts:

1) Waste flow: this flow mainly indicates the flow of solid particles within thesystem,fromMSWtobottomashviaincineration.

2) Fluegasflow:thisflowmainlyindicatestheflowofgasphasewithinthesystem,

14

from the air preheated, injected into the combustion chamber, heated byincineration,exchangedwithboilerandthenexhaustedaftertreatment.

3) Water flow: this flowmainly indicates the flow ofwater and steamwithin thesystem,injectedwaterfromoutsource(municipaltapwater),heatedbyboilertosteam,drivetheturbineandthenexhausted.

Certain percentage of energy will be lost due to radiation during the masstransportationandheatexchangingprocesses.Fromthethreemass flow, itcanbeclearlyclarifiedtheinputandoutputofenergyofthesimulatedsystem:

EnergyInput:1) MSWfeed;2) Extrafuelsassistingincineration(ifneeded);3) Energyusedforairpreheating;4) Energyusedforfeedwaterpreheating.

EnergyOutput:1) Electricitygenerated;2) Energyremainedinexhauststeam;3) Energyremainedinbottomash;4) Energyremainedinexhaustedfluegas;5) Other energy losses during the process due to the radiation or efficiency of

equipment.

To set a justifiedWTE system to calculate the energy flow baseline for this study,technologicalrestrictionsaswellasemissionandsafetyconcernsmustbetakenintoconsideration.Steamtemperatureshouldbe limitedtoavoidcorrosionrisks. Inthecase ofmixedwaste combustion, the average temperature rangeof combustion isbetween1,000°Cto1,200°C[2]andthefurnacetemperatureis1,050°C[11].ForChina,thetemperatureistypicallyalowerrangefrom850~950°Cduetothelowheatvalueofwaste.Besides, formostAPCsystem,thefluegasesshouldnotbecooledbelow200 °C to avoid the risk of condensation of aggressive compounds[12]. MultipleresearchesandWTE facilitieshasbeen studied toensure theparameter chosearelogicalandsensible.OperationparametersofsomeexistingstudymodelsandWTEplantsissummarizedinTable2.

Accordingtotheworkingdatafromstudies,thesimulatedsystemrunsasbelow:1) Combustion System: The MSW (12MJ/kg, 10 t/h) is burned with grate-fired

furnaceandnoextrafuelsisadded.Dryairisimposedasprimaryandsecondaryairfeedandisheatedto120°Ctoobtainacombustiontemperatureof1100°C.Assume the air is preheated respectively without using heat from combustionsystem.Theamountofairisestimatedtoensurearesidualoxygenconcentrationofthefluegasequalto7%,accordingtotheEuropeanregulations[13].Accordingto the “CEWEP Energy Efficiency Report (Status 2007-2010)”[14], the meanprimaryairfedof314WTEplantsis3m3/kgMSWwhilethesecondaryairfedis

15

1.5m3/kgMSWwithoutfluegasrecirculation.Setthefedrateas4m3/kgand2m3/kg respectively for this model. With plenty supply of oxygen, assume theconcentrationofCOisnegligibleandtheunburnedcarboninthebottomashis0.5%ofLHV.Thethermodynamicequilibriumofcombustionproductsisimposedaftersecondaryairinjection.

2) HeatRecoverySystem(BoilerandSuper-heater):Thewaterfeedstotheboilerispreheated to 120 °C, 4.5 MPa to ensure certain heat efficiency. The workingconditionsoftheRankinecyclewithinboilerwerefixedatasteamtemperatureof400°Candpressureof4.0MPa.Aftertheradiationheatexchangewithboiler,severalunitsofsuper-heaterandaneconomizerwereconsideredcorrespondingto the water-wall of combustion chamber, the convective section of theevaporator, feed-water preheater as well as adjuster of flue gas temperaturerequiredbythepracticeofWTEfacilities.Assumethatthefluegasattheendoftheradiantsectionisabout850°C,enteringtheeconomizerat430°C,exhaustedfor treatment at about 200 °C according to the temperature requirement bysemi-drycleaningsystem[15].Assumetheheattransferefficiencybetweenwaterandfluegasis95%.Thetreatedfluegas(150°C)isnotrecirculated.

3) Power Generation System: The multi-stage back-pressure steam turbine isconsideredforthemostbasicWTEmodel.Nobleedingsteamsforotherusewiththemodel.Accordingtothestudies,anisentropicefficiencyof70%isimposed[16],electrical and mechanical efficiency are together set to be 95%[17]. The steamexhausts from turbine with pressure of 1MPa. Considering the electricityproductionof83electricity-onlyWTEplant inEurope[14],adoptagenerate levelof0.45MWh/tMSW,fortheturbine.

2.1.3.EnergyFlowofSimulatedWTEModel

Usingthemodelbuilt in2.1.2,theenergyconsumptionandlossforeachprocessiscalculated.Theprinciplesandmainformulasare:

1)TheenergyinputfromMSW:E(MSW)=IncinerationCapacityofMSW*LHV

2)Theenergytransactioncalculationofairandwater/steamisbasedontheirheatvalueorenthalpyunderprocessstatus;similarly,theoperationstatusofflowcanbeestimatedfromtheirheatvalueorenthalpy: �E(Process)=MassFlowRate*Time*[enthalpy(status1)–enthalpy(status2)]

E(Transfer)=�E(Process)*Efficiency

3)Electricityproductionfromsteamturbine: ElectricityProduceCapacity=Productivity*IncinerationCapacityofMSW

=�E(SteamPassTurbine)*ElectricalandMechanicalEfficiency*IsentropicEfficiency

16

The step-by-step calculation is listed in Table 3 and the result can be brieflysummarized as Table 1. Figure 8 represents the overall energy flow of simulatedsystembasedononehour scale (10 tonsofMSWcombusted).Witha combustioncapacityof10t/h,theplantgenerates16,200MJelectricityperhourwhileproducing34.6tonsofsteam(1MPa,180Celsius)whichunderlying58%oftotalenergyinput.Despiteutilizationortreatmentofexhauststeam,only15%oftheenergyfromMSWis sufficiently used (electricity and flue gas cleaning). This portionmay increase inpart by recirculating part of the treated flue gas to down the consumption of airpre-heating. In terms of the unavoidable energy losses, the combustion and heattransformation efficiency matters the most, attributing to nearly half of the totallosses.Besides,theisentropicefficiencyofsteamturbineisakeyfactortoreducingthe energy losses. Despite these energy losses, such process consumes 24,410MJextraenergyforairandwaterpre-heating.Alternativeenergysourcescanbewood,building materials or fossil fuels (coal, diesel, etc.). The large water consumption,approximately 3.5 ton per ton of MSW, also stresses the importance of exhauststeamtreatmentwhichwillbediscussedinlaterchapters.

Table1EnergyFlowResultofBasicSimulationModel

EnergyInflow Amount(MJ) Percentage EnergyOutflow Amount(MJ) Percentage

MSW 120,000 83.10% GrossElectricity 16,200 11.21%

Airpre-heating 8,333 5.77% ExhaustSteam 83,681.40 57.90%

Waterpre-heating 16,076.9 11.13% FlueGasCleaning 5,187 3.59%

ExhaustFlueGas 10,776 7.46%

BottomAsh 150 0.10%

OtherLosses 28,537 19.74%

17

Figure8EnergyFlowofBasicSimulatedModel–WithoutExhaustSteamTreatmentandUtilization(Unit:MJ/h,BasedonMSWincinerationcapacityof10t/h)

18

Table2DesignparametersofsomeWTEplantsandsimulatedmodels

Type Description

WasteFlow FlueGasFlow Waterflow

ReferenceCapacity LHVofMSW

ExtraFuelAdded

LossDueto

UnburntCarbon

Primary/Secondar

yairTemp.

