PACKER TEST - SINGLE BH01€¦ · PACKER TEST - SINGLE Test Method British Standard 5930: 1981...

Transcript of PACKER TEST - SINGLE BH01€¦ · PACKER TEST - SINGLE Test Method British Standard 5930: 1981...

PACKER TEST - SINGLE Test Method British Standard 5930: 1981 "Code of Practice for Site Investigations" Part 21.5 Packer Test Depth: 12.5 to 21

Client: Auckland Council

Project: Hackett Diversion - St Mary's Bay CSO

Job No. 255303

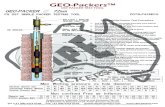

Hole Packer:Depth, D: (m bgl) 21.00 D Packer Model: Boyart Longyear

Cased to: (m bgl) 1.80 (NW / HW / PW) Packer Type: Pneumatic (USE nitrogen, NO CO2 or oxygen)

Flowmeter calibration No. 879553/13

Test Section Packer Inflation Pressure: 150 (PSI)Diameter (dia): (m bgl) HQ3 (NQ3 / HQ3 / PQ3) (driller to determine inflation pressure according to vendor instructions)From, (A): (m bgl) 12.50 A SKETCH OF TEST ARRANGEMENTTo, (B): (m bgl) 21