September - October 2007 Issue 8

Transcript of September - October 2007 Issue 8

FireFly wireless seismic - first survey in Wyoming

Automatically cleaning your data

Statoil and Landmark - $13m basin scale reservoir software

September - October 2007 Issue 8

™

Associate Member

layout1.qxp 23/08/2007 13:17 Page 1

layout1.qxp 23/08/2007 13:17 Page 2

Contents

1

Statoil and Landmark- $13m 'basinscale' softwareStatoil and Landmark have agreed to worktogether on a $13m project (investing$6.5m each) to develop new software whichcan be used to model entire basins, not justreservoirs.

Venture's risk analysis softwareWe interviewed North Sea oil and gas com-pany Venture Production about their proj-ect analytics software Primavera Pertmasterto analyse its changing project risk expo-sure for projects

Weighing up the drilling optionsOil and gas companies can weigh up theirdrilling options taking into account eco-nomic and political factors, as well as justengineering factors, using new softwaretools from Schlumberger

Collaborative geophysicsOil and gas software company Paradigm be-lieves it is close to working out how to dowhat other companies just talk about - toenable geophysicists, petrophysicists, androck physicists to plan projects at their on-set and conduct them collaboratively andconcurrently

Input Output - developments withwireless seismic Input Output has completed two projectsfor its new wireless seismic system FireFly, inWyoming and Texas.

Merrick's new data and RFID toolsMerrick Systems of Houston has developedtwo tools, one to bring data from differentsoftware packages onto the same screen,and another to manage surface and down-hole equipment using RFID

Future Fields conference report IQPC's Future Fields conference in Londonin May 2007 included healthy coverage ofhow digital oilfield techniques can improvesurveillance, leading to improved safety; itlooked at how systems can be successfullyintegrated in smaller fields, and the kind ofthings which often go wrong with digitaloilfield installations 14

6September/October 2007 Issue 8

September - October 2007- digital energy journal 1

Landmark and IT infrastructureWe interviewed Haris Rahi, Business Devel-opment Manager for Landmark’s OptimizedComputing Solutions and Services group,about how Landmark is helping oil and gascompanies optimise their IT infrastructures,including data management and disasterrecovery systems.

Automatic data cleaningIntervera of Calgary and Innerlogix of Hous-ton have an interesting new business - au-tomatically cleaning up oil and gas data.

Fast growth for BB VisualBBVisual Group, a group of visualisation andcollaboration technology companies estab-lished in late 2005 reports total annual rev-enues of NOK 30m (USD$5m)

Digital Energy Journal213 Marsh Wall, London, E14 9FJ, UKwww.digitalenergyjournal.comTel +44 (0)207 510 4935Fax +44 (0)207 510 2344

Editor Karl [email protected]

Technical editor/ IT managerKeith [email protected]

Consultant writerTracey Dancy, Paras Consulting

Production, design and circulationKaterina [email protected]

Advertising salesAlec EganTel +44 (0)207 510 [email protected]

Offshore Europe 3D offshore training simulators and achance to compare your ROV flying skillswith the professionals - some of the thingsyou'll find at this year's Offshore Europeexhibition in Aberdeen

Informing you about developments in information technology and communications in the upstream oil andgas industry

Digital Energy Journal is published on print 6 times a year, covering informa-tion technology and communications inupstream oil and gas production,drilling / completions and exploration.

Each issue of Digital Energy Journal ismailed to 2000 oil and gas executives, aswell as distributed at major trade shows

Subscriptions: £GBP 195 a year for 6 is-sues. To subscribe, please contact circula-tion manager Katerina Jeffery on [email protected]. Alternatively you cansubscribe online at www.d-e-j.com

Printed in the UK by

THE MAGAZINE PRINTING COMPANY

www.magprint.co.uk

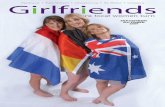

Front cover - FireFlyhandheld equipmentused in a wirelessseismic survey inWyoming. For moreinformation see page 12.Image Input Output

XTO Energy and Energy XXI sign up toOFS PortalWe talked to OFS's CEO Bill Le Sage about

how he is trying to persuade more

independent oil companies and national oil

companies to transact with their service

providers, and to use PIDX

PPDM - Version 3.8 out shortlyPPDM, the Public Petroleum Data Model As-sociation, will shortly be releasing version3.8 of its data model.We spoke to CEO TrudyCurtis about what it means

Spotfire - analysing dataData analysis tool Spotfire has met a lot ofsuccess in the oil and gas industry, beingused by nearly all oil majors.

8

12

13

24

26

30

Section - Oil and gas operations

Section - data

37 46

30

36

40

42

layout1.qxp 23/08/2007 13:17 Page 1

digital energy journal - September - October 20072

News updateEnergistics new chairmanwww.energistics.orgMike Benjamin, vice president of marketingfor Schlumberger Information Services hasbeen selected as the new Energistics chair-man.

Mr Benjamin has 20 years of upstreamoilfield experience having worked forSchlumberger in various roles in Paris andthe US, including director of recruiting,training and employee development world-wide.

He succeeds Jonathan Lewis of Hal-liburton who held the chairmanship for oneyear and will remain on the board.

Also joining Energistics Board is MarkGreene, executive partner in Accenture’s re-sources energy consulting practice.

Statoil - largest computer inScandinavia www.statoil.comStatoil reports that its supercomputer in Sta-vanger, Norway, thought to be the largestcomputer in Scandinavia, is ready for use. Itwill be used by geologists in both Houstonand Stavanger / Trondheim.

The computer has 256 interconnectedservers with 1024 processors, and can exe-cute 12 teraflops per second. It fills 17 racks,with each rack 2m tall, 60cm wide and 80cmdeep.

It has already been used to create seis-mic images of reservoirs beneath salt layersin the Gulf of Mexico, which takes an enor-mous amount of data processing because ofthe complex ways the salt reflects the seis-mic waves.

Shell uses Techsia reservoir softwarewww.techsia.comShell and Techsia have entered a worldwidecooperation agreement to further developand implement Techsia’s petrophysicalreservoir characterisation softwareTechlogC.

TechlogC is a reservoir characterisationsoftware package for analysis and interpre-tation of log and core data. Shell will use theplatform in the office and at the wellsite.

Landmark connects to OpenSpiritwww.openspirit.comLandmark has announced plans to developan adapter to OpenSpirit, which will enableLandmark software to integrate with othersoftware systems which work with Open-Spirit, including GeoFrame (Schlumberger),Recall (Petris), KINGDOM (Seismic Mi-croTechnology), and Petra (GeoPLUS) ap-plications.

The adapter should be available by late

2007. Landmark users will be able to use itsDecisionSpace environment to run softwareapplications side by side from different ven-dors.

Centrilift pump - one year at 190°Cwww.bakerhughes.comBaker Hughes reports that its Centrilift elec-trical submersible pump (ESP) has been run-ning for over a year at temperatures of over190° C (375° F), in a steam assisted gravitydrainage project in Alberta, Canada.

Baker Hughes spent four years devel-oping the pump, designing it to run reliablyat temperatures of up to 220° C (430° F).

WellDynamics and Expro telemetryintegrationwww.welldynamics.comIntelligent wells company WellDynamicshas integrated its technology with Expro In-ternational’s cableless electromagnetic wellcommunications system.

With the Expro system, data can becommunicated through the steel well casingand tubing, so no cables are required.

With the two systems together, cus-tomers will be able to install WellDynamics’well monitoring and control systems, with-out the trouble of installing cable in the well.

AVEVA on world’s largest FPSOwww.aveva.comChevron has selected AVEVA software formanaging critical engineering informationfor the operation of Agbami, which will bethe largest Floating Production, Storage andOffloading unit (FPSO) in the world.

AVEVA’s NET Portal is a web-enabledsolution for integration and collaborative useof engineering information including 3Dmodels, piping and instrumentation dia-grams, schematics, documents and data fromany application.

New Ikon Science staffwww.ikonscience.comIkon Science has appointed Peter Dolan asnon executive chairman. Mr Dolan has pre-viously worked in exploration roles for Mo-bil, Ball & Collins (assimilated into PremierOil) and then as a founder and director of JE-BCO Seismic Ltd.

David Gawith has been appointed prin-cipal geoscientist. Mr Gawith worked for BPfor 25 years in the UK, Europe and the FarEast, and was founder and director of Earth-Models Ltd (later purchased by Ikon Sci-ence) and of G&G Research Ltd.

