Reuse of Fermentation Brines in the Cucumber Pickling …infohouse.p2ric.org/ref/15/14362.pdf ·...

Transcript of Reuse of Fermentation Brines in the Cucumber Pickling …infohouse.p2ric.org/ref/15/14362.pdf ·...

e

.. '\.

,'

xi

A

a F I z

RESEARCH REPORTING SERIES

4 Environmental Monitoring 5 Socioeconomic Environmen!a! Studies 6 ? 6 Special Reports ? !J,scellant.ous Repfx ts

Scientific and Technical Assessment Reports ISTAR, interagency Energv-Enviror8rtent ResParc? 3nC De le,oL.7Yr:

Thts report has been assjgned 10 !he EY'JIRONMENTAL F NOLOGY sertes This series descr.bes rssearch performed I opsiraie lnstrumen!ation equipmep! ana methodology lo r v,ronmer;!aI &?gradatton lrom poin! an< non-poinl Sources 0 prc'rldes the new or impro.ied techr,oioc;y requNred for the Contrg! ar'3 :reatce-I c ' ooiiil:Non sources to meei erivironmer!al qualitv sta.!darOs

pi,.w m.i TECHNICAL Inruxrrons 00 REPORT rhr rctrrS? DATA heforc colnplrnnpl

I' 3 REClPl REPORT N O

5 REPcmT DATE EPA-600/2-78-207 T I T L E A N O S U S T T L E

REUSE OF FERMENTATION BRINES I N THE CUCUMBER September 1978 issuing date

E P E R F O R M I N G ORGANIZATIOH CODE

8 P E R F O R M I N G ORGANIZATION REPORT NO. PICKLING IWSTRY A U T H O R I S I

R. F. kFee ters and U. Coon*; M. P. P a l n i t h r and I 10. P R O G R A M ELEMENT NO. b l . Veltin *** N. Fehrin er***

Pickle Packers International II.CONTRACTICRANT N O 108 East Hain Street P.O. Box 31 5-803825

PLRFoRhrlNG ZRG;NIZATION N A W f A N D ADDRESS lBB610

60174 St . Charles , I L 13. T V i E OF R E P O R T A N O P E R l O D C O V E R E D _-____________----..-

I. S P O N S O R I N G A G E N C Y N A M E A N D A D O R E S Industrial Environmental Research Laboratory

U.S. Environmental Protection Agency EPA/600/12 Cinciunati, Ohio 45268

Final ReDOrt 5/75 - l.2177 Office of Research and Development 14. S P O N S O R I N G A G E N C Y CODE

i. SUPPLEMENTARY NOTES *Department of Food Science and Human Nutrition, M S t . Univ., East Lansing,MI4882&

**Vlasic Foods, Inc, West Bloomfield, M I 48033 **Detroit District Office U.S. M 48826

feas ib i l i ty of recycling spent cucunbek fermentation brine. procedures, heat treatment and chemical treatment, were used. tha t brine recycling w a s practical on a comerical scale. procedure resulted i n salt stock which were equivalent i n quality t o contkol cucumbers.

Studies were conducted t o determine the adequacy of the brine treatment

i. ABSTRACT

The project evaluated on a comerical scale the technological and economic Two brine treatment

The results showed Either brine treatment

procedures employed. s e c . was scf f ic ien t t o assure inactivation of pectinlses from nolds found to be ccTnon OF. cu:uaber f r u i t s and flowers. temperature of 7 P F or higher w a s required. tained a t 11.0 o r higher f o r a t l eas t 36 h r t o assure 99% inactivation of pectin- ases from the molds which were investigated.

An eco;iomic evaluation of the recycling procedures snowed a sa211 net savings

The data confirmed tha t a heat treatment of 175°F for 30

For effective cnenical treatment a brine In addition, the pH had to be main-

f o r the heat treatment procedure and a small net cost for chemical treatment. Selection of the process fo r a particular plant w i l l depend upon the local conditions

Food Processing f'(,"'.f '9' Pi

B r i n a ~ Circulation Economic Analysis Treatment

Y

- 8 O l S T R l B U T l O N S T A T E U E N T le S E C U R I T V CLASS [Tliit RIPPI]

-lo. SECURITY CLASS (Thtl P W l Unclassified

Unclassified Release to Public

I

EPA-60012-78-207 September 1978

REUSE OF FERMENTATION BRINES IN THE CUCUMBER PICKLING INDUSTRY

by

R. F. McFeeters and W. Coon Department of Food Science and Human Nutrition

Michigan State University, East Lansing, Michigan 48824 and

M. P. Palnitkar and M. Velting Vlasic Foods, Inc., West Bloomfield. Michigan 48033

and N. Pehringer

Detroit District Office, U.S. Food and Drug Administration Detroit, Michigan 46826

Grant No. 5-803825

Project Officer

Harold W. Thompson Food and Wood Products Branch

,Industrial Environmental Research Laboratory Corvallis Field Station

Corvallis, Oregon 97330

INDUSTRIAL ENVIRONMENTAL. RESEARCH LABORATORY OFFICE OF RESEARCH AND DEVELOPMENT

U . S . ENVIRONMENTAL PROTECTION AGENCY CINCINNATI, OHIO 45268

DISCLAIMER FOREWORD

This report has been reviewed by the Industrial Environ- mental Research Laboratory-Cincinnati Food and Wood Products Branch, U . S . Environmental Protection Agency, and approved for publication. Approval does not signify that the contents necessarily reflect the views and policies of the U . S . Environ- mental Protection Agency, nor does mention of trade names or commercial products constitute endorsement o r recommendation for use.

When energy and material resources are extracted, processed, converted, d used, the related pollutional impacts on our environment and even on our alth often require that new and increasingly more efficient pollution ntrol methods be used. The Industrial Environmental Research Laboratory- ncinnati (IERL-Ci) assists in developing and demonstrating new and improved thodologies that w i l l meet these needs both efficiently and economically.

This report shows the results of a comercinl evaluation of the reuse "spent brine" in the cuctnnber pickling industry. It appears that the

This can lead to important cumber pickling industry can economically recover nnd reuse most of the rmentation brines generated in tank yards. ductions in waste generation in this industry vithout significant changes the quality of the products produced. of interest to the processors in this industry,and environmental regula-

For further informntion on this project contact the Food and

As a result, this report should

ry agencies. od Products Branch, Induetrial Pollution Control Division, Industrial vironmental Research Laboratory-Cincinnati.

David C. Stephan Industrial Environmental Director Research Laboratory

Cinc idnat i

ii iii

. e

. . . . * - . I .

ABSTRACT

The p r o j e c t e v a l u a t e d on a couanercial scale the technolo- g i c a l and economic f e a s i b i l i t y of r e c y c l i n g s p e n t cucumber fe rmenta t ion b r i n e . 'pwo b r i n e t r e a t m e n t procedures , h e a t t reat- ment and chemical t r e a t m e n t , were used. The r e s u l t s shaved t h a t b r i n e r e c y c l i n g was p r a c t i c a l on a commercial scale. b r i n e t r e a t m e n t procedure r e s u l t e d in s a l t s t o c k which were e q u i v a l e n t i n q u a l i t y t o c o n t r o l cucumbers.

S t u d i e s were conducted t o determine the adequacy of the b r i n e t r e a t m e n t procedures employed. h e a t t r e a t m e n t o f 175'F f o r 30 sec. w a s s u f f i c i e n t t o asBure i n a c t i v a t i o n o f p e c t i n a s e s from m o l d s found to be common on cucumber f r u i t s and f lowers . For e f f e c t i v e chemical t r e a t m e n t a b r i n e tempera ture o f 72'F or h i g h e r w a s requi red . t h e pH had t o b e main ta ined a t 11.0 or h i g h e r for a t l e a s t 36 h r to a s s u r e 99% i n a c t i v a t i o n of p e c t i n a s e s from t h e molds which were i n v e s t i g a t e d .

small n e t s a v i n g s f o r the h e a t treatment procedure and a s m a l l n e t c o s t f o r chemical t rea tment . S e l e c t i o n o f the p r o c e s s f o r a p a r t i c u l a r p l a n t w i l l depend upon the l o c a l c o n d i t i o n s .

by P i c k l e Packers I n t e r n a t i o n a l , Inc. , under the p a r t i a l spon- s o r s h i p of the U.S. Environmental P r o t e c t i o n Agency. report covers a p e r i o d from May, 1975 t o December, 1977; d a t a c o l l e c t i o n was completed as of October , 1977.

E i t h e r

The d a t a confirmed t h a t a

I n a d d i t i o n ,

An economic e v a l u a t i o n of t h e r e c y c l i n g procedures showed a

This report was submi t ted in f u l f i l l m e n t of G r a n t S-803825

This

CONTENTS

Foreword . . . . . . . . . . . . . . . A b s t r a c t . . . . . . . . . . . . . . . F i g u r e s . . . . . . . . . . . . . . . Tables . . . . . . . . . . . . . . . . Conversion F a c t o r s and Metric P r e f i x e s

Acknowledgment . . . . . . . . . . . . 1. I n t r o d u c t i o n . . . . . . . . . 2 . Conclusions . . . . . . . . . . 3 . Recommendations . . . . . . . . 4 . Experimental Design . . . . . . 5. R e s u l t s and Discussion . . . .

References . . . . . . . . . . . . . . Appendix . . . . . . . . . . . . . . .

. . . . . . . . . . . iii

. . . . . . . . . . . i v

. . . . . . . . . . . v i

. . . . . . . . . . . v i i

. . . . . . . . . . . x i

. . . . . . . . . . x i i i

. ( . . . . . . . . . 1

. . . . . . . . . . . 4

. . . . . . . . . . . 5

. . . . . . . . . . . 6

. . . . . . . . . . . 2 3

. . . . . . . . . . . 6 8

. . . . . . . . . . . 71

iv V

FIGURES

Number

1 Schematic diagram o f t h e b r i n e recovery u n i t . . . . 8

2 Regenera t ive h e a t exchanger system used f o r t h e

3 General des ign of t h e commercial e v a l u a t i o n

4 Score sheet f o r taste p a n e l e v a l u a t i o n of

5

b r i n e recovery unit . . . . . . . . . . . . . . . 9

o f b r i n e r e c y c l i n g . . . . . . . . . . . . . . . . 1 2

hamburger d i l l c h i p s . . . . . . . . . . . . . . . 15 ..

