s XL Wins “Outstanding In this issue Homebuilt” at Sun N ... · Velocity Views 4 Volume 15 The...

Transcript of s XL Wins “Outstanding In this issue Homebuilt” at Sun N ... · Velocity Views 4 Volume 15 The...

Velocity Views13rd Quarter 1998

In this issueN140JP Wins Big .............1

Jean Prudhomme’sVelocity XL wins a topaward at Sun N Fun

Sun N Fun 98....................2Duane reviews happen-ings at this year’s EAAevent

Factory News ...................3Insurance problems,newSUV, Open House,Oshkosh Dinner sign up,avionics q’s, Builders’ line

Your Velocity Family........6Your world wide Velocityfamily has many benefits

Factory KPCs ...................7Kit plans changes to keepyour manual up-to-date

Safety Corner ...................8Accident & IncidentReports and MaintenanceService Difficulties.

Short Circuit ...................10Electrical, instrument, andavionics related tips fromMartin Hadley

Views from the West......11Fly-in a big success, plusother news from theMachados

Builder Forum ................13Tips, information & letters

Buy Sell or Trade ...........19

Volume 15

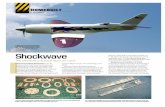

Prudhomme’s XL Wins “OutstandingHomebuilt” at Sun N Fun

Imagine bringing your newly built Velocity to Sun N Fun and winning a topaward! Well that’s exactly what happened to Jean Prudhomme! N140JP won atop Sun N Fun award for the “Outstanding Homebuilt”. As you can imagine,Jean was just glowing with pride and satisfaction. Well done, Jean!

Photos by Jeff Barnes

Velocity Views 2 Volume 15

VelocititesBoycott Sun NFun PortableToiletsBy an anonymous writer who absolutely

hates using those portable toilets!

I have some very good memoriesof Sun N Fun. Prior to finishing myVelocity RG, I used to spend theentire week camping out at Sun NFun with my Long EZ friends. Thereare only two things about this experi-ence that I remember as “not sopleasant”: rainy weather and usingthe portable toilets!

This year when the Swings invit-ed me to display my Velocity at theirbooth, my immediate reaction was“Do I have to use those portable toi-lets?” At that point, Martin Hadleysuggested “No, we’ll boycott!” Weall agreed that we would not eat ordrink anything all morning long,thus allowing us to stay in a holdingpattern until we got back to themotel rooms. Well, you can see bythe photos that we failed!

This will serve as a thank you toall of you who flew your Velocity,flew your spam can, flew the airlines,or drove to Sun-N-Fun. Of specialnote were our Canadian pilots TimEngland, who flew his V6 poweredVelocity down from eastern Canada,Mike Hillyer who flew 2300 milesfrom western Canada, and our goodfriend Jean Prudhomme who flewthe showcase and many other flightsthroughout the week. Jean also tookhome a top award for his Velocity XLRG. Thanks also for Wes Rose whobrought his beautiful Elite downfrom Michigan and had it on displayin our exhibit most of the week, andalso Rick Lavoie who also had hisStandard RG on display and filled infor Scott and me when we got busy.

Our Monday night dinner wasattended by 114 builders with a fewwannabes thrown in for good mea-sure. Dinner was excellent and wewill be using this same country clubfor future Sun-N-Fun get-togethers.Doug Dours was present to give usan update on his Delta Hawk dieselengine program. He utilized our tentVCR to show the engine running inthe Velocity. We will keep our fin-gers crossed for a flying Delta Hawkat Oshkosh. We also heard from anaggressive engineering team with athree rotor, direct drive turbo or PRUturbo Mazda engine. Horsepowerranges from 200 to 500 depending on

Sun N Fun 1998 size and configuration. They plan ona unique monitor system that willcompare a base line healthy engine toyour engine and provide an instantindication to the pilot of anythingthat is not proper. This would includethings like bearing temperatures, sealtemperatures, water and oil tempera-tures, spark plug condition, and some20 additional probes placed in criticallocations throughout the engine.With this system, the pilot could usea telephone link to the manufacturerand down load all the information onthe engine condition and get aninstant reply as to what is wrong withit. Another unique program is the useof a multi-bladed highly curved pro-peller of relatively small diameterdirectly driven, (no reduction units)turbo boosted, intercooled, turning inthe 3500 RPM range producing 300 ormore horsepower. The projectedweight of this unit, with cooling sys-tem is in the 350 lb. range. Don’t callme on this unit as there is a lot moreto producing an aircraft engine thantalk. Just ask Doug.

I must admit that I am writingthis news letter on American Airlinesenroute to Puerto Vallarta Mexico.Bonnie and I are taking a few daysrest after Sun-N-Fun to be with somefriends. As some of you know, ourdaughter, Kelly, works for Americanand the cost for the round trip for twois about $50.00. (Eat your heart out)Our first stop in Mexico is at a TacoBell for some real American food.

Duane

Jean Prudhomme’s award winning paint job includes this mural painting of a birdsmashing into his wing. Only Jean would think of this idea. It looks just great in color!

“I especially enjoy using the Portabletoilets around 2:00 pm. during the heatof the day”, explains Martin Hadley.Hadley, leader of the great boycott, final-ly breaks down after 6 days of success-fully avoiding the portables. “If Lavoieand Barnes hadn’t taken me out forlunch that day, I could have made it.”

Photos byJeff Barnes

Continued on next page

Velocity Views33rd Quarter 1998

by Duane Swing

Lavoie breaks down and finally uses theportable toilets! “I tried to hold out til wereached our motel rooms,” says Lavoie

Above photo shows Jeff Barneschecking out the big “Explorer”.“This is the only plane here that hasmore stuff in it than JeanPrudhomme’s XL. It even has aflushing toilet!”, exclaims Barnes.This may explain why Bonnie wasoften seen sneaking over to theExplorer!

Speaking of the Prudhomme XL,towards the end of the week, Duanemade the mistake of turning over thePA announcing for the daily “air-craft showcase fly-bys” to Scott andme. While walking over, Scottexplained that I could say anything Iwanted to because nobody would belistening anyhow. So when Jean flewby, I announced the stuff about theplane, and added that the new XLwas so big that Jean had a TV, VCR,16 CD stereo changer, and a hot tubbehind the rear seat! Well I guessthat some people (besides Duane)did hear this, because when Jeanlanded, people went to his plane tosee all this stuff! Jean delivered oneverything except the hot tub. Heexplained that the Sun N Fun offi-cials made him remove it for the fly-bys.

AVEMCO INSURANCECHANGES

We received a call from AvemcoInsurance the other day complainingabout the high cost of repair of theVelocitys that have been damagedand/or destroyed. As a result,Avemco has issued a statement to allthe Avemco offices to not insure anymore Velocitys until some sort ofconditions regarding training or min-imum flight times have been estab-lished.

I have long pleaded withAvemco to not insure any Velocityunless the pilot has had a check outby a Velocity factory pilot within 60days of his first flight. Avemco didnot, at the time, think this was neces-sary as long as the pilot met the stan-dards needed for insurance in a likeairplane. To Avemco, a Cessna 172was the same as our fixed gear air-plane and a Cherokee Arrow was OKfor a Velocity RG. This has now allchanged.

Avemco acknowledged the prob-lem, in part, was due to the averageFBO not having a clue as how torepair a Velocity and chargingextremely high amounts for seeming-ly light repair. One of Avemco poli-cies is to allow $15.00 an hour for thebuilder of the airplane to do his ownrepairs. This has opened the door tosome very high repair bills as theowner/builder can charge just aboutanything he wants under this policy.We were told of one builder (noname) that charged Avemco almost700 hours to repair the damagecaused in a gear up landing, plusanother $2000.00 in parts. It may beaccurate, but not what I wouldexpect in a gear up landing. I person-ally know of a Velocity owner (notbuilder) who had a repair bill pre-pared by a friend for almost $2500.00and then had the actual work doneby one of our more professional

builders for under $100.00. He didn’tgive the money back to Avemco I canassure you. I know of another case ofa pilot who accidentally got hisVelocity airborne on the first highspeed taxi (no check out) and lostcontrol resulting in damages that noone wants to repair. The owner hadmost of the work done by someoneelse and couldn’t fix it if he wantedto. One of our more professionalbuilders looked at the airplane andrefused to accept the responsibilityfor repairs as there were so manyother things wrong with the airplanethat made the airplane unairworthyeven before the crash. Avemco hadno choice but to consider it a totalloss and paid the claim.

I don’t know just what Avemcowill ultimately decide to do, but I canassure you that it will cost all of us alot more money from now on. I alsolook for a much higher deductibleand probably more pilot in com-mand time needed to qualify forinsurance.