Dr Pamela Gutteridge joins Ikon Sci-ence as a Principal Geoscientist. Ms Gut-teridge has a B.Sc. in Mathematics and a

PhD in engineering from Imperial College,London, and has worked in the oil industryfor 22 years, initially with BP and subse-quently with RCSquared / Veritas.

JP Kenny uses SIMULIA pipe simulatorhttp://www.simulia.com/Pipeline and subsea engineers JP Kenny hasdecided to use the Simulia software forpipeline design in a number of its West Aus-tralian gas field projects.

The software, produced by DassaultSystèmes, can be used to optimise pipelinedesign and plan for various different scenar-ios such as cyclones.

Ikon Science launches Petrel plug-inwww.ikonscience.comIkon Science has launched a plug-in toSchlumberger’s Petrel reservoir modellingsoftware, as part of its new version 5.2 ofRokDoc.

The plug in is called ‘modelling whilepicking’.

With the RokDoc plugin to Petrel, userscan access the predictive power of rockphysics from within the modern interpreta-tion workflow.

Events can be picked in the Petrel geo-logical model which updates the geophysi-cal 2D RokDoc model in real time.

The impact of changes to either modelby changing pick, pressures, fluids etc canbe realised immediately.

With the plugin interpreters can createinsights, reduce risks and check the validityof their picking decisions.

Apache Corporation uses RokDocwww.ikonscience.comApache Corporation has agreed to use IkonScience’s RokDoc software internationally,following a successful implementation in itsAberdeen offices.

Apache will also be using the RokDoc‘Modelling While Picking’ tool, which al-lows events picked in the Petrel geologicalmodel to automatically update the RokDoc2D geophysical model in real time.

Tigress consolidates Iraqi oil datawww.geotrace.comTigress Software has completed a threemonth project to consolidate large volumesof Iraqi exploration and production data intoa single, manageable database.

Data included maps, geophysical, geo-logical and petrophysical information as wellas engineering and production data.

The data was previously disorganized,which made it impossible to evaluate.

layout1.qxp 23/08/2007 13:17 Page 2

layout1.qxp 23/08/2007 13:18 Page 3

digital energy journal - September - October 20074

News updatePetris buys Production Accesswww.petris.comPetris has acquired the software assets ofProduction Access, including its OperationsCenter software, which can be used to man-age drilling / production operations data, andincorporate it into company financial sys-tems.

Petris sees the acquisition as a good fitwith its software portfolio, which altogethernow includes tools for geoscience, drilling,production and pipelines.

BG Energy buys SRO data replicatorwww.srosolutions.netBG Energy in Trinidad has implementedsoftware from SRO Solutions to automati-cally replicate databases onboard its remoteassets.

BG was having problems with its pre-vious system, where the remote assets inter-rogated a central database directly, due to la-tency over the VSAT communication systemand poor response times.

SRO has also installed the system forAtlantic Oil Services, to replicate databasesbetween three rigs and the central databaseat its Amsterdam office.

Roxar markets Geomodelling’s seismicmodelling softwarewww.roxar.comSoftware and metering company Roxar hasmade a deal with Geomodelling Technology,to act as a reseller for its seismic modellingsoftware VisualVoxAt.

Roxar envisages that customers can useVisualVoxAt to draw rock layer maps fromseismic data, together with Roxar’s reservoirmodelling software IRAP RMS, its historymatching / uncertainty estimation softwareEnABLE, and its reservoir simulation toolTempest.

eProduction new WellFlo versionwww.ep-solutions.comeProduction Solutions, part of Weatherford,has launched version 4.0 of its WellFlo wellengineering software.The new version is designed to functionmore intuitively, and more closely matchconstructed well models to reality, the com-pany says.

The software is designed to help wellcompletion and production engineers to con-figure, tune, analyse, design and build theirwell systems. It can also be used to modeland analyse electric submersible pumps, gaslift, and inflow / outflow. It can integratewith reservoir modelling software.

Statoil contracts IP network to Orangewww.orange-business.comStatoil has re-contracted Orange BusinessServices to build and manage its internation-al IP network, in a €9.3m contract covering3 years, 40 sites and 23 countries.

It includes both data and telephony, andincludes strict requirements for uptime andperformance.

Orange has been running Statoil’s ITnetwork since 1999 (previously as FranceTelecom). Statoil renewed the contract fol-lowing an open competition which manyother telecoms companies participated in.

SOIL expands to Houston www.oilcamp.comOil and gas communications company Oil-Camp has announced that it is extending itsSecure Oil Information Link (SOIL) serviceto Houston, connecting with the existingSOIL nodes in Stavanger and Aberdeen.

The service can be used for secure dataexchange.

OilCamp’s new parent company,RigNet, is helping it extend the service toHouston; RigNet is headquartered there.

CapRock works with Phoenicia in Libyawww.caprock.comOil and gas VSAT satellite communicationscompany CapRock has formed an alliancewith Libyan business consultancy PhoeniciaGroup. Phoenicia is the sole licensed privatesatellite Internet and telecommunicationsprovider in Libya.

The two companies will work togetherproviding VSAT services to the Libyan oiland gas industry, including VSAT terminalsoff and onshore, network monitoring, andtechnical support.

CorrOcean acquires Roxar www.roxar.comOil and gas monitoring technology companyCorrOcean of Trondheim, Norway, has ac-quired 100 per cent of oil and gas technolo-gy company Roxar of Stavanger, at a priceof NOK 2220m (USD $369m).

Calling the deal an acquisition by Cor-rOcean is perhaps misleading - since beforethe deal CorrOcean had annual revenues ofNOK 152m ($25.3m) compared to Roxar’sNOK 946m ($157m). The acquisition struc-ture is understood to be a method of bring-ing both companies into private hands.

CorrOcean sees itself as the marketleader in subsea sand monitoring, and it seesRoxar as the market leader in subsea multi-phase and wetgas metering, and as such, be-lieves the two companies will make a goodstrategic fit.

AutoTrak used on 11,282m Exxon well www.bakerhughes.comBakerHughes INTEQ reports that its Auto-Trak drilling system has been used on thelongest well in the world according to meas-ured depth (length of the well).

The well, located on Sakhalin-1 (off theEast Coast of Russia), is 11,282m long, andwas drilled by ExxonMobil. It will be oper-ated by Exxon Neftegas Ltd (ENL).

AutoTrak is a complete electronics sys-tem for drilling, including measuring whiledrilling, logging while drilling, and drillbitdirection control.

Qinetiq’s in-well gravity gradiometer www.qinetiq.comUK defence and security technology compa-ny QinetiQ is developing a 3D gravity sen-sor called Scorpius which will work at thebottom of oil and gas wells, anticipated to beready for deployment in 2008.

It will measure changes in gravity overtime and distance, which can help indicatewhere hydrocarbons are and how fast theyare being drained.

It has been given a contract to developthe sensor by Gravitec Downhole Instru-ments Ltd, a joint venture between GravitecInstruments Ltd and Shell Technology Ven-tures Fund 1 BV (itself managed by KendaCapital BV).

The gravity sensor will be an adapta-tion of Gravitec’s gravity gradiometer foruse in oil and gas downhole. This gradiome-ter was considered the only one which wassmall enough and sensitive enough to workat the bottom of wells.

QinetiQ envisages that if the gradiome-ter works successfully, it should provide animpetus for further development of the sen-sor for static surface monitoring of reservoirsand airborne surveying.

Input/Output permanent subseamonitoring venturewww.i-o.comInput Output has formed a joint venture withHydro Technology Ventures (part of oil andgas company Hydro) and Reservoir Innova-tion AS to develop permanent subsea fullwave seismic monitoring systems.

The system will enable geoscientists tosee how the seismic response changesover time (4D seismic).

Sign up to our free e-mail newsletter atwww.d-e-j.com for the latest news in your inbox every monday

layout1.qxp 23/08/2007 13:18 Page 4

layout1.qxp 23/08/2007 13:20 Page 5

digital energy journal - September - October 20076

News update Subsurface

It will be possible to use the software forlarge scale, basin exploration activities, evenin areas as large as half of Russia.

Altogether, the software will be forbasin modelling, seismic processing / mod-elling, seismic prestack analysis, and strati-graphic (rock layer) modelling.

Statoil will use the software, and Land-mark will have rights to resell it to other oiland gas companies. The software develop-ment will last 3 years.

Statoil is keen to reach what it describesas a ‘distinctive exploration technology po-sition,’ being able to do things with explo-ration technology better than other compa-nies.