E f f e c t of pH on h e r t i n a c t i v a t i o n of P e n i c i l l i u m l a n t h i n e l l u m p e c t i n a s e . Experiments were done i n brine c o n t a i n i n g 12% N a C 1 , 0.6% lac t ic a c i d and 0.1% Ca++ i o n . . . . . . . . . . . . . . . . . . . . . 6 4

TABLES

Number

1 C h a r a c t e r i s t i c s of 1st c y c l e s p e n t b r i n e i n t h e s p r i n g of 1975 b e f o r e and a f t e r h e a t or chemical t rea tment . The t r e a t e d b r i n e s were used as cover b r i n e s f o r 2nd c y c l e f e r m e n t a t i o n s . . . . . . . . . . . . . . . . . . 2 4

t h e s p r i n g o f 1976 b e f o r e and a f t e r h e a t o r chemical t r e a t m e n t . The t r e a t e d b r i n e s were used as cover b r i n e s f o r 3rd cycle f e r m e n t a t i o n s . . . . . . . . . . . . . . . . . . 25

3 Summary d a t a on fe rmenta t ion tanks, 1975 . . . . . 2 8

4 Summary d a t a on fermenta t ion t a n k s , 1976 . . . . . 28

5 A n a l y s i s of s p e n t b r i n e remaining i n t h e

2 C h a r a c t e r i s t i c s of 2nd c y c l e s p e n t b r i n e i n

fe rmenta t ion tanks i n the winter a f t er removal of e a l t s t o c k cucumbers from the 2nd c y c l e (1975) and 3rd c y c l e (1976) fe rmenta t ion t a n k s . . . . . . . . . . . . . . . . . . . . . . 30

6 Analys is of spent b r i n e remaining i n t h e fe rmenta t ion tanks in t h e w i n t e r a f t e r removal of s a l t s t o c k cucumbers from t h e 2nd c y c l e (1975) and 3rd c y c l e (1976) f e r m e n t a t i o n tanks . All d a t a a r e expressed a s mg/l o f b r i n e . . . . . . . . . 3 1

7 Q u a l i t y of 2nd c y c l e s a l t s t o c k cucumbere

8 Q u a l i t y of 3rd c y c l e s a l t s t o c k cucumbers

9 Comparison of 2nd c y c l e product wi th t h e

fermented in recyc led b r i n e , 1975 . . . . . . . . 32

fermented i n recyc led b r i n e , 1 9 7 6 . . . . . . . . 32

c o n t r o l (averages) , 3 samples/group, 9 judges and 7 groups . . . . . . . . . . . . . . 34

. . ..

vi v i i

,

Number * 10 Comparison of 3rd c y c l e product w i t h the

c o n t r o l (averages) , 3 samples/group, 11 judges and 5 groups . . . . . . . . . . . . . . 35

11 Analys is o f v a r i a n c e t a b l e f o r t e x t u r e d i f f e r e n c e s of hamburger d i l l c h i p s made from 2nd c y c l e s a l t s t o c k cucumbers . . . . . . . . . . . . . . . . . . . . 36

Analys is o f v a r i a n c e t a b l e f o r f l a v o r d i f f e r e n c e s of hamburger d i l l c h i p s made from 2nd c y c l e s a l t s t o c k cucumbers . . . . . . . . . . . . . . . . . . . . 37

1 3 Analys is o f v a r i a n c e t a b l e f o r t e x t u r e d i f f e r e n c e s of hamburger d i l l c h i p s made from 3rd c y c l e sa l t s t o c k

1 2

cucumbers . . . . . . . . . . . . . . . . . . . . 38

1 4 Analys is of v a r i a n c e t a b l e f o r f l a v o r d i f f e r e n c e s of hamburger d i l l c h i p s made from 3rd c y c l e s a l t stock cucumbers . . . . . . . . . . . . . . . . . . . . 39

Analys is o f variance table f o r o v e r a l l q u a l i t y d i f f e r e n c e s of hamburger d i l l c h i p s m a d e from 3rd c y c l e s a l t s t o c k

16 S a l t s t o c k cucumber a n a l y s i s . D i s t r i -

15

cucumbers . . . . . . . . . . . . . . . . . . . . 40

b u t i o n o f minera l l e v e l s i n commercial s a l t s t o c k d u r i n g t h r e e c y c l e s of fe rmenta t ion . A l l d a t a are expressed a s mg/kg of cucumbers . . . . . . . . . . . . . . 4 2

1 7 Desa l ted cucumber a n a l y s i s . D i s t r i b u t i o n o f m i n e r a l l e v e l s i n d e s a l t e d cucumbers d u r i n g three c y c l e s of fe rmenta t ion . All d a t a are expressed as mg/kg of cucumbets . . . . . . . . . . . . . . . . . . . . 43

1 8 Savings from r e c y c l i n g 1 , 0 0 0 g a l of

1 9 Economic e v a l u a t i o n of chemical t rea tment

Operatkng costs and savings us ing h e a t

s p e n t b r i n e . . . . . . . . . . . . . . . . . . . 45

of s p e n t b r i n e s . . . . . . . . . . . . . . . . . 45 20

t r e a t m e n t f o r s p e n t b r i n e s . . . . . . . . . . . . 46

2 1 N e t p r e s e n t va lue c a l c u l a t i o n f o r comparison of chemical t rea tment w i t h h e a t t r e a t m e n t of b r i n e . The d i f f e r e n c e between t r e a t m e n t costs p e r 1,000 g a l f o r chemical compared t o h e a t t r e a t m e n t of b r i n e was $16.43 i n 1976. For 1.7 m i l l i o n g a l this is a t o t a l d i f f e r e n c e i n t r e a t m e n t cost of 1700 x $16.55 - $27,931. With a maintenance cost o f $500/yr f o r t h e u n i t t h e n e t d i f f e r e n c e is $27,431 . . . . . . . . . . . . . . . . . . 48

22 Raw waste l o a d summary . . . . . . . . . . . . . . . 50

23 EPA e f f l u e n t g u i d e l i n e s - 1977 . . . . . . . . . . . 50

2 4 EPA e f f l u e n t g u i d e l i n e s - 1983 . . . . . . . . . . . 51 25 T h e o r e t i c a l s a l t use and d i s c h a r g e d u r i n g

fe rmenta t ion , s t o r a g e , untanking and d e s a l t i n g of cucumbers. R e s u l t s are expressed as t h e l b of s a l t r e q u i r e d ger bu (50 lb) of f r e s h cucumbers . . . . . . . . . . 53

26 Recoveries (0 ) of added p e s t i c i d e s . . . . . . . . . 56

27 L o w e s t l e v e l s a t which r e s i d u e s were

28 E f f e c t of h e a t and NaOH t r e a t m e n t on

29 E f f e c t of h e a t and NaOH t r e a t m e n t on

30 E f f e c t of h e a t and NaOH t r e a t m e n t on

31 E f f e c t of h e a t o r NaOH t r e a t m e n t on PCNB

32

q u a n t i t a t e d . . . . . . . . . . . . . . . . . . . 57

c a r b a r y l i n p i c k l e b r i n e . . . . . . . . . . . . . 59

p a r a t h i o n i n p i c k l e b r i n e . . . . . . . . . . . . 60

endosul fan i n p i c k l e b r i n e . . . . . . . . . . . . 6 1

and PCA i n p i c k l e b r i n e . . . . . . . . . . . . . 62

de te rmina t ion of thermal s t a b i l i t y of p e c t i n a s e s i n b r i n e s . . . . . . . . . . . . . . . 63

thermal s t a b i l i t y i n p r e l i m i n a r y experiments . D-values w e r e o b t a i n e d a t pH 3.3 i n 12% NaC1, 0.6% l ac t i c a c i d and 0.1% Ca++ i o n . . . . . . . . . . . . . . . . . . 63

Sources and i d e n t i t y of fungi used f o r

33 D-values of p e c t i n a s e s with the g r e a t e s t

v i i i

5 i x

A*:& c 'r +"-

34 E f f e c t of NaCl concentration on the heat inact ivat ion o f pectinase from Penic i l l ium janthinellum a t 7 5 O C . . . . . . . . 6 5

35 Inactivation of pect inase from Penici l l ium a t high pH i n spent br ine .

22OC ( 7 1 . 6 O F ) . S a l t concentration 8.0% . . . . . . . . . . . . . . . 6 5

CONVERSION FACTORS AND METRIC PREFIXESa

. . To ccnvert from

Degree Fahrenheit (OF)

inch (in)

foot (ft)

gallon (gal)

bushel (bu)

3.8 gal/bu

grain (pr)

ounce (02)

pound (lb)

gallons per minute (gal/min)

ounces per gallons (oz/gal)

pounds per ton (lb/ ton)

pounds per 1000 pounds (lb/1000 lb)

tons per year (ton/yr)

gallons per ton (gal/ton)

CONVERSION FACTORS

to

Degree Celsius (OC)

metre (m)

metre (m)

metres (m3)

metre3 (m3)

0.408 m3/m3 1

kilogram (kg)

kilogram (kg)

kilogram (kg)

metre3/second (m3/s)

(kg/m3)

(kg/kkg)

(kg/kkg)

(kkg/yz)

(m3/kkg)

kilogram/metre3

kilogram/kilokilogram

kilogram/kilokilogram

kilokilogram/year

metre3/kilokilogrars

Multiply by

t°C = 0.56 (t0~-32)

2 . 5 4 x l o - *

3.048 x 10-1

3.784 10-3

3.524 x IO-*

1.0

6 . 4 8 x 10-5

3.11 x

4.536 x lo-'

6.308 x l o - ;

8.218

4.643 x 10-1

1.0

9.074 x 10-1

4.17 x 10-3

X xi

To convert from to

pounds per gallon kilograns/metre3 ( W g a l ) W m 3 )

pounds per 1000 (lb/ 1000

cost per pound ($/lb)

cost per gallon ($/gal)

cost per 1000 gallon cost/metre3 ($/lo00 gal) (S/m3)

cost per ton ($/ton)

Prefix Symbol

kilo k

centi C

cost/kilokilogram (S/kkg)

METRIC PREFIXES

Multiply by

1.1984 x lo2

1.1984 x 10-I

4.536 x lo-'

2.642 x lo2

2.642 x 10-1

1.102

Multiplication factor Example

103

10-2

2 kg = 2 x 103 grams

2 cm = 2 x 10-2 metre

ACKNOWLEDGMENTS

P i c k l e Packers I n t e r n a t i o n a l , I n c . , a p p r e c i a t e s t h e coopera t ion of t h e Department of Food Science and Human N u t r i - t i o n , Michigan S t a t e Univers i ty : Vlasic Foods, 1nc. i and t h e P P I Ecology Committee i n t h e p lanning , a d m i n i s t r a t i o n and e x e c u t i o n of this p r o j e c t . The D e t r o i t Dis t r ic t O f f i c e of t h e U.S . Food and Drug Adminis t ra t ion w a s very h e l p f u l i n provid ing a s s i s t a n c e on p e s t i c i d e a n a l y s i s .

M r . Herman B l u m ' s a s s i s t a n c e i n i n i t i a t i o n of t h e p r o j e c t and h i s advice and l e a d e r s h i p d u r i n g t h e p r o j e c t were p a r t i c u - l a r l y va luable . M r . Michael V e l t i n g , Mr. Richard Bowman, M r . Scott Smith, M r . Maury K i t t e l , and M r . Charles S a n t e r r e were o t h e r members of Vlasic Foods, Inc. , who made s i g n i f i c a n t c o n t r i b u t i o n s t o t h e o p e r a t i o n of the p r o j e c t . The a s s i s t a n c e of p l a n t personnel a t Imlay C i t y , Michi#an is a l s o acknowledged.

P e c t i n a s e i n a c t i v a t i o n s t u d i e s were done by Ma. Suparath Chavana and M r . Nicholas Pa lamidis . A s s i s t a n c e with cucumber b r i n i n g , sample c o l l e c t i o n , and a n a l y s i s a t MSU w a s provided by Mr. Michael F i s h e l , Ms. Debra P a t t e r s o n , W. Luci Chua and Ms. Patr ic ia Fodel l . Members of the Michigan S t a t e U n i v e r s i t y Cucumber Research Committee provided t r a n s p o r t a t i o n , r e p a i r s e r v i c e s , and advice throughout t h e p r o j e c t .