FlowRate

FlueGasTemp.at

Super-heaterInlet

FlueGasTemp.Outlet

FeedWater

SteamTemp.

SteamPressure

SteamFlowtoTurbine

Exhauststeam

IsentropicEfficiencyofTurbine

TypeofTurbine

GrossElectricPower

SimulatedModelStudy

Representativeofanumberofplantsin

NorthernItaly

65,000ton/year

10.11MJ/kg

BuildingMaterials 0.8%LHV 120°C 15.55Nm3/s

(dry,11%O2)

Max650°C(Controlledbyeconomizer)

160°C / 400°C 45bar 8.70kg/s 2.6bar / Condensing 588kWh/t[18]

390,000ton/year

10.11MJ/kg

BuildingMaterials 0.8%LHV 120°C 91.93Nm3/s Max650°C 140°C / 440°C 65bar 51.87kg/s 2.6bar / Condensing 807kWh/t

SimulatedModelStudy

Respectstotechnologicalrestrictionsrelatedtoelectricityproduction

100,000ton/year

9.61MJ/kg Biomass / / / / / / 400°C 4MPa 40t/h

1.1MPa(Bleed)

70%Condensing 600-700

kWh/t[19]

1.1MPa Non-Condensing

200-270kWh/t

SimulatedModelStudy

Fluidizedbedcombustor,parametersareestimatedfromanumberofplants

usingFBC

56.52t/h 10.5MJ/kg / / / / 820-920°C

(Typically) 200°C / 380°C 40bar 377°C,37bar / 90% Condensing 740kWh/t [12]

WTEPlantMVAZistersdorfWTE

plantinAustria,withgratefurnace

17.3t/h 12MJ/kg Null / / / / 195°C / 405°C 42bar / / / / 116,000MWh

(795kWh/t)

[20]

WTEPlantIVMWTEplantin

Belgium,withmoveablefurnace

14t/h 10MJ/kg

Oil(404,259liters/y)

/ / / / 180°C / 400°C 35bar / / / / 38,811MWh(425kWh/t)

WTEPlant L90AffaldsforbrændingWTEplantinDenmark

24t/h(180,000

t/y)

11.5MJ/kg

Oil(315,000liter/y)

/ / / / / 130°C 400°C 42bar 25.13kg/s / / / 136,393MWh(633kWh/t)

WTEPlant AarsFjernvarmeværkWTEplantinDanmark

5t/h(Line2) / Null / / / /

45-55°C(After

cleaning)

/ 430°C 47bar / / / / 17,277MWh(340kWh/t)

WTEPlant RenoNordline4inAalborg,Denmark

20t/h(160,000

t/y)

12MJ/kg / <0.23% 145°C/

125°C / 620°C 180°C / 425°C 50bar 80t/h(22.42kg/s) 220°C 17.9MW [21]

StudyonWTEPlant

StudyofefficientparametersofmiddletolargesizedWTEplants

/ / / / / / 850-950°C / / / / 6kg/kWh0.005-0.009MPa

70% Condensing / [22]

StudyonWTEPlant

Studyontheeffectofsteamparametertowardselectricitygeneration

750t/d 6.22MJ/kg / / / / / / /

400°C 4MPa 83.9t/h / 82% / 341kWh/t[23]

450°C 6.4MPa 76.5t/h / 82% / 363kWh/t

WTEPlant WTEplantdesignedinYuxi,China 200t/d / / 0.5-1.5% 220°C / 850°C 200°C 140°C,5.0

MPa 415°C 4.0MPa 15.3t/h / / / / [24]

SimulatedModelStudy

Theworkingconditionswereimposedbasedonprocessdataofmany

recentincinerationplantsinItalyandEurope.

185t/d 15.38MJ/kg / neglected 115°C 17.5Nm3/s,

10.6Nm3/s

700°C(1150°C,1atmfor

combustion)

170°C 120°C,7.0MPa 450°C 6.0MPa

6.0MPa,22.8kg/s,449°C

0.1MPa

79%(highpressure)81%(lowpressure)

Condensing 19.2MW [15]

*1bar=0.1MPa

19

Table3EnergyFlowAccountingofWTEPlants(ForChapter2.1)

Process Formula EfficientAmount(MJ/h) Losses(MJ/h) Efficiency(%) Remark

TotalchemicalenergyinMSW 12MJ/kg*10t/h=120,000MJ/h 120,000 - - LHV=12MJ/kgCapacity:10t/h

Heating up of primarycombustionair

1.25kJ/m3/°C * 4m3/kg MSW * 10t/h * (120°C - 20°C) /90%=5,555.6MJ/h 5,000 555.6 90%

Heatvalueofair:1.25kJ/m3/°CHeattransferefficiency:90%Airfed:4m3/kgMSW

Heating up of Secondarycombustionair

1.25kJ/m3/°C * 2m3/kg MSW * 10t/h * (120°C - 20°C) /90%=2,777.8MJ/h 2,500 277.8 90%

Heatvalueofair:1.25kJ/m3/°CHeattransferefficiency:90%Airfed:2m3/kgMSW

Energyinbottomash 0.5%*12MJ/kg*25%*10t/h=150MJ/h - 150 - Unburnedcarbon:0.5%LHVMassreductionofMSW:75%

Energy input in flue gas inchamber

1.4kJ/m3/°C*1.3*6m3/kg*10t/h* (1100°C -120°C)=107,016MJ/h 107,016 12,834 89.3%

Heatvalueoffluegas:1.4kJ/m3/°CVolumeoffluegas:1.3*V(airfed)1415Loss=chemicalenergyinMSW–energyinbottomash–energyinfluegas

Heatemitfromfluegasinradiantsection

1.4kJ/m3/°C*1.3*6m3/kg*10t/h* (1100°C -850°C)=27,300MJ/h 27,300 - - Fluegastemperatureoutofradiantsection:850°C

Heat emit from flue gas insuper-heaters

1.4 kJ/m3/°C * 1.3 * 6m3/kg * 10t/h * (850°C - 430°C) =45,864MJ/h 45,864 - - Fluegastemperatureoutofsuper-heaters:430°C

Heat emit from flue gas ineconomizer

1.4 kJ/m3/°C * 1.3 * 6m3/kg * 10t/h * (430°C - 200°C) =25,116MJ/h 25,116 - - Fluegastemperatureoutofsuper-heaters:430°C

Energyforfluegascleaning 1.4 kJ/m3/°C * 1.3 * 6m3/kg * 10t/h * (200°C - 150°C) =5,460MJ/h 5,187 273 95% Usedforsemi-dryprocesswaterevaporation

Efficiency:95%

Energyinexhaustfluegas 107,016+5,000+2,500–27,300–45,864–25,116–5,460=10,776MJ/h - 10,776 Calculatebyseparatetheparttransferredfromenergyinput

Feedwaterpreheating (506.813kJ/kg – 88.144kJ/kg) * 9.6kg/s * 3600s / 1000 /90%=16,076.88MJ/h 14,469.2 1,607.7 90% Enthalpyofwater:506.813kJ/kg(120°C,4.5MPa),88.144kJ/kg(20°C,4.5MPa)

Heattransferefficiency:90%

Heating up of water ineconomizer 25,116MJ/h*95%=23,860.2MJ/h 23,860.2 1,255.8 95%

Energyinwater:506.813kJ/kg*9.6kg/s*3600s/1000+23,860.2MJ/h=41,375.7MJ/hEnthalpyofwater/steam:41,375.7MJ/h/(9.6kg/s*3600s/1000)=1197.212kJ/kgStatusofwater/steam:257.4°C,4.5MPa,evaporationfractionof4.48%