I will still promote the Velocityor Velocity West check out and I amsure Avemco will too. Expect check-outs to be at least 10 hours for an RGand perhaps 5 hours in a FG. This isonly a guess on my part. There mayalso be more detailed inspectionsnecessary for insurance. Look forAvemco to insist on the EAA TechAdvisor inspections and log entriesfor these inspections.

My honest take on all this is thatit was bound to happen sooner orlater. We have heard of many of theaccidents that not only didn’t have tohappen, but that were easily pre-ventable with only common senseapplied. Those of you who read thisand can claim partial responsibilityfor what has happened, shame onyou. We will all suffer as a result.

Duane

Velocity Views 4 Volume 15

The guys in the shop continue towork on our newest airplaneN101VA. Its filling and sanding timehere with all the glass work complet-ed. For those of you who don’tremember, N101VA is going to be alow budget, low weight, low power,single gull wing door, no frills ver-sion of our standard fixed gear (1/2Elite) aircraft. We are using a lightweight version of the popularLycoming O 320 engine modified forfuel injection and producing about170 horsepower at 2800 rpm. Thelightweight Subaru Stratus 180horsepower auto conversion wasalso considered but we stuck withthe Lycoming for this airplane. Wewill be using a light weight M-T electric constant speed prop so wecan get a full 170 horsepower fortakeoff, (160 horsepower continuousat 2700 rpm.) Remember, a 200horsepower Lycoming at 2400 rpm attakeoff is only producing about 170horsepower. By keeping the weightto an absolute minimum (about 1240lbs. empty wt.) we hope to produce agood performance airplane withgreat economy. The IO 320 enginewill use about 8.3 gph at 75% cruisepower, and 7 gph at 65%. The panelwill be a VFR set-up with a singlecom/gps and xpounder/encoder.Our greatest departure from our pre-sent airplanes will be the eliminationof most of the center console. Thiswill allow entry into the right seats.In order to do this, we must convertour beloved center stick control to astandard yoke. I know, I can hearyou now. Have they all lost theirminds! This is, however, the easiestsolution to the problem.

Why the push for a down sizeairplane, you ask? It is simple, wehave molds stuck all over this placethat are not being used because ofthe XL. I know there are a lot of peo-ple out there who just can’t justifyspending what it takes to build anXL. This airplane should be capableof taking to the air, even with a con-

stant speed prop, for under $40,000.One way to recapture this segment ofthe market is to force our way backin. With the elimination of the centerconsole, we can reposition the seatsfor maximum rear end room.Remember, the Velocity Standard isalready 2” wider than a Cessna 172.The main problem in the past is thecenter console. This is keeping thepilot almost 4” away from the frontseat passenger giving the impressionof a narrow fuselage. This is especial-ly true of the Elite because of thestrake being pulled back by about afoot.

We had hoped to be flying theairplane to Oshkosh, but it just can’tbe done. Since we will be sendingTravis up with the fast build fuselageand wings of the XL, we may loadthe new model in the trailer and sendit too. Time will tell.

More FactoryNewsBuilder Phone Line

We are still getting a lot of callson the weekends and after hoursusing our regular number. NOTICE,I will no longer answer the -1860number on the weekends and after5:00 PM. Call on weekends or after5:00 PM using our special buildersnumber: 561-589-0309. REMEMBERTHE -0309, that’s the only difference.

Avionics Questions

As you will read later in thisnewsletter, Martin Hadley will beleaving us for greener pastures.Martin will still be available for panelwork and Velocity will keep ourdealerships for the various items nor-mal for an instrument panel. Thereis, however, going to be a difference.Namely follow-up work and ques-tions you may have regarding your

instrument panel or wiring in gener-al. We just don’t have the personnelhere to give you much help in thisregard. Martin will be available toanswer questions on panels he haswired but those questions must firstbe addressed to Velocity. Remember,Martin no longer will be getting apaycheck from Velocity and he can’tafford to spend a lot of time trying tofigure out a problem that may notpertain to what he has done. If youneed for Martin to quote a panel foryou, or you have questions for himthat only he can answer, call us withwhat you have in mind and we willhave Martin call you back to go overyour needs. We hope this will notcreate any problems with our cus-tomers.

Duane

Update on the Newest “Low Cost” VelocityThe SUV “Sports Utility Velocity”

Calling All

Flying

Velocitys!

I Want You!

Looking for Photos and

Stories of:

• First Flights

• Flying Adventures

• Photos of your Velocity

Send to Rick LavoieVelocity Views Newsletter

How about it? Send mesome nice photos of yourVelocity today. Keep in touchwith your Velocity family.Share your experiences andwe all benefit. Thanks!

Velocity Views53rd Quarter 1998

Sign up for the1998 VelocityOshkoshBanquet

FRIDAY, July 31, 1998 -The 1998 Velocity OshkoshBanquet is all lined up forJuly 31st to be held at theHilton Convention Center'sLaSalle Ballroom. Socialtime starts at 6:30pm, withdinner served at 7:00pm.Cost per adult is $18.00,three entrees to choose, costper child (age 4-10) is $9.00.

Call the Velocity office tobe put on a sign up list, orstop by the Velocity boothprior to noon on July 31st(Friday). Thanks.

Bonnie

August 8th FactoryOpen HouseWorkshop Schedule

Saturday August 8, 1998 - Factory’s quarterly open housein Sebastian Florida (X26)9:00am Coffee and donuts10:00am Workshop: ADVANCE COMPOSITE TIPS (How to

make a mold for glassing parts) Scott Swing11:00am Workshop: PAINTING AND SPOT PAINTING TIPS

(How to prime, sand, and paint your Velocity)Scott Swing & Rick Lavoie

Noon Lunch1:00pm Workshop: FRANKLIN ENGINE INSTALLATION TIPS

(Lavoie’s N570 will be uncowled) Duane Swingand Rick Lavoie

1:00pm Workshop: HARDWARE (understanding AN & MShardware) Martin Hadley

2:00pm General Q&A with the Swings3:00pm Demo rides in the XL

Please be sure to call the factory and RSVP! Friday arrivalscan book a room at the Sand Drift Hotel (800-226-4546) herein Sebastian. When you call us to RSVP, let us know whenyou plan on arriving so we can make arrangements for trans-portation, etc.

Note: Workshops for the November open house will be:• Hands on Electrical (soldering, crimping wire & coax con-

nections, terminals, AWG wire, switches, panel harness,tools, etc.) Martin Hadley

• Pre-first flight inspection check list (Swings)• Lycoming engine installation tips (Swings)

Our OshkoshDisplay Areahas Moved

Please make note thatthe Velocity booth atOshkosh will be back in theold “North” aircraft displayarea. This is the same placethat we used to be in twoyears ago. Look for displayareas #419 and 420! This isjust facing “Stone Road”.

Bonnie

Please Renew Your 1999Subscription to VV Early

Please consider renewing your subscription for the 1999Calendar year today! If possible, please pay by check versuscredit card. You can prepay as many years in advance as youlike too! If all your info in my data base is still correct, thenjust drop a check in the mail to Rick Lavoie. Thanks!

Velocity Views 6 Volume 15

Your World WideVelocity Family

Chances are good that no matterwhere you fly to, you have familythere. Velocity family!

Case in point. Judy and I hadplanned a flying adventure fromFlorida to New Mexico in ourVelocity. I had mentioned in one ofmy Franklin e-mail messages on thereflector that I’d be off for a trip toSanta Fe. The next day, I had a returne-mail from Lino Moya explainingthat we needed to first come visitwith them in Albuquerque! I e-mailed back that we really had noplans to go to Albuquerque. Hewrote back that we had to go toAlbuquerque! So Judy and I thoughtit over and adjusted our plans...andwe are glad that we did.

We left St. Augustine, Florida,early Saturday morning on April 4thwith our English springer spanielDarla in the back seat. With the timechanges, we figured we would be inAlbuquerque in time for margaritasand dinner. We landed in Jackson,Mississippi, for our first leg fuel andearly lunch stop. I discovered oilleaking from my starter. It appearedthat Pat Goodman used some siliconeto seal a bearing on a starter that wasnot made to be exposed to oil (exter-nal fly-wheel vs. internal drive). Weended up spending the night inJackson, while a friend back homeput my spare starter on a commercialflight to Jackson. I ended up makinga temporary repair to stop the oilleak, and, after a 24 hour delay, wewere off again for New Mexico. Ihate when things don’t go asplanned, and Judy knows how closewe were to heading back to Florida.Knowing that I had some Velocityfamily members at the other end ofmy trip made all the difference. Itgave me the confidence to continue,knowing they had a hangar I couldwork at and I could borrow tools tochange out the starter.

by Rick Lavoie

From left to right: Judy and Rick Lavoie, Gary and Cheryl Simpson, Lino Moya and hiswife Jeannine Cde Baca, pictured in front of Velocity N570 at New Mexico’s AngelFire airport. This airport is at 8,382 ft, surrounded by mountain tops, includingWheeler Peak at 13, 161 ft. Density altitude for take off that day was just under 11,000

We finally landed atAlbuquerque’s Double Eagle airportto find our new friends all waitingfor us (Gary and Cheryl Simpson,Lino Moya and his wife JeannineCde Baca). It was a very nice feeling!After getting settled into our motelroom, we all went out for dinner toEl Pintos for some great margaritasand New Mexican food!

