U.S. Status of Fast Reactor Research and Technology · PDF fileU.S. Status of Fast Reactor...

-

Upload

duongduong -

Category

Documents

-

view

217 -

download

1

Transcript of U.S. Status of Fast Reactor Research and Technology · PDF fileU.S. Status of Fast Reactor...

U.S. Status of Fast ReactorResearch and Technology

Robert HillArgonne National LaboratoryARC National Technical Director

June 21, 2012

2

Advanced Reactor Concepts (ARC)

The mission is to develop and refine future reactor concepts that could dramatically improve nuclear energy performan ce (e.g., sustainability, economics, safety, proliferation re sistance)

The strategic approach is to:� Tackle key R&D needs for promising concepts

– Fast reactors for fuel cycle missions– Fluoride salt cooled thermal reactor for high-temperature missions

� Develop innovative technology features with potenti al benefits to many concepts

� Utilize international collaborations to leverage an d expand R&D investments– Continuation of multi-lateral Generation-IV R&D Projects– Investment in strategic bilateral or trilateral partnerships

� Stimulate ideas for transformational reactor concep ts

3

Advanced Reactor ConceptsOrganizational Structure

ARC is organized into several technical areas:� Management and Integration ( Hill-ANL)� Fast Reactor Concepts (Grandy-ANL)� Thermal Reactor Concepts (Holcomb-ORNL)� Energy Conversion Technology (Rochau-SNL)� Nuclear Data (Hill-INL)� Generation-IV International Support (Connell-INL)� Transformational Concepts

Other DOE-NE R&D initiatives include advanced react or applications� Modeling and Simulation (NE-4)� Transmutation Fuels (NE-FCT)� Related University Program (NEUP) Contributions

Advanced Fast Reactor Concept Development

4

Concept development studies have several important purposes� Identify the key R&D needs and challenges � Pursue fundamental understanding of technical utili zation of

advanced technology options in integrated reactor s ystem– Confirm feasibility of innovative features– Estimate the impacts and benefits to prioritize new features

� Evaluate broad range of technology options– Different configurations and power sizes (e.g., SMR concepts)– Different coolant options, fuels, etc.

Thus, this work guides the R&D directions by screen ing the idea space with favorable technology options promoted to specific R&D technical areas

Concept Development Studies

6

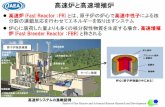

Fuel Cycle Mission:Fast Spectrum Reactors

� For closed fuel cycle options, must develop and dem onstrate recycle reactor technology– Significant waste management and resource extension benefits– Fast reactor needed for final transmutation system

� For future fast reactor technology, the key researc h focus is capital cost reduction (i.e., major commodity reduct ions or efficient electricity generation) through– Improved design approach (e.g., compact configuration)– Advanced technologies (e.g., materials, energy conversion)– Advanced simulation for optimized design

� A second research focus is assurance of safety to p romote design simplification and licensing

� A third, related focus is high system reliability

Fast Reactor Advanced Concept Studies (examples)

� Areas previously investigated include:

� Impact of Advanced Materials –potential for stronger materials reducing plant commodity usage

� Impact of Increasing Core Outlet Temperature – increased power output due to increased efficiency

� Advanced System and Components include:

– Compact fuel handling mechanisms– Advanced Balance of Plant Systems– Vented Fuel– Ultra-Long-lived fast reactor cores– Integrated primary purification

systems– Advanced heat exchanger

technology options

Fast Reactor Advanced Concept Studies (examples)

� FY11 and FY12 work focused on SMR (~100 MWe) concepts: unique features include long-lived core and fuel shuffling strategies

� Developed compact fuel handling mechanism:

– Single rotating plug configuration– Pantograph design– Offset from center

� Detailed analysis and design options for core restraint

– A key feature for inherent safety reactivity feedbacks

– NUBOW bowing analysis code recovered and refined

– Limited free bow design� AFR-100 safety analyses conducted

– Verify inherent safety in double fault transients

QR

NP

TLP

ACLP

B

C

Cor

ere

gion

TLP restraintring

ACLP

a. b. c.

AFR-100 Upper Internal Structure

Recent work to develop compact reactor configuration:

� Upper Internal Structure– Very complicated structure within

the primary plant– Made from 316SS and clad with

Alloy 718 for thermal fatigue resistance

– UIS is lifted by a lifting drive mechanism to clear some systems and components before and during rotation

– UIS is keyed into the core barrel structure to prevent lateral movement during seismic events

– Advanced Fuel Handling System is integrated with the UIS

March 20129

Mechanisms Engineering Facility

� The facility will test small and intermediate-scale sodium components, examples include:

– Components for advance fuel handling systems such as grippers, spline shafts, universal joints, bearings, etc.