John Reidar Granli, vice president ofexploration research and development forStatoil, says that the software tool should bea catalyst for helping the company developnew workflows (ways for people to work to-gether).

At the moment, Statoil has specialistsin areas such as gravity magnetics, seismicprocessing, seismic modeling, seismic depth

conversion, seabed logging, structural mod-eling, hydrocarbon maturation / migration,geochemistry and source rock models.

Helping them work together better willenable Statoil to get more out of their expert-ise, he says. It will also make remote collab-oration work better. “It is about de-siloingthe way we work,” he says.

Mr Reidar Granli believes that the newsoftware should make it more intuitive forpeople to find the data they want, and also itwill make it easier to integrate geophysical

data with other data, which he calls the ‘con-ceptual stuff’.

It should also stimulate more interac-tion between specialists and operational peo-ple.

“This will provide us with a toolbox tobetter integrate geophysical data,” he says.By looking at the basin as a whole, they willbe able to factor in knowledge about the en-tire basin and how it was formed, and howtemperature and porosity varies across it, hesays.

Ultimately it will provide a better “fi-nal outcome on business resources and risk,”he says. “We’re driving exploration technol-ogy to new heights.”

The software will be built using Land-mark’s DecisionSpace software framework.DecisionSpace can be used to run many dif-ferent software applications and databasesside by side. This is the “most ambitious useof DecisionSpace to date,” says Chris Usher,senior director of Decisionspace and inno-vative technologies at Landmark.

Statoil has been working with Land-mark for many years, and they have also col-laborated on developing a pre-stack interpre-tation tool. Landmark has done similar jointsoftware development projects with BP andConocoPhillips.

However Landmark says this is thelargest single joint project it has ever done.

“Landmark has a rich history of collab-oration with Statoil,” says Peter Bernard,senior vice president of business develop-ment and marketing with Halliburton.

Landmark will set up ‘rich dedicatedteams’ to focus on different areas of the soft-ware development, he says.

LandmarkLandmark sees developing basin-wide soft-ware as a gap in the market.

It hopes that the software will becomeas much an industry standard for basin-widemodeling as Schlumberger’s Petrel is forreservoir modeling.

[Basin modeling] “is a part of the work-flow that’s never really benefited from inte-grated software,” says Mr Usher.

“We believe a basin scale system hasbeen neglected. We thought - there’s a mar-

Statoil and Landmark - $13m 'basinscale' software development projectIn possibly the largest ever joint software development deals in the oil and gas industry, Statoil andLandmark have agreed to work together on a $13m project (investing $6.5m each) to develop newsoftware which can be used to model entire basins, not just reservoirs

ket that’s waiting.”Landmark is very pleased to be able to

develop its software working so closely withStatoil. “They’ll give you access to peoplein a focused way,” he says. “You have ahuge user base.”

However Landmark will not specifi-cally develop the software for Statoil’sneeds; it will have one eye on Statoil and theother eye on selling it in the open market toother customers.

Statoil will get a significant commer-cial advantage from being so involved in thesoftware at its early stages, Mr Usher says.“They will get a user base faster than every-body else.”

A basin model is essentially a reservoirmodel which is much larger and more com-plex. “We see there’s a continuum betweenreservoir scale and basin scale models. Atthe heart of it will be the same stuff,” MrUsher says.

However the basin simulator reveals alot more about how the oil has migratedover time, which is a very important factorin building up the overall picture. “So it’s alittle bit different,” he says.

Landmark expands services businessMeanwhile Landmark is on a move to getinto more services businesses and consult-ing.

The underlying philosophy is some-thing like this: Landmark will offer serviceslooking after oil companies’ ‘digital assets’,equivalent to the services its parent compa-ny, Halliburton, offers, to look after theirphysical assets.

“We’re thinking about Landmark nowholistically at the asset level, and being ableto produce the asset in real time,” says JorgeEstrada,

Landmark regional general managerEurope-Eurasia at Halliburton.

“We’re doing integrated reservoir stud-ies - helping them produce the reservoirsfaster,” he says. “We’re integrating from thereservoir to the production facility.”

It has also established a line sellinghardware, distributing systems from Dell,Sun and HP, to help its customers optimisetheir system.

“The most ambitious use of DecisionSpace todate” - Chris Usher, senior director ofDecisionspace and innovative technologiesat Landmark

layout1.qxp 23/08/2007 13:20 Page 6

layout1.qxp 23/08/2007 13:20 Page 7

digital energy journal - September - October 20078

News update

Offshore Europe, held this year in Aberdeenon Sept 4-7, is one of the world’s largest oiland gas exhibition and conferences with ananticipated 32,000 attendees and 1400 ex-hibitors.

Speakers in the plenary session will in-clude Malcolm Brinded, executive directorE&P with Shell; David Lesar, president andCEO, Halliburton; Robert Olsen, chairmanand production director, ExxonMobil; andFrank Chapman, chief executive of BGGroup.

Technical papers which might be of in-terest to Digital Energy Journal readers in-clude using artificial intelligence to predictthe relative permeability of carbonate reser-voirs (Saudi Aramco); reservoir historymatching (Scandpower); surveillance of theDraugen Field (Shell); using geochemicalfingerprinting for production allocation in asubsea tieback (Shell), cradle to grave fieldmaintenance (BP); surveillance and loggingfor brownfield optimisation (Shell / Schlum-berger); powered rotary steerable drilling(Schlumberger / Nexen).

In the exhibition, there will be a special‘Intelligent Energy’ Zone with exhibitorswith new IT products.

This is our preview of some of the ex-citing IT and comms technology on display.

Aclaro Softworkswww.aclaro.comAclaro Softworks will exhibit its enterprisebusiness solutions for the petroleum indus-

try, including tools for common data naviga-tion, data integration, analysis, charting andreporting, reserves reporting, budgeting,planning, capital allocation, financial report-ing and performance monitoring.

Aclaro has offices in Houston and Cal-gary and over 50 clients in North and SouthAmerica, Europe, and Africa, from small in-dependent to super-major.Stand 1650 - Intelligent Energy Zone

AVEVAwww.aveva.comEngineering IT company AVEVA will launchits AVEVA PDMS 12 three dimensionalplant design software software at OffshoreEurope.

The software is designed to help differ-ent project teams work together on the samedesign, even if they are in different places.

Aveva oil and gas clients include AkerKvaerner, BP, Chevron, CNOOC OffshoreOil Engineering, ExxonMobil, Petrofac, Sin-gle Buoy Moorings and Shell.Stand 1351

Caprockwww.caprock.comSatellite communications company Caprockwill exhibit its desktop videoconferencingequipment, enabling clients to hold videoconferences over satellite links from theirdesktop, using IP connectivity. Stand 715

Deloittewww.deloitte.comDeloitte will exhibit its digital oilfield offer-ings, in particular its Advanced Collabora-tive Environments to enable experts to worktogether remotely.

It has assisted BP to re-organise its on-shore operations, to provide real time sup-port to its offshore assets.Stand 1601 - Intelligent Energy Zone

Diamouldwww.diamould.comDiamould will exhibit its electrical, fibre op-tic and hydraulic connectors for subsea anddownhole environments.

Items on show include medium andhigh-power ROV-mateable connectors andumbilical cable terminations. Stand 1231

Energy Institute / Energyzonewww.energyinst.org.ukThe Energy Institute will exhibit Energy-zone, an online service developed togetherwith Total to help young people learn moreabout careers in the energy industry, includ-ing oil and gas and renewable energy.

It will explain the different economic,technical, scientific and political careersavailable.Stand 1568

eProduction Solutions / Weatherfordwww.eproductionsolutions.comeProduction Solutions will exhibit its laserwater cut meter, Red Eye 2G which canmeasure the range of oil and water concen-tration in a commingled stream, by examin-ing how well the fluid absorbs infra red light.It can work for any oil water mixture (0 to100 per cent water).

It replaces the company’s previous RedEye Water-Cut Meter, which worked well athigh water cut levels, but not so well at low-er water cut levels.

The 2G model can take lower water cutmeasurements because it can simultaneouslymeasure multiple wavelengths that includeboth water and oil absorbent peaks.