Heating up of water in radiantsection 27,300MJ/h*95%=25,935MJ/h 25,935 1,365 95%

Energyinwater/steam:41,375.7MJ/h+25935MJ/h=67,310.7MJ/hEnthalpyofwater/steam:67,310.7MJ/h/(9.6kg/s*3600s/1000)=1947.646kJ/kgStatusofwater/steam:257.4°C,4.5MPa,evaporationfractionof49.26%

Heating up of water insuper-heaters

(3210.87kJ/kg–1947.65kJ/kg)*9.6kg/s*3600s/1000 -67,310.7MJ/h=43,657MJ/h 43,657 2,207 95.2% Enthalpyofwater:1947.646kJ/kg(257.4°C,4.5MPa),3210.87kJ/kg(400°C,4.2MPa)

Loss=45,864MJ/h–43,657MJ/h

Electricitygenerated 0.45MWh/t*10t/h*3600=16,200MJ/h 16,200 852.6 95% Productivity:0.45MWhelpertonofMSWElectricalandmechanicalefficiency:95%

Energy from steam to drive theturbine (16200MJ/h+852.6MJ/h)/70%=24,360.9MJ/h 17,052.6 7,308.3 70% Isentropicefficiencyofturbine:70%

Energyinexhauststeam 3214.37kJ/kg * 9.6kg/s * 3600s / 1000 – 24,360.9MJ/h =86,727.7MJ/h 86,727.7

Enthalpyofwater:3214.37kJ/kg(400°C,4.0MPa)Enthalpyofexhauststeam:86,727.7MJ/h/(9.6kg/s*3600s/1000)=2509.483kJ/kgExhauststeamstatus:179.9°C,1MPa,evaporationfractionof76.53%

Energyinexhauststeamfromthesystem

86,727.7 – (88.144kJ/kg * 9.6kg/s * 3600s / 1000) =83,681.4MJ/h 83,681.4 Calculatedbyseparatethepartofenergyinfeedwater(20°C,4.5MPa)

20

2.2.ExhaustSteamCondensation

2.2.1.Condensingsteamturbine

For the conventional WTE utilities, the primary type of turbine adopted is thecondensing turbine. The exhaust steam from power generation turbine is directlyrejectedintosurfacecondenserswhichmaintainsanalmostvacuumconditionatthedischarge of the turbine. Operated with an exhaust pressure much lower thanatmosphericone, themaximizedpressuredropenlarges theenergyextracted fromsteaminput.Accordingtothestudy,theeffectivenessofcondensingsystemcanbequantified through theprinciple: the lower thepressure thegreater theeffects[25].From the previous calculation, we notice that there still 60%-80% of the energyremainingintheexhauststeam.Therefore,thecoolingsystemusuallyextractsheatat2to4timestherateofelectricpowergeneratedandanysmallimprovementcanthen lead to large fuel saving and efficiency enhancement for the plants[26 ].Simultaneously,theexhauststeamisconvertedintopurewaterbycondensationandcanbefurtherreusedinboilerasfeedwatertoachieveacloseloopofwateraswellascuttingdownthefreshwaterconsumption.Thesurfacecondenserhasshellsandanarrayoftubesandcanbeclassifiedaswater-cooledcondenserandair-cooledcondenseraccordingtothecoolingmedium.

Forthewater-cooledcondenser,itcanbecooledbyriver,lakeorcoolingtowerwater.Commonly, the coolingwater flows through the tubeswhile the steam enters theshellsideandthecondensationoccursontheoutsideoftubes(Figure9).Thenthecondensate drips down and are collected at the bottom pan of condenser calledhotwell.Asa smallamountofair isknownto leak into theshell sideundernearlyvacuumpressure, a relatively small air ejector isused to remove thosegases fromthe condenser. Typically the coolantwater temperature has a 10 degree rise frominlet tooutletunder full load[27].Water fromnaturalwaterbody (sea, lakes, rivers,etc.) is adopted for chilling inmany power plants. However, the scarcity of watersupplyandanexcessivelyhigherenvironmental impactatoverheatingofthewatertablesusedasheatsinks[28]withdrawtheadoptionofwater-cooledcondensers.

21

Figure9Water-cooledsurfacecondenser

Fortheair-cooledcondenser,itusuallyconsistsofanarrayoffannedtubemodulesarranged in parallel rows[29]. This kind of condenser feeds the steam through thetubeswhilethecoolantairflowingaroundthetubesoutside,forcedbyaxialflowfanunits located above or below (Figure 10). As a result, heat from the condensingsteam is rejected to theenvironment via the finned tubes. Theproblem is that anair-cooledcondenser,however,issignificantlymoreexpensiveduetothehighenergyconsumption to drive the fans. Also it cannot achieve as low the steam turbineexhausttemperatureandpressureaswater-cooledcondenserduetothe limitationof inlet air temperature,which is greatly infectedby the climate conditionof localenvironment[ 30 ][ 31 ]. The condensation temperature within the condenser isconsidered to be 6°C-20°C above air inlet temperature for general purposes andvaries according to the ambient temperature[32]. The air temperature reaches a20°C-30°Criseasitpassesthroughthecoils[33].

Figure10Air-cooledsurfacecondenser

22

2.2.2.ThermodynamicSimulatedModelofCondensingWTEPlant

The assumption of combustion and boiler system operating condition keeps thesameasthesimulationmodelofchapter2.1.2.Boththewater-cooledandair-cooledcondensers will be studied. The differences and changes for a condensing powergenerationprocessarelistedasfollows:

(1) Theheatremovedfromtheexhauststeam(containsinoutletcoolingwaterorair)willnotbefurtherused,buttreatedasenergylosses.Assume95%oftheenergyremovedfromexhauststeamistransformedintocoolant.

(2) The cooled steam from the condenser would be recycled to the boiler, extraenergymayneededforwaterpre-heatingaccordingtothecalculationresult.

(3) Accordingtotheformerstudies,assumethecondensingpressure(exhauststeampressure)ofwater-cooledcondenseris0.1MPawhile0.25MPafortheair-cooledcondenser. The input coolant water (air) has a temperature of 20°C. A 10°Ctemperature rise is considered for the coolingwater, a20°C for the coolingair.The output temperature of cooled exhaust steam (liquid) is 60°C.No steamorwaterleakageisconsideredforthismodel.

(4) Considering theelectricityproduction capacity rangeof83electricity-onlyWTEplant in Europe (0.075-0.873MWh/tMSW)[14], adopt a generate level of 0.65MWh/tMSWforthewater-cooledturbine,0.60MWh/tfortheair-cooledturbine.Themulti-stagecondensingsteamturbineisconsideredandnobleedingsteamsforotherusewiththemodel.Accordingtothestudies,anisentropicefficiencyof80% is imposed[16], electrical andmechanical efficiency are together set to be95%[17].

2.2.3.DiscussionofCondensationSimulationModelofWTEProcess

According to the modified model we built in 2.2.2, the calculation for bothwater-cooled and air-cooled condensationWTE system is listed in Table 5. For thecondensingsteamturbinesystem,thegrosselectricitygeneratingcapacityisaround22,000MJ to 23,000MJ, contributes to 15-17% of total energy input, 20% of theenergycontaininginMSWcombusted.Thisportioncanbefurtherincreasedto30%withlowerextractsteampressureof5-8kPawhichishundredtimeslowerthanourmodel. Compared to thebasic non-condensing cycle in Chapter 2.1, 7000MJmoreelectricityisproduced,increasingtheenergyefficiencybyatleast5%.