– Instrumentation including detectors for rapid detection of impurities and improved methods for sodium level measurement

– In-service inspection and repair technologies

10

Fast Reactor Advanced Concept Studies - Thorium fuelled AFR -100 core

� Purpose - The feasibility study of fuel changes from U-based fuel to Th-based fuel in a small SFR

� Various approaches with Th-TRU:1) Conventional 4-batches operation with Th-TRU (18.6wt%). No

U-Zr startup core.2) Progressive replacement of U-Zr assemblies with Th-TRU (14.4-

22wt%). No equilibrium operation3) Progressive replacement of U-Zr assemblies with Th-TRU

(18.6wt%). 4-batches equilibrium strategy

� Different performance with various pros and cons (p eak power; reactivity swing; discharge burnup…)

Characteristic Unit (1) (2) (3)

Average TRU wt% wt% 18.60% 18.65% 18.60%

Burnup reactivity swing %∆k/k 0.73 1.3 1.25

Average power density W/cm3 58.3

Peak power density W/cm3 110.3 112.7 114.8

Radial power peaking factor

- 1.32 1.36 1.45

Average/Peak BU – U-Zr

% n.a.7.4%/ 12%/

11.9% 22.2%

Average/Peak BU –Th-TRU

%10.2%/ 7.8%/ 10.2%/

16.2% 17.4% 16.2%

Burnup distribution at EOEC for (1)

1.000

1.005

1.010

1.015

1.020

0 5000 10000 15000 20000

k_

eff

EFPD

(1) Conventional; 4-batches equilibrium

(2) Progressive replacement; no equilibrium

(3) Progressive replacement; 4-batches equilibrium

Information Recovery Efforts

� Another aspect of the concept development scope involves information recovery efforts

– Recovery of Information at FFTF (PNNL)– Recovery of Information at EBR-II (INL)– TREAT information recovery (ANL)– Retrieval of fast reactor information from OSTI

� Some key activities that have been pursued include:– NUBOW code recovery – supports core restraint design– SWAAM (sodium-water interaction) code recovery

• Upgraded to include sodium-CO2 interactions– FFTF Transient Testing and Startup Physics Testing Data– FFTF Design Standards and Procurement Specifications for

major FFTF systems and components

Fast Reactor Safety

13

Fast Reactor Safety and LicensingR&D Tasks

� International Passive Safety Evaluations– IAEA-coordinated projects on SFR Passive Safety (Monju and Phenix benchmarks)– Benchmark Analysis EBR-II Shutdown Heat Removal Tests (starting in FY12)

• U.S. contribution as the next IAEA-coordinated research project (CRP)• Largest CRP in IAEA history with more than 20 organizations in 12 countries

� Database Development for Safety Model Validations– Archiving of data for EBR-II/FFTF/TREAT Tests and SFR fuels and materials– FY12 marks successful completion of EBR-II and TREAT Test Databases

� Safety Technology Assessment and Regulatory Develop ment Plan– Evaluation of the status of the existing technology base, identifying where gaps exists

and additional effort is required– Regulatory Development Plan is finalized to help identify future R&D focus

� International collaborations– Gen-IV International Forum (GIF) SFR Safety and Operations PMB– GIF SFR Safety Design Criteria Task Force– U.S.-China Safety Code Collaboration– U.S./Japan/France bilateral and trilateral collaborations (Safety STCs).

Monju Benchmark: Objectives

� IAEA coordinated research project for benchmark analysis of Monju plant turbine trip test

– Analysis of sodium circulation in the upper plenum of Monju for validation of the 3-D CFD models

– Coolant mixing and temperature distributions in the hot pool for evaluation of thermal stratification

– Assessment of sharp temporal and spatial temp. gradients in reactor vessel and upper core structures

– Other benchmark participants include JAEA/Univ. of Fukui, CEA, KAERI, IPPE, IGCAR, and CIAE

Monju: MOX-fueled, loop-type prototype sodium-cooled fast reactor with three primary coolant circuits producing 714 MW-thermal (280 MW-electric) energy

16

Importance of Bypass Flow through Inner Barrel Holes

0

1000

2000

3000

4000

5000

6000

7000

365 390 415 440 465 490Temperature (C)

Ele

vatio

n (m

m)

.