It will also exhibit its multiphase me-tering solution, and control panels.Stand 46

Offshore Europe preview3D offshore training simulators and a chance to compare your ROV flying skills with the professionals -some of the things you’ll find at this year’s Offshore Europe exhibition in Aberdeen

32,000 people are expected at this year’s Offshore Europe in Aberdeen. Picture taken 2005

layout1.qxp 23/08/2007 13:21 Page 8

September - October 2007 - digital energy journal 9

News update

ExtronicsUK supplier of intrinsically safe and explo-sion proof equipment Extronics will exhibitits USB digital camera for use in hazardousareas (right),which the com-pany believes isthe smallest de-vice of its kindon the market.

It is de-signed to beuseful for sitesurveys, acci-dent reports andmaintenance re-porting, becauseit can be easilycarried in thepocket.

The cam-era is certified for use in Zone 1 hazardousareas, and can take 2.0 megapixel images. Ithas a 256 mb storage capacity (400 pictures).It weighs 50g.

Extronics will also exhibit its data log-ger, which can work in a hazardous environ-ment powered by a battery, and upload datato a central server wirelessly, using GSM orGPRS. It has a battery life of around 3 years.It has three analogue inputs and three digitalinputs.

It will also exhibit its wireless commu-nications technology, which can communi-cate using 802.11 protocol.Stand 890

Flir Systemswww.flir.comFlir Systems will exhibit its thermal imagingcameras, which can be used to spot problemsin oil and gas equipment. It will show itsGasFind infra red gas leak detector (see be-low) which can detect gas leaks much fasterthan with traditional methods, the companysays. It can detect small leaks from severalmetres away and big leaks from hundreds ofmetres away, and scan over 3,000 processconnections per hour.

It will also exhibit its ThermaCAM

p640 heat camera, which has a 640 x 320pixel detector, giving an image resolutionfour times bigger than the standard 320 x240 model. This means the operator cantake a picture twice as far away without anyloss of accuracy.Stand 1243

General Roboticswww.generalrobotics.co.ukUK subsea simulator company General Ro-botics will launch two new products at Off-shore Europe, a visualisation module and alive data module.

The visualisation module will allowfast animation and clash checking.

The live data module provides realtime monitoring and 3D visualisation of off-shore equipment, using data from live datafeeds.

At its stand, you will be able to watchsubsea equipment in action, using real datafrom vessels working offshore.

Visitors to the stand will be able to try

flying a remote operated vehicle (ROV)themselves (see above). There will be a dai-ly prize and certificate for the pilot whoshows the best natural talent at a simulatedmission.

Professional ROV pilots will also beable to compete but for a separate prize.Stand 839

HRH Geological Serviceswww.hrhgeology.comHRH Geological Services will exhibit itsGravitas Software System, launched in2006, which can be used to gather well in-formation in a central database in real time,so that users can create reports, charts andlogs.

It will also exhibit its new HRHGeostream Service, where HRH employstrained geologists on the rig to interpret the

Gravitas data, and send their interpretationsback to the oil company operations geologiston shore.Stand 215

ICS Triplexwww.icstriplex.comAutomation company ICS Triplex willlaunch a new safety control system, designedto offer greater levels of choice and flexibil-ity.

It is the result of many years of researchto develop the shortcomings of existing safe-ty and control systems, the company says.

ICS Triplex will have a restaurant at itsstand, where visitors can meet celebrity chefAntony Worrall Thompson.Stand E4

It Buddies Ltdwww.itbltd.co.uk IT Buddies Ltd of Aberdeen will present itsautomatic risk assessment software for man-ual handling tasks, developed together withBP.

BP has been using the system on its off-shore platforms since 2006.

The software meets government regu-lations for risk assessment, and can replacepaper based systems. The software can alsobe used to share best practises around thecompany, and have an auditable trail that thishas been done.

The company also provides competen-cy systems support, general skills trainingand IT skills training.Stand 1138

Lios Technologywww.lios-tech.comLIOS Technology will exhibit its permanentdownhole temperature monitoring (DTS,Distributed Temperature Sensing) and com-munications system.

In the well, LIOS installs a fibre optictemperature monitor, which can be more re-liable and cheaper than conventional elec-tronic temperature monitoring systems.

Data can be communicated to the officeusing a variety of different data protocols,including DNP3, IEC60870-5, WITSML,and Modbus (Master/Slave) protocols, andproprietary systems. It can communicatewith SCADA systems and talk to differentsystems at the same time.

There is a data storage unit, which au-tomatically stores data if the communicationlink is broken. It can store 72 hours of data.Once the link is re-established, the commu-

Practise flying a remote operated vehicleusing General Robotics’ simulator

layout1.qxp 23/08/2007 13:22 Page 9

10 digital energy journal - September - October 2007

Oil and gas operations

nication automatically restarts. Stand 1493 G -German Pavilion

Phenomaticswww.phenomatics.comPhenomatics of Austria will launch its virtu-al reality training simulator (shown below),

which can be used to put trainees in chal-lenging situations they might encounter onan offshore oil installation, so they can prac-tise how to deal with them, so they are pre-pared if they encounter the same situation inreal life.

Phenomatics has created a virtual off-shore scenario, and a virtual refinery, whichpeople can try out.

Uses wear 3D goggles - they have a dif-ferent picture for each eye, so the user seesthings in three dimensions, and can feel likehe/she is actually inside the facility, not justviewing it on a screen.

The system is already used as part ofregular training at a refinery in Schwechat,Austria.Stand 1431

PiSYSwww.pisys.co.ukAberdeen company PiSYS will exhibit itsmultipurpose training simulator for the oiland gas industry.

The simulator is used widely in theNorth Sea and elsewhere around the worldfor training control room operators and Off-shore Installation Managers (OIMs), helpingthem experience a variety of different reallife emergencies without any actual risk tolife or equipment.

The company recently delivered one ofits largest systems to SENAI Brazil andPetrobras, to train rig and FPSO controlroom operators, with a system which puts thetrainee inside a control room mounted on amoving platform, so the trainee can feel themovement from wind and sea, collisions, vi-brations, temperature changes and commu-nication systems.Stand 215

[email protected] will launch its computer aideddesign (CAD) / project management tool forcompletion engineering and management. Itwill help create multi-lateral and multi-zonedesigns. The software enables effective andco-ordinated collaborative working, includ-ing engineering, accounting, procurementand management personnel.

There are also completion specific 2Dand 3D CAD design tools and drag, fluid dy-namics and nodal analysis models.

The software is designed by completionengineers & project managers, for comple-tion engineers, the company says, and aimsto remove the frustrations and inefficienciesof working with the many uncoordinatedsoftware packages that are currently requiredto design a complex modern completion sys-tem.Stand 1625 - Intelligent Energy Zone

RoxarSoftware and metering company Roxar willdemonstrate what it can do having recentlyjoined forces with Norwegian monitoringequipment company CorrOcean.

The combined company has 800 staffand 28 offices, with expected turnover of$180m. It claims to be the world’s largestprovider of subsea instrumentation to the oiland gas industry.

At Offshore Europe Roxar will exhibitits subsea multiphase meter. It recently se-cured a US patent for the meter’s subsea re-trievable canister, following extensive test-ing with ExxonMobil. If the electronics failthey can be easily replaced, without replac-ing the entire meter.

Roxar will demonstrate its oil in watermonitor, which can provide informationabout the amount of sand and oil in water,using ultrasonic pulse echoes. This monitoris used on Statoil’s Sleipner A North Seaplatform to monitor overboard discharge.

CorrOcean will exhibit its subsea pres-sure and temperature sensors. CorrOceanproduces silicon piezoresistive sensorswhich can measure pressure and temperaturefrom the same measurement bridge.Stand 940

Sensornetwww.sensornet.co.ukSensornet will exhibit its Digital Flow Pro-filing solution which can be used to monitorthe flow distribution in production and in-jection wells in real time.

The permanently installed Pseudo PLTsystem is particularly useful when monitor-ing the affect of changes to production andinjection.

It can provide information which is of-ten not accessible when using productionlogging technology, the company says.

Sensornet will also exhibit its forth-coming Oryx DTS (Distributed TemperatureSensor). This compact surface monitoringunit has a low power consumption and worksin a wide temperature range, so it can beused in harsh environments. Stand 1615 - Intelligent Energy Zone

SpecTecwww.spectec.netSpecTec will exhibit its AMOS BusinessSuite management software for oil and gasassets, with modules for maintenance man-agement, asset control, spare parts control,purchasing, budget, documentation control,procedures control and staff management.