We ended up usingAlbuquerque as our base, and tooksome side trips to Santa Fe, Taos, andAngle Fire. We did Santa Fe by planeand car, spending two nights in thatpicturesque and very artistic city.Judy, being an artist, was in heavenin Santa Fe. She is already wonderingwhen we will be going back to NewMexico to continue visiting her list ofmuseums, galleries and historic sites.

We loved New Mexico, but trulythe best part of the trip was makingnew friends. Everyone got along justgreat. It helps when you all have acommon interest, and we quicklydiscovered we shared many. It wasone of the good unplanned parts ofthe vacation: we did not know eachother before the trip, except throughthe newsletter and e-mail. It just hap-pened! We all know the value ofsharing knowledge between Velocity

builders, but our new friendships gobeyond just our flying interests. Andany of you who travel know what agreat advantage it is to get pointed inthe best direction by people who livewhere you are visiting.

In fact, Lino and Jeannine recent-ly visited us for a week here in St.Augustine. They flew over in theirCherokee 180, for Jeannine’s firstvisit to the East Coast. Lino made themost of his time here, getting a facto-ry checkout in Velocity’s N81VA.They were kind enough to make ourvacation to New Mexico very enjoy-able, and we happily reciprocatedwhen we learned that they plannedto visit Florida. We did a day triptogether in our Velocity to Key Westand both our visitors had thrillingrides over St. Augustine in ourfriend’s open cockpit Stampe. Andthey ate almost as much shrimp aswe ate chiles in New Mexico!

So if you are planning a flyingadventure or vacation, think aboutgetting together with some of ourgrowing Velocity family membersthat you have yet to even meet! Youmost likely will make some lifelongfriends, and have new contacts andresources in your Velocity buildingand flying experiences.

Velocity Views73rd Quarter 1998

KPCs continued on next page

Kit PlansChanges“KPCs”

Note: Check the date at the bottom ofyour page. If it matches the “Date ofChange” shown in the KPC, your manu-al has already been corrected.

KPC 084Affects: All VelocitysManual Section: 4.4.6 Hinge ArmInstallationDate of Change: 15 April, 1998

We have made a change to the hard-ware attaching the elevator to thecanard. Use a MS27039-1-09 screw,(2) AN960-10L washers, and aMS21042-3 locknut. See the figurebelow:

The factory is supplying the newscrews at no charge. Call to order.

KPC 085Affects: All RG’sManual Section: 9.4.2Date of Change: 10 May, 1998

The plans fail to clearly mentioninstalling two SF1216-8 Oilite bush-ings into the gear tops. Install theseflanged bushings into the front andaft sides of each gear leg with micro-glass.

KPC 086Affects: All XL’s onlyManual Section: 10.1.5 (FG) and10.2.2 (RG)Date of change: 10 May, 1998

To strengthen the attachments of theaileron control bracket, the over-center linkage (RG), and the gasspring(RG), the foam on the keel willneed to be removed. Proceed as fol-lows:

Remove the outer skin and foamalong the premarked lines on theoutside of the previously installedhardpoints. Sand the outer skin offanother 3/8” and transition the foamdown to the inner skin. Round theedges, microslurry the foam, andglass two BID over the whole innerskin area and extending 1” onto thekeel outer skin.

See the Figure below:

KPC 087Affects: All VelocitysManual Section: 10.5.1 MountMaster Cylinders (10.4.1 for non-Elites)Date of Change: 10 April, 1998

Change the directions to read as fol-lows:

Measure and mark horizontal andvertical reference centerlines on themolded brake box on the front face ofthe canard bulkhead. (When findingthe vertical centerline, do not includethe portion that is angled in yourmeasurements - just use the portionthat is parallel to the bulkhead face).

Drill two 1-1/2” holes, centered 1/2”above the horizontal centerline and2-1/4” out from the vertical center-line. Using the master cylinders as aguide, drill four 5/16” holes formounting.

See the figure below:

KPC087

KPC084

KPC086

Velocity Views 8 Volume 15

Safety CornerAccident & Incident Reports,Maintenance & Service Difficulties

KPC 088Affects: All VelocitysManual Section: 20.2.1Canard/Elevators

The two diagrams in Figure 20-1 con-tradict previous chapters concerninghow to attach the canard. The torsiontab hardware should be listed as anAN4-7A bolt, and a MS21042-4 nut-plate, with two AN970-4 washers.The canard lift tabs are attached tothe canard bulkhead with an AN6-16A bolt, one AN960-616 washer onthe front side, one AN970-6 washeron the aft side, and one AN363-624locknut.

KPCsContinued from previous page

Fatal Accident Report

A friend of mine decided tolearn how to fly in spite of his wife’sconcern about his safety and sanity.His wife refused to fly with him aslong as the airplane had only oneengine and it wasn’t long before hepurchased a used Piper Seneca andgot his multi engine rating. Therefirst cross country together was fromSebastian to Houston Texas to visitfriends. As the weather began todeteriorate he radioed his intentionsto deviate to the south out over theGulf of Mexico, something he wouldnever have done in his Cessna. Atsome point he lost reference to thehorizon and crashed in the Gulfnever to be found. This is an acci-dent that didn’t have to happen. Callit poor judgement, the desire to “getthere”, his security of knowing hehad a “twin”, whatever, it just didn’thave to happen, but it did.

The point of this story is thatmost accidents just don’t have to

happen. Case in point is the recentaccident that took the life of MarlinHowe. Marlin and Cory had builttheir Velocity with a Franklin enginemodified to burn auto fuel. Fromearly on, they had reported problemswith the fuel system and at one pointreported that they had experiencedwhat Marlin called fuel vapor lock.Other problems were reported withthe engine driven fuel pump failingto allow fuel to flow through whenthe electric pump was turned on.Parallel fuel lines with dual electricpumps were installed along with asolenoid by-pass valve to re-circulatethe fuel back to the header tank tocorrect this problem. After modifica-tions were done, many flights weremade to confirm that their dedicatedefforts were paying off with a failsafe system. Then it happened.

On takeoff from their home air-port with Marlin flying and a rela-tive in the airplane, the engine beganrunning rough and surging and ulti-mately quit. Marlin was unable toget the plane back to the airport andstruck trees about a mile from theairport where the airplane nosedover and impacted the groundkilling both Marlin and his passen-ger. Rather than my speculation, letme quote the initial NTSB interviewwith witnesses.

“A witness, standing on theramp area parallel to the runway,observed the airplane proceedingdown the runway 17, abort the take-off and taxi back to the end of therunway. The aircraft then successful-ly took off and when it was about500 feet off the ground the airplaneturned right on course and headedover Camp Robinson. I then heardthe engine sputter and attempt torestart. Subsequently, this witnessobserved the airplane (as if it wasattempting to make it back to the air-

port.) The airplane was “very low”,just above the trees.” A mechanic atthe airport observed the airplaneabort a takeoff and taxi back to run-way 17. During the taxi, he notedthat the engine was running “roughand sputtering.” Another mechanicheard the airplane 3 to 4 secondsafter takeoff when the engine cut out“like the throttle was pulled back,then increase and decrease and thenbackfire once and quit.” Anotherwitness/pilot at the airport observedthe aircraft’s departure and after afew seconds heard the motor “startto surge high to low RPM (maybe 5times)” and then stop. Another wit-ness from the FBO reported that theairplane spent a lot of time on therun-up area, possibly 20 to 30 min-utes, prior to his first take-offattempt. A call on Unicom was madeto ask if Marlin was having any trou-ble with the airplane. His responsewas that he was having a radio prob-lem and was trying to sort it out.

Did Marlin have a repeat of hisprevious fuel vapor lock problem?Was there something wrong with hismodified Franklin engine? The NTSBwas not sure if they could get theengine in a condition for a test run asthe crash had done considerabledamage to the accessories. A teardown inspection will probably bedone if the NTSB will take the timeto do one. We have been asked toparticipate if this is done.