30 sec (test data)

30 sec (holes with sharp edge)

30 sec (holes with round edge)

0

1000

2000

3000

4000

5000

6000

7000

365 390 415 440 465 490Temperature (C)

Ele

vatio

n (m

m)

.

30 sec (test data)

30 sec (holes with sharp edge)

30 sec (holes with round edge)

1 min (test data)

1 min (holes with sharp edge)

1 min (holes with round edge)

0

1000

2000

3000

4000

5000

6000

7000

365 390 415 440 465 490Temperature (C)

Ele

vatio

n (m

m)

.

30 sec (test data)30 sec (holes with sharp edge)30 sec (holes with round edge)1 min (test data)1 min (holes with sharp edge)1 min (holes with round edge)2 min (test data)2 min (holes with sharp edge)2 min (holes with round edge)

0

1000

2000

3000

4000

5000

6000

7000

365 390 415 440 465 490Temperature (C)

Ele

vatio

n (m

m)

.

30 sec (test data)30 sec (holes with sharp edge)30 sec (holes with round edge)1 min (test data)1 min (holes with sharp edge)1 min (holes with round edge)2 min (test data)2 min (holes with sharp edge)2 min (holes with round edge)5 min (test data)5 min (holes with sharp edge)5 min (holes with round edge)

0

1000

2000

3000

4000

5000

6000

7000

365 390 415 440 465 490Temperature (C)

Ele

vatio

n (m

m)

.

30 sec (test data)30 sec (holes with sharp edge)30 sec (holes with round edge)1 min (test data)1 min (holes with sharp edge)1 min (holes with round edge)2 min (test data)2 min (holes with sharp edge)2 min (holes with round edge)5 min (test data)5 min (holes with sharp edge)5 min (holes with round edge)15 min (test data)15 min (holes with sharp edge)15 min (holes with round edge)H

oles

with

sha

rp e

dge

Hol

es w

ith r

ound

edg

e

SFR Licensing Gap Analysis

• Design options• Event classes• Event sequence• Systems or components • Fuel, core, primary, vessel

Gap Analysis Coordination tasks• Establish objectives, high level criteria • Establish structure, sequence• Define system design options, safety relevant features • Define panel topic areas, panel objectives, membership

Fuels and Materials Panel(Chair: L. Walters)

Accident Sequence Panel(Chair: J. Sackett)

Computer Codes and Models Panel

(Chair: R. Schmidt)

Sodium Phenomena Panel(Chair: M. Corradini)

• Design options• Core support• Control rods, internals• Vessel, piping, •Intermediate heat exchanger

• Na events• Event conditions• Fires, aerosols, radionuclide chemistry

• Accident analysis codes•Neutronics - cross sections, reactivity coefficients, temperature dependence, codes •TH – convective flow, heat transfer, codes

Source Term Panel(Chair:. D. Powers)

•Radionuclide release to primary system –fuel types, FP chemistry Na, TH transport, vessel•Radionuclide release to environment secondary transport, chemistry, aerosol transport

� All five of the PIRT-like gap analysis panels compl eted� In FY12, results of the five groups are being integ rated and prioritized by an

experts panel with contributions from the chairs of five gap analyses� A “Regulatory Development Plan” for identified gaps is key FY12 deliverable

• Will help guide FY13+ R&D priorities in Fast Reactor Safety and Licensing Technical area

Summary of SFR Safety and Licensing Research Plan Recommendations

• Documentation of safety related codes and experiments risk being lost• Piecemeal and underfunded efforts will lead to lost information which may need to be reproduced in

the future

Coordinated Knowledge Management and Preservation E ffort

• Adequate stewardship and documentation of U.S. safety related codes required for licensing (e.g., LIFE-Metal)

• Modernization of U.S. Codes to satisfy current licensing needs• Code (e.g., SAS4A) improvements related to seismic response of the entire SFR system will be

required post-Fukushima • Probabilistic safety analysis of containment response capabilities need to be developed for SFRs

within the U.S. (i.e., incorporation of sodium phenomena into MELCOR)

Improvements to U.S. safety related codes

• Ensures that future testing capabilities are not lost in budget conscious environments• Identify testing to address phenomenological uncertainties which could be performed to maintain

facilities

Continued U.S. experimental facility utilization, ev en if on a small scale

• The current process makes removing AT designations on documents which no longer need to be protected extremely difficult.