The software is installed in over 600 oiland gas sites, including Italy, Norway, Rus-sia, Libya Nigeria, Congo, Kazakhstan, Aus-tralia, China. Oil and gas customers includeSaipem, AGIP, SBM, Western Petroleum,Upstream Petroleum, BP, NGSCO, NYKand Bergesen. SpecTec has 23 offices in 18countries.Stand 894

Spotfirewww.spotfire.comSpotfire will exhibit its DecisionSite enter-prise analytics software, which can be usedto analyse oil company data.

The software can display the results vi-sually, so they can be immediately under-stood.

The software can be used in many as-pects of E&P business.

Typical areas the software might beused include seismic acquisition design, loganalysis, attribute analysis, 4D trends, basinmodeling, petrophysical and core analyses,reservoir engineering, production optimisa-tion, lost time drilling production analysis,supply chain, contractor performance, QHSEStand 1631 - Intelligent Energy Zone

Well Dynamicswww.welldynamics.comWell Dynamics plans to celebrate the 10thanniversary of intelligent well completionsat Offshore Europe, a technology the com-pany claims to have introduced. It will haveanniversary cake at its stand.

It will exhibit its broad complement ofintelligent well products and services, thatrange from reservoir engineering studies toadvanced completion design, zonal isolationand flow control, reservoir monitoring andsurface digital infrastructure - and of courseits seasoned, professional team.Stand 1605

layout1.qxp 23/08/2007 13:22 Page 10

11September - October 2007- digital energy journal

layout1.qxp 17/08/2007 14:33 Page 11

12 digital energy journal - September -

Oil and gas operations

The first FireFlysurvey for BPwas in the plainsof south-centralWyoming, a no-toriously chal-lenging area forexploration andproduction.What are thechallenges facedwhen planning aland seismic sur-vey in this typeof geographicalregion?The Wamsutter field is in an area which isboth environmentally sensitive and archeo-logically significant, so seismic crews areconstrained in the areas in which they canoperate and the manner in which they do so.

Using traditional seismic methods,these 'no-go' areas can lead to the data qual-ity being compromised through an inabilityto access the land in order to deploy sensorsand their associated cables.

Why is cableless technology able to reduceenvironmental impact on seismic surveys onland?By eliminating the cables, we reduce thenumber of people and vehicles that need toaccess the land.

Crews are able to operate in what weterm a "one-touch" mode - once the stationhas been deployed, we only need to return toit one more time, when we pick it up to har-vest the data.

We've eliminated the need for conven-tional surveying, which often requires sur-vey crews to visit the station location morethan once, along with the associated surveymaterials, stakes and flagging, all of whichneeds to be picked up again after the survey.

We spoke to Paul Brettwood, director for FireFly solutions at Input Output, about the first field use of InputOutput's FireFly wireless land seismic technology in Wyoming and Texas, for BP and Apache

Wireless seismic on land - Fireflyabout 235 km2 with around 4,500 shots andan active receiver template of 3,456 three-component receivers. Data from this surveyis still in the early stages of pre-processingbut the initial comments are that the qualityis good with good signal-to-noise ratio.

Can you describe to me how the FireFly'sreal-time surveying works? The source and receiver X /Y coordinatesfrom the initial survey design are loaded in-to the handheld NavTools, (which are essen-tially PocketPC's with integrated GPS re-ceivers), and the layout crews are directedto the precise location where they need todeploy a sensor.

Once the sensor is on the ground, aGPS reading is taken. In this way, the actualX/Y location of the sensor is recorded, ratherthan where it is supposed to be.

At Wamsutter, BP flew a LIDAR [lightdetection and ranging] survey over the proj-ect area, providing a very accurate elevationmodel. Combining this elevation data withthe actual X/Y locations from the GPS read-ing at the sensor allows us to accurately lo-cate the sensor location in 3D space, with-out needing a lot of conventional surveying.

Furthermore, these X/Y/Z coordinatesare combined with the actual seismic dataduring acquisition, saving time and effortand improving accuracy in the processingstage that follows.

How much does FireFly save compared to acable system?As a general rule, cables make up as muchas 80 per cent of the weight of a convention-al system, so eliminating them directly con-tributes to reducing the transportation andmobilisation costs of a seismic crew.

There are also time savings with thissystem: BP saw a reduction of 50 per centin both layout and pickup times at Wamsut-ter based on their previous experience withcable-based systems in the region.

The actual shooting phase showed aneven greater efficiency gain: 10-days withFireFly versus 50-days for a cable system.

Are you planning more commercial tests forFireFly and when are you planning to com-mercialise this technology?Now that the Apache test has been complet-ed, we will be starting to plan the next BPsurvey. We are on-track to bring out the firstcommercial system during Q3 of 2007.

Paul Brettwood,director for Fireflysolutions at InputOutput.

What are the main technological benefits ofFireFly?Perhaps the key one is the scalability of thesystem in terms of the number of stationsthat can be deployed.

Cable-based systems suffer as the sta-tion count goes up, because of the numberof cables involved and the associated weightand telemetry problems. FireFly overcomesthese problems by eliminating cables.

Alongside this is the introduction ofwhat we term an ecosystem of supportingtechnologies which include navigation andpositioning, power-management and dataquality control.

Together with new survey design andprocessing technologies which leverage thedenser image sampling, these technologiesresult in fewer people being used to deploythe system (thereby reducing cost and health,safety and environmental exposure), elimi-nating conventional surveying and guaran-teeing data integrity, which in turn reducesthe effort required in the processing centre.These factors significantly reduce the totalcycle-time of a given project.

How much data was acquired in the two sur-veys? Do you have any results on the quali-ty of the data acquired? The Wamsutter survey area covered about72 km2 and comprised 7,200 shots intoabout 8,500 three-component digital sensors.This gave a dataset with between 5 and 24-times the fold coverage than all the other sur-veys in the area. BP reports that the initialresults of the fast-track processing are veryencouraging. Whilst the survey was shot pri-marily to record better P-wave data, the con-verted-wave data looks very good.

The Apache Upshur survey covered

Installing FireFly wireless seismic devicesWireless seismic units which fit in a backpack- await deployment

layout1.qxp 23/08/2007 13:24 Page 12

13September - October 2007- digital energy journal

Oil and gas operations

Merrick Systems of Houston has developedan innovative software tool which can bringdata from different data sources and softwareapplications and put it on one screen.

It has been called “One VirtualSource,” a reference to the way it can makedata from different sources look like it allcomes from the same source.

The tool was developed by Jose Al-varez, now CTO of Merrick, who was work-ing on the project for three years as his ownprivate project before joining the company.

The company claims that it can workwith almost any data source or software. Itdoes not disturb or duplicate the data fromany existing systems or applications, anddoes not need any modifications to the ex-isting infrastructure.

The data analysis tools present in thevarious software packages can still be used,even if they are analysing data from a differ-ent software package.

Customers are using it to visualise largeamounts of data, and streamline and auto-mate engineering workflows.

The system has been used for work-flows including model based real time opti-misation of an offshore platform; unattendedsurveillance by exception; assisted wellboreand production network modelling; produc-tion deferment tracking; model based pro-duction test validation; and multi-variate op-portunity rankings.

One popular use is for generating “elec-tronic well files” (see image). These are re-ports containing all of the relevant informa-tion about the well, including petrophysical,production, and pressure data, as well asrecorded events, hyperlinks to external doc-uments, logs, Excel spreadsheets, and mod-els.

If additional information is requiredfrom any of the underlying applications, hy-perlinks also provide the capability to launchany of these applications in context.

All of these workflows were developedat a customers’ site, to comply with the op-erator’s specified best practices.

So far Merrick has conducted three pi-lots for major and international oil compa-nies, in some of the largest fields in theworld.

“We respect whatever the company isusing in terms of databases and applica-tions,” says Philippe Flichy, vice president

of business development with Merrick. “Weare only providing the glue between them.”

“We’re creating a kind of window intodifferent data sources and software applica-tions at once.”

RFIDA second new Merrick product line is fittingRFID (radio frequency identification) tagsonto oil and gas equipment in order to knowwhere your equipment is at all times, what itis, how it is used and how you can make bet-ter use of it.

It provides primary data capture ofcomponents used while drilling wells and in-terfaces to 3rd party visualization and engi-neering optimisation applications. It savestime on drilling rigs while reducing risk andextending drilling capabilities.

The flagship rig-site application iscalled ‘Rig-Hand’ and is led by a drilling ex-pert on Merrick’s staff, Ian Binmore.