W e f u r t h e r acknowledge M r . Harold Thompson of t h e I n d u s t r i a l Environmental Research Laboratory of t h e Environ- mental P r o t e c t i o n Agency f o r his guidance and numerous h e l p f u l s u g g e s t i o n s i n a l l phases of t h e p r o j e c t .

aStandard for Mezric Practice. kLISI/ASTM Designation: E 380-76', IEEE Std 268-1976, American Society for Testing and Materials, Philadephia, Pennsylvania, February 1976. 37 pp.

xli xiii

I . , ". . . _ I . . .. - "... I . . ,

SECTION 1

INTRODUCTION

P e r c a p i t a p i c k l e consumption i n t h e United S t a t e s h a s shown s t e a d y i n c r e a s e s s i n c e 1930 from 1.07 kg to 3.75 kg i n 1976. There are two major classes of cucumber p i c k l e s , f r e s h pack a i d p r o c e s s pack. Fresh pack products a r e prepared by p r o c e s s i n g f r e s h cucumbers d i r e c t l y i n t o f i n a l p roducts . The process pack r e q u i r e s i n i t i a l fe rmenta t ion of cucumbers, s t o r a g e a t h igh s a l t c o n c e n t r a t i o n s , and subsequent d e s a l t i n g p r i o r t o p r o c e s s i n g i n t o consumer or i n s t i t u t i o n a l products . I n 1975 t h e p r o c e s s pack o p e r a t i o n u t i l i z e d 206,000 metric t o n s o f green s t o c k o r 6 4 % of t h e green s t o c k purchased by p r o c e s s o r s (1). This d i s t r i b u t i o n of product u t i l i z a t i o n makes t h e tank y a r d I '

a major source o f waste i n t h e i n d u s t r y . Kirk ( 2 ) r e p o r t e d t h a t . s p e n t b r i n e accounted for 8% o f t h e to ta l h y d r a u l i c load, 4 4 % of t h e BOD and 59% o f t h e s a l t genera ted i n t h e manufacture of p r o c e s s pack products .

t i o n s . These i n c l u d e s p i l l a g e , t ank overf low dur ing r a i n y p e r i o d s , l eakage from wooden t a n k s , s p e n t fe rmenta t ion b r i n e and " p r o c e s s w a t e r " genera ted d u r i n g d e s a l t i n g o p e r a t i o n s . This p r o j e c t was designed t o e v a l u a t e r e c y c l i n g of s p e n t b r i n e s a s a means f o r c o n t r o l of this s o u r c e of waste.

There are s e v e r a l sources o f w a s t e s from tank y a r d opera-

U6ual fe rmenta t ion p r a c t i c e s w i l l r e s u l t i n product ion of about 40% by volume spent b r i n e i n a fe rmenta t ion tank . The cucumber fe rmenta t ion is normally done a t 6.5% NaCl ( 3 ) . How- e v e r , when t h e fe rmenta t ion i s completed, a d d i t i o n a l s a l t i s added t o i n s u r e a g a i n s t d e t e r i o r a t i o n of t h e f r u i t d u r i n g tank y a r d s t o r a g e . As a r e s u l t , s p e n t b r i n e s u s u a l l y c o n t a i n 9-15% NaC1, the BOD w i l l be 10,000-15,000 mg/l and t h e pH w i l l b e 3.2-3.5. These c h a r a c t e r i s t i c s make b i o l o g i c a l t r e a t m e n t of w a s t e r e l a t i v e l y d i f f i c u l t . Discharge of b r i n e s produced by tank y a r d , o p e s a t i o n s may n o t be p o s s i b l e i n some l o c a t i o n s wi th limits on t o t a l d i s s o l v e d s o l i d s .

I n a s s & s i n g environmental c o n t r o l s t r a t e g i e s a v a i l a b l e for managing these b r i n e s one may wonder i f it is f e a s i b l e t o either r e c l a i m t h e s a l t conta ined t h e r e i n , or t o r e c y c l e t h e s p e n t s o l u t i o n .

1

I

Durkee e t a l . ( 4 ) has developed a procedure f o r s a l t recovery from fermenta t ion b r i n e s by e v a p o r a t i o n of t h e water and i n c i n e r a t i o n of t h e o r g a n i c m a t t e r . S a l t recovered by t h i s method has been used s u c c e s s f u l l y i n cucumber f e r m e n t a t i o n s (5). However, t h i s technique has n o t been adopted commercially due t o t h e high c o s t o f equipment and energy.

One i s t h e p o t e n t i a l f o r l o s s of product q u a l i t y i f p e c t i n a s e s were c a r r i e d over i n t h e recyc led b r i n e a t l e v e l s s u f f i c i e n t t o s o f t e n cucumbers dur ing months of fe rmenta t ion and s t o r a g e i n t h e b r i n e . I t is a l s o p o s s i b l e t h a t p roducts of fermenta- t i o n could i n h i b i t subsequent fe rmenta t ions o r cause abnormal fe rmenta t ions . There could a l s o be a b u i l d u p o f t o x i c com- pounds. The d e s t r u c t i o n of t h e s e products might r e q u i r e i n c i n - e r a t i o n o r o t h e r d r a s t i c techniques. Pa thogenic organisms w i l l n o t , however, be a problem due t o t h e low pH and h igh s a l t c o n t e n t of t h e b r i n e .

When cons ider ing b r i n e r e c y c l i n g , many concerns arise.

Geisman and HeMe ( 6 , 7) developed a chemical t r e a t m e n t procedure f o r rec la iming s p e n t fe rmenta t ion b r i n e s . Their procedure r e q u i r e s r a i s i n g t h e pH o f s p e n t b r i n e to 10 or 11. This t r e a t m e n t c l a r i f i e d t h e b r i n e , s i n c e a p r e c i p i t a t e formed which occluded suspended cells. It was a l s o presumed t o i n a c t i v a t e p e c t i n a s e a c t i v i t y . A f t e r a 48-hr h o l d i n g p e r i o d , the pH was a d j u s t e d t o 7 and t h e b r i n e used as a cover b r i n e f o r fe rmenta t ion . Normal fe rmenta t ions r e s u l t e d from use of t h i s b r i n e . This showed t h a t i n c i n e r a t i o n was n o t r e q u i r e d f o r r e u s e of s a l t and provided a p r a c t i c a l a l t e r n a t i v e t r e a t m e n t .

P a l n i t k a r and McFeeters ( 8 ) showed t h a t chemica l ly t r e a t e d b r i n e could be used f o r m u l t i p l e fe rmenta t ion c y c l e s w i t h o u t loss of s a l t s t o c k q u a l i t y . They a l s o sugges ted t h a t h e a t i n g of b r i n e could be used a s an a l t e r n a t i v e t r e a t m e n t and sugges ted 175'F f o r 30 sec . a s a reasonable h e a t t r e a t m e n t .

The r e c y c l i n g procedures were compared t o c o n t r o l s i n which cucumbers were fermented i n f r e s h s a l t b r i n e . The c o n t r o l fe rmenta t ions were done accord ing t o normal commercial b r i n i n g procedures . The commercial fe rmenta t ions were c a r r i e d o u t a t

. t h e Imlay C i t y , Michigan p l a n t of V l a s i c Foods, I n c .

C r a n f i e l d ( 9 ) had previous ly r e p o r t e d on a system f o r p a s t e u r i z a t i o n of b r i n e , s a t u r a t i o n of t h e t r e a t e d b r i n e by a d d i t i o n of s a l t and reuse of t h e t r e a t e d b r i n e a s a s a t u r a t e d s a l t s o l u t i o n . 8

The primary o b j e c t i v e s of t h i s p r o j e c t were t o e v a l u a t e t h e commercial , t e c h n o l o g i c a l , and economic f e a s i b i l i t y of b r i n e r e c y c l i n g by both h e a t and chemical t r e a t m e n t s and t o determine t h e r e l a t i v e merits of t h e s e two procedures .

2 3

SECTION 2

CONCLUSIONS

1. Br ine r e c y c l i n g i s an e f f e c t i v e procedure f o r reduct. ion of waste i n the manufacture o f s a l t - s t o c k p i c k l e s .

2 . Both the h e a t and chemical t r ea tmen t s f o r s p e n t b r i n e are p r a c t i c a l f o r use i n c u r r e n t commercial tank ya rd o p e r a t i o n s .

a t l eas t 99.98% d e s t r u c t i o n of p e c t i n a s e s from f u n g i which were found t o be common on cucumber f r u i t s and f lowers .

4 . R a i s i n g the pH o f ->72'F s p e n t b r i n e t o 1 1 . 2 o r h i g h e r f o r .,' a t l e a s t 37 h r w i l l dec rease P e n i c i l l i u m ' a n t h i n e l l a n p e c t i - nase a c t i v i t y i n s p e n t b r i n e s t o <1% of i b c t i v i t y : T h i s shou ld be an adequate t r e a t m e n t f o r b r i n e r e c y c l i n g .

3 . Heating s p e n t b r i n e f o r 30 sec. a t 1 7 5 ' F w i l l a s s u r e

5. S a l t - s t o c k cucumbers produced from fe rmen ta t ions us ing r e c y c l e d b r i n e s are e q u i v a l e n t t o c o n t r o l s a l t s t o c k i n b l o a t e r losses, t e x t u r e , and f l a v o r . Consumers have n o t d e t e c t e d any s i g n i f i c a n t d i f f e r e n c e s i n p roduc t s p repa red from s a l t s t o c k fermented i n r ecyc led b r i n e .

6 . No s i g n i f i c a n t accumulations of me ta l s or p e s t i c i d e s occur as a r e s u l t of b r i n e r e c y c l i n g .

7 . The r e s u l t s show tha t b r i n e can b e reused f o r a t least three f e r m e n t a t i o n c y c l e s on a commercial b a s i s . There are also no i n d i c a t i o n s o f adverse e f f e c t s o f r e c y c l i n g on s a l t - s t o c k q u a l i t y o r bu i ldup o f t o x i c c o n s t i t u e n t s . This s u g g e s t s t h a t b r i n e can con t inue t o b e r eused beyond t h r e e c y c l e s .

8. Under the c o n d i t i o n s o f t h i s p r o j e c t , h e a t t r e a t m e n t o f b r i n e r e s u l t e d i n a sma l l n e t s av ings wh i l e t h e r e was a s m a l l ne t c o s t f o r chemical t r ea tmen t . The r e l a t i v e economics o f these t w o r e c y c l i n g procedures may vary wi th i n d i v i d u a l c i rcumstances. However, the use o f r e c y c l i n g i s an economical ly f e a s i b l e means f o r reducing the waste from t ank y a r d o p e r a t i o n s .

SECTION 3

RECOMMENDATIONS

1. a r i n e r e c y c l i n g should b e adopted by t h e processed cucumber p i c k l i n g i n d u s t r y as a means t o reduce was te s .

2 . Both h e a t and chemical t r e a t m e n t s of t h e spen t b r i n e a r e e f f e c t i v e from a t e c h n i c a l viewpoint . S e l e c t i o n o f a procedure can be based upon economic c o n s i d e r a t i o n s and upon :he r e l a t i v e compa tab i l i t y o f t h e procedures x l t h each p a r t i c u l a r t a n k ya rd o p e r a t i o n .