I will not attempt to speculate asto Marlin’s decision to “go ahead”with this flight. I do, however,believe that many of you wouldprobably say that he should haveaborted the flight after his firstattempt. It is impossible for any of usto assume we would have done any-thing differently unless we were inMarlin’s shoes. He made a decisionto continue with the flight and that’swhere it ends.

Marlin was a very giving personwho spent a lot of his life inChristian family counseling, andother Christian work. He was one ofthe few who understood the Swingfamily’s heartbreak when one of our

Velocity Views93rd Quarter 1998

flock doesn’t return to the nest, andhad called me to express his condo-lences at Mark Ewart’s death. Hesaid to me that God has an ultimateplan for all of us and that anyattempt we may make to alter Hisplan or any guilt feelings we mayhave as a result of what has hap-pened just isn’t part of what Godwould want. Those words ring loud-ly in my ear as I write this story.

To Patricia Ann, Cory and therest of the family, my heart goes outto you. You have suffered more thanwe will probably ever know. Godsurely has some great things in storefor someone like Marlin and it is myprayer that you will be able to seebeyond the moment.

Duane

Safety Caution: Why all theVelocity Accidents?

One of our Velocity builderscalled me after the Marlin Howeaccident and ask me: “What’s goingon with all these accidents? Whycouldn’t Marlin land someplaceother than in the trees? Is theresomething amiss in the gliding char-acteristics of the Velocity? Whatshould we know that your not tellingus?

One of our Velocity family prob-ably answered this question best at aconversation I had with him at Sun-N-Fun. His name is Ray Watkins andhe has probably put more hours onhis Velocity than any other builder.Ray is an aircraft controller out ofJacksonville, Florida, and regularlytravels back and forth to his parents’home somewhere west of Florida. Ididn’t ask him how many hours hehas on his Velocity, however I’msure he is getting close to 1500 ormore. He told me that when he firststarted flying his Velocity, he spentmany hours finding just how far hecould glide in a simulated engine outcondition. Many simulated engineout landings were made so that if itever happened in real life, panicwould not set in and result in a cata-strophic ending. He also said that he

is always looking for an emergencylanding spot on all his cross coun-tries just in case something happens.These are words most of us heardwhen we first started flying.Practicing things that could gowrong will prepare us for the daywhen they do. I can tell you firsthand that they will.

Why do we continue flying whenwe know something is wrong? Whydo we even take off when we knowsomething is wrong? These are ques-tions I have a hard time answering.Doug Doers summed it up prettygood for those of us at our Sun-N-Fun dinner. He related an incidentwhen prior to take off in his Velocity,he smelled gas. His passenger, whowas a Cessna pilot, convinced himthat that smell is quite common in aCessna and not to worry. Afterdeparting the airport area, the smellgot worse, but Doug didn’t react fastenough and the engine just quit. Hehad departed the airport area andhad no choice but to land off airport.There was no damage to the airplaneand a check of the fuel system dis-covered a broken fuel fitting. Doughad this to say. “If you see somethingthat doesn’t look right; if you hearsomething that doesn’t sound right;if you feel something that doesn’tfeel right; and if you smell somethingthat doesn’t smell right, DON’TFLY”. This sounds like good advicefor all of us.

Duane

Service Warning:Franklin Fuel Pump

I have disassembled-assembledand tested the automotive fuel pumpthat Pat Goodman installed on theFranklin engine and can answersome questions that have been ofgreat concern to me. First of all, thepump does have an internal flappervalve that will allow fuel flow withthe electric Faucet pump that we use.It does take some pressure to unseat-seat the valve but it is possible byjust blowing into the “in” port. Iwould guess about 3 to 4 lbs. of pres-sure is enough. Does this mean that Iwould endorse the auto version of

this pump. No, I would not. Thepump has another flaw that isimportant to the safety of an air-plane. In the event the maindiaphragm should rupture, thereappears to be a straight path of fuelinto the oil system of the engine, oroil under pressure would be forcedinto the fuel system. A pin holewould probably not be noticed as tohow the engine was running, how-ever, you would ultimately fill thesump of the engine with fuel, or berunning the engine with some oilmixed with the fuel until the sumpgoes dry. Not a good thing. This canbe demonstrated by putting your fin-ger over the allen set screw hole andblowing into the shaft end of thepump. You will notice air spewingout of a mouse hole just above thelower gasket seal. If this hole is notplugged, engine oil under pressurewill flow out of this hole. PatGoodman seals this hole with someJB Weld. This certainly stops the oilfrom exiting out the hole but wouldnot prevent oil/gas from mixing inthe event of a diaphragm failure. Themodified Franklin pump preventsthis from happening by installing anadditional seal in the base of thepump, thus preventing the fuel fromgetting into the oil system and viceversa. I am sure that the PZLFranklin factory pump also uses thesame internal flapper valve. We askthe Franklin people if they used a“check valve”. They said no. If weask them if they had an internal flap-per valve to allow fuel to flow in theevent of pump failure, they wouldhave probably said yes. I’m sure theFranklin pump has the same inter-nals as the auto pump.

It is, therefore, my recommenda-tion that all the Pat GoodmanFranklin engines have the Goodmansupplied auto pump removed andinstall instead the PZL Franklin fac-tory modified aviation fuel pump.

Duane

Velocity Views 10 Volume 15

Short Circuitby Martin Hadley

Departures

For those of you that have notheard, and those of you that thoughtit was a rumor, I must admit that Iam leaving Velocity.

Four wonderful and long yearsago I was approached by Duane tojoin the Velocity family. It has beenquite an opportunity and experiencefor me. I have never worked for amore enthusiastic, encouraging, andgenerous group of people than theSwings.

While I will not be an employeeof Velocity, it does not mean that Iam leaving the Velocity “family”. Iwill still be sub-contracting instru-ment panel work for Velocity, I havemade arrangements with Rick Lavoieto continue this feature, and I am stillan active participant of the Reflector,the E-mail ‘chat room’ if you will, forVelocity builders. I am also consider-ing developing some future electricaloptions for the factory such as readyto install electrical systems. Note Isay “considering”! Nothing is certainat this point with regards to suchdevelopments. Maybe with enoughinput from you all it may be found tobe a worth while endeavor.

I will remain in the Palm Bay /Sebastian area for a yet undeter-mined amount of time. My wife’s onagain, off again move with the FAAis currently in the “Off” mode, butwe are expecting to hear some “BIG”(boy, have I heard that time and

again the last two years!) newsaround October. We’ll see!?!

If you have any current unfin-ished business with Velocity in thearea of electrical, instrument, andavionics, please call me as soon aspossible so that we can close it beforeI leave. Velocity will still provideavionics, electrical, and instrumentsales. For the moment, anyway, theyjust will not have me around!

This is not a goodbye, just a noteto let you all know what is going on.

Grounded!

The other day I was asked tocheck an aircraft that had beenrecently finished. It seemed therewere already some gremlins movinginto the electrical system. Sureenough, upon inspection, some veryweird things were happening.

It just so happened that we werein the process of installing a fuelpressure gauge. The gauge was in,the pressure sensor was hooked up,but the sensor was not plumbed intothe fuel system yet. When power wasapplied to the aircraft, the fuel pres-sure gauge read “O” PSI. That partworked fine. But when we went tostart the airplane to check on a mal-functioning tachometer, we noticedthe fuel pressure gauge read fullscale, or 30 PSI and it wasn’t evenplumbed in!

I knew right then and there whatI was looking for. Poor grounds!Even in a newly completed aircraft,grounding was giving us problems.I’ll tell you what I found and hope-fully you can NOT do what thisbuilder did.

The engine was freshly over-hauled and had an extremely goodpaint job. The biggest cause to almostall of our systems was the fact thatvirtually none of the grounds on theengine had the paint removed frombetween the ring terminals and theengine case. The battery cablegrounding point (right behind thealternator bracket on the bottom of aLycoming) had a thick coat of painton it. While the builder didn’t have

to worry about his engine corroding,he certainly set himself up for electri-cal problems.

The next thing that I found wasin the hardware that he had chosento use. While steel hardware is OK touse, do not use the chrome platedstuff! In the scheme of things, elec-trons tolerate passing from copperthrough tin plating (the plating onyour copper ring terminals) to alu-minum fairly well if it is compressedtight enough.. If you want toabsolutely make sure you have agood ground connection, you mayuse a star lockwasher between theterminal and the body to be ground-ed. Properly secured, the washer will‘bite’ into both metals and provide agood ground.

If you add chrome to the mix,you set yourself up for what is called“dissimilar metal corrosion”. This isone of those things that takes sometime to develop, but it acts like ter-mites in wood. It’ll eat and pit bothmetal materials, usually destroyingthe softer material completely.Chrome, while nice and pretty, itisn’t a good electrical connect com-pared to a lot of metals. The rule is,don’t use chromed bolts or washerswhen hooking up grounds (or powerconnections for that matter!).