• The U.S. NRC is not set up to handle AT documents.

Treatment of the Applied Technology (AT) designatio n must be streamlined

18

Fast Reactor Advanced Materials

19

Fast Reactor Advanced Materials Consists of Several Key Areas

� Advanced Alloy Development: – Charged with procurement of alloys, defining and testing material

processing, and acquiring basic properties.� Advanced Alloy Testing:

– Using the new materials, mechanical testing is performed. This currently includes thermal aging, tensile testing, fracture toughness, impact testing, and creep-fatigue.

� Materials Performance Criteria and Methodology:– Licensing needs for advanced materials and resolution of design

methodology are key long-term needs for application of advanced materials.

� Environmental Testing (Sodium Compatibility):– Information on sodium compatibility of selected alloys is very

limited. Sodium testing capability was reconstituted at ANL and ORNL and through an FOA at the University of Wisconsin.

Tensile Property Comparison

� TMT increased strength without the significant redu ction in ductility (e.g., Gr.92-1-TMT).

� Cu-alloyed modified-Gr.92 steels showed superior st rength but poor tensile ductility (e.g., 9Cr-2WCuVNb and 9Cr-2WCuVNbTiC).

� The optimized-Gr.92 (9Cr-2WVNbC) and modified-Gr.92 (9Cr-1WVTaC and 9Cr-2WVNbTiC) are downselected for further study in FY12 due to th eir significant enhancement in strength without noticeable trade-of f in tensile ductility.

� A new alloy composition (advanced HT-UPS) was propo sed.– Fe-13Cr-16Ni-Mo-Nb-C-N (wt%) base

– Goal is to improve weldability, while maintaining lower material cost.

– 50lb cast ingot arrived.

– A half of the ingot has been processed (hot-forged and hot-rolled).

� A new alloy composition (advanced HT-UPS) was propo sed.– Fe-13Cr-16Ni-Mo-Nb-C-N (wt%) base

– Goal is to improve weldability, while maintaining lower material cost.

– 50lb cast ingot arrived.

– A half of the ingot has been processed (hot-forged and hot-rolled).

Preparation of Advanced HT-UPS

Cast ingot After hot-forging After hot-rolling

� Above goal is achieved with this new alloy composit ion.� Above goal is achieved with this new alloy composit ion.

23

Environmental testing of Advanced Materials

� Environment effects (thermal, radiation and/or cool ant) can have a significant impact on mechanical performance and alloy stability

� Thermal Aging – Time at temperature may degrade material properties.

� Irradiation Testing – Initial irradiation and PIE on candidate alloys will start in

FY09– Initial Testing will help prioritize PIE from MATRIX-II– Some HT-UPS samples from FFTF/MOTA experiments

have also been identified– Data interpretation and semi-empirical modeling will guide

future tests and needs� Corrosion in Sodium

– Corrosion in liquid metals must be evaluated and understood for the candidate alloys

– The pumped-Na loop at ANL will be utilized in addition to convection-driven loops at ORNL

– Initial burden-modeling activities will also provide insight into transfer of C, O, and/or N around the reactor loop

Modeling Creep-Fatigue Behavior of Ferritic Steels

24

� Established an updated database for G91 steel: stress relaxation data were recovered from 13 creep-fatigue tests completed in early 1990s at ORNL.

Cyclic Softening Model

� Developed the Damage Rate Based Model to predict hold-time creep-fatigue life using tensile, creep and fatigue properties

Damage Rate Based Life Prediction Model

� Using the existing database, developed the mechanism-based Cyclic Softening Model and the Stress Relaxation Model by incorporating strain hardening and dislocation creep mechanisms.

Stress relaxation data recorded on strip charts

Digitized stress relaxation data.