Merrick’s RFID tags are the onlyproven tags able to withstand the harsh con-ditions downhole; including high heat, vibra-tion and pressure.

Basic information about the downholecomponents used are typically still trackedtoday by pencil and paper, a time consuming

and error prone approach that frequentlycauses serious problems to drilling opera-tions.

Many times service companies and op-erators do not even accurately known wherevaluable components are located when theyare sudden. Rig-Hand and Tool-Hand RFIDsystems will greatly benefit both servicecompanies and operators to maximise theuse of their assets.

Primary physical information aboutpipe, such as dimensions, strength, and loca-tion in the drillstring can also be combinedtogether with other data, for example, thewellbore geometry or the fluids used to drillthe well, the hook load and pipe rotationspeed.

This enables numerous sophisticatedengineering optimisations to take place innear real-time, extending the capabilities ofdrilling and reducing costs.

Rig-Hand may even be able to reducethe number of very expensive catastrophicdrill string failures that occur too, becauseyou can record how much stress the pipe hasbeen under for all the different times it hasbeen used. This enables operators to proac-tively recognise at what point a componentis more likely fail inside the well.

Merrick’s data and RFID toolsMerrick Systems of Houston has developed two tools, one to bring data from different software packagesonto the same screen, and another to manage surface and downhole equipment using RFID

Merrick’s software can draw “Electronic well files” - reports containing all of the relevantinformation about the well, including petrophysical, production, and pressure data, as well asrecorded events, hyperlinks to external documents, logs, Excel spreadsheets, and models.drawing data from different software packages

layout1.qxp 23/08/2007 13:24 Page 13

14 digital energy journal - September - October 2007

Oil and gas operations

Future Fields conference report

Eric Heijnsbroek, TAQA

Eric Heijnsbroek, director of Abu Dhabi Na-tional Energy Company (“TAQA”)’s Sea-horse Project, spoke at IQPC’s Future Fieldsconference about his experience using digi-tal oilfield tools on TAQA’s exploration andproduction assets in the Netherlands.

The digital oilfield was actually begunwhile the assets were in the hands of theirprevious owners, BP. They were sold toTAQA in early 2007.

Production at the field is very much indecline; in fact TAQA was more interestedin buying BP Nederland’s storage terminalsthan its offshore operations, because it want-ed to build up its position as a storage termi-nal operator.

However TAQA is continuing BP’s ef-forts to try to use digital oilfield techniquesto get as much out of the fields as possible.

TAQA now reckons that its digitaloilfield efforts are earning Eur 500,000 peryear by increased production.

It has already managed to bring manyoffshore personnel to work in shore offices.This enables them to have a much betterhome life, and work standard 8 hour shiftsinstead of the 12 hour shifts normal on off-shore oil platforms.

This has allowed many personnel tostart building up a normal social life. Theidea of having a social life when you areworking 12 hour shifts offshore is a myth,Mr Heijnsbroek said; you are rarely able togo out in the evening the same time as your

friends want to. The field was operated by 100 staff; so

far the number has been reduced by 5, al-though the company believes it may be pos-sible to reduce it by 12.

In the onshore collaboration centre, ithas a team of 6 staff from offshore, 3 staffwith onshore, and 1 external person. Theywork onshore and offshore in rotation. Whenthey are onshore, they work 8 hour shifts;when they work offshore, they work 2 weekson and 3 weeks off.

Tactics for encouraging staff to use col-laboration centres included concentrating onthe things which staff would like to get fromit, not the things they don’t like; and alsoworking first of all with staff you think willlike using the centre, not staff you think willhate it.

Mr Heijnsbroek stressed the impor-tance of being very sensitive when you aretalking about demanning anything. Compa-nies often use the word ‘demanning’ whenthey mean moving people from offshore jobsto shore jobs, but employees may not recog-nise this.

“If you say the ‘demanning’ word,some people start to detest everything youdo,” he said. “Demanning is terrible is some-one loses his job, but great if he gets a betterjob he can enjoy.”

BP Netherlands first started thinkingabout remote operations after its experiencetrying to bring an asset manager into the of-fice, Mr Heijnsbroek explained. The manag-er had managed to wire up the platforms sohe could control them from his laptop. Thisled BP thinking, why don’t we do everythingthis way, so we don’t need so many staff onthe rigs?

One important step has been to stream-line the alarms, and make sure the unneces-sary alarms are deactivated, he said.

Mr Heijnsbroek said that people hadasked him why he was putting so much ef-fort into making it possible for staff to man-age production platforms onshore. “Peoplesaid to me, why are you doing this, youcould just do your job for 2 years and getpromoted. Why take this additional step?”

Ronald CramerRonald Cramer, senior advisor, Shell GlobalSolutions US Inc. in Houston, presented a

picture of the benefits that digital oilfieldtools can provide, from a safety, surveillanceand optimization point of view.

“For me the biggest benefit is technicalintegrity,” he said. “If real time informationcan be used to spot something untoward intime to pre-empt a major incident, the sav-ings in human exposure to risk and equip-ment damage may be incalculable.”

Mr. Cramer suggested that the data inmonitoring systems should be regularly re-viewed for near misses, rather than only ex-amining the evidence after an accident hasactually occurred. It is not uncommon in in-cident investigations, to discover that therewas data available which could have enabledoperators to detect something was goingwrong and to have taken action to preventthe accident.

Productivity benefits are also interest-ing. “If you can find out about a problemsooner and fix it sooner, you’re getting moreoil,” he said.

The extent of production increase byeffective use of real time data correlates toprior production efficiency – application toefficient operations results in modest gains,application to less efficient operations canresult in very significant gains.

It is important to let users articulate theproblems they are having, be clear exactlywhat problems they are trying to solve, andthen work out precisely where automationcan contribute to the problem, and build sys-tems accordingly, he said.

A common mistake is to “bite-off morethan you can chew”, on the assumption that

IQPC's Future Fields conference in London in May 2007 covered how digital oilfield techniques canimprove surveillance, leading to improved safety; it looked at how systems can be successfully integratedin smaller fields, and the kind of things which often go wrong with digital oilfield installations

Helping rig personnel to start building asocial life - Eric Heijnsbroek, director of AbuDhabi National Energy Company (“TAQA”)’sSeahorse Project

Real time information could prevent amajor incident - Ronald Cramer, senioradvisor, Shell Global Solutions

layout1.qxp 23/08/2007 13:25 Page 14

layout1.qxp 23/08/2007 13:26 Page 15

16 digital energy journal - September - October 2007

Oil and gas operations

MODELING SIMULATION WELL & COMPLETIONINTERPRETATION PRODUCTION & PROCESS www.roxar.com

UNCERTAINTY

flows guide users through process activities,requesting user decisions (eg approve / donot approve) and triggers actions, he said.

It is important to consider carefullywhether it is worthwhile building a guidedworkflow tool.

Mr Milligan suggests that they workwell for repeated processes which involveseveral members of staff; and the processesdo not have to be one day long, they can beas long as a year long.

Building guided workflows can be par-ticularly good for document management, hesaid.

One potential pitfall is overkill onworkflow. “Don’t guide people through theireveryday work,” he said. “You don’t need toprescribe every action of every day.”

Guided workflow does not work wellin intense data analysis, and monitoring realtime data. “Surveillance does not need guid-ed workflow,” he said.

Mr Milligan cautioned against keepingprocesses too rigid. “You don’t always knowwhat the process needs will be, or where it’sgoing to end up at,” he said.

Mr Milligan also suggested that youshould see the process as a gradual transfor-mation, rather than change the way the en-tire company operates.

“It’s better to roll out the entire process

workflow tools for the oil and gas industry.Most of us are familiar by now with a

guided workflow tool - like when we booktickets on the internet or apply for a loan, thesoftware takes us through a series of stepswhile we answer questions and input details.

All the time, the software is connectingwith other databases; for example a userdatabase which has information about us;different databases of what flights are avail-able; and the bank database which tells thesystem if we have money in our account.

Most of the time we are using work-flow software we are not really aware of it(we just think about the form we are fillingin), and this is very important, Mr Milligansays. “If the user doesn’t know its guidedworkflow, we’ve done our job well.”

In the oil and gas industry, the work-

the more you have the better it will be. “Peo-ple sometimes don’t spend enough time dis-tilling and refining the basic requirements,”he said.

It is also important to maximise thecommodity and minimise the specialty.Keeping the specialist stuff to a minimumreduces cost and implementation time. Andif you can’t measure something, rememberthat you may be able to estimate it, he said.