One source for proper groundingtechniques is in the AC 43.13-1A &2A that Velocity and most aviationbook stores sells. If you are unsureabout what you are doing, check thebook. Velocity will sell the book atcost to a Velocity builder, plus S&H.

Once we removed the paint atthe ground points and changed thehardware, the engine gauges startedworking a lot better! In areas ofextreme temperature fluctuations,stick with steel hardware. In areaswhere the temperature range is notmuch different than the outsideambient temperature, use brass hard-ware where possible and practical.

Grounds can cause more “grem-lins” that most any other installationerror. Remember, metal to metal, softmaterials next to each other, anddon’t let them get loose!

Safe and Speedy Construction!

Velocity Views113rd Quarter 1998

Views from the WestGreetings once again to all of

you from us here at Velocity West,Velocity Inc’s representative forsales, service and builders supporton the West Coast. Admittedly thetext of this column may be a bit shortthis time around, hopefully leaving alittle more room for some pictures.Something about “a picture is wortha thousand words” comes to mind!Plus, we thought you simply mightenjoy them as much as we do. Nowfor the meat.....

3RD “BUBBA” FLYS!!: On May15th, I had the great opportunity ofperforming the first flight on the 3rdVelocity XL “to come off the line”.It’s tough work, but somebody’sgotta do it!! Needless to say, theflight went very smooth. I’ve beenfortunate enough in my flying expe-rience to have done this a time ortwo in the past, but I must admit,this particular “first flight” was prob-ably the most uneventful (and mostrelaxing) of them all. I stayed up formost of an hour, retracted the gearand explored much of the flightenvelope. This particular XL is

owned by Mr. Rodney Brim and wasbuilt as a joint project, with his totalinvolvement (both physical andmental), here at Velocity West.Although a few minor changes weremade during the construction of thisairplane, essentially this Velocity XL-RG is stock. One significant changewas the powerplant. Rodney optedfor the biggest and lightest he couldfind. No argument here! Ly-ConAircraft Engines of Visalia,California started with a stock 260hp, parallel valve’d engine, did theirmagic to it and ended up with a 325hp, dyno proven, monster! Did Imention I had no problem with this!Love that horsepower!

The other interesting thing aboutthis airplane was the propeller thatwas used on the first flight.Although currently configured withan MT constant speed prop, the firstflight was accomplished with a 76”IVO in-flight adjustable prop.Warning: Kids, don’t try this athome! The ground clearance at thepropeller tip was something lessthan 4 inches! Why you

ask?....because Ivo asked me to and Ilike the guy. Basically Ivo wanted toget some data on his propeller’s per-formance at high horsepower andhigh speed, so I volunteered. Thereason for the 76” was simply thatthis was the longest prop he makes.Needless to say, both the takeoff andlanding were very flat! Managed todo it without any damage to theprop or airplane. Only once though!After that flight we reduced the propdiameter to 72”, flew a few moretimes, generated the data Ivo want-ed, and sent it off to him. Althoughwe have since removed the prop andreplaced it with the aforementionedMT propeller, the IVO worked verywell. Certainly something to consid-er in the future as Ivo refines a propfor this particular application.Hopefully more about that in thefuture.

FIRST ANNUAL VELOCITYWEST FLY-IN: If you missed it, theconsensus is you missed a goodtime! We had it all....great speakers,lots of airplanes, good food, plentyof smiles and even a little rain. If youmissed it, not to worry, we plan todo it next year. I really want to thankeveryone who attended, especiallythose who volunteered to speak atour forums, flew their Velocity’s inand/or stuck around to the bitter

The Velocity West Fly-in, held on May 16th, featured many seminars

The row of Velocitys included Mark’sfirst creation... looking as good as the dayit was sold!

Continued on next page

Velocity Views 12 Volume 15

Views From the WestContinued from previous page

end and helped us clean-up! A spe-cial thanks goes to Mr. Bruce Shively,who not only took the pictures thatyou see here, but also gave Nancyand I a pair of T-Shirts with ournames air-brushed on the front andan absolutely beautiful Velocity air-brushed on the back. Nice touchBruce!

CHECK-OUT’S AVAILABLE ATVELOCITY WEST: Velocity West isproud to announce the addition ofScott Baker CFII, to the staff. Scotthas been fully trained in flying thevarious Velocity models and is avail-able to you for Velocity proficiencytraining and check-out services. Formore deatils on cost and his avail-ability, feel free to contact Scott orNancy directly here at Velocity West.The airplane currently being used forthis work is the company demonstra-tor model, N94VA, which is aVelocity Elite LW (fixed gear).

NEW RG CONSTRUCTIONVIDEO: As I write this article, we arejust finishing up the rough filming ofan updated RG construction video.Assuming all goes well with the edit-ing, this new tape series (it will belabeled Tape Series #7) should beavailable by mid July. Naturally itwill go out with any new RG kit pur-chase, but if you already have an RGkit in your garage and want the mostup-to-date flick, give the factory orus here at Velocity West a call andplace an order. We’ll get it out to youas soon as possible.

AUTOMOTIVE ENGINEUPDATE: John Kiss is still workingon the V-6 and I’m still working onthe V-8. The V-8 should go on the air-frame about mid-July. Currently theV-8 is running on the test stand withan AirFlow Performance fuel injec-tion system and I love it! Nuff saiduntil we fly it!

FLY-IN’S AND WHERE WE’LLBE: As of today, we expect to beattending OSHKOSH, Arlington, theGolden West Regional Fly-in in

Atwater, California and the AOPAConvention in Palm Springs. We’vetalked Duane into bringing the proto-type XL out for Arlington. TheArlington EAA Regional Fly-in isJuly 8-12. Hope to see you there!

Until later, as always, take care.

About 90 people feasted at the “Texas B-B-Q dinner

More photos from Velocity West’s Fly-in

Dessert anyone? Nancy, Mom & daugh-ter had a good time cooking these sweets!

Nancy & Mark MachadoAll that work and still smiling

Velocity Views133rd Quarter 1998

BuildersForum

Builders Forum is full of tips, information and letters (“material”) supplied toVelocity Views Newsletter from individuals that are Velocity builders (or want to bebuilders). It is provided as “USE AT YOUR OWN RISK” material. NeitherVelocity Inc. (The Velocity Factory) nor Velocity Views Newsletter (Lavoie Graphics& Rick Lavoie) have endorsed this material, and disclaim any liability for the use ofthis material. Individuals who use this material for the operation, maintenance, orconstruction of their homebuilt aircraft do so at their own discretion and at theirown risk. Any variance from the builders manual is high risk.

Painting and Spot touch upFrom Rick Lavoie, St. Augustine Florida

Not wanting to repeat things onpainting and finishing, I thought I’dbetter first list past articles for yourreference:• V1 p12 “Finishing Tips” byyours truly, covers sanding, priming,pin holes, painting, etc. I havelearned a lot since then, but it is agood platform to start with.• V2 p8 “Q&A” by Scott Swingcovers pin holes, primer, finish coats.• v3 p21 “Finishing YourVelocity” by John Harvey, is a 7 pagehow-to article that covers a completesystem for finishing your Velocity(soup to nuts) as recommended by aprofessional. This is a two part articlethat finishes on page 13 of vol 4.• v10 p17 “Pin Hole & PrimerTips” by yours truly, covers a betterand faster way to fill in pin holes.I’d suggest that you read the abovefour articles first.

Since my first article on painting,I have changed to a new system. MyVelocity was painted using Dupont’sChromasystem, which is a base colorcovered with a clear coat. The clearcoat is comparable to an Imron typepaint. One of the reasons that Ichoose this system, is that it allowsyou to spot paint.

I’ll cover what I do to spot paint(touch up paint) an area, as this willkill two birds with one stone.

Suppose that I accidentallydropped a wrench on my wing. Inow have an ugly ding about the sizeof a penny. Do I have to paint theentire wing over? No, not with thissystem. I can spot repair this area,and when I’m finished, you will behard pressed to locate this defect.