Stress Relaxation Model

In-service Inspection Technology Development:Under-Sodium Viewing

25

USV System Evaluation −Sodium Tests

26

Sodium TestsScanning Size: 1” x 1”; Resolution: 50 pixel/inch

Lateral Resolution: 1mm; Vertical Resolution 0.5mm

Test Tank

Dump Tank

Scanning System

Temperature Control Modules

Gold-plated Focal Lens

Transducer

Waveguide

Target 1” away

Target 1.25” away

Advantages of Argonne UWT:

� Reduce the background noise and spurious signal

� Minimize the waveguide attenuation

� Create a clear window to detect target reflection

� Maximize the signal to noise ratio

Argonne WGT Prototype (D=0.625”, L=12”)

Intensity Image

Time-of-Flight Image 12” UWT @650OF

18” UWT @310OF

1st Generation USV Test FacilityIn

tensi

ty,

V

Time-of-Flight, µs

USV Ongoing and Future Works

27

� Linear UWT Array• Fabricate and evaluate linear UWT array• Develop signal and image processing software• Demonstrate crack detection/loose-part identification

capabilities

� Develop brush-type linear UWT Array• Construct a brush-type waveguide for side-view

imaging application• Develop dry-coupling technique for linear UWT array

application• Develop the imaging algorithm applicable to the linear

UWT array

� Sodium Test• Complete new USV test facility for in-sodium tests of

linear UWT array (ANL) and phased array transducer (PNNL)

• Demonstrate crack detection/loose-part identification capabilities in sodium

� US-Japan Collaboration

2nd Generation of USV Test Facility

Dump Tank

Cold Trap

Sodium

PumpFlowmete

r

Positioning System

Test Tank

UWT Array

Positioning System

Advantages:

� Larger opening and tank for linear array

� Larger Testing Components/Targets

� Easier target and transducer setup and replacement

� Add an EM pump (5G/min) and cold trap to circulate and clean sodium

� Better temperature control and Higher Operation Temperature (650OC)

� Closed-loop design for Safer operation

DAQ & Image

Processing

Sodium Flow Control Center

Heating Control Center

Pulser Receiver

Gain Filter

Gas Flow Control Center

UWT Linear Array

Brush-type Linear UWT

ArrayTime-of-Flight Intensity

High temperature linear ultrasonic array

Acoustic field map exhibits significant

inter-element crosstalk and inconsistent

coupling between piezo-elements and

nickel alloy faceplate

• Robust array for immersion (Mk 1)

• 12 discrete transducer elements

• Lead meta-niobate piezoelectric

• Frequency = 2MHz

• Faceplate polished nickel foil

• Operating in liquid sodium (260C)

• Demonstrating array imaging in sodium

Ultrasonic Image of Joyo Fuel Subassembly Mockup

Loose pin

C-scan image

A-scan image

Top of MARICO pin

Top of fuel pins

Bottom plate

Loose MARICO pin

Advanced Energy Conversion Technology

30

Supercritical CO 2 Cycle Coupled to an Advanced Liquid Metal Reactor

Page 31

Turbine Generator

Compressor/Recompressorwith turbine

Recuperators (8)CO2 Storage

Advanced BOP Trade Study – Summary and Conclusion

� Pre-conceptual design of 1,000 MWe supercritical CO2 cycle BOP was developed by vendor - PWR

� Design contained sufficient detail for cost & schedule estimates to ± 35%� BOP Sizing studies were completed – 1 x 1,000 MWe configuration was

selected for this study� Piping, Heat Exchanger, Turbomachinery designs were completed� Preliminary cost comparison (2011$) between steam and S-CO2 plant

completed� The turbine building for S-CO2 plant about 50% the size of steam plant,

however not much floor area for maintenance or equipment laydown

� Results are based upon an Interim Report – it will be revised as appropriate once we receive responses to our comments from the vendor team

32

S-CO2 Brayton Cycle

• Major system upgrades are nearly completed to attain the original testing capabilities of:

– 75,000 RPM on both Turbo-Alternator-Compressor (TAC) units.

– 780 kWth input power.– Peak operating temperature of 1000°F.– Peak operating pressure of 18.7 MPa.– 5.7 kg/sec mass flow rate.– Net power generation on the order of 250 kWe.

• Recent focus has been to:– Complete upgrades.– Perform acceptance testing of the upgraded test

article (TA) at the contractor facility.– Prepare test facility site at Sandia, Albuquerque (see

photos at right).– Transport the TA from the contractor facility to

Sandia Albuquerque.– Perform commissioning tests on the TA to verify

functionality.– Open the Nuclear Technology Users Facility (NTUF)

for commercial component demonstration testing.

Technology Development Efforts

� Contributed to the DOE-EERE Sunshot FOA proposal with NREL, EPRI, and industry participants. This initiative focuses on developing SCO2 Brayton technology for concentrated solar power applications with dry cooling.

� Communicated with industry interests regarding the DOE-NE Brayton cycle TA testing capabilities at NTUF. Likely established NTUF’s first commercial customer.