During his talk, Mr Cramer led effortsto establish a joint industry/academia forumto establish safety and technical integritystandards/benchmarks in digital oil field ap-plications.

Greg Milligan, SAIC Greg Milligan, senior consultant with SAIC,spoke about how his company is developing

Attentive delegates at IQPC's Future Fields conference in London in May

layout1.qxp 23/08/2007 13:26 Page 16

It has been dormant for 22 years. Thefield was previously drilled by Occidental,but 22 years ago they did not have access totoday’s seismic technology, and did not hitany of the reservoirs.

However Addax managed to produce it,with first oil on March 2nd 2005 and maxi-mum production since then of 43,800 barrelsof oil per day.

Addax made use of the best availablemodern tools. It began by doing a 3D seis-mic survey, and put together a 3D model us-ing Petrel.

One problem was that the Nigeria oiland gas authorities have not approved oilproduction from different reservoirs beingco-mingled, so Addax has installed slidingsleeves in its wells, which allow oil from in-dividual zones to be kept separate. The slid-ing sleeves an be remotely operated, toswitch production from different zones onand off.

The oil production is gathered in an FP-SO (floating production storage and offload-ing vessel), and the sliding sleeves are oper-ated from here.

Now Addax is experimenting with geo-chemical fingerprinting to identify howmuch of a multi-zone oil stream comes fromeach zone. “The authorities are yet to fullyaccept this technology,” he said.

On the FPSO, the oil and gas in pro-duction streams are separated, and the gas isre-injected.

Lee Cross, SAS Lee Cross, director of global energy practisewith software giant SAS, spoke about theidea of doing statistical analysis on data toidentify patterns. The beauty of this methodis that the computer does not need to haveany understanding of what the data means.

17September - October 2007- digital energy journal

Oil and gas operations

to a few select users then slowly add on usersas you feel more comfortable, adjust theprocess as you move forward,” he said.

SAIC is still managing all of the proj-ects it has implemented so far. “We have notyet handed over administration of the sys-tem to an oil company - we’re always twosteps away,” he said.

Guided workflows are particularlyhelpful for jobs where staff change positionregularly; they make it clear to people whatthey are expected to do.

“The tasks and processes we capturecan coach and help them on the job,” hesays. “It helps them work through what theyare supposed to be doing.”

A good workflow system can also givepeople tips when they are stuck, he said.

Prof Nikolaou, University of Houston

Dr. Michael Nikolaou, associate professorchemical engineering at the University ofHouston, said that the purpose of collabora-tive technology is letting users have all thedata they need at any time to make informeddecisions, and the components of this are da-ta acquisition, visualisation, data processing,decision making and decision implementa-tion, he said.

The benefits of doing this are that peo-ple can have a better social life, interact witheach other more, and you can make betteruse of a decreasing number of experts, hesaid.

The standard problem with collabora-tive technology is that it is driven by engi-neers, who love making changes; but sys-tems are used by operators, who hatechanges like nothing else.

The criteria for a successful adoptionof collaborative technology include “a will-ingness to take a risk, technical backbone, amix of short and long term business objec-

tives, time, visibility and measurement, in-volvement,” he said.

Real time does not necessarily mean ina split second. “It can be decade to decadeand still real time,” he said. “Optimising anentire operation is so complex and youcouldn’t do it second by second.”

Dr Nikolaou said that people should notfeel that they have to implement every pieceof new technology and encourage colleaguesto do the same. To illustrate his point, heasked conference delegates how many ofthem had upgraded their PCs to Vista (notincluding ones who had purchased a new PCwith Vista) and none of them had. “Doingnothing is an extremely competitive idea,”he said.

For example, at today’s technology lev-els, it may still be sensible not to opt for mul-tiphase flowmeters operating continuously,in every well. “People say - we do not havereliable multiphase flowmeters we can usein real time. They are expensive,” he said.“Most people measure multiphase flow oncea month.”

There are still plenty of unfulfilledpromises from technology, including that ex-pert systems will replace the need for ex-perts, and neural networks can learn any-thing.

Prof Nikolaou dismissed ideas thatpeople in the oil and gas industry are conser-vative. “People in oil and gas industry havea ‘can do’ attitude. They say, I want to makethis work. They may be risk adverse. Butthere’s reason to be risk adverse - you haveto make sure it works. Frankly I have onlypraise for the people in this industry,” hesaid.

Professor Nikolaou presented some ofthe experiences of the refining industry,which has been doing real time decisionmaking since the 1950s, although they took10 to 15 years before they could fully do re-al time optimisation. People originallyplanned to get all the available data anddump it into a huge computer, but then de-cided this was a bit too ambitious and lookedinstead for ways to split the problem intomanageable chunks.

Tony Ezealkum, Addax Petroleum Tony Ezealkum, asset manager with AddaxPetroleum in Nigeria, spoke about his expe-riences looking for technology to automateOkwori field, a relatively small field off-shore Nigeria.

The field is complex to produce, withover 100 small fault dip closures. The oil-field is 50km away from any other facilityand there is not a great deal of energy avail-able to drive recovery.

Tony Ezealkum, asset manager with AddaxPetroleum in Nigeria

Dr. Michael Nikolaou, associate professorchemical engineering at the University ofHouston

layout1.qxp 23/08/2007 13:27 Page 17

18 digital energy journal - September - October 2007

Oil and gas operations

The computer system builds up an un-derstanding of how the data behaves in nor-mal operation; if the data suddenly starts be-having differently to normal patterns a hu-man can be alerted that something might beup.

Pattern identification techniques havealready been used successfully in many dif-ferent arenas. For example, large investmentbanks continuously analyse share data tolook for patterns. If the data follows a knownpattern in the future, the bank can get a bet-ter idea of which prices are likely to go upand down as the pattern plays out, and invest/ sell accordingly.

Banks also use feed credit card trans-actions through this model, to see if thetransaction fits with the user’s usage pattern,and if it doesn’t, disallow the transaction.

The US Department of Defence usesthe software to try to predict what resourcesit will need for every soldier, by building uppatterns of what resources soldiers haveneeded in the past.

In the oil and gas industry, the systemhas been used by Shell to try to predict whena sanding is about to occur.

The software can analyse well data andlook for changes which typically occur be-fore a sanding. Then next time, when it spotsthe same changes happening, it can alert op-erators that a sanding is about to happen, socorrective action can be taken in time.

Stan de Vries, InvensysStan de Vries, director of industry solutionswith automation and software company In-vensys, spoke about some of the things he

has seen going wrong with digital oilfield in-stallations.

Having made over 170 flights during2006, mainly visiting Invensys digital oil-field installations, Mr de Vries believes heprobably knows more than many peopleabout what makes one good or bad.

The first indication of a poor digital oil-field installation is that it is not being used,

he said. There are plenty of digital oilfieldinstallations which have been installed andnever used, particularly in the North Sea.

The big killers of an investment in dig-ital oilfield are that the system is nottrustable, it isn’t effective, the results aren’teffectively measured, he said.

Many times companies put a lot of ef-fort into developing a system for one asset,and find it can’t easily be adopted in otherareas.

Often, staff are not trained how to usethe system. A good illustration of whatmight happen if people are given tools andnot trained to use them, is like giving chain-saws to lumberjacks for the first time. If theytry to use a chainsaw the same way as theyuse an axe, it doesn’t work and they end upunsatisfied.

Mr de Vries showed an image of peo-ple working in a collaboration centre, butthey were all looking at their own screens,as though they were still working in individ-ual offices. This indicates that the collabora-tion centre has failed, he said.

On the trust issue, Mr de Vries pointedout that if a gauge is only 70 percent reli-able, people will choose not to use it at all.“If you inflict something which people don’ttrust, it’s a failure,” he said.

“Many senior operators spend 40 percent of their time on phone and e-mail. Theysay, I don’t trust the data, but I trust you.”

Another pitfall is to try to enhance in-frastructure before enhancing a workflow.Mr de Vries cited one energy companywhich embarked on a project to implementSCADA across the whole company, andthen requested more funds to take advantageof the infrastructure. “They never got there,”he said.

As an example of a successful installa-tion, in Kazakhstan, oil company KPO im-plemented a real-time back allocation tech-nique, to try to estimate what the productionfrom individual wells was, from the totaloutput flow. “They found they sometimeshad manifold position errors wrong forweeks,” he said.