3 . Care should be t aken t o i n s u r e p rope r design of a r ecyc l ing system, proper t r a i n i n g of o p e r a t i n g personnel and p rope r supe rv i s ion of t h e p rocedure , s i n c e improper r e c y c l i n g t echn iques ho ld t h e p o t e n t i a l f o r s i g n i f i c a n t economic l o s s e s .

1

4 . Undertake an e v a l u a t i o n o f calcium hydroxide as a p a r t i a l o r t o t a l replacement o f sodium hydroxide i n the chemical t r ea tmen t procedure. The use o f calcium hydroxide would s i g n i f i c a n t l y reduce t h e a c c i d e n t r i s k s a s s o c i a t e d with this procedure.

5 . Evaluate t h e need t o remove the p r e c i p i t a t e formed dur ing chemical t r ea tmen t . I f p r e c i p i t a t e removal i s unnecessary, it would reduce b r i n e l o s s e s and reduce handl ing of t h e b r i n e .

6 . E f f o r t s should be made t o reduce t ank leakage and overf low, s i n c e s i g n i f i c a n t b r i n e losses occur from t h e s e sou rces .

7 . A major e f f o r t i s needed t o develop s a l t - s t o c k s t o r a g e technology, which w i l l allow reduc t ion i n t h e s a l t l eve l s maintained i n b r i n i n g t a n k s , s i n c e wastes gene ra t ed i n t h e d e s a l t i n g o p e r a t i o n are second only t o spen t b r i n e a s a sou rce of waste i n t ank y a r d o p e r a t i o n s .

4 5

I

SECTION 4

EXPERIMENTAL DESIGN

B R I N E TREATMENT PROCEDURES

Chemical Treatment of Brine

Chemical t r e a t m e n t of s p e n t b r i n e was c a r r i e d o u t by t h e a d d i t i o n o f Food Grade NaOH p e l l e t s t o a tank of s p e n t b r i n e ( 8 , 0 0 0 - 1 0 , 0 0 0 g a l ) t o r a i s e t h e pH of t h e b r i n e t o 11 o r g r e a t e r .

determined by t i t r a t i n g a 32-02, s p e n t b r i n e sample from a w e l l mixed tank w i t h 1 0 % NaOH s o l u t i o n t o a pH of 11.5. Approximately 80% of t h e c a l c u l a t e d NaOH requirement w a s added t o t h e tank and the b r i n e was c i r c u l a t e d . A eample of t h i s p a r t i a l l y a d j u s t e d b r i n e w a s t i t r a t e d t o pH 11.5, and t h e NaOH requirement c a l c u l a t e d . This amount of NaOH was added and the tank w a s c i r c u l a t e d w i t h a pump. A characteristic change i n c o l o r of t h e s p e n t b r i n e t o d a r k e r ye l low, development o f an ammonia-like odor and formation of a p r e c i p i t a t e occurred as t h e pH was r a i s e d . This two-step NaOH a d d i t i o n procecure provides i n s u r a n c e a g a i n s t major errors i n t h e amount of NaOH added and a t t a i n m e n t of t h e proper f i n a l pH.

A p r e c i p i t a t e formed when t h e b r i n e pH was r a i s e d . This p r e c i p i t a t e s e t t l e d i n the tank . A f t e r s e t t l i n g , t h e c l e a r b r i n e was pumped i n t o a c l e a n tank. d i scarded . The pH o f t h e NaOH t r e a t e d b r i n e w a s a d j u s t e d t o pH 4 . 5 - 4 . 7 w i t h 300 g r a i n v inegar . The amount of v i n e g a r requi red was determined by t i t r a t i o n of a sample wi th a c e t i r ac id . Addit ion was done by t h e same procedure as t h e a d d i t i o n of NaOH. A f t e r a c i d i f i c a t i o n of t h e b r i n e , it was h e l d u n t i l it was used as a cover b r i n e .

The m u n t of NaOH r e q u i r e d f o r each b a t c h of b r i n e was

The p r e c i p i t a t e l a y e r was

Grea t c a r e must be e x e r c i s e d when us ing sodium hydroxide for pH adjus tments . fol lowing precaut ions :

I n j u r i e s were prevented by use of t h e

2 . These people were s p e c i f i c a l l y t a u g h t the problems and dangers a s s o c i a t e d wi th handl ing NaOH.

goggles , acid-base r e s i s t a n t g l o v e s , and r a i n s u i t was r e q u i r e d f o r handl ing NaOH.

4 . A water hose was turned on when NaOH was be ing handled so any s p i l l s could be r a p i d l y washed. r e a d i l y a v a i l a b l e .

5. NaOH was slowly added by manual a d d i t i o n w h i l e t h e b r i n e tank was mixing t o minimize t h e p o s s i b i l i t y of l o c a l h igh concent ra - t i o n s o f NaOH on t h e s u r f a c e of t h e t a n k ,

3. P r o t e c t i v e c l o t h i n g i n c l u d i n g wrap around

Eye wash equipment was

Heat Treatment of Spent Br ine

recovery system developed by t h e APV Company, Inc . o f Tonawanda, N e w York and V l a s i c Foods. A schemat ic diagram of the u n i t is shown i n f i g u r e 1. Figure 2 shows a drawing of t h e h e a t exchanger system. The u n i t has a t i t a n i u m a l l o y h e a t exchanger t o resist b r i n e c o r r o s i o n , a 200 g a l s t a i n l e s s s teel hold ing t a n k , and a s c r e e n i n g system t o remove p a r t i c u l a t e m a t e r i a l s from t h e b r i n e b e f o r e it e n t e r s t h e h e a t exchanger .

68OC (155'F) by r e g e n e r a t i o n from t h e hea ted b r i n e . Heat ing from 68OC up to 90.5OC (195'F) i s done wi th h o t water hea ted by b u r n i n g propane. This s y s t e m al lows up t o 60% of t h e h e a t i n g t o be o b t a i n e d by c o o l i n g t h e t r e a t e d b r i n e t o a tempera ture o f 35OC (95OF).

The e n t i r e u n i t i s mounted on a 6 x 1 6 f t t r a i l e r so i t can be moved between tank rows. I n r o u t i n e o p e r a t i o n i t was most e f f i c i e n t to pump b r i n e from nearby rows of t a n k s t o minimize t h e number of t i m e s t h e u n i t had t o be moved. The u n i t can b e loaded on a t r u c k and t r a n s p o r t e d t o o t h e r tank y a r d l o c a t i o n s . I n t h i s way one u n i t has been used t o s e r v e more than one l o c a t i o n . The u n i t has r e q u i r e d r e l a t i v e l y l i t t l e maintenance and does n o t appear t o be d e t e r i o r a t i n g s i g n i f i c a n t l y even though s e v e r a l m i l l i o n g a l l o n s of b r i n e have been t r e a t e d .

Spent b r i n e was hea ted wi th a t ra i lef- mounted b r i n e

The h e a t exchanger h e a t s b r i n e from ambient tempera ture t o

1. Only c o l l e g e s t u d e n t s who had taken i n t r o d u c t o r y chemistry handled t h e sodium hydroxide.

6 7

PROPAhE GAS SUPPLY

F i c u r e 1. Schematic diagram of t h e b r i n e recovery u n i t .

i '

i

j

1

5 3 h m m

c m

x a 9 4J rd al .c Q) >

9

B o t t l e d propane gas was used as the f u e l source. The h e a t exchanger had a h e a t c a p a c i t y of 50 gal/min. To p rov ide an e x t r a margin o f s a f e t y , t h e b r i n e i n this p r o j e c t was t r e a t e d t o 190'F f o r 30 sec. Whenever f e a s i b l e , t h e h e a t i n g o f b r i n e w a s done on warmer days (>2loC o r 70°F) s i n c e w a m r b r i n e r equ i r ed less f u e l f o r t r ea tmen t .

An o p e r a t o r con t inuous ly monitored t h e h e a t i n g o p e r a t i o n t o a s s u r e p r o p e r t r e a t m e n t o f t h e b r i n e and t o p r o t e c t the equipment i n case o f malfunct ion. A second person was r e q u i r e d on a pa r t - t ime b a s i s t o a s s i s t i n pumping b r i n e t o t h e u n i t .

The f l a t - b o t t o m des ign of c u r r e n t wood tanks made it i m p r a c t i c a l t o remove a l l t h e b r i n e from t anks . Usual ly abou t a 6 inch l a y e r o f b r i n e c o n t a i n i n g d i r t , p i c k l e d e b r i s , and o t h e r r e s i d u e s remained. This b r i n e was d i sca rded through t h e 5ung h o l e i n t h e bot tom o f t h e t anks . I t was necessa ry t o thoroughly c l e a n t h e t anks p r i o r t o f i l l i n g with t r e a t e d b r i n e . Though the t anks canno t b e s t e r i l i z e d and t h e b r i n e w i l l be open t o the a i r , the contaminat ion o f the b r i n e by pumping i n t o a d i r t y t ank i s a e s t h e t i c a l l y unpleasing and cou ld r e s u l t . , I

i n c o n s i d e r a b l e y e a s t growth i n the b r i n e b e f o r e use, The b r i n e comes froio t h e h e a t exchanger a t a temperature o f 90-10O0Ft The re fo re , i t w i l l n o t s a n i t i z e a poorly cleaned t ank p r i o r t o cool ing. Tanks were c l eaned by manually sc rubb ing the t anks w i t h 0.5 oz /ga l calcium h y p o c h l o r i t e s o l u t i o n fol lowed by washing w i t h h y d r a t e d l ime and r i n s i n g w i t h f r e e h water. I f tanks were n o t used immediately f o r b r i n e s t o r a g e , t h e y were f i l l e d w i t h f r e s h water t o p r e v e n t the wood from c o n t r a c t i n g .

The t r e a t e d b r i n e was h e l d a t i t s o r i g i n a l pH, u s u a l l y a t pH 3.2-3.5. J u s t p r i o r t o u s e , t he pH was r a i s e d t o 4.5 w i t h NaOH p e l l e t s u s ing t h e procedure desc r ibed ear l ier . E t c h e l l s e t a l . (10) have recommended a similar pH adjustment f o r f r e s h b r i n e used i n c o n t r o l l e d f e rmen ta t ion . I n l a b o r a t o r y experiments this pH ad jus tmen t was found t o b e necessa ry i n o rde r t o minimize b l o a t i n g problems and t o o b t a i n a normal a c i d development d u r i n g f e rmen ta t ions . The q u a n t i t i e s o f N a O H r equ i r ed f o r t h i s ad jus tmen t have been s a f e l y handled i x normal commercial o p e r a t i o n s us ing t h e p recau t ions p r e v i o u s l y desc r ibed . I t would b e worthwhile t o o b t a i n d a t a on t h e use of l i m e , C a ( O H ) 2 , f o r t h i s adjustment . Calcium s a l t s have been added t o p i c k l e s as f i rming agen t s . L ime would be cons ide rab ly less expens ive than NaOH and easier t o handle .

10

Cont ro l s f o r Fermentat ions W i t h Recycled Br ine

Commercial p r a c t i c e f o r cucumber f e rmen ta t ions has h i s t o r i c a l l y been t o cover the f r e s h cucumbers wi th f r e s h l y p repa red b r i n e . A t the conc lus ion o f f e n n e n t a t i o n and s t o r a g e , t h e b r i n e r e a a i n i n g a f t e r s a l t s t o c k w a s removed from tanks w a s termed " s p e n t b r i n e " and d i s c a r d e d . To e v a l u a t e the e f f e c t s o f b r i n e recyc1ir.g it was necessa ry t o compare the s a l t s tock and b r i n e s frcm fe rmen ta t ions wi th r ecyc led b r i n e s with fer- mentat ions i n xhich green s t o c k cucumbers were covered with f r e s h l y prepared s a l t s o l u t i o n s .