No extra feed water is needed by cooling down and recycling the exhaust steam(water), thus cutting down 50% of the energy consumed by water pre-heatingcomparedtothebasicmodel.However,thewaterdemandforchillersisconsiderable.With10ton/hMSWcombustedcapacity,theestimatedwaterflowratefor10degreerise in condenser is as much as 1,629 ton per hour. Affected by the size, coolingcapacityandambienttemperatureofwater-cooledcondenser,somechillerunits inmarketevenshowslargerwaterconsumptionupto9,000tonperhour[34]underthe

23

working capacity of simulatedWTEplantmodel. For large scale powerplants, thispart of water is always taken from and emitted to nearby water bodies, causingseries heat pollution effects towards the ecosystem. The injection of heat fromcoolingwatertonaturalwaterbodysignificantlyincreasesitstemperature,leadingtothereductionofdissolvedoxygenanddeathofaquaticanimals.Also,ahigherwatertemperature promotes the reproduction of disease-causing bacteria and virus andincreasesthetoxicityofsomechemicals(cyanideandheavymetalions)[35].

Fortheair-cooledchillers,anestimationof2,800,000m3/hairisneededtocarryouttheheatfromexhauststeam.Whencalculatewitha162.25kW(~585MJ/h)eight-fanair-coolingmodelfromcondenserproducerFRITERMA.S.[32],120unitswithtotalairflow rate of 4,757,000m3/h is consumed for this combustion scale, togetherwith1109MJ/helectricpowertodrivethefans.

From the discussion above, the traditional electricity-only WTE plants withcondensing steam turbine more sufficiently generate power from MSW than thebasicmodelandwellused20-30%ofenergy fromtotal input.However,abouttwothirdsofenergyfromMSWlossesduringcondensationprocesses.Therelativehighenvironmental impacts and energy consumption also attract consideration againstthisinefficientoperationmode.

Table4EnergyFlowResultofCondensingSimulationModel

Energy

Inflow

Amount

(MJ)Percentage

Energy

Outflow

(W)

Amount

(MJ)Percentage

Energy

Outflow

(A)

Amount

(MJ)Percentage

MSW 120,000 87.57%Gross

Electricity23,400 16.93%

Gross

Electricity21,600 15.62%

Air

pre-heating8,333 6.08%

Refrigerant

Loss68,036 49.21%

Refrigerant

Loss70,288 50.84%

Water

pre-heating8,706 6.35%

Flue Gas

Cleaning5,187 3.75%

Flue Gas

Cleaning5,187 3.75%

Exhaust

FlueGas10,776 7.79%

Exhaust

FlueGas10,776 7.79%

Bottom

Ash150 0.11%

Bottom

Ash150 0.11%

Other

Losses30,706 22.21%

Other

Losses30,256 21.88%

24

Table5EnergyFlowAccountingofWTEPlants(ForChapter2.2)

Process FormulaEfficientAmount

(MJ/h)Losses(MJ/h) Efficiency(%) Remark

Feed water

preheating

(506.813kJ/kg– 254.915kJ/kg)

* 9.6kg/s * 3600s / 1000 /

90%=9,672.9MJ/h

8,705.6 967.3 90%

Enthalpy of water: 506.813kJ/kg (120°C, 4.5MPa),

254.915kJ/kg(60°C,4.5MPa)

Heattransferefficiency:90%

Electricity generated

fromturbine(W)

0.65MWh/t * 10t/h * 3600 =

23,400MJ/h23,400 1,231.6 95%

Productivity:0.65MWhelpertonofMSW

Electricalandmechanicalefficiency:95%

Electricity generated

fromturbine(A)

0.60MWh/t * 10t/h * 3600 =

21,600MJ/h21,600 1,136.8 95%

Productivity:0.60MWhelpertonofMSW

Electricalandmechanicalefficiency:95%

Energyfromsteamto

drivetheturbine(W)

23,400MJ/h /95%/80% =

30,789.5MJ/h24,631.6 6,157.9 80% Isentropicefficiencyofturbine:80%

Energyfromsteamto

drivetheturbine(A)

21,600MJ/h /95%/80% =

28,421.0MJ/h22,736.8 5,684.2 80% Isentropicefficiencyofturbine:80%

Energy in steam from

turbine(W)

3214.37kJ/kg * 9.6kg/s *

3600s /1000–30,789.5MJ/h

=80,299.1MJ/h

80,299.1

Enthalpyofwater:3214.37kJ/kg(400°C,4.0MPa)

Enthalpyofexhauststeam:2321.444kJ/kg

Exhauststeamstatus:99.61°C,0.1MPa

Energy in steam from

turbine(A)

3214.37kJ/kg * 9.6kg/s *

3600s /1000–28,421.0MJ/h

=82,667.6MJ/h

82,667.6

Enthalpyofwater:3214.37kJ/kg(400°C,4.0MPa)

Enthalpyofexhauststeam:2392.002kJ/kg

Exhauststeamstatus:127.41°C,0.25MPa

Energy in exhaust

steam from

condenser(W)

251.222kJ/kg * 9.6kg/s *

3600s/1000=8682.2MJ/h8,682.2

Enthalpyofwater:251.22kJ/kg(60°C,0.1MPa)

Calculatedbyseparatethepartofenergyinfeedwater

(20°C,4.5MPa)

Energy in water from

condenser(A)

251.348kJ/kg * 9.6kg/s *

3600s/1000=8686.6MJ/h8,686.6 Enthalpyofwater:251.35kJ/kg(60°C,0.25MPa)

Energytocoolant(W)(80,299.1 MJ – 8682.2 MJ) *

95%=68,036.1MJ68,036.1 3580.8 95%

Water condition: Inlet 20°C, 2 MPa; Outlet 10°C

increase. Water flow rate: 68,036.1MJ/h / (127.564

kJ/kg-85.7984kJ/kg)=1629.0ton/h

Energytocoolant(A)(82,667.6 MJ – 8686.6 MJ) *

95%=70,287.7MJ70,287.7 3699.4 95%

Air condition: 1.5MPa, T(inlet) = 20°C, 20°C increase.

Heat value of air: 1.25 kJ/m3/°C. Air flow rate:

70287.7MJ/h/1.25kJ/m3/°C/20°C=2,811,508m3/h

*W:water-cooledcondensationmodule;A:aircooledcondensationmodule.

25

2.3.ExhaustSteamforDistrictHeating

2.3.1.DistrictHeatingandCogenerationWTEPlants

DistrictHeating(DH)isdefinedasthedistributionofthermalenergyfromacentral

heatsourcetoitssurroundingresidentialbysteamorhotwaterthroughaninsulated

pipenetwork.Thesteamorhotwateristhendirectedintobuildingsandcirculated

through heating equipment. In the case of hot water systems or newer steam

systems, heat exchangers are frequently used. This successfully isolates the users

from the thermal system, thus preserving the integrity of both DH system and

customers. DH best suits to those areas with high population density and cold

climatewhichhelpensuring stableand competitivepricing[36]

. Typically the central

heatsupplyforDHcanbefromcoal-firedplants,oil-firedplantsorWTEplants(heat

only).Anotherapproach,called“cogeneration”orCombinedHeatandPower(CHP),

is applying the by-product steam of some other utilities to achieve high energy

utilizationefficiency.ForaCHPplant,theenergyefficiencycanreachashighas80%

to90%.

Currently,221of314EuropeanWTEplantssellheatasenergyproduct;184ofthese

are CHPproduction plants. These plants generate from700-899 kWhof electricity

andfrom400toupto2,000kWhofheatpertonofMSWincinerated[14]

.TheDanish

WTEfacilitiesobtainanaverageenergybalanceofupto0.6MWhelectricityplusup

to2MWhheatpertonofMSW,thustriplingtheamountoftotalenergyobtained.In

United States, twenty eight of the 88 WTE plants sell steam as product and 21

cogenerate a total of about 470MW of heat (corresponding to 1.6 million lbs of

steam per hour) and 272 MW of electricity[37]

. Despite the increasing of energy

efficiency,therearestillsignificantadvantagestobegainedfromacogenerationWTE

plant fordistrictheating: LowerGHGemission levelsofWTE facilities compared to

othertechnologiesandoverallfuelconservation.