Let’s say that this “ding” has pen-etrated the surface right down to theglass, without damaging the glass.Here is what I’d do step by step.First off you need good equipment ifyou want good results. For spotpainting, I have a DeVilbiss modelEGA Series 502 touch up gun.• Sand the damaged area with about150 dry sandpaper. Prime theexposed area with a two part epozyprimer (US Paint is what I use, D8001base & D3001 Converter mix ratio1:1). Let the primer totally cure. Youwill have a bit of overspray from theprimer. That is ok, as you need tosand out a much larger area than thatoriginal ding anyway. Wet sand thearea with 220, then 320, and finish upwith 600 wet. When done sanding,this area should look dull, but verysmooth, and free of any pin holes orsurface defects. The original ding(size of a penny) is now primed, andyou have also wet sanded into thesurrounding clear top coat area,which has removed the primer over-spray, and dulled the top coat sur-face around the original area of the“ding”. Dry this area, and tack itclean.• Dupont 222S Mid-Coat AdhesionPromoter - spray one coat at 30-45psiat the gun.• Dupont ChromaBase (with 7175SActivator) - mix at 1:1 ratio and sprayat 45psi until primed area matchesoriginal base color. In my case that iswhite and since the primer is whitetoo, it only takes two coats to cover.• Dupont ChromaClear (with 7575SActivator) - mix at 4:1 ratio and sprayabout 2 coats at 35-45psi• Dupont ChromaClear Blender7601S - spray one coat at 20psi. Thisis your last step involving spraying.Clean up and get away from yourplane for several days. Let it cureprior to completing the next step.• Let’s talk about the spray area. In

theory, my damaged area (nowprimed) represents 1 square inch ofarea (100%). When you wet sandedthat area, you sanded out beyond byan area at least 3 times larger (300%).You sprayed your adhesion coat overthis 300% area. You then sprayed thebase color coat only where you need-ed it (probably about 150%). Youthen sprayed the clear coats over the300% area that was wet sanded.Finally, you sprayed the blender coatat about 350% (a bit larger area thanwhere you clear coated).• Ok, the paint has cured and lookspretty good, except that you can tellwhere you did the touch up. We canfix that! Get out your small sandingblock again and use 1500 wet paper.Wet sand out this entire area, includ-ing any overspray.• Get out your big buffer/polisher.Apply some “DRX 25” compoundwith a paint brush, then buff it clean.Repeat this if needed until it looksreal good. Be sure to get the correcttype pad for DRX 25 for your buffer.• Let’s bring out that shine by polish-ing with “Liquid Ebony”. Again besure to get the correct polishing pad(different from the pad used for DRX25). Squirt some on, then buff itclean.• Stand back and admire your work.Invite someone that did not see youroriginal “ding” to look your birdover. Bet they won’t find anythingwrong!

Additional notes:- Be sure that you clean out yourspray gun between steps. I use a“wash grade” lacquer thinner toclean out my gun.- Buy and wear a quality paintingmask.- Read the painting directions oneach can.- Pre-mix the base and clear so that

Continued on next page

Velocity Views 14 Volume 15

the activator has time to activateprior to spraying! You can use smallcups if you are just doing a smallarea.- Moisture from your air compres-sor? Be sure that you have a goodquality air compressor (2 stage), oth-erwise you will be fighting moisturecoming out of your spray gun. To besafe, I put a moisture remover (biground thing that holds what lookslike a brown roll of toilet paperinside) between the compressor andmy hose. I also put a small moistureremover between my gun and thehose (in case there is any moisture inthe line).

Painting your entire plane?If I were painting the entire airplane,the only thing (from above touch upsteps) I would not use is the“blender”. Plus, of course, I’d usemy bigger spray gun. A good tip ifyou are painting your entire plane isto paint it one component at a time!Pros can get by painting an entireplane, but give yourself a break anddo one component at a time. I’d rec-ommend the following:- Left wing (make a stand to act asyour main spar and bolt it on)- Right Wing- Fuselage- Canard, cowls, ailerons, and otherloose partsThat’s four days instead of one, butyou’ll get better results for sure!

••••••

Installing an ELT antennaFrom Jim Agnew, Tampa Florida

I wanted an internal ELT anten-na for my 173 Elite FG to eliminatedrag and to be placed in thestrongest area of the aircraft to giveme the best chance that the antennawould survive a crash.

I decided to use the Jim WeirELT antenna as described in the May1997 issue of KITPLANES page 72.After several rounds of correspon-dence with Jim I settled on the placeto place the antenna with the leastcompromises. The antenna (pleaserefer to the picture) is glassed on the

easy maintenance. The #6210 is thealuminum housing, a filter (2” thick)bolts and the cover screens. This isthe same filter used on Mooney’swith IO-360 engines and providesabout 40 sq. in. of filter area. Thiswas also the area recommended byBrackett in their literature for 360 ci.200 HP engines. Solving the place toput it was more of a challenge. SinceI have the 173 wing and after read-ing Alan Shaw’s notes on wingmounted oil coolers I decided thatthis was a good place to put it.

I started 1” behind the rudderconduit and cut our an opening inthe web leaving 1” all around for aflange. Lay-up a 2 bid flange on thiscutout out piece. The opening isabout 6” front to back and the wingsurfaces determine the height. Sincethe filter housing is about 8” long Itunneled into the wing 9” and left aconsistent 1” of foam on the upperand lower wing surfaces. I next mea-sured back 3 1/2” from the wingspar and cut a round end slot paral-lel to the spar 1 1/4” high x 8” long.This size is based on the injector totalintake area and is a little larger. Youthen cut and form a sloping andcurving plenum back toward thefront face of the foam cutout to formthe intake plenum. The air filterassembly stands upright against thefront of the wing cutout. After fillingthe foam with microballoon andglassing (I used one Kevlar BID forstiffness ) you are ready to install thefilter (do it backwards for mainte-nance purposes and remember toreverse the element). Add some nutplates to the wing flange to mountthe cutout piece. On the cutout pieceadd an appropriate flange for a pieceof Scat duct to the fuel injector and Isuggest that you construct a popdoor with a light spring in case thefilter plugs then the door will openby suction and the engine will keeprunning.

You will note that I did not addan external lip or scoop since Alansaid that this is a very high pressurearea I will try it without the lipscoop. If it works as expected youwill have less drag and when inground effect on takeoff & landingyou should get a little additional

back side of the main spar and isbetween the main and wing spars.This is the strongest place with thelength to accommodate the antennaelements and would normally endup in a vertical position. The antennaconsists of four pieces of copper foiltape, two are 22.5” and two 10.5”. Asyou can see in the picture the anten-na consists of two Vs with one long& one short leg. the Vs are placedwithin 1/2” of each other and thenormal three ferrite beads are placedon the coax. when you make the Vsmake sure that the proper length ofboth pieces is preserved and thatyou cut the ends at a slight angle sothe coax shield and center conductorare soldered to BOTH pieces of foilon their respective foil Vs. I thenglassed over the elements & ferritebalun with one fine bid. The twopieces of 1/2” foam covered withfine bid on each side of the balun areto protect the beads from breakagewhile installing the wing. The onlyplace the coax is glassed down isbetween these foam blocks. The coaxthat runs along the lower strake edgeis held in place with silicone glue.Don’t use tight clamps or tie the coaxdown too tightly since you wantthings to move in a crash and notbreak the coax. Run the coax to yourELT, test for function and you aredone

If you refer to the picture to youcan see how this is done. Manythanks to Jim Weir for all of his help.

Installing a real air filterFrom Jim Agnew, Tampa, Florida

I wanted a real air filter in my173 that would provide well filteredair and easy maintenance. I decidedto use a Brackett model 6210 foamfilter based on its high filtration and

Continued from previous page

Velocity Views153rd Quarter 1998

unplanned and unthought of intothe duct. I settled on a 1 1/2” idDWV copper pipe that was availablefrom a plumbing wholesale shop, Iused 10 feet. With a wall diameter ofonly .042 inches it gave a total cop-per cross section nearly equivalent to#2 AWG. I got a ground-wire that isactually lighter than #3AWGbecause there is no insulation on it.

The first thing needed was toanneal the pipe. This was spectacu-lar, unfortunately I didn’t get pic-tures! Do this at dusk to get the fullpyrotechnic effects. Also, don’t dothis in your own home, go outside.Clamp the center of the pipe in avise, fill it with flame from a largetorch. When the entire pipe is glow-ing red, and flame is shooting out ofthe far end it’s ready to quench.Quickly douse the entire pipe invery cold water. Look out, this babywill move a lot as the moleculeschange character. Amazingly, afterall the movement is done there’s astraight soft pipe left over.

The center section of the pipe,that was clamped, needs to be sepa-rately annealed because the viseabsorbs too much heat. I missed thisstep and it made a little differencewhich I’ll talk about later. If you’regoing to cut the pipe into two pieces,as I did, do it before annealing. Itmakes a much cleaner (rounder) cut.

The fuselage of a Velocity is acompound shape that defies easypipe bending, and an annealed 11/2” pipe is not that soft. I needed toproduce a pattern for the pipe bend-ing.* Outline the original duct line onthe fuselage with a marker.* Mark the centerline of the duct asthe target for the pipe.* Use 1/4” foamboard to transfer acurve pattern from the fuselage to awooden form.