CO."IMEFlCIAL E' . 'XGATION OF BRINE RECYCLING

Fermenta:ion b r i n e s were r ec l a imed and reused through t!!ree c m p l e t e fer:e?.tation c y c l e s p e r t r e a t m e n t as shown i n f i g a r e 3 . i h e p r o j e c t kegan i n 1975 w i t h t h e s e g r e g a t i o n of f i r s t cyc le s p e n t b r i n e from the g e n e r a l t ank y a r d b r i n e s . A f t e r h e a t i n g or chemical t r ea tmen t , it w a s used f o r second c y c l e fermenta- t i o n s i n 1975. The second cycle b r i n e was saved and t r e a t e d i n the s p r i n g of 1976 f o r t h i r d c y c l e f e rmen ta t ions . Con t ro l f e rmen ta t ions i n which cucumbers were covered w i t h f r e s h s a l t b r i n e were rui! i n both 1975 and 1976.

S i z e 3A-3B :3.8-5.1 c m d i m ) rmixed cucumbers were used f o r a l l t anks . These s i z e s of cucumbers are fermented i n g r e a t e s t volume commercially. In a d d i t i o n , t h e l a r g e s i z e cucumbers are most s u s c e p t i b l e t o b l o a t i n g . One o b j e c t i v e o f the p r o j e c t w a s t o determine i f b r i n e r e c y c l i n g would s i g n i f i c a n t l y a f f e c t b l o a t i n g . Tank s i z e s v a r i e d from 800-1,200 bu capac i ty . For t h e c o n t r o l f e r n e n t a t i o n s , f r e s h l y p repa red , 6.6% NaCl cover b r i n e was use<. aecycled b r i n e was added t o cucumbers wi thou t d i l u t i o n . The s a l t c o n c e n t r a t i o n s v a r i e d from 1 0 - 1 2 % NaC1. .p.e s a i t concen t r a t ion d e c l i n e d a s t h e b r i n e e q u i l i b r a t e d with t h e water i n the cucumbers. I n a l l t anks dry e a l t w a s added i o 'he t anks 35 r equ i r ed t o m a i n t a i n t h e s a l t concen t r a t ion of 0.5% (25' SI :;rinq the f e rmen ta t ion . A t t he end o f t h e fermentat ior . ge r iod , s a l t was added accord ing t o t h e usua l s chedu le t o s ; T d l y r a i s e t h e s a l t t o 11%.

Tanks were f i l l e d i n groups o f t h r e e c o n s i s t i n g o f a c o n t r o l t a m , 3 tank i n which h e a t e d b r i n e was used and a tank i n t o which ck.?r,ically t r e a t e d b r i n e was added. During the 1975 season , n i n e complete groups o f t anks were fermented t o give n i n e r e p l i c a t e s p e r t r ea tmen t . During the 1976 season , e i g h t groups o f tar.i.5 were fermented. I n this i n s t a n c e , t he number of groups was i i m i t e d by the amount o f the second cyc le chemical ly t r e a t e d b r i n e a v a i l a b l e .

m.

11

Fresh Salt Brine

1974 1st Cycle Fermentation

1 1 s t Cvcle Spent Brine

Treatment Treatment c 1975 2nd Cycle Fermentation

1 1975 2nd Cycle

F ermenta t i on

1 2nd Cycle 2nd Cycle

S p e n t Brine Spent Brine

C hmical Treatment Treatment

1 Pasteurization

I I + 1976 3rd Cycle

.) 1976 3rd Cycle Fennenta tion Fermentation

3rd Cycle Spent Brine

1 3rd Cycle

Spent Brine

1975 Control Fermentation

1 1s t Cycle

Spent Brine

1976 Control Fermentation

1st Cycle Spent Brine

1

Figure 3. .General design of t h e commercial e v a l u a t i o n of b r i n e r e c y c l i n g .

When groups of tanks were f i l l e d , 1 ,000- lb t o t e boxes o f . cucumbers were dumped a l t e r n a t e l y i n t o t h e tanks t o assure s i m i l a r cucumbers were p u t i n each tank . Fresh cucumber samples were e v a l u a t e d f o r mechanical damage, c a r p e l s e p a r a t i o n , loose seed c a v i t i e s , and o t h e r d e f e c t s .

Recycled b r i n e was sampled i n t h e s p r i n g b e f o r e and a f t e r t r e a t m e n t p r i o r t o use i n t h e fe rmenta t ions . These samples were used f o r s a l t , pH, a c i d , reducing s u g a r , suspended. s o l i d s , BOD, COD, K j e l d a h l n i t r o g e n and m i n e r a l a n a l y s e s . Addit ion of s a l t was recorded throughout t h e fe rmenta t ion , Br ine from each tank was sampled f o r t h e same a n a l y s e s l i s t e d above i n the w i n t e r when cucumbers were removed f o r process ing . Two 5-gal p a i l s of cucumbers were taken from each tank f o r a n a l y s i s of n i t r o g e n and minera l components. One p a i l of cucumbers was d e s a l t e d i n t h e l a b o r a t o r y wi th t a p water . A 1 0 k 5 sampie of s a l t s t o c k and d e s a l t e d cucumbers was d i c e d w i t h a vege tab le d i c e r and homogenized wi thout a d d i t i o n of water w i t h a Bronwill Poly t ron homogenizer. A 1 l i te r sample of each homogenate was k e p t f o r a n a l y s i s .

The b r i n e and cucumber samples w e r e T e f r i g e r a t e d when they were c o l l e c t e d i n t h e tank yard. The samples were frozen i n t h e l a b o r a t o r y . For minera l and K j e l d a h l n i t r o g e n a n a l y s e s , t h e samples were h e l d from 1-6 months p r i o r t o a n a l y s e s . Brine samples f o r de te rmina t ion of BOD, COD, suspended s o l i d s , t i t r a t a b l e a c i d i t y , and NaCl were r e f r i g e r a t e d . The BOD was run w i t h i n 3 days of r e c e i p t of the samples. The o t h e r a n a l y s e s were completed w i t h i n 1 week.

To e v a l u a t e t h e commercial q u a l i t y of s a l t s t o c k produced wi th recyc led b r i n e , samples of 200 cucumbers were taken from each tank. They were c l a s s i f i e d i n t o t h r e e c a t e g o r i e s by tank yard personnel . Good cucumbers were t h o s e wi th no i n t e r n a l d e f e c t s . Commercially a c c e p t a b l e cucumbers inc luded t h e good cucumbers p l u s t h o s e w i t h s l i g h t b l o a t e r o r honeycomb d e f e c t s which could be s l i c e d i n t o d i l l c h i p s wi th only smal l l o s s e s . Commercially unacceptable s t o c k had s e v e r e b l o a t e r o r hor.Pycomb d e f e c t s which made it s u i t a b l e only f o r less va luable r e l i s h s t o c k . T h e t e x t u r e Qf d e s a l t e d cucumbers was eva lua ted by a puncture t es t w i t h a 5/16 inch d iameter probe. This was similar t o t h e t es t developed by B e l l and E t c h e l l s (11) ':sin9 a Magnus-Taylor manual p r e s s u r e tester. The test was d0r.e w i t h an I n s t r o n Universa l t e s t i n g ins t rument ( I n s t r o n Corp., Canton, M A ) . The f o r c e r e q u i r e d t o puncture the cucumber was determined by running a 5 /16 inch d iameter probe v e r t i c a l i y i n t o t h e f r u i t a t a speed of 50 cm/min. The r e c o r a e r was set t o record 20 kg p r e s s u r e f u l l scale. Twenty cucumbers from each tank were punctured. The average peak f o r c e requi red to puncture t h e cucumbers was c a l c u l a t e d .

12 13

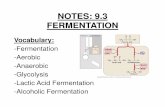

A taste panel e v a l u a t i o n of t h e f i n a l p roduct made from 2nd and 3rd c y c l e s t o c k and t h e cor responding c o n t r o l s t o c k was conducted. Hamburger d i l l c h i p s from t h e 2nd and 3rd c y c l e s were prepared by d e s a l t i n g t h e s t o c k and u s i n g commercial procedures Of Vlasic Foods, Inc.

t h e taste test e v a l u a t i o n ( 1 2 ) ("Reference Guidebook f o r Sensory T e s t i n g , " 3rd e d i t i o n , 1 9 6 6 , C o n t i n e n t a l Can Co., I n c . , Chicago, I L ) . The s c o r e s h e e t is d i v i d e d i n t o three p a r t s . In t h e f i r s t p a r t t h e c o n t r o l sample i s e v a l u a t e d f o r f l a v o r , t e x t u r e and o v e r a l l q u a l i t y i n an " e x c e l l e n t " t o "poor" r a t i n g . I n t h e second p a r t t h e judges compare t h e h e a t and chemical t r e a t m e n t s w i t h t h e c o n t r o l on t h e scale of 0 (no d i f f e r e n c e ) t o 5 (very l a r g e d i f f e r e n c e ) . P a r t I11 compares o v e r a l l q u a l i t y of t h e t r e a t m e n t s wi th t h e c o n t r o l product on t h e s c a l e of 1 (much worse) t o 4 (same) t o 7 (much b e t t e r ) . The d a t a were analyzed us ing a n a l y s i s of v a r i a n c e procedures .

analyzed f o r s a l t , pH and t i t r a t a b l e a c i d i t y . These were t h e , normal a n a l y s e s performed i n commercial o p e r a t i o n s . S a l t w a s measured u s i n g a hydrometer t o de te rmine the p e r c e n t s a t u r a t i o n of a s a l t s o l u t i o n . I n a d d i t i o n , s a l t w a s measured by t i t r a t i n g b r i n e samples wi th 0 . 1 7 1 N AgN03. expressed as degrees sa lometer . A 1% change i n s a l t concen- t r a t i o n i s approximately e q u i v a l e n t t o a change o f 4 * salometer. The pH was measured w i t h a g l a s s e l e c t r o d e . Ti t ra table a c i d i t y w a s determined by t i t r a t i o n of a b r i n e sample wi th NaOH t o phenolphtha le in end p o i n t o r pH 8. R e s u l t s were expressed as p e r c e n t l a c t i c a c i d .

B l o a t e r damage was e v a l u a t e d on each commercial tank of cucumbers accord ing t o t h e c r i t e r i a used i n s t a n d a r d commercial o p e r a t i o n s a t V l a s i c . The t a n k s were emptied from October t o March. The s a l t s t o c k was d e s a l t e d t o approximately 4 % NaCl according t o the commercial p r a c t i c e of V l a s i c Foods, L:c. and processed i n t o f i n a l p roducts , p r i m a r i l y hamburger dill c h l p s .

s o l i d s (15) us ing s t a n d a r d methods. Reducing s u g a r was determined wiLth t h e d i n i t r o s a l i c y l i c a c i d r e a g e n t ( 1 6 ) . Nitrogen was measured using a microKjeldah1 procedure ( 1 7 ) .