� Specific objectives for near-, mid-, and long-term testing of the TA are being developed.

� Risks to the smooth and continued access to TA testing are being identified, and contingency plans developed to minimize down time.

Time 3200 s0.916 kg/s T, °C

32.3 P, MPa

152.1 150.7 7.7638.415 8.403 RPM

25,00031.8 19.3

7.702 0.060

140.6 35.078.7 7.764 8.455

8.428

141.6 33.1 35.6 34.6-0.560 0.056 7.754 0.116

1.213 kg/s78.4 35.6

-0.560 -0.560

HeaterAlt

Cooler

CT

LTR

Steady-State Results

� The results of the steady-state calculations from the Plant Dynamics Code (PDC) model are surprisingly close to the experimental data

– Pressures, temperatures, flow rates– Despite all the uncertainties of the

experimental data– Special adjustments for heat loss were

needed

35

Co

de

Pre

dic

tio

n

Experimental Data

0.935 kg/s T, °C32.3 P, MPa

152.9 152.8 7.703 Q, kW8.390 8.383 RPM88.80 25,000

32.3 19.37.707 0.123

3.10145.8 35.1 79.00

80.3 7.751 8.4108.390 -6.55

139.8 35.1 36.4 35.07.735 8.408 7.711 0.116

1.203 kg/s80.4 36.5

8.399 7.719

163.90

PDC Steady-State Results

4.70

1.50

HeaterAlt

Cooler

CT

LTR

A variety of R&D issues for coupling new energy con version to a fast reactor� Updated small-scale sodium Plugging Phenomena Loop has been

– Modified to assure constant temperature in plugging zone� Fundamental Phenomena for IHX

– Concern with thermal shock for compact heat exchangers– Ability to fill and drain also requires development– Small-scale facility designed to look at freeze and thaw issues

� Na-CO2 Interaction– Focused on sodium-to-CO2 heat exchanger conditions– The apparatus has been procured, testing will start in FY12

� Dynamic Modeling of Supercritical CO 2

– Continues ongoing work formerly under Gen IV FY 2010 Work Package, “Energy Conversion – Brayton Cycle Control Analysis”

– Focused upon S-CO2 cycles for SFR, LFR, and VHTR and system level plant dynamic analyses for S-CO2 cycles

Heat Exchanger – FRTesting and Modeling

1,800 cubic feet per minute (cfm) air blower with variable frequency drive and chiller

Test section and heaters inside of stainless steel air duct half-wall

Installation of test section air cooling system

Fundamental Sodium -CO2Interaction Tests

� Small-scale sodium facility is being assembled to provide fundamental data on interactions between sodium and CO2 released into sodium through stainless steel micro-leak configurations and self-plugging of stainless steel micro-leak configurations under realistic conditions of sodium-to-CO 2 heat exchanger failure

� Envisioned failure mode for compact diffusion-bonded heat exchangers involves formation of microcrackslimiting flow of CO 2 into sodium with possibility of self-plugging of crack channels due to formation of solid reaction products

Advanced Modeling and Simulation

39

Goals, Strategy and Accomplishments

� Goal: Apply modern, high-performance computing tech niques to nuclear reactor modeling

– Use advanced simulation tools to improve safety, reduce cost, explore advanced designs – Provide local data needed to enable predictive fuel performance simulations– Understand and reduce uncertainty of computational models

� Strategy: Develop flexible, mission-agile toolbox f or construction of virtual reactor models

– Adopt multi-scale strategy to enable application to problems relevant to industry using a wide range of computing platforms

– Utilize modular architecture to enable component-wise use by most advanced users or integrated user interface driven application by less advanced users.

– Develop collaborations with customers to define near term applications/demonstrations

� FY11 Accomplishments: Delivered initial modules and continued to demonstrate applicability to SFR simulations

– Modules scheduled for FY11 delivery – Nek5000 v4 (CFD) , MOAB v4 (framework), MC2-3 (cross-sections), and SN2ND (neutron transport)

40

PROTEUS Neutronics Modules

� UNIC transport solver modules– MOC-FE (3-D & 2-D MOC), SN2ND (2nd Order Discrete

Ordinates), PN2ND (2nd Order Spherical Harmonics), NODAL (nodal transport)

• All codes use generalized second order finite element mesh to provide true representation of exact geometry

• Provides variety of homogenization options ranging from conventional nodal methods to fully explicit geometry