Asmentionedabove,districtheatingcandividedintotwodifferentmodesaccording

to themedium: steam system and hot water system. To feed a steam carried DH

system, the steam bleeds has to be extracted with higher-pressure to fulfill the

requiredpressuredropinthepipingnetwork.Extractionturbineisusedinthiscase

whichhasopenings for extractionof a portionof the steamat some intermediate

pressure, the rest of the steam is condensed, as illustrated in Figure 11. Part of

electricitygeneratingcapacity is lostduringcogenerationprocessandwelldepends

onthepressure,flowrateandnumberofextractionsofextractedsteam.Theratioof

electricity lost toheatgenerationordinarily range0.1 to0.2kWhofelectricityper

kWh of thermal energy obtained[38]

. A steam pipeline system normally services

consumerswithin2-3milesfromthecentralheatsourcewhichisshortandlimited.

Consideringexistingproblems for steamDH system likepipeline corrosion, storage

26

capacity,transmissiondistanceandheatloss,itisnowreplacedbymoreefficientand

economicalhotwatersystem.

Figure11ExtractionSteamTurbine

Tosupplyahotwaterthermalsystem,theWTEplantsnormallyproducehotwaterby

placing a heat exchanger at the back pressure turbine exhaust, transforming the

energy in low pressure steam from turbine bleeds to DH system’s water supply.

Extraction steam turbine is adopted by some CHP facilities to heat the water in

multiplestages[39]

.Inthiscase,thewaterflowofWTEfacilityiskeptseparatingfrom

the water network for thermal market. Simultaneously, the dropped energy level

conveyedbyexhauststeamremarkablyreducestheloadsandcostforcondensation,

especially for those whose coolant is not returned. The maximum supply

temperaturesofhotwatersystemsaredesignedbetween110-130°Candreturnat

50-70 °C. The recommended temperatures forhotwaterDH supply is between93

and 121 °C, the ratio of thermal energy extraction to electricity generation in

medium scale is 2.0 to 2.5MW thermal perMW electricity[40]

. Hot water system

allowsthetransmissionofheatover longerdistancesupto20mileswithrelatively

lowheatlossbetween5%-10%.Thepressurewithinpipelinesdependsonthesystem

size and ambient operating temperature, mostly varying from 9-17 bar in winter

seasons.SteelisthemostfrequentlyutilizedpipematerialinDHsystemsinorderto

preventgroundwaterdamageonexternalpipesurfaces.

2.3.2.ThermodynamicSimulationofCHPWTEPlant

The assumption of combustion and boiler system operating condition keeps the

same as the simulationmodel of chapter 2.1.2. According to the application ratio,

choose hotwater DH system for the simulatedmodel. The supply temperature of

110 °C and return temperature of 60 °C is considered for the model, with a

transmissionheat lossof5%.Thepressureofhotwater system is set as10bar (1

MPa).Threedifferentheatexchangemodeswillbestudied:

27

(1) The firstmodel usingmultiple stage back pressure steam turbinewithout any

bleeds in themiddle.All theexhaust steam from turbine is directed to aheat

exchanger for DHwaterwarming,with an assumed heat transfer efficiency of

95%.Assume theoutflow steam (water) status fromheatexchanger is 120 °C,

0.8MPa.TheoutflowisrecirculatedinWTEplantviapumpasfeedwaterandin

this case there is no need for extra feedwater pre-heating.Other parameters

assumptionsofturbinekeepthesameasbasemodelin2.1.2.

(2) Thesecondmodelusingextraction/condensing steamturbine. In thismodel, a

water-cooledcondenser (95%efficiency) isconsideredafter thesteamturbine.

Assume50%ofsteamisextractedat1MPaatextractionturbinestage.Adopta

generate level of 0.43MWh/tMSW (70% isentropic efficiency) for the turbine

beforeextraction.Assumetheexhauststeamfromcondensingsteamturbineis

undersamestatusasChapter2.2(99.61°C,0.1MPa,Enthalpyof2321.444kJ/kg,

80% isentropic efficiency). The exhaust steam (60°C, 0.1 MPa) chilled is

recirculatedasfeedwater.A10°Ctemperatureriseisconsideredforthecooling

water.

(3) The thirdmodelusingextraction/backpressure steamturbine.Assume50%of

steam is extracted, 60°C and 1.3 MPa, at extraction turbine stage. Both the

bleedsandexhauststeam(179.9°C,1MPa)areusedfortwo-stagewaterheating

toDHsystem:thefirststageisdonebyexhauststeamwhiletheextractedsteam

is used for the 2nd stage, bring the DH temperature to 110°C. The condensed

steamfromsecondstageheatexchangercascadesintothefirstexchanger,then

returnedtotheplantsystemasfeedwater.Adopta70%isentropicefficiencyfor

bothstageofturbine.Toestimatethemassflowcanbeheatedbywastesteam,

suppose the mixed steam (water) from exchanger has the same amount of

energy as water at 1MPa, 120°C. In this occasion, no extra feed water

pre-heatingisconsideredformodelthree.

2.3.3.DiscussionofCondensationSimulationModelofWTEProcess

Accordingtothemodifiedmodelwebuiltin2.3.2,thecalculationforthreeexhaust

steamtreatmentmodelislistedinTable8.Whenapplyingalltheexhauststeamfrom

back pressure turbine for DH (Model I), the WTE still generates 16,200 MJ gross

electricityperhourtogetherwithapproximately62,500MJthermalenergy.Although

7,000 MJ of electric power is sacrificed, the overall efficiency of the WTE plants

increasesfrom21%toover65%,thusover70%oftheenergyfromcombustedMSW

is sufficiently used. In some advanced cogeneration WTE plants of Norway and

Germany,theefficiencycanbeevenashighas80%-90%.

28

Table6EnergyFlowResultofThreeDHSimulationModel

AllforDH(I) DH+Condensing(II) TwoStageExtraction(III)

Amount

(MJ)Percentage

Amount

(MJ)Percentage

Amount

(MJ)Percentage

GrossElectricity 16,200 12.60% 18,669 13.99% 12,907 10.00%

DH 62,545 48.66% 31,273 23.44% 67,010 51.94%

WaterPre-heating 0 - 4,353 - 0 -

RefrigerantLoss - - 33,985 25.48% - -

FlueGasCleaning 5,187 4.03% 5,187 3.89% 5,187 4.02%

ExhaustFlueGas 10,776 8.38% 10,776 8.08% 10,776 8.35%

BottomAsh 150 0.12% 150 0.11% 150 0.12%

OtherLosses 33,686 26.21% 33,360 25.01% 32,993 25.57%

Useful 83,932 65.29% 55,129 41.32% 85,104 65.96%

Compared to traditional fossil fuels fired cogeneration power plants, considerable

economic and environmental benefits can be achieved. According to European

environmental policy, European power plants have to annually demonstrate a CO2

emission allowance corresponding to their actual CO2 emissions. The price for the

second commitment period (2008 to 2012) is 22 € (23.61USD) per ton of CO2

[41].

Assumingthat50%oftheenergyfromfossilresources isusedtosupply62,500MJ

DHdemandinCHPplants,thefuelconsumption,economicandenvironmentalcost

ofsomerepresentativesourcesarelistedinTable7.Dependingonthefueltype,2-15

million dollars can be saved each year, 30 thousand tons of coal (or 5.6 million

gallons of oil) consumption and more than 40 thousand tons of carbon dioxide

emissioncanbepreventedbyadoptingexhauststeamfromaWTEplantforDH.