The d i f f e r e n c e test s c o r e s h e e t ( F i g u r e 4 ) was used f o r

During the fermenta t ion of t h e cucumbers, t h e b r i n e s w e r e

The r e s u l t s were

Br ine was analyzed f o r BOD ( 1 3 ) , COD (14), and suspended

Brine and cucumber sampLes were assayed f o r l e a d , cadmium and chromium by atomic a b s o r p t l o n spec t rophotometry . A method d e s c r i b e d by Sprague and S l a v i n (18) and by Thomas e t a l . (19) was used w i t h q u a n t i t i e s of samples a p p r o p r i a t e f o r cucumbers and b r i n e . A 40 m l a l i q u o t of b r i n e or a 4 0 g sample of ground cucumbers w a s added t o a 250 m l Erlenmeyer f l a s k t o g e t h e r wi th 35 m l of c o n c e n t r a t e d n i t r i c a c i d . The sample was b o i l e d

T e s t Sample No.

DIFFERENCE TEST

Name: Date:

I . Sample K is t h e s t a n d a r d , o r r e f e r e n c e sample. P l e a s e r a t e K below:

O v e r a l l Q u a l i t y of K Come n t s ( c i r c l e one) F lavor Texture

E x c e l l e n t E x c e l l e n t E x c e l l e n t Good Good Good F a i r F a i r F a i r Poor Poor Poor

11. Please compare t h e samples t o iC f o r t e x t u r e and f l a v o r d i f f e r e n c e s . T e s t samples may o r may n o t be d i f f e r e n t from the r e f e r e n c e sample. R a t e each sample accord ing t o this d i f f e r e n c e scale:

R a t i n q Dif fe rence from Standard

0 No d i f f e r e n c e 1 Very s l i g h t d i f f e r e n c e 2 S J i g h t d i f f e r e n c e 3 Moderate d i f f e r e n c e 4 Large d i f f e r e n c e 5 V e r y l a r g e d i f f e r e n c e

Dif fe rence Rat ings Comments Texture 1 Flavor Texture 1 Flavor

I 1

111. Q u a l i t y of samples compared t o K :

T e s t Sample # T e s t Sample #

Much worse Moderately worse S l i g h t l y worse Same S l i g h t l y b e t t e r Moderately b e t t e r Much b e t t e r

F i g u r e 4 . Score s h e e t f o r t a s t e pane l e v a l u a t i o n of hamburger d i l l ch ips .

14 15

i

g e n t l y on a h o t p l a t e f o r approximately 3 h r u n t i l it turned clear and had reached a volume of 1 0 m l . The sample was then cooled t o room tempera ture and t h e pH a d j u s t e d t o 3.0 w i t h ammonium hydroxide. A f t e r cool ing aga in to room tempera ture , 5.0 m l o f 2 % ammonium p y r i l i d i n e d i th iocarbamate was added. The f l a s k was s w i r l e d and then al lowed t o s t a n d f o r 1 0 min. Then 1 0 o r 20 m l o f methyl i s o b u t y l ke tone (MIBX) was added. The s o l u t i o n was shaken f o r 2 min and al lowed t o s t a n d u n t i l it became clear. The MIBK phase was then removed and analyzed.

Mercury a n a l y s i s was based on t h e method developed by Hatch and O t t ( 2 0 ) . I n determining mercury l e v e l s , 4 0 ml of b r i n e o r 40 g of ground cucumber w a s t r a n s f e r r e d t o a 2 5 0 m l Erlenmeyer f l a s k and d r i e d on a h o t p l a t e a t 71°C f o r approx- imate ly 20 h r or u n t i l t h e sample appeared mois ture f r e e . The sample was cooled t o -1B0C, then 20 m l c o n c e n t r a t e d n i t r i c a c i d was added and t h e sample was allowed t o s t a n d f o r 1 h r a t room temperature . A f t e r h e a t i n g on a steam b a t h f o r 4 h r , 1 5 m l o f c o n c e n t r a t e d s u l f u r i c a c i d was added and h e a t i n g w a s cont inued u n t i l t h e brown n i t r o u s fumes were d r i v e n o f f (approximately 1 1/2 h r ) . w/v) w a s added. The sample w a s h e a t e d on a s team b a t h for 30 min t o complete t h e sample p r e p a r a t i o n . cooled t o room temperature , t h e mercury c o n c e n t r a t i o n was measured w i t h a Coleman model MAS-50 mercury a n a l y z e r .

Phosphorus, calcium, magnesium, manganese, i r o n , copper , boron, z i n c , and aluminum l e v e l s were determined by atomic emission spec t roscopy (21). Brine or ground cucumber samples were d r i e d i n p o r c e l a i n c r u c i b l e s on a h o t p l a t e a t < l O O ° C over a 32-hr p e r i o d . furnace a t 4 O O O C f o r 7 h r . Michigan S t a t e U n i v e r s i t y Leaf Analys is Labora tory .

The sample was cooled on ice and 1 5 m l o f KMnO4 ( 5 %

When t h e s o l u t i o n was

The d r i e d samples w e r e ashed i n a muff le Samples were ana lyzed by t h e

SPECIAL STUDIES

C e r t a i n s t u d i e s were done s e p a r a t e from commercial b r i n e r e c y c l i n g t o e v a l u a t e p o t e n t i a l d i f f i c u l t i e s w i t h r e c y c l i n g . These i n c l u d e d an e v a l u a t i o n of p e s t i c i d e b u i l d u p w i t h m u l t i p l e reuse of b r i n e , de te rmina t ion of t h e tempera ture and pH s t a b i l i t y of f u n g a l p e c t i n a s e s which are m o s t l i k e l y t o occur in f e r m e n t a t i o n b r i n e s and a measurement of l y s i n o a l a n i n e i n chemical ly t r e a t e d b r i n e .

'.* .

E f f e c t of Br ine Recycl ing on t h e Buildup of P e s t i c i d e Residues

S e l e c t e d cucumber p l o t s were t r e a t e d wi th twice t h e recommended dosage of p e s t i c i d e s a t h a l f o f t h e recommended i n t e r v a l s b e f o r e h a r v e s t . T e r r a c h l o r Super X ( p e n t a c h l o r o a n i l i n e ) , Demesan ( c h l o r o n e b ) , p a r a t h i o n , Thiodan ( e n d o s u l f a n ) , and Sevin ( c a r b a r y l ) . Demesan was n o t a p p l i e d i n 1 9 7 7 because it was dropped from cons ider - a t i o n f o r use on cucumbers.

The p l a n t s were t r e a t e d wi th

The cucumbers were shipped t o Michigan S t a t e Univers i ty and b r i n e d w i t h o u t s i z i n g or washing. Approximately 110 l b of cucumbers were p laced i n each of seven tanks and covered w i t h b r i n e t o g i v e a pack-out r a t i o of 57:43 by weight of cucumbers t o b r i n e . For t h e f i r s t c y c l e a l l seven tanks of f r e s h cucumbers were covered w i t h f r e s h 6.6% NaCl s o l u t i o n . I n subsequent c y c l e s t h e c o n t r o l tank was covered wi th f r e s h b r i n e , t h r e e tanks were covered wi th h e a t t r e a t e d b r i n e from t h e previous c y c l e , and three tanks were covered wi th chemical ly t r e a t e d b r i n e .

The fe rmenta t ions were c a r r i e d o u t d n d o o r s under u l t r a - v i o l e t l i g h t s to r e t a r d t h e growth of f i l m y e a s t s . Dry food- grade s a l t was added t o t h e tanks a s r e q u i r e d t o main ta in t h e s a l t c o n c e n t r a t i o n a t 6 .6%.

A t t h e end of the f e r m e n t a t i o n , u s u a l l y 3-4 weeks, t h e cucumbers were removed from t h e t a n k s , t h e b r i n e s were t r e a t e d and used as a cover b r i n e on t h e n e x t b a t c h of f r e s h cucumbers.

Samples were taken f o r p e s t i c i d e a n a l y s i s of f r e s h washed and unwashed cucumbers, b r i n e d cucumbers, and b r i n e b e f o r e and a f t e r h e a t o r chemical t r e a t m e n t . The cucumbers f o r t h e washed sample were sprayed wi th t a p water from a spray nozz le f o r 2 min. The water f low rate w a s 10 kg/min. For f r e s h and b r i n e d cucumber samples, 1 0 kg o f cucumbers were d iced on a v e g e t a b l e s l icer and then homogenized wi th a Bronwil l Poly t ron t i s s u e g r i n d e r .

Br ines and cucumbers were analyzed by e x t r a c t i o n of p e s t i c i d e m a t e r i a l s ' f o l l o w e d by g a s - l i q u i d chromatography. S o l v e n t s used i n t h e a n a l y s i s were methylene c h l o r i d e , ace tone , e t h y l a c e t a t e , and petroleum e t h e r ( b o i l i n g range 30-60OC). These s o l v e n t s were o b t a i n e d commercially, d i s t i l l e d i n g l a s s , from Burdick and Jackson L a b o r a t o r i e s , I n c . , Muskegon, Michigan 49422 . Chloron b , PCNB,#entachloro i l i n e (PCA) , p a r a t h i o n , paraoxon, Bravo%, Dathal , D i f o l a t s endosulfan I , endosul fan I f , endosul fan s u l f a t e , and c a r b a r y l were obta ined from P e s t i c i d e Reference S tandards Sec t ion , Chemistry Branch, R e g i s t r a t i o n Div is ion , room 5 1 7 5 , South Agr icu l ture Bui ld ing , Environmental P r o t e c t i o n Agency, Washington, DC 20460 .

16 17

Bio Beads 5-X3-200-400 mesh, c o n t r o l no. 13127 , c a t a l o g no. 154-2750, were purchased from Bio-Rad L a b o r a t o r i e s , Richmond, C a l i f o r n i a 9 4 8 0 4 .

Two gas chromatographs were used f o r t h e a n a l y s i s . The ins t ruments , columns and o p e r a t i n g c o n d i t i o n s were a s follows:

(1) Perk in Elmer model 910 equipped wi th ni t rogen-phosphorus d e t e c t o r ( N P D ) . Columns - 1 . 8 m x 4 mm i d g l a s s columns packed w i t h 108 OV-101 and 10% OV-101 + 15% OV-210 (1 + 1) , both on Chromosorb W-HP, 80-100 mesh, condi t ioned 48 h r a t 250 O C wi th c a . 20 ml/min N 2 flow.

Opera t ing c o n d i t i o n s - temperatures ( " C ) - column 210 , i n j e c t o r 230 , d e t e c t o r 250; n i t r o g e n c a r r i e r g a s , 60 ml/min; N P D bead temperature - 1 0 t u r n p o t s e t t i n g 630 or t o g i v e approximately 5 0 % f u l l s c a l e d e f l e c t i o n (FSD) f o r S ng c a r h r y l on 1 mv r e c o r d e r , b u t n o t t o exceed a d u l l r e d glow of d e t e c t o r bead. D e t e c t o r gas f lows - hydrogen 3 ml/min, a i r 38 ml/min. Ni t rogen and phosphorus c o n t a i n i n g compounds can both be determined under t h e above c o n d i t i o n s , however, t h e response f o r phosphorus i s ex t remely h igh . To circumvent making l a r g e d i l u t i o n s , t h e phosphorus compounds w e r e q u a n t i t a t e d with a flame photometr ic d e t e c t o r .

e l e c t r o n c a p t u r e d e t e c t o r (ECD) and flame photometr ic d e t e c t o r (FPD) connected i n p a r a l l e l wi th column e f f l u e n t s p l i t t e r .