� FastRANGE transport solver modules� modernized version of legacy SFR toolset (DIF3D, DIF3D-K, REBUS,

VARI3D, ETOE, FTU, MC2-2, RIGEL, MERMC, TWODANT-ANL) to support coupled multi-physics simulations

� MC2-3 module provides high resolution cross-section libraries for fast spectrum applications

� Codes are developed in sub-version repositories for version tracking and verification is completed by automated buildbot

� Validation efforts in progress using legacy data– Simulations of ZPR-7 experiments completed using SN2ND and MC2-

3 (230 group L5T5 with P3 scattering kernel)– Results shown are for fission in the EU foils and capture in the DU

foils for a selected ZPR-7 loading– Results using SN2ND + MC2-3 were equivalent in accuracy MCNP– Legacy VARIANT code could not obtain a similar solution

41

SHARP Thermal Fluids Modules

� Nek5000 DNS/LES module provides accurate, highly-scalable, high-order spectral element CFD

� Nek5000 URANS module provides simulations of unsteady turbulent flow at lower cost than DNS/LES

� STAR-CCM+ module provides access to steady and unsteady RANS solvers of commercial CFD code STAR-CCM+

� SHARP-IF module uses intermediate fidelity simulation toolset using momentum sources to mimic effects of geometric details

� SAS11 modules– lumped parameter representation of T/H and Structural

Mechanics applicable to full system– provides continued access to legacy SFR fuel

performance models� Codes are developed in sub-version repositories for version

tracking and verification is completed by automated buildbot� Validation efforts in progress with legacy data and

international benchmark data– Most recently completed OECD T-Junction Thermal

Mixing Benchmark– Nek5000 provided best predictions of temperature

measurements among all submissions

Wire-wrap vs. Spacer Grid Study

217-pin Wire-Wrapped Assembly

T-junction Thermal Mixing

SHARP Framework Modules

� MOAB module provides highly scalable data management for mesh based simulations

– Currently integrated into UNIC, Nek5000, Star-CCM+ and DIABLO

� MB Coupler module provides scalable parallel solution transfer between meshes of different types

� MeshKit modules provide efficient, parallel meshing capability for reactor geometries

– MeshKit Generation Library provides consistent API access mesh generation functionalities, including the RGG reactor geometry/meshing tool

– CGM Geometry Library provides support for CAD and other geometry types

• Includes interface to Open.CASCADE, an open-source library for geometry

• compatible with (and can import models from) CUBIT's CGM

� Lasso relations library allows associate of mesh to geometry without requiring software dependency between mesh and geometry libraries

� Meshing capabilities have been successfully demonstrated for a variety of reactor configurations with Nek5000 (open source CFD code) and STAR-CCM+(black box commercial CFD code)

43

Awareness of geometry in addition to mesh simplifies specification of material regions. Efficient solution transferenables use of appropriate mesh type for each physics andeach resolution scale.

Flexible reactor geometry and mesh generation tool supportsboth rectangular and hexagonal lattices, as well as details likewire wrap spacers, assembly cans or bypass flow gaps.

Nuclear Data

44

Nuclear Data Effort onFour Major Topics

February 3, 2011 45Advanced Reactor Concepts Working Group Oak Ridge National

Laboratory

Uncertainty ApplicationsUncertainty Applications

Covariance EvaluationsCovariance Evaluations MeasurementsMeasurements

Advanced Measurement Development

Advanced Measurement Development

Pino PalmiottiINL

Won Sik YangANL

BNL

Michael Herman

BNL

Patrick TalouLANL

Fredrik TovessonLANL

Mike HeffnerLLNL

Tony HillINL

Fredrik TovessonLANL

Mike HeffnerLLNL

Tony HillINL

David AsnerPNNL

Wor

k P

acka

ge M

anag

ers

ARC FCRD

FCRD & ARC

FCRD & ARC

A Time Projection Chamber (TPC) was developed under a NERI-c grant to provide precision fission cross section measurements

� Sub-percent fission measurements will significantly reduce uncertainties that impact reactor and fuel cycle construction, operation and safety costs

� TPC will provide 3D “pictures” of the charged particle trajectories

– Alpha backgrounds removed– Sample auto-radiograph (α particles)– Beam non-uniformities– Multi-actinide targets

� TPC will use thin backing foils (<50 µµµµg/cm 2)– Minimize beam interaction backgrounds– Maximize efficiency– Minimize multiple scattering of fragments– H2 drift gas will also minimize scattering

� TPC will provide data on both fission fragments simultaneously

– Random backgrounds removed (vertex requirement)– Fission vertex with <100 µm resolution (fission

radiograph)

AlphasFission fragments

Co-Funded by NE (FCRD and ARC) and NNSA

Nuclear Data Accomplishments

� Fission data was collected using the nominal fission ratio detectors for U-234 in November and December 2011. Once analyzed this data will complete the uranium series, with cross sections for U-233, 234, 235, 236 and 238.