The wooden form was laminatedout of plywood to about 1 1/2” atone end and almost 8 inches at theend which formed the inboard curvebehind the keel extension. A 1 1/2’PVC was cut in half to support thepipe while bending, this wasattached to the form with woodscrews. Nine inch pieces of the PVC

boost pressure and additionalpower. Maybe not much but at highdensity altitude every little bit helps.

If you refer to the picture to youcan see how this is done. Manythanks to Alan Shaw for all of hishelp.

••••••

Installing aCopper-Pipe ductFrom Bill Schweitzer of San Jose CA

I have heard that compositeplanes are notoriously electricallynoisy due to difficult shielding of themain power wiring. This is particu-larly true in canard pusher designswhere the long run between batteryand starter/alternator is required forbalance. Some Velocity buildershave had bad luck installing sensi-tive equipment such as strike findersbecause of this.

Bob Nuckolls suggested in “TheAeroElectric Connection”(http://www.aeroelectric.com/)that the ground strap for a canardmight be a copper pipe with noisywires running inside it. I did somesimple calculations based on thecross section of #2AWG wire to findout what size pipe I would like touse for this experiment. I wanted thelightest pipe possible with thelargest internal diameter so that Icould get whatever wires were yet

were attached to short pieces ofwood with the opposite curve as theform, these fit over the top of thepipe while clamping. The clampswere started at the forward end ofthe pipe (the simplest curve) and thepipe stuck straight out from the firstcurve. A second clamp was used toslowly bend the pipe along thecurve. It took about 10 iterations ofclamping to pull it down to the form.The pictureshows the bendthat was donefor the smallpipe that wasused betweenthe firewall andthe keel extension. I had to do thisbecause there was no way to get thewhole ten foot length through fromone side or the other.

After the shape was close to fit-ting as I wanted in the fuselage Iused a separate, slightly tighter-curve form to make adjustment tovarious portions of the pipe. The twopieces were aligned just behind thekeel for a slip joint. The long pipestill had a circular cross section, andI wanted it to be flatter so I could fitthe original duct over the top. Tomake this adjustment Ibuilt a spindle roller andforced the pipe throughit. Since there is a twistto the pipe as it follows the fuselage Ineeded to track the top centerline ofthe pipe while rolling it. I markedthat with a marker before starting.The base is shaped like the fuselage,the roller matches the opening of thefiberglass duct. This is where themissed annealing made a difference.The roller could not flatten the cen-ter 8” of the pipe and got stretched abit going over that section.Fortunately, the piece of the duct infront of the copilot’s seat is just right.The pipe needs to remain perfectlycircular where the joint is soldered.

A 1 1/2” straight copper sleevejoint was used just behind the keel tojoin the two pipes. This was solderedonto the long pipe outside the plane.The final joint was soldered in place,very carefully. The picture shows the

Continued on next page

this side of the cockpit. The heattransfer to the copper pipe shouldmake an interesting extension to theVelocity factoryexperiments.

I have notattached any strapsto the pipe forground wire con-nections. Instead, Isoldered half of a 11/2” straight cop-per sleeve joint oneach end of the copper pipe. Thesetabs extend about 1 inch beyond thepipe. The corners are flattened androunded. Both tabs were attached tothe pipes outside of the plane. A3/8” hole is drilled on one cornerand a 1/4” hole in the other. #2AWGwires to the engine block and thebattery will connect here. Also a #8AWG wire (or as needed) will con-nect at the end of the pipe and gothrough the nearest bulkhead to con-nect to grounding busses for panelequipment and wing area wiring.Eventually I will need to drill 3/4”holes in the pipe for access to thewires inside. This will be done aboutsix inches behind the canard bulk-head and just in front of the firewall.

•••••

Velocity Views 16 Volume 15

retractable gear, the alignment hadto be changed.

The entire pipe is now attachedto the fuselage floor with strips ofmicroglass at about 18” intervals.That is just enough to hold every-thing in place. The annealed pipe isnot expected to provide any struc-tural integrity. I’ve not decided howmuch of the original fiberglass duct Iwill install over the copper pipe. I’mgoing to run the return oil line on

layers of aluminum foil and ceramictile that surrounded the entire heat-ed area during the operation. Thiswas no time to burn a hole in thefuselage for a NACA scoop or aspeed brake. Notice how the pipecurves around the keel extensionand goes through a hole in the gearbulkhead more inboard than the nor-mal duct. This is done because thecircular pipe is taller than the fiber-glass duct. To make room for the

Right Seat DateBy Judy Lavoie

WARNING: This article is not writ-ten by a pilot (although I have lots ofright seat time) or a builder (just anassistant at moving wings, cuttingfiberglass, interior stuff, etc.). It isstrictly intended for your entertain-ment.

As someone who likes to fly forwhere it gets me, rather than just forthe sake of flying, I have a flyingadventure to share with you. Lastyear I started a new tradition which Icall “Mystery Date” (borrowed froma board game from the ‘60s). For mybirthday, my husband Rick isresponsible for planning and execut-ing a special date for me. The less Iknow about it, the better...for me, thesurprise is half the fun. Psychiatristswould say I started this as a way of

getting some attention – after all,Rick was an intense 2 months awayfrom his first flight in N570 VelocityRG when we had our first MysteryDate last year. But he pulled off agood time and promised it would beeven better the next time, “...since bythen the plane will be done...”.

Anyway, my birthday rolledaround again this May and I gentlyreminded Rick of our tradition, withplenty of advance notice (I didn’twant him to have to rush his plan-ning!). As the day got closer, he let itslip that he had several choices inmind, and, since they all involvedflying, he’d let the weather help himchoose. Our schedule didn’t allow anovernight trip, so we’d be going justfor the day. All I was told was not toplan any work for the day, and to beready to take off at 8:30am, in casualclothes.

While returning from my sunrise

walk with our dog Darla on mybirthday morning, I had a suspicionwe’d be heading west: the wind wasstrong from the west, and I have astrange knack for attracting a headwind, no matter what direction wefly (would you expect a headwindwhile heading to Florida from NewMexico?)! Otherwise the weatherwas fine, with a broken layer atabout 1000’.

As we taxied to the run-up areafor Runway 24 in St. Augustine, Rickisolated the radio transmission so Iwouldn’t hear his flight plan info. Irelaxed to the music of Yanni in mystereo headset and put my nose intoa magazine I had packed. I resistedlooking at the maps on Rick’s lap.After take-off we seemed to stayclose to the runway heading, and theclouds soon obscured any ground

Continued on next page

Velocity Views173rd Quarter 1998

landmarks I might recognize. Rickswitched me on the radio to ask if Iknew where we were going yet and Itold him that I didn’t want to, so heput me back on music. My readingkept me from peeking at the instru-ments for clues.

After about an hour’s flight, weseemed to be descending. I lookedout to see a heavily settled areathrough the breaks in the clouds.Judging from the direction and time,I wondered if this was Tampa. I washoping now that maybe our destina-tion was St. Petersburg, since Rickknew there was an art museumexhibit there which I had posted anarticle about on our refrigeratormany weeks before. We got belowthe ceiling and we were undoubted-ly on Florida’s Gulf Coast. I had putaway my magazine, and was nowsearching for sites to confirm myguess, but none of the tall bankbuildings we could now see revealedthe name of a city. Rick’s landingpattern took us out over the water. Itwas beautiful! In the distance I couldsee a helicopter hovering over a boat,and as we made our turn for final wepassed right over a sailboat with allthe passengers waving at us. Thisairport was something like landingon an aircraft carrier. The numbersfor Runway 24 were practically atthe edge of the water! And the wholeairport was squeezed onto a penin-sula right in the city. I could see thewindsock was directly in line withthe runway, so I knew Rick wouldlike his landing – especially since therunway didn’t look too long. Thename “Albert Whitted Airport” did-n’t help me to know it was St.Petersburg, but when we opened thedoor and the lineman asked if we’dneed transportation Rick finallyspilled the beans and said “We’ll begoing to the art museum.” I wasdelighted! It was special for me,since Rick is no museum buff.

My Mystery Date turned out tobe an enjoyable time for both of us,with the art museum in the morning,a great lunch in a café on the marina,a stop in a wonderful gallery, and an

Right Seat DateContinued from previous page

afternoon visit to another museumfor an excellent feature exhibition onthe Titanic. Everything was in walk-ing distance and the weather wasterrific.

Our journey ended back in St.Augustine at about 4:30, wherewinds gusting from 18 to 28 knotsgave us some bounces in hazy visi-

bility. We didn’t learn until we land-ed that there was a tornado warningposted!