Table7ConsumptionandCostofFossilFuelsDH

Fuels

Calorific

Value

(kJ/kg)[42]

Amount

(ton/h)

UnitPrice

(USD/t)

FuelCost

(USD/h)

CO2 EF

(g/kWh)[43]

CO2

Emission

(ton/y)

CO2

Emission

Allowance

(USD/y)

HardCoal 27,431 4.56 50.08 228.21 270 41,062.24 969,479

Oil147,708

(kJ/gal)

846

(gal)

2.08

(USD/gal)1,759.68 360 54,749.65 1,292,639

Waste 12,000 10 0 0 20 3,041.65 71,813

FortheCondensing-DHmodel,itgenerate18,700MJgrosselectricitywith31,300MJ

heat.ComparedtothewholecondensingWTEplants,itsacrifices20%ofelectricity

capacitytoearna20%additionofoverallefficiency.Forthecondensingturbinepart,

theproductivitydecreasedfrom0.65MWhelto0.14MWhelduetothedecreasing

steampressureandamount.Halfoftherefrigerantdemand,800tonsofwaterper

hour, is saved as well as the energy loss during condensation. Changing the

proportionofsteamextractedaftertheturbineforDHandkeepingtheothersteam

29

parametersthesame,theenergyoutputandefficiencyofplants isshowninFigure

12.ItisclearthatenergyconveyedbysteamforDHismuchmoreefficientlyutilized

than that fordrivinga condensing turbine.The totalenergyefficiencyofCHPWTE

plantclimbsstably,from16%to65%,astheextractedproportionofsteamincreases.

Simultaneously, the water consumption and energy loss for exhaust steam

condensationkeepscuttingdown.Toreachthehighestworkingefficiency,theplant

isunderthesameoperationstatusasmodelIwebuilt.

Forthethirdmodel,theDHsystemisheatedbyexhauststeamintwostages.Among

these threemodels,model III generatepowerwithhighestheat-electricity ratioof

5.2. The efficiency under this operation condition is approximately 65%, nearly

equalstomodelI.Similarly,theefficiencyandpowerratiomayvaryunderdifferent

steamextractproportionandpressure.

Figure12EnergyOutputforCogenerationWTEPlantswithDifferentSteamExtractionRatio

From the discussion above, applying the exhaust steam as a source of DH is an

energy efficient, environmental friendly and economical solution for both WTE

facilities and heat consumers. More than 70% of power from MSW can be well

utilized. Furthermore, the energy consumption and losses of pre-heating and

condensationisavoided,andcuttingdowntheoperatingexpensesoftheWTEplants

atthesametime.

30

Table8EnergyFlowAccountingofWTEPlants(ForChapter2.3)

Process FormulaEfficient

(MJ/h)

Losses

(MJ/h)

Efficiency

(%)Remark

Energy from

steam to DH

water(I)

(2509.483kJ/kg–504.207kJ/kg)*9.6kg/s*3600s/1000*95%=65,837.2MJ/h 65,837.2 3,465.1 95%

Enthalpy of steam (hot water):

2509.483 kJ/kg (179.9°C, 1 MPa),

504.207 kJ/kg (120°C, 0.8 MPa),

461.987 kJ/kg (110°C, 1 MPa),

251.977 kJ/kg (60°C, 1 MPa); Water

massflow:87.1kg/s

EnergyforDH(I) 65837.2MJ/h*95%=62545.3MJ/h 62,545.3 3,291.9 95% Transmissionloss:5%

Electricity

generated from

extractionturbine

(II)

0.45MWh/t*10t/h*3600=16,200MJ/h 16,200 852.6 95%

Productivity: 0.45MWhel per ton of

MSW

Electrical and mechanical efficiency:

95%

Energy from

steam to drive

the extraction

turbine(II)

(16200MJ/h+852.6MJ/h)/70%=24,360.9MJ/h 17,052.6 7,308.3 70% Isentropicefficiencyofturbine:70%

Energy from

steam to drive

the condensing

turbine(II)

(2509.483kJ/kg–2321.444kJ/kg)*4.8kg/s*3600s/1000=3,249.3MJ/h 2,599.5 649.8 80% Isentropicefficiencyofturbine:80%

Electricity

generated from

condensing

turbine(II)

2599.5MJ/h*95%=2,469.5MJ/h 2,469.5 130.0 95%

Productivity: 0.14MWhel per ton of

MSW (5 ton MSW base considering

steamextraction)

Energy from

steam to DH

water(II)

(2509.483kJ/kg–504.207kJ/kg)*4.8kg/s*3600s/1000*95%=32,918.6MJ/h 32,918.6 1,732.6 95% Watermassflow:43.6kg/s

EnergyforDH(II) 32918.6MJ/h*95%=31272.7MJ/h 31,272.7 1,645.9 95% Transmissionloss:5%

Energy in exhaust

steam from

condenser(II)

251.222kJ/kg*4.8kg/s*3600s/1000=4341.1MJ/h 4,341.1 Enthalpyofwater:251.22kJ/kg(60°C,

0.1MPa)

Energy to coolant

(II)(40114.6MJ–4341.1MJ)*95%=33,984.8MJ 33,984.8 1,788.7 95%

Water condition: Inlet 20°C, 2 MPa;

Outlet10°Cincrease.Waterflowrate:

33,984.8MJ/h / (127.564 kJ/kg -

85.7984kJ/kg)=813.7ton/h

Energy for feed (506.813kJ/kg–254.915kJ/kg)*4.8kg/s*3600s/1000/90%=4836.4MJ/h 4,352.8 483.6 90% Enthalpy of water: 506.813kJ/kg

31

water preheating

(II)

(120°C, 4.5MPa), 254.915kJ/kg (60°C,

4.5MPa); Heat transfer efficiency:

90%

Energy from

steam to drive

the extraction

turbine(III)

(3214.37kJ/kg–2796.04kJ/kg)*9.6kg/s*3600s/1000=14,457.5MJ/h 10,120.2 4,337.3 70%

Enthalpy of steam: 3214.37 kJ/kg

(400°C,4MPa),2796.04kJ/kg (195°C,

1.3 MPa); Isentropic efficiency of

turbine:70%

Electricity

generated from

extractionturbine

(III)

10120.2MJ/h*95%=9614.2MJ/h 9,614.2 506.0 95%

Productivity: 0.27MWhel per ton of

MSW

Electrical and mechanical efficiency:

95%

Energy from

steam to drive

the 2nd stage

turbine(III)

(2796.04kJ/kg–2509.483kJ/kg)*4.8kg/s*3600s/1000=4,951.7MJ/h 3,466.2 1,485.5 70% Isentropicefficiencyofturbine:80%

Electricity

generated from

2nd stage turbine

(III)

3466.2MJ/h*95%=2,469.5MJ/h 3,292.9 173.3 95%

Productivity: 0.18MWhel per ton of

MSW (5 tonMSWbased considering

steamextraction)

Energy from

steam to DH

water(III)

[(2509.483kJ/kg+2796.04kJ/kg)*4.8kg/s-504.348kJ/kg*9.6kg/s]*3600s/1000*95%

=70,536.7MJ/h70,536.7 3,712.5 95% Watermassflow:93.3kg/s

EnergyforDH(III) 70536.7MJ/h*95%=67,009.9MJ/h 67,009.9 3,526.8 95% Transmissionloss:5%

*I,II,IIIstandsformodelone,twoandthree.