� A high precision U-235 capture cross section data set will be delivered to evaluators in FY2012. This work was made possible by a new fission tagger (PPAC) developed to improve the accuracy of capture measurements on fissile isotopes.

� The fission TPC successfully collected fission ratios of U-238 to U-235 in the neutron beam at LANSCE in Dec 2011-Jan 2012.

� Plutonium-239 was successfully loaded into the TPC in February 2012, and the instrument installed on the flight path at LANSCE for beam experiments, marking a world’s first in imaging fission from Pu-239.

47

Partially instrumented TPC in the LANSCE flight path

Fast Reactor Fuels R&D

48

AFC-2D Experiment Status

� Inserted September 2008� Burnup objective 40 at.%� 14 cycles of irradiation completed� 685 EFPD through EOC 150B

� Discharged from ATR in December 2011� Cooling in ATR Canal, awaiting shipment to HFEF

East Flux Trap Irradiation Housing

AFC-2E Experiment Status

� Inserted August 2009� Burnup objective >20 at.%� 11 cycles of irradiation complete� 483 EFPD through EOC 150B

� Discharged from ATR in December 2011� Cooling in ATR Canal, awaiting shipment to HFEF

East Flux Trap Irradiation Housing

4

2

5

1

3

67

AFC-3A,3B Began Irradiation in Outboard-A Positions (Cycle 150B, October 2011)

� AFC-3 Design– Cd-shrouded– Rodlet design

unchanged– 5 individually

encapsulated rodlets/position

– Freedom to add/remove individual capsules during any outage

A-10 (AFC-3A)(AFC-3B) A-11

AFC-3 Advanced Metallic Fuel Concept for Ultrahigh Burnup — Irradiation Test Plan

AFC-3A AFC-3B

FY Cycle A10-1 A10-2 A10-3 A10-4 A10-5 A11-1 A11-2 A11-3 A11-4 A11-5

2011 150B

U-10Mo

solid

75% SD

U-10Mo

annular

55% SD

materials

U-10Zr

annular

55% SD

U-1Pd-10Zr

U-2Pd-10Zr

solid

75% SD

U-4Pd-10Zr

solid

55% SD

3 years

U-4Pd-10Zr

annular

55% SD

3 years

materials

U-10Mo

solid

55% SD

4-5 years

U-10Mo

solid

55% SD

6-8 years

2012

151A U-aIn-10Mo

U-bIn-10Mo

annular

75% SD

materials

151B

U-In-Mo

annular

55% SD

3 years

152A

153A

U-10Zr

annular

65% SD

U-10Mo

annular

65% SD

U-10Mo

annular

75% SD

U-In-Mo

U-Pd-Mo

solid

65% SD

2-3 year

U-PuGa-1Pd-Zr

U-PuGa-2Pd-Zr

solid

75% SD2013

153B

154A

154B

155B

U-10Zr

annular

75% SD

U-Pu-MA-Mo

annular

65% SD

U-Pu-MA-Mo

annular

55% SD

3 year

U-Pu-Pd-M-Zr

solid

75% SD2014

156A

156B

157A

157B

SD = smear density

Initial "Challenge" problems defined

Initial 1st year experiments defined

2nd and 3rd year experiments proposed

Materials experiments

Experiment discussed, but not finalized

Short-term, early PIE to

demonstrate feasibility

Long-term to demonstrate the

““““Grand Challenge””””

� Fast reactor R&D is focused on key technologies inn ovations for performance improvement (cost reduction) and safety1. System Integration and Concept Development2. Safety Technology3. Advanced Materials4. Ultrasonic Viewing5. Advanced Energy Conversion (Supercritical CO2 Brayton cycle)6. Reactor Simulation7. Nuclear Data8. Advanced Fuels

� Fast reactors have flexible capability for actinide management– A wide variety of fuel cycle options are being considered

� International R&D collaboration pursued in Generati on-IV and multi-lateral arrangements

Summary

53