As another example of a successful in-stallation, Mr de Vries told a story of Total’s23 offshore oil platforms in the Netherlands,where everything is benchmarked, and allwork processes are managed using tem-plates, using safety engineering design.

The production is overseen by just oneperson.

“I wanted to see if one person couldhandle 23 platforms on collaboration cen-tres, and he was calm as anything,” he said.“They fundamentally improved HSE per-formance and improved business perform-ance. There is an enormously high degree of

trust.”Mr de Vries went on to talk about other

challenges the oil and gas industry faces. The median age of people entering the

oil and gas industry is 29; the median age ofpeople leaving the industry is 52. So oil andgas companies should focus on making surethat most day to day work is done by 29 yearolds, and the 52 year old people are workingon continuously improving the processes.

There are plenty further obstacles tosharing production information.

Some countries, including Russia, treatproduction data as a national secret, so thereare complex security rules preventing peo-ple from seeing it. In other countries, peo-ple’s need to see production information canbe considered linked to race, gender and age.

When it comes to preventing accidents,the important thing is to enable people tohave a good understanding of the evolvingconditions. “When people say observe, ori-ent, decide and act, the emphasis is on ori-ent,” he said.

“In many cases, the information is com-ing at them too slowly for them to realisewhat is happening. There are a number ofslowly evolving events. There has to be amuch better way to handle slowly and quiet-ly evolving events.”

Dene Vanstone, Scandpower Dene Vanstone, senior consultant with SPTGroup, talked about his company’s imple-mentation of its e-field Dynamic ProductionManagement (EDPM) on the Na Kika fieldin the Gulf of Mexico, run jointly by BP andShell. The Scandpower software creates a re-al time computer simulation of how fluid isflowing through pipes between the well headand the rig.

It constructs the computer simulationby filling in gaps from the available data. Forexample, the input data might be pressure,temperature and flow rate at the well headand at various points in the pipeline.

Companies can use the simulation toget a good idea of what is happening in partsof the pipes which they can’t monitor, andkeep the fluid flowing smoothly. The systemcan provide warnings of (for example) abuild-up of liquid in the base of a riser,which can indicate slugs about to occur, sothe plant can be prepared for them.

SPT’s flow simulator is different to oth-er simulators on the market, because it canmodel non-steady state flow (ie how the flowcharacteristics change during a start-up).Other simulators on the market can onlymodel steady state flow, he said.

The system has four operating modes:real time monitoring, look ahead (forecast),what happens if I do this (planning), and

Stan de Vries, director of industry solutionswith automation and software companyInvensys

layout1.qxp 23/08/2007 13:27 Page 18

OIL&GASEXCHANGE

UKTechnology in focus: Maximisingtoday's E&P performance throughtomorrow’s technology

The 8th Annual

29th & 30th November 2007Novotel West Hotel • London, United Kingdom

Develop sustainablepartnerships withNOCs to safeguardyour future business

Turn around yourcurrent workforceneeds to retain thebest in the business

Transform yourinformationmanagementsystems into arevenue generatingvehicle

Capitalise on newtechnology forprofitable E&Poperations incurrent and newregions

Implement novelasset managementstrategies tooptimise productionand ensure safety

Presented by:

Wolfgang Schollnberger,International Energy

Advisor & FormerTechnology VicePresident for BP

Michael Elsayed, Group Leader of ITStrategy, Planning

and Standards, SAUDI ARAMCO

Neil Hodgson,Exploration

Director, MATRA

PETROLEUM

ConGoedman,

Head BusinessInformation,

SHELL

For more information and to book:Call: James Waters on +44 (0) 207 368 9457Email: [email protected]: www.oandg-exchange.com

EXCLUSIVE INSIGHT:Space Drilling

Technologies by Brian Glass, SeniorStaff Scientist, NASA

Sponsors:

layout1.qxp 23/08/2007 13:27 Page 19

20 digital energy journal - September - October 2007

Oil and gas operations

we go along. There are also legal implica-tions.

Whilst we can reasonably keep docu-ments which might prove important in thefuture, if we keep absolutely everything, andare ever required to produce any piece of da-ta which could be relevant to a case, that willlead to some very time consuming search-ing.

But you would be excused for being notconvinced. There’s plenty of data on the in-ternet, and nobody ever talks about archiv-ing that. Could it be a generational issue -with younger people far more at ease withthe idea of enormous amounts of data?

And just like everyone has their ownway of cleaning out their house, everyonehas their own way of doing data manage-ment, there is no universal good way of do-ing it, it is not even possible for one personto work out how they want to do it and stickto this method because the needs are con-stantly changing. And of course the job isnever finished.

In the words of Eric Heinsbroek, SeaHorse Project director with Abu Dhabi Na-tional Energy Company, “Data managementis like juggling with crystal balls and rubberballs. You have to know which the crystalballs are because there are always too manyballs in the air.”

StandardsThere was also widespread discussion aboutstandards.

In particular, speakers said that the cur-rent standards efforts are just the tip of theiceberg for what we can see in future, as ef-fective data management becomes more andmore critical to running a successful busi-ness.

In future we can expect to see standardsfor every aspect of data management to en-sure that our data systems fit together as re-liably as a screw fits into a socket.

This will take a great deal more stan-dards efforts.

To illustrate how much standards wemight see in future, you could consider howmany standards are involved in, for exam-ple, a building; or indeed, how many stan-dards are involved in creating a single screw,covering at minimum the head shape, the di-ameter, the length, distance between thethreads, and the materials.

For example, said Stan de Vries, direc-tor of Upstream Solutions with Invensys, agroup of compressor manufacturers couldget together and develop a standard way ofcommunicating monitoring data from theircompressors, so in the future any compres-sor could talk to any monitoring device.

thority, Norway, spoke about the relationshipbetween integrated operations and safety.

The Petroleum Safety Authority is con-cerned that there have been no reduction inaccidents over the past few years, and is un-der pressure to find ways to improve safety,and believes integrated operations could helpthis come about.

The Authority views integrated opera-tions as a “socio-technical system change,”he said, or in other words, a general changeto the way things are done technically andpeople-wise, with many new processes be-ing introduced.

It holds the potential for reducing riskin many areas, but also creates a potential foran increase in risk and uncertainty, he said.Integrated operations can lead to manage-ment shifting its focus from safety to im-proving production, he said.

The Authority is also concerned aboutcomputer viruses, after an experience withone operator where a virus implemented ona laptop computer by an employee inVenezuela affected hundreds of computersworldwide.

“IT is becoming more functionally crit-ical,” he said. “You get more open systemsand increased number of interfaces.”

However IT staff are starting to under-stand risk management, he said, and devel-oping reporting systems for IT incidents,similar to the reporting systems in place forany other accident.

. Ultimately, company health and safe-ty management need to develop a strategyfor how they use integrated operations, hesaid.

“Integrated operations can improvehealth and safety if realistic visions of riskreduction through integrated operations so-lutions are developed.”

Data archiving There was interesting discussion during theconference about the correct attitude to dataarchiving. Like deciding when to archive (iethrow away) our no longer wanted posses-sions, it is a subject many of us would rathernot think about from day to day, but have tothink about sometime.

One big difference between archivingdata and archiving possessions is that, de-spite the exponential growth in the amountof data we have, we can still store it for nextto nothing.

This leads to an interesting discussionof whether to bother archiving it at all.

The case for doing data archiving isthat, however you look at it, we will need todelete old data at some stage or other, wemay as well have a procedure for doing it as

comparing the model with what actuallyhappened (retuning).

Engineers can use the system to findout how fast different parts of the systemwould cool down in different conditions, soit can work out if hydrates would be likelyto form and block the pipe.

A hydrate inhibition tool can tell youhow much hydrate inhibitor to add. There aretools to track the flow of pigs through thepipe. You can see how the flow patternchanges through the pipe.

At Na Kika, at simulates pipelines 1770to 2135m underwater, carrying the oil andgas to the Na Kika semi-submersible rig.

There had been numerous problemswith flow assurance, including formations ofhydrates in the pipe, severe slugging and anunstable flow in general. This was leadingto numerous unplanned shut-downs and lostproduction.

BP had come up with a wish list ofthings they wanted from a simulator, includ-ing having data always available and up todate, being able to evaluate the effect of do-ing things before actually doing them, andincreasing understanding of the operabilityof the system.

It embarked on a pilot program, in-stalling a system on the North loop.

The input data (pressure, temperatureand flow) was gathered continuously by theSCADA system, and which is then fed intoSPT’s flow simulator in OPC data protocol.