32

3.MainDesalinationTechnologies

Thoughourearthisa“bluemarble”,awaterworld,butabout97.5percentofthatisundrinkablehighsalinitywaterandunfortunatelytwo-thirdsoffreshwateristuckedawayinfrozenglaciersorotherwiseunavailableforouruse.Asaresult,morethanonesixthpeople(1.1billion)aroundworldarewaterstressed,ordonothaveaccessto potable water. Under the current fresh water consumption rate, two-thirds ofpopulationmay face water shortages by 2025. The good news is that technologyadvances and cost reduction in seawater desalinationhavemade it a realistic andpromising solution to fresh water supply. By 2012, desalination have alreadycontributefortwo-thirdsofworldfeedwater,morethan60millioncubicmetersperday,mainlyforMiddleEastandGulfStates.Theproductioncostofdesalinationhavedowned to approximately 0.45-1USD/m3 in 2013 compared to9USD/m3 in 1970.Butforsomedevelopingareas,theexpensesisstillaround3-5USD/m3.

Salinewaterdesalinationcanberealizedessentiallybyeither thermalprocessesormembrane processes. Effective integration or cogeneration of desalination andpowerfacilitiescanreducethecostofdesalinationandelectricpowerproduction.Inmany countries, power demand may fluctuate from 100% in summer to 30% inwinterduetoairconditioningsystemswhereaswaterdemandremainsstablealltheyear round. Thermal andmembrane processes are coupled in some cogenerationplantstosolvethelargevariationbetweensummerandwinter.Currentdesalinationmarket is major occupied bymembrane technologies because of its lower energyconsumption and decreasing cost. The most widely used is reverse osmosis (RO),accounting for 60% of the total industry. Other membrane techniques likeelectrodeionisation (EDI) and electrodialysis (ED) only occupy approximately 4%oftotal desalination capacity. With new technology keeps developing, the energyconsumptionofdesalinationhavesignificantlyreducedtoaslowas3kWhpercubicmeter.However,comparedtolocalfreshwatersupplytechniqueswhichconsumes0.1-1 kWh/m3, desalination is still energy-intensive and need further sustainablesolutions.

Figure13Totalworldwideinstalledcapacitybytechnology[4]

33

3.1.RODesalinationTechniques

1) TechnicalPrinciples

The coreprincipleofROdesalination is a natural phenomenon,osmosis, bywhichwaterautomaticallypassesthroughasemi-permeablemembranefromlowersalinitysolutionintoamoreconcentratedsolution.Noheatingorphasechangetakesplacein this process.Whenpressure is applied to thehigher salinity solution, thewaterwillbeforcedtoflowinareversedirectionthroughthesemi-permeablemembranewhileleavingthesaltbehind.

Figure14MechanismofOsmosisandReverseOsmosis

2) TechnicalDescription

For an RO desalination plants, it essentially consists of four parts: a pretreatmentsystem, a high pressure pump, a core membrane system and the post treatmentsystem. In some of the plants, there is an energy recovery system between thepumpsandmembranetocutdowntheenergydemandofdesalinationplants.

ThefeedsalinewaterisfirstpretreatedtopromisethecleannessofROmembranessurface. Therefore, suspended solids contained in feedwatermust be removed toprevent salt precipitation or microbial growth. Pre-treatment may involveconventional water treatment methods such as screen separation, chemicalsedimentation and filtration, or advancedmembrane processes likemicrofiltration(MF)orultrafiltration (UF)[44].Also,pHadjustment is sometimes requiredbasedonwatercharacteristics.

Highpressurepumpsectionsuppliesthepressureneededtoencourageclarifiedfeedwater flowing throughmembrane, typically between 55-85 bar depending on thetemperature and salinity of water[45]. The normally operation pressure is 2-17 bar(30-250psi)forslightlybrackishwater,17-28bar(250-400psi)forbrackishwaterand55-82 bar (800-1200 psi) for seawater[46][47]. The high pressure pumps involve themajor energy requirement of the whole RO processes, around 5-7 kWh per cubicmeter treated. The recent development ofmore efficient energy recovery devices,pressureexchangerandenergyrecoverypump,realizetherecoveryofenergyfromconcentrate brine flow via piston system, thus greatly reducing the overall energyconsumptiontoapproximately1-3kWh/m3.

34

Figure15RODesalinationPlants

The membrane assembly consists of a pressure vessel and a semi-permeablemembrane elements inside, varying from one to eight per vessel. Themembraneinhibitsthepassageofdissolvedsaltswhilepermittingwatertopassby,thusdividingthe feedwater flow into a freshproduct streamand a concentratedbrine stream.However,nomembraneworksperfect so that theremaybea small percentageofsalt remaining in the product water. The most widely accepted RO membraneconfigurationtypeisSpiralwoundwhichgenerallycomposedofcelluloseacetateorof other composite polymers. Spiral wound module is actually a flat sheet ofmembrane wrapped around a central collecting tube. The pressurized feed waterflowsinspaceswithinthemembraneenvelope,purifiedandcollectedinthetube.Aswaterpurified, the remaining salinewaterbecomemoreconcentrated, resulting inover-saturation of salts and ever-boosting energy input to overcome the naturalincreasedosmoticpressure. In this case, certainportionof feedwater iswithdrawfromthemembraneelements.Thedischargedamounttypicallyrangesfromaround20%forbrackishwaterto50-80%forseawater.Theconcentrateflowisnormallyjust1.5-3.5bar (20-50psi) less than the feedpressurewhile theproductwater runsatatmosphericpressure.

Figure16SpiralWoundROMembrane45

Themainpurposeofdesalinatedwaterpost-treatment istostabilizethewaterandprepare it for distribution. This mainly includes re-mineralization, pH adjustment,disinfectionanddegasificationbeforedeliveredtodistributionsystem.

3) ProductionCost

35

The production cost for RO desalination plants is influenced by massive factorsincludingelectricityprice, laborcost, feedwaterquality, treatmentcapacityandsoon[48]. According to “Courtesy of Water Desalination Report”, the sea water ROdesalination cost is generally within the variation of 700-1200 USD/acre-foot(0.58-1.00 USD/m3). In United States, the brackish water RO desalination cost isabout0.10-1.05USD/m3.Asidefromfixedcapitalcost,themostsignificantcostsaretypicallythecostsofelectricity(40-55%),membranereplacement(5-10%),andlabor(~5%)[49].

Figure17AnnualizedSWROCostTrends

4) ProductivityandEffectiveness

Currently the RO technology can separate over 99% of salt from seawater with aproductivityof15-24liters/m2membraneperday(1.7-3.3m3/d/membrane[50]).Madeofcompositepolyamide,themembranefornowissaidtobeguaranteeda5yearslife without replacement. Besides, the woundedmembrane elements greatly savethespaceofdesalinationplants, resulting inaveryhighspace/productioncapacityratio,rangingfrom25,000to60,000liters/day/m2[47].

5) Disadvantages

- Inpractice,ROtechnologyishighlydependsonareliableenergysource;

- Limitedbythedesignofwaterintakeandpretreatment,ROdesalinationplantsusing seawater may be interrupted by stormy weathers because of there-suspensionandincreasingsuspendedparticulateconcentration;

- Even new materials is applied to strength the RO membrane, it is still verysensitive to abuse so that extra construction for feed water pretreatment isalwaysinneed;

- Therearebacterialcontaminationrisksonmembranesurface,causingtastesand

36

odorsproblemsonproductwater;

- ThehighlyconcentratedbrinefromROtechnologymustbecarefullydisposedtoavoid hazardous environmental impacts on oceanic and underground watersystem.