Column - 1 .8 m x 4 nun i d g l a s s column packed w i t h 1 0 % OV-101 on Chromosorb W-HP, 80-100 mesh condi t ioned f o r 4 8 h r a t 250'C with ca . 23 m l / min N 2 flow.

Opera t ing c o n d i t i o n s - temperature ("C) - column 200 , i n j e c t o r 230 , d e t e c t o r s 350 (ECD) , 2 2 0 (PPD) . Argon c a r r i e r gas - 60 ml/min, s p l i t a t column e x i t w i t h 1 p a r t t o ECD and 19 p a r t s t o FPD. P u r g e ' g a s t o ECD - 70 ml/min argon-methane (95 + 5 ) . ECD a t t e n u a t i o n set t o g ive 40-60% FSD f o r 1 ng i n j e c t e d h e p t a c h l o r epoxide wi th s i g n a l f e d t o 1 mv r e c o r d e r . FPD o p e r a t i n g c o n d i t i o n s - hydrogen 50 ml/min, a i r 80 ml/min, e l e c t r o m e t e r s e t t i n g s so t h a t 2 ng of i n j e c t e d p a r a t h i o n g i v e s 40-60% FSD i n t o a 1 mv recorder .

( 2 ) Tracor model MT 222 equipped wi th l i n e a r i z e d 6 3 N i

Gel permeation chromatography was performed with d GPC Autoprep 1001 ( A n a l y t i c a l Bio Chemistry L a b o r a t o r i e s , I n c . , Columbia, Missouri 65201) equipped wi th a 2 . 5 x 50 CIT. column packed wi th Bio Beads S-X3. Methylene c h l o r i d e a t B 5 m l / m i n flow r a t e was used as t h e s o l v e n t . Usual p r a c t i c e was to d i s c a r d t h e e f f l u e n t f o r 29 min and then t o c o l l e c t the sample f o r 2 4 min. However, dump and c o l l e c t i o n times may vary depending upon flow r a t e , column packing , e t c . Each cclumn and ins t rument should be c a l i b r a t e d wi th t h e compounds of i n t e r e s t b e f o r e a n a l y s i s of samples i s begun.

samples were concent ra ted w i t h a 500 m l Kuderna-Danish c o n c e n t r a t o r f i t t e d w i t h a t h r e e - b a l l Snyder column (Kcntes G l a s s Co. , K-570000 o r e u i v a l e n t ) . The lower j o i n t of t h e c o n c e n t r a t o r must f i t a f 19 /22 of a 1 0 m l Mil ls- type graduated tube (Kontes Glass Co., K-570050 o r e q u i v a l e n t ) .

a 500 ml, s t a i n l e s s steel cup ( Ivan S o r v a l l , I n c . , Newton, CT 0 6 4 7 0 or e q u i v a l e n t ) .

Br ine s o l u t i o n s were shaken b e f o r e sampling t o o b t a i n an even d i s t r i b u t i o n of any s e t t l e d m a t e r i a l . Raw and b r i n e d cucumbers were chopped i n a food chopper t o g ive a homogenous mass. Samples were e x t r a c t e d accordi,ng t o t h e procedure of Luke e t a l . ( 2 2 ) . Brine ( 4 0 g ) was Weighed i n t o a 1 2 5 m l , g l a s s s toppered Erlenmeyer f l a s k , 80 m l of ace tone was added, and t h e sample was thoroughly mixed. For raw o r br ined cucumbers a 1 0 0 g chopped sample was added t o t h e b lender cup, 200 m l ace tone was added and t h e sample was blended a t high speed for 2 min. The s l u r r y was c e n t r i f u g e d and t h e super - n a t a n t decanted through a g l a s s wool plug i n t o a 303 ml g l a s s s toppered Erlenmeyer f l a s k . A l t e r n a t e l y , t h e sample could be f i l t e r e d w i t h s u c t i o n through a 12 cm Buchner funnel f i t t e d w i t h s h a r k s k i n f i l t e r paper .

Samples were blended w i t h a S o r v a l l b lender equipped w i t h

E ighty m l of e x t r a c t s , whether from b r i n e o r cuc.xmbers, w a s t r a n s f e r r e d t o a 1 l i t e r s e p a r a t o r y f u n n e l , One hlmdred ml each of petroleum e t h e r and methylene c h l o r i d e were added. The f u n n e l was shaken v igorous ly f o r 1 min , t h e l a y e r s were al lowed t o s e p a r a t e and t h e lower aqueous phase was dra ined i n t o a 2 5 0 m l s e p a r a t o r y f u n n e l c o n t a i n i n g 7 g NaC1. This funnel was shaken f o r 30 sec t o d i s s o l v e most of t h e NaC1. The upper phase from t h e 1 l i t e r s e p a r a t o r y funnel was passed through a 5 cm column of anhydrous g r a n u l a r Na SO4 i n t o a 500 m l Kuderna-Danish c o n c e n t r a t o r f i t t e d w i t h a 1 0 m? graduated tube. The 1 l i t e r s e p a r a t o r y funnel was r i n s e d wi th 1 0 0 ml methylene c h l o r i d e . This s o l v e n t was then added t o t h e 250 ml separa tory funnel t o r e - e x t r a c t t h e aqueous phase. The funnel was shaken for 1 min and t h e lower methylene c h l o r i d e phase was dra ined through t h e Na2S04 column i n t o the Kuderna-Danish concent ra tor .

18 19

The aqeous phase w a s e x t r a c t e d wi th another 1 0 0 ml p o r t i o n of methylene c h l o r i d e . A f t e r e x t r a c t i o n , this s o l u t i o n was a l s o d r i e d and added t o t h e concent ra tor . The combined =e thylene c h l o r i d e e x t r a c t s were evaporated t o about 2 m l wi th t h e a i d of a t h r e e - b a l l Snyder column. I t was necessary t o t a k e care t o p r e v e n t s o l v e n t from b o i l i n g i n t o t h e column a t the beginning o f t h e evapora t ion .

The c o n c e n t r a t e d e x t r a c t was d i l u t e d t o 7.0 ml w i t h methylene c h l o r i d e i n t h e graduated tube. The sample (5.0 m l ) was loaded i n t o the sample loop of t h e Autoprep 1001 and chromatographed by dumping 29 min (145 m l ) and c o l l e c t i n g f o r 2 4 min (120 m l ) . "Cleaned up" e x t r a c t was c o l l e c t e d and c o n c e n t r a t e d i n t h e Kuderna-Danish c o n c e n t r a t o r t o approxi- mately 2 m l . The tube conta in ing sample w a s removed from t h e c o n c e n t r a t o r . The sample was evapora ted t o dryness w i t h a s l i g h t c u r r e n t of a i r o r n i t r o g e n and minimal h e a t . The d r i e d sample was d i s s o l v e d i n 3.0 m l e t h y l a c e t a t e f o r i n i t i a l i n j e c t i o n on the gas chromatograph equipped w i t h the NPD f o r q u a n t i t a t i o n o f c a r b a r v l . Appropriate d i l u t i o n s were made f o r i n j e c t i o n on the ECD/FPD equipped chromatograph.

was Sample r e p r e s e n t e d i n t h e f i n a l e t h y l a c e t a t e e x t r a c t s

Cucumbers: 100 g/(200 m l + 9 4 ml - 1 0 m l ) x 5 m 1 / 7 m l ; where 94 ml w a s t h e volume of water p r e s e n t i n t h e cucumbers, 10 ml w a s t h e water-acetone c o n t r a c t i o n f a c t o r and 5 m1/7 m l w a s t h e q u a n t i t y of sample used f o r GPC cleanup.

Br ine : 40 g/80 m l + 34 m l - 2.5 m l x 5 m1/7 m l : where 34 m l was t h e volume o f water i n t h e b r i n e sample c o n t a i n i n g 15% s o l i d s and 2.5 m l w a s t h e water-acetone c o n t r a c t i o n f a c t o r .

c a l c u l a t e d a s fol lows:

P e c t i n a s e I n a c t i v a t i o n

The p o s s i b i l i t y f o r i n t r o d u c t i o n of p e c t i n a s e s i n t o s p e n t b r i n e s , e i t h e r from t h e previous fe rmenta t ion o r dur ing p e r i o d s of b r i n e s t o r a g r , was a major concern i n the development of r e c y c l i n g procedures . c o n t r o l l e d , s e r i o u s s o f t e n i n g of cucumber s a l t s t o c k could result.

I f t h e s e enzymes were n o t p r o p e r l y

E t c h e l l s e t a l . ( 2 3 ) d i d a survey of t h e f u n g i p r e s e n t on cucumber f r u i t s and f lowers . They i d e n t i f i e d t h e most common molds and found t h a t a l l of t h e s p e c i e s i n v e s t i g a t e d produced p e c t i n a s e a c t i v i t y . I t was t h e i r op in ion t h a t enzymes from t h e dominant molds would b e t h e usua l cause of commercial cucumber s o f t e n i n g .

P e c t i n a s e was produced by growing each of t h e organisms s t u d i e d on t h e fo l lowing medium ( 2 4 ) : NH4N03 (1 g / l ) , MgS04 (0.3 g / l ) , y e a s t e x t r a c t (Difco) ( 0 . 1 g / l ) , KH PO4 ( 0 . 0 1 M) and c i t r u s p e c t i n (Sigma) (5.0 g / l ) . The pH was a 8 j u s t e d t o 6 .4 wi th 4 N NaOH p r i o r t o s t e r i l i z a t i o n of the medium. Fernbach f l a s k s c o n t a i n i n g 1 l i t e r o f media were i n o c u l a t e d wi th a p p r o p r i a t e organisms and shaken a t 1 1 0 r p m on a r o t a r y shaker . C u l t u r e s were grown a t room tempera ture ( 2 1 - 2 4 O C ) u n t i l enzyme a c t i v i t y reached i ts maximum l e v e l .

f o r 5 min a t 12,000 x g. The s u p e r n a t a n t was f i l t e r e d through a 0.45 u pore d iameter M i l l i p o r e f i l t e r . The ce l l f r e e f i l - t ra te , c o n t a i n i n g p e c t i n a s e a c t i v i t y , was concent ra ted with an Amicon model 4 0 2 u l t r a f i l t r a t i o n ce l l using a UM-10 membrane wi th a molecular weight c u t o f f of approximately 1 0 , 0 0 0 d a l t o n s .

For thermal i n a c t i v a t i o n s t u d i e s p e c t i n a s e c o n c e n t r a t e s were added t o b r i n e s o l u t i o n s such t h a t dur ing i n a c t i v a t i o n 1 2 % NaC1, 0 . 6 % l ac t ic a c i d and 0.1% Ca++ ion were p r e s e n t i n t h e b r i n e . The b r i n e pH w a s a d j u s t e d t o 3.3 t o 4.7 depending upon t h e p a r t i c u l a r experiment . Br ines were haa ted f o r s p e c i f i c time i n t e r v a l s i n 4.5 mm I . D . test t u b e s s e a l e d w i t h p a r a f f i n and cooled i n an ice b a t h . The enzyme a c t i v i t y remaining was measured by the rate of v i s c o s i t y change i n a 1 . 0 % p e c t i n s o l u t i o n i n pH 4.0, .015 M lactate b u f f e r . The t i m e r e q u i r e d f o r 90% i n a c t i v a t i o n o f enzyme a c t i v i t y (D-value) w a s d e t e r - mined from the l i n e a r p o r t i o n o f a p l o t of t h e logar i thm of t h e p e r c e n t a c t i v i t y remaining as a f u n c t i o n of t i m e .