So for those of you who aredeeply devoted to building yourplane, take a break for a MysteryDate with your special someone. Ifyou’re really lucky, you’ll get oneplanned for you!

Mike Watson First Flight

N104MW parked just after her maiden voyage. Mike Watson’s Velocity 173 RGis powered by a Franklin engine with an Ivo Prop

Instrument panel for N104MW, built by Mike Watson of Mt. Vernon New York

Velocity Views 18 Volume 15

Subscription Order Form❏ Renewal ❏ New Subscription

For renewals, please check your mailing label (last page of the newsletter) for accuracy.

Name:

Mailing Address:

Home Phone #: Work Phone #:

Fax #: (If) e-mail address:

(If) Factory DMO #: (If) Which Model Velocity:

(If) Registration #: N (If) Velocity now flying?:--------------------------------------------------------------------------------------------------------------------------------------1999 Calendar Year Subscription (Volumes 17-20):❏ $ 35.00 in US funds for addresses within the United States❏ $ 43.00 in US funds for International addresses (extra $8 covers air mail and special handling)

Back Issues are $35 per Calendar Year:❏ 1998 (Volumes 13-16)❏ 1997 (Volumes 9-12)❏ 1996 (Volumes 5-8)❏ 1995 (Volumes 1-4)

❏ Check enclosed (US Bank or International Money Order)

It is more cost effective for me if you pay by check. Credit card option is available pri-marily for international subscribers in order to make it easy to pay in US funds. Thanks!❏ Master Card ❏ Visa

Card #_________________________________________________ Expiration Date_________________

Print your name as it appears on your credit card:___________________________________________

Your Signature authorizing me to charge your credit card:_____________________________________

NOTE: Your credit card statement will show the charge in the name of Lavoie Graphics

Mail with your payment to:Rick Lavoie, 26 Marshview Dr, St. Augustine FL 32084-5873

Or you can Fax to 904-461-3146 if paying by Master Card or Visa e-mail: [email protected]

Renew for the 1999 Calendar Year Today!If I already have your correct information (address, etc.) in my data base, then torenew, all you need to do is mail me a check! Otherwise, please complete the orderform below (please print clearly). Also, you can renew online via the internet on ourweb site: lavoiegraphics.comP.S. You can prepay future years as well...Thanks, Rick Lavoie

Velocity Views193rd Quarter 1998

Buy Sell or TradeVelocity parts, tools, kits, flying

Velocitys: Free and exclusive to all Velocity Views Subscribers.

Factory Information

Velocity Inc.Factory & Home Office:

200 W Airport RdSebastian FL 32958Ph: 561-589-1860Builder Assist Ph: 561-589-0309Fax: 561-589-1893Internet web site:http://www.velocityaircraft.comE-mail address:[email protected]

Velocity West (Sales & Service)1410-B Flightline DrLincoln CA 95648Ph: 916-645-6866Fax: 916-645-6944E-mail address:[email protected]

Avionics/InstrumentsFor Sale

One only Terra TX-760D ComTransceiver and TN-200D Navreceiver with Glide Slope and Tri-Nav C indicator. Side by side trayand connectors. Best price I couldfind advertised was $2959.00Special price on this unit only$2500.00

2 each Electric Turn Coordinators(E.G.C.) with plugs. Used with tags$295.00 each

Sigma Tek Vacuum Attitude Gyro,can’t tell from new with tags$350.00

Call Velocity Inc.

V-6 EngineFor Sale

Chev. V-6 4.3L engine with all alu-minum block and heads. Oil pumpand water pump driven piggy backfrom accessory case. Was installedon my Velocity, but I ran out oftime. Includes Northwest Aero ofAuburn, WA reduction drive,engine mount, custom radiator, top& bottom cowl assembled andready to mount on Velocity.$13,000 located in Sebastian,Florida.

Call Byron McKean, Payson, AZ520-474-7097

Two Things YouCan Do to Helpthe Newsletter• Renew early or on time(not later than December20th)

• Pay by Check instead ofCredit Card

Credit card option is avail-able primarily for interna-tional subscribers (in order topay in US$ easily). For allothers, it is best for me if youpay by check. Why? Theextra cost of processing creditcard payment adds up, butthe biggest expense is theextra time it takes me toprocess credit card payments.

CHECK-OUT’S

AVAILABLE AT

VELOCITY

WESTVelocity West is proud to

announce the addition ofScott Baker CFII, to the staff.Scott has been fully trained inflying the various Velocitymodels and is available toyou for Velocity proficiencytraining and check-out ser-vices. For more deatils oncost and his availability, feelfree to contact Scott orNancy directly here atVelocity West. The airplanecurrently being used for thiswork is the company demon-strator model, N94VA, whichis a Velocity Elite LW (fixedgear).

Velocity Fly-ins???Looking for Input

With a flying fleet of about100 Velocitys, we should beable to plan some decent fly-ins. We want your input andhelp!

We want you to let usknow what you would like tosee for factory sponsored fly-ins. It takes about 4-6 monthsadvance lead time for plan-ning.

Contact Duane Swing orRick Lavoie with your inputby e-mail or phone:[email protected]@lavoiegraphics.com

Velocity Viewsis published Quarterly by:

Lavoie Graphics26 Marshview Dr

St. Augustine, FL 32084-5873Rick Lavoie,Editor904-461-3146 (fax)

e-mail: [email protected]

Velocity Views newsletter ispublished by Rick Lavoie / LavoieGraphics as an agent for VelocityInc. (the factory). Prior to printing,the factory reviews each volumepublished for accuracy.

Velocity Views newsletter mate-rial has been supplied voluntarilyfrom the Velocity Factory,Builders, & Vendors. This materialis printed for informational pur-poses only. Opinions expressed arethose of the author. LavoieGraphics & Rick Lavoie do notendorse and are not liable for thecontents of such material. Use ofthis material is at your own risk.Any variance from the factoryplans is a high risk endeavor. Anycontemplated modificationsshould be reviewed and approvedby Velocity Inc.

Velocity Views is a Trademark ofLavoie Graphics

Copyright © 1994 - 98 LavoieGraphics All Rights Reserved.

No part may be reproduced or trans-lated, stored in a database or retrievalsystem, or transmitted in any form byelectronic, mechanical, photocopying,recording, or other means, except asexpressly permitted by the publisher.

Rick Lavoie, Newsletter Editor26 Marshview DrSt. Augustine FL 32084-5873 FORWARD & ADDRESS CORRECTION

FIRST CLASS

• 1998 Calendar YearSubscription (Volumes 13-16):The annual cost is $35.00 for mail-ing addresses within the UnitedStates. For all other mailingaddresses, the cost is $43.00 in USfunds (covers air mail & specialhandling).

All subscriptions are sold on acalendar year basis. New sub-scribers joining mid year will beprovided with back issues forthat calender year.• Back Issues 1995, 1996, &1997, are available for sale at$35.00 per year in US funds.Specify the year(s) you wantwhen ordering back issues.• Renewals: Look at the top ofyour mailing label for the finalvolume number your subscrip-tion covers.Simply mail a check to RickLavoie each year to keep yournewsletter coming.

Subscriptions

Submitting Articles

Listed below are 4 options forsubmitting your text. Please send usphotos and drawings too!1) Send it on a 3-1/2” computer disk(Mac or DOS). This saves us from re-typing all that text. Don’t formatyour text, just give us raw text, withno underlining, bold, or any othertype of formats. We also can takeZip100.2) E-Mail your text file to me:[email protected]) If you don’t have access to a com-puter, then we can scan in yourtyped page.4) If you print neatly so we can readit clearly, we’ll intype it on our com-puter for you!Note: If you need your photos &materials returned, please include aself addressed envelop.

“Paid thru Vol ?” on your labelindicates the final volume yoursubscription covers.

It is more cost efficient for us if youpay by check, but if you elect to paywith Master Card/Visa, be sure toinclude the following, printed clearly:• Name as it appears on your Card.• Credit Card number• Expiration Date• Master Card or Visa?NOTE: On your statement, thecharge will be processed in thename of Lavoie Graphics

Delivery DatesQuarter: Mailed by:1st January 15th2nd April 15th3rd July 15th4th October 15th

Submission DeadlinesQuarter: Mail Date:1st December 1st2nd March 1st3rd June 1st4th September 1st

![[Homebuilt Aircraft] Zenith Chris Heintz Drw & Construction Manual 1976](https://static.fdocuments.net/doc/165x107/577cdb181a28ab9e78a74e23/homebuilt-aircraft-zenith-chris-heintz-drw-construction-manual-1976.jpg)