3.2.ThermalDesalinationTechniques

As itsname implies, thermaldesalination techniquesheatup the salinewater andgather pure product water mainly by distillation. Distillation is defined as apurification processes of fluid via evaporation and condensation. The condensedproduct of distillation is usually of single compound and free from salt due to thedifferent evaporation point. This simple principle based thermal technologies iswidelyusedinseawaterdesalinationbutrarelyusedinbrackishwaterdesalination,mainlybecauseof itshighcosts involved.Solarpowerarenowoftencoupledwiththermal desalination facilities to cut down their cost and unrenewable energyconsumptions. The two major thermal ways of desalination are Multiple EffectDistillation (MED) and Multi-Stage Flash Distillation (MSF). Depending on theavailabilityandqualityofenergyon-site,MEDplantssometimesfitwiththermalormechanical compressor to enhance their performance and optimize their energyrequirements, called MED-TVC (Thermal Vapor Compression) and MED-MVC(MechanicalVaporCompression).Theyaretypicallypoweredbysteamtogetherwithsome electricity. For thermal desalination processes, no special pre-treatment isrequired. But to protect the evaporators and pipelines, filtration is sometimesappliedtoremovelargesolidparticles.

3.2.1.MultipleEffectDistillation(MED)

1) TechnicalPrinciples

TheMEDmethod is said to be themost efficient, economical and easy operatingthermaldesalinationprocess,occupiedapproximately28%ofdesalinationmarket.Itis a low temperature thermal process that collect fresh water by distillation in asequenceofvesselscalledeffects.Eachoftheeffectmaintainsalowertemperatureandpressurethanthepreviousone.Sincetheboilingpointofwaterdecreaseswithreduced pressure (Table 9), the salinewater can efficiently keep evaporating in allvesselswithpressurecontrol,evenunderlowtemperatureof40°C.

Table9WaterBoilingPointTablePressure 1bar 0.47bar 0.32bar 0.25bar 0.1bar

Boilingpoint 100°C 80°C 70°C 65°C 45°C

2) ProcessDescription

The core of MED process is the MED evaporator. It consists of a serious ofconsecutiveeffects,2-16typically,remainedatdecreasingleveloftemperatureandpressure.Figure18showstheschematicthree-stageMEDevaporatorandazoomed

37

pictureofsingleMEDcell.Eacheffectcontainsabundleofhorizontalheattransfertubeswhereinheatingsteamisintroducedandcondensed.Feedseawaterissprayedfromtopofthebundleandflowsdownwardtube-by-tubewithgravity.Theseawatercools the tube externally, condensing the steam inside into purified water.Simultaneously, the heat released from the inner steam flow warms up the feedwater and partly evaporates it. The seawater gradually concentrates withevaporationandgivesbrineatthecellbottomwhichwillthenbetransporttonextstage. The vapor formedoutside the tube is directed to flow inside tubes for nextstageandusedasheatingsourcewhere theprocess repeats. In the lasteffect, theproducedsteamcondensesinaconventionalshellandtubesheatexchangercooledbyfeedseawater.Extracondensingseawaterotherthansprayedfeedflowisrejectedbacktothesea.Theconcentratedbrineiscollectedcelltocelltillthelastone,thenextractedbycentrifugalpumps.

ForMED desalination, only the first effect with highest pressure requires externalheat source and greatly withdraw the energy consumption of this process. Theheatingsteamofthefirsteffectisgenerallylowpressurecondensingsteam(0.3-0.5bar,70-90°C).Otherheatingmedialikehotwater,wasteenergyfrompowerplantsorsolar heat can also be applied for thismethod. Tomaintain the effect cells at lowpressure,theseawatertemperaturestypicallyremainsbelow65-70°C,thusavoidingunnecessary heating and allowing a good control of scaling. Typical pressure dropacrossthesystemis5-50kPa(lessthan5kPa/stage).Themoreeffectsaprocesshas,thehigherperformanceratioitgenerallyreaches.

(a)

(b)

Figure18SchematicofMEDEvaporatorandSingleEffectUnit[51]

3) EnergyConsumptionandProductionCost

38

TheenergyconsumptionofMEDprocessisresultfromvariesoperationfactors:TopBrineTemperature(TBT)knownasthemaximumtemperatureofthebrinesolution;Number of stages; Gain Output Ratio (GOR) known as the ratio between productwater amount per unit mass of dry saturated steam supplied to the system. ThetypicalelectricpowerconsumptionofMEDis1.5-2.5kWh/m3,thethermalenergyis60-110 kWh/m3 corresponding to GOR value from 10 to 6. Electrical equivalentdefinedastheamountofelectricalenergycannotbeproducedbecauseofextractionofheating steam is alsoused toevaluate theenergy consumption for theprocess.ForMED technique, the electrical equivalent for thermal energy is 5-8.5 kWh/m3,6.5-11kWh/m3inall.TheproductioncostforMEDtechniqueis0.7-1USD/m3whilethecapitalcostis3.5-4USDperinstalledgallonperday.

4) Productivity

For recent years, the unit treatment capacity of MED technology is significantlyincreased from4,500m3/d todramatic45,000-68,000m3/d[52].The typicalworkingcapacityofanMEDunitisabout5,000-15,000m3/d[53].

3.2.2.MED-TVCandMED-MVC

As an enhancement of conventional low-temperature MED process, MED-TVC(Thermal Vapor Compression) and MED-MVC (Mechanical Vapor Compression) isinvolvedinmanythermaldesalinationfacilitiestooptimizetheperformanceofMEDevaporators,particularlyinmanycogenerationplants.

The MED-TVC evaporator fitted a thermal compressor, called thermocompressor,withbasicMEDunitstotakeadvantageofpressureofavailablesteam(usually2.5-3bar,120-150°C)extractedfromback-pressureorextractionsteamturbine.Thesupplysteam, called motive steam, is fed into thermocompressor through a nozzle. Themotive steam expansion within compressor body forces the sucking out of lowpressurevaporfromevaporator.Bothmotiveandsuctionsteamsarethenmixedbydiffusionandfinallydischargedwiththepressuresuitableforfirstvessel.Thelatentheat in last stage vapor is recycled to evaporator at the same time and becomesavailableagainforMEDdesalinationprocesses,leadingtoenergysavings.

AhigherGORcanbeobtainedwithMED-TVCunits,usually12-15andcanevenupto17. The thermal energy can reduced to 40 kWh/m3 with a GOR of 16 while theelectricpowerconsumptionstaysthesame(1.5-2.5kWh/m3).Therearealsostudiessuggestalowerelectricityconsumptionvariationof1-1.7kWh/m3fortheMED-TVCprocess[52].Butwithrelativehighextractsteampressure,theelectricalequivalentforMED-TVCprocessishigh,9.5-25.5kWh/m3forthermalenergy,and11-28kWh/m3inall.Moreover,therecyclingofpartofvaporpermitstheevaporatorrunninginlargerscale.ThetypicalunitproductivityofMED-TVCis10,000-35,000m3/d,doubledthansimpleMEDunits.

39

Figure19SchematicofMED-TVCProcess[51]

Figure20SchematicofThermocompression

Unlike mainly thermal powered MED and MED-TVC processes, the MED-MVCevaporator isaMEDevaporatoronlypoweredbyelectricalenergy.All the featuresdescribedforMEDevaporatorapplyforMED-MVCprocess,butthevaporproducedby the coldest effect is recovered to the first bundle through a mechanicalcompressor. The electric powered compressor brings the extract vapor to thepressure condition prevailing inside the first vessel, enabling the latent heatre-availablefordistillation.Theheatfromdistillatedproductanddischargedbrineisrecovered to preheat the seawater feed by two heat exchangers. Due to this highefficiency operationmode, theMED-MVC process does not calls for extra coolingstuffsotherthanfeedseawaterwhichmakesitattractiveincoolingsourceintensiveplaces.