Fungal cells were removed from t h e medium by c e n t r i f u g a t i o n

I n a c t i v a t i o n of p e c i i n a s e a t h igh pH was done i n s imula ted s p e n t b r i n e s i n which C a of a p r e c i p i t a t e . Glycine (0.02 M) was added t o provide b u f f e r c a p a c i t y a t high pH i n the b r i n e . I t was necessary t o f l u s h wi th n i t r o g e n gas and t i g h t l y c l o s e t e s t tubes with corks o r rubber s t o p p e r s t o p r e v e n t t h e b r i n e pH from dropping dur ing incubat ion . The pH drop was a p p a r e n t l y a r e s u l t of C02 a b s o r p t i o n dur ing i n c u b a t i o n .

The pH of t h e h igh pH b r i n e s was a d j u s t e d t o 4 . 0 with 1 N H C 1 p r i o r t o measuring t h e remaining enzyme a c t i v i t y . A c t i v i t y was determined a s d e s c r i b e d above. The i n a c t i v a t i o n of p e c t i - nases a t h igh pH d i d n o t fo l low f i r s t o r d e r r e a c t i o n k i n e t i c s . A s a r e s u l t , D-values could n o t be determined.

i o n w a s omi t ted t o avoid formation

20 21

Enzyme c o n t a i n i n g b r i n e s f o r i n a c t i v a t i o n experiments i n commercial s p e n t b r i n e s were prepared by d i a l y z i n g enzyme c o n c e n t r a t e i n a l a r g e excess of s p e n t b r i n e . This was done t o p r e v e n t d i l u t i o n of b r i n e c o n s t i t u e n t s by the enzyme s o l u t i o n .

Lys inoa lan ine Content of Chemically Trea ted Br ine

Formation of l y s i n o a l a n i n e by base t r e a t m e n t of p r o t e i n had been r e p o r t e d by DeGroot and Slump ( 2 6 ) . Woodward and S h o r t ( 2 7 ) had r e p o r t e d t h a t f r e e l y s i n o a l a n i n e was t o x i c t o r a t s . Though cucumber brines are low i n p r o t e i n , t h e h i g h pH r e q u i r e d f o r chemical treatment provided t h e p o t e n t i a l f o r formation of this compound.

To de termine whether s i g n i f i c a n t amounts of l y s i n o a l a n i n e could be formed by chemical t r e a t m e n t a f i r s t c y c l e , commercial spent sample b r i n e was used. The b r i n e was a d j u s t e d t o pH 1 1 . 4 and h e l d a t room tempera ture (23OC) f o r 8 days. The c l e a r s u p e r n a t a n t b r i n e w a s r e m v e d anc?.the pH a d j u s t e d t o 4 .6 wi th g l a c i a l acetic a c i d . Samples of u n t r e a t e d and base t r e a t e d b r i n e were d i a l y z e d a g a i n s t w a t e r t o r e m v e s a l t and low molecular weight components. The d i a l y z e d samples were concent ra ted on a f l a s h e v a p o r a t o r w i t h t h e water b a t h hea ted t o 40’12. A l i q u o t s of t h e c o n c e n t r a t e s were hydrolyzed a t 1 0 0 ° C wi th 6 N HC1. The h y d r o l y s a t e w a s chromatographed on a Beckman , l20C amino a c i d a n a l y z e r using the column f o r b a s i c amino a c i d . Authent ic l y s i n o a l a n i n e w a s chromatographed t o v e r i f y the p o s i t i o n on t h e chromatogram and f o r q u a n t i t a t i v e s t a n d a r d i z a t i o n o f t h e column.

2 2

SECTION 5

RESULTS AND DISCUSSION

CHARACTERISTICS OF RECYCLED BRINES

Br ine samples were c o l l e c t e d b e f o r e and a f t e r h e a t and chemical t rea tment f o r t h e f i r s t c y c l e b r i n e s i n 1 9 7 5 and f o r second c y c l e b r i n e s i n 1976. Tables 1 and 2 show t h e m e a n v a l u e s f o r t h e resul ts of t h e a n a l y s i s done on t h e s e b r i n e samples. The d a t a were analyzed by an a n a l y s i s of v a r i a n c e procedure t o determine t h e changes which occur a s a r e s u l t of h e a t o r chemical t rea tment .

There were no s i g n i f i c a n t d i f f e r e n c e s between t h e u n t r e a t e d b r i n e s used f o r t h e f i r s t c y c l e h e a t t r e a t m e n t and chemical t r e a t m e n t i n 1975. This was expected s i n c e t h e s e b r i n e s were randomly s e l e c t e d from t h e tank yard and ass igned t o e i t h e r t h e h e a t o r chemical t rea tment . A more l j m i t e d a n a l y s i s of b r i n e samples was done previous ly ( 8 ) . The l e v e l s observed i n t h i s p r o j e c t for the mineral components of t h e b r i n e s were s i m i l a r t o t h o s e obta ined i n t h e e a r l i e r s t u d y .

Heat t rea tment caused few changes i n t h e b r i n e . The pH and t i t r a t a b l e a c i d i t y were i n c r e a s e d and decreased , r e s p e c t i v e - l y . NaOH w a s added a f t e r h e a t t r e a t m e n t t o e f f e c t those changes. There was approximately a doubl ing of t h e aluminum l e v e l .

Chemical t rea tment caused a number of changes i n t h e b r i n e s . The pH and t i t r a t a b l e a c i d i t y changed a s expected. Reducing s u g a r s dec l ined under t h e a l k a l i n e c o n d i t i o n s . Formation and removal of a p r e c i p i t a t e reduced t h e suspended s o l i d s . BOD and COD i n c r e a s e d as a r e s u l t of v inegar a d d i t i o n f o r pH adjustment . S e v e r a l of t h e minera l components of b r i n e , i n c l u d i n g P , Ca, Mg and F e , d e c l i n e d a s a r e s u l t of chemical t r e a t m e n t . I t was found p r e v i o u s l y (8) t h a t t h e p r e c i p i t a t e formed c o n s i s t e d ’ p r i m a r i l y of minera l m a t e r i a l . t h e only minera l component t o show an i n c r e a s e .

Aluminum was

23

TABLE 1. CHARACTERISTICS OF 1ST CYCLE SPENT BRINE I N THE SPRING OF 1975 BEFORE AND AFTER HEAT OR CHEMICAL TREATMENT. THE TREATED BRINES WERE USED AS COVER BRINES FOR 2ND CYCLE FERMENTATIONS

Parameter Heat t r e a t m e n t Chemical treatment Unt rea t ed T r e a t e d Unt rea ted T r e a t e d

Acid % l ac t ic S a l t %

PH Sugar mg/l Suspended solid8 m g / l BOD mg/l COD mg/l Kjeldahl N m g / l C d mg/l Hg W/ l P mg/l C a mg/l Mg mg/l t4.n mg/l Fe mg/l Cu mg/l

Zn m g / l A1 mg/l C r mg/l

B mg/l

0.45 B* 13.1

3.58 A

405 B 254 B

10300 b 14200 b

594 . 0 15 0

130 B 1010 B

1 4 1 B 2.7 6.2 B 1 .6 1.4 4.9 5.3 a

.003

0.17 A

12.5 4.63 B 272 AB 204 B

9700 b 12800 b

507 .038 0

111 B 978 B 130 B 2.5 6.7 B 1.6 1 .3 4.3

10.7 b .003

0.47 B 13.2

3.53 A

392 B 231 B

10600 b 14000 b

564 .093 0

116 B 1020 B

130 B 3.4 7.2 B 2.0 1 . 4 5.0 6 . 1 a

.003

0.23 A 12.7

4.80 B

190 A 55 A

14000 a 17200 a

523 .058

0 26 A

714 A 12 A

1.9 2.5 A 1 .3 1.2 3.2

11.6 b .001

*Samples w i t h d i f f e r e n t letters are s i g n i f i c a n t l y d i f f e r e n t . With upper case letters, d i f f e r e n c e s are s i g n i f i c a n t a t t h e 1% l e v e l . W i t h lower case letters, d i f f e r e n c e s are s i g n i f i c a n t a t t h e 5% level.

TABLE 2. CHARACTERISTICS OF 2ND CYCLE SPENT BRINE I N THE SPRING OF 1976 BEFORE AND AFTER HEAT OR CHEMICAL TREATMENT. THE TREATED BRINES WERE USED AS COVER BRINES FOR 3RD CYCLE FERMENTATIONS

Heat t r e a t m e n t Chemical t r ea tmen t Unt rea ted T r e a t e d U n t r e a t e d Trea ted

Parameter

A c i d % l ac t i c S a l t %

PH Sugar mg/l Suspended solids mg/l BOD mg/l COD mg/l Kjeldahl N mg/l Cd m g / l Hg mg/l P m g / l Ca m g / l Mg mg/l Mn m s / l Fe mg/l Cu mg/l B m g / l Zn mg/l A 1 mg/l

0.62 B* 1 1 . 4

3.52 C 263 B 298

12500 b 18600 b

583 0.013 0.003

139 A

1042 A 173 A

1 . 4

9.3 1 . 4 1 . 4 4.8 8.3 A

0 .21 A 11.8

4.55 A 222 B 206

14000 ab 19300 b

621 0.012 0.003

128 AB

1123 A 183 A

1 .7 11.2

1 . 6 1.6 5 . 6

12.3 A

0.63 B 0.26 A 11.0 10.8

3.66 B 4.95 A 258 B 115 A 15 8 87

14500 ab 17400 a 19500 b 22700 a

601 507 0.012 0.015 0.003 0.003

100 B 11.0 C

960 A 652 B 140 B 5 c 1 . 0 0 .6

17 .5 4.9 1 . 0 1.6 1 . 3 1 . 5 4.2 3.6 7.1 A 31.2 B

*Samples w i t h d i f f e r e n t le t ters are s i g n i f i c a n t l y d i f f e r e n t . With upper case le t te rs , d i f f e r e n c e s are s i g n i f i c a n t a t t h e 1% level. With lower case le t te rs , d i f f e r e n c e s are s i g p i - f i c a n t a t the 5% l e v e l .

24 25

In 1 9 7 6 the second cyc le s p e n t b r i n e s were t r e a t e d p r i o r to the t h i r d c y c l e fe rmenta t ions . P r i o r t o t r e a t m e n t , a few d i f f e r e n c e s w e r e observed between t h e b r i n e s which had been h e a t t r e a t e d and chemical ly t r e a t e d the prev ious y e a r . The pH of t h e chemical t r e a t m e n t b r i n e was 3.66 compared t o 3.52 f o r the h e a t treatment b r i n e . This d i f f e r e n c e was s i g n i f i c a n t a t t h e 1% l e v e l . I t is thought t o be the r e s u l t o f v inegar a d d i t i o n which caused an i n c r e a s e i n b u f f e r c a p a c i t y i n the chemical t r e a t m e n t b r i n e . Phosphorus and magnesium were a l s o reduced i n t h e chemical t r e a t m e n t b r i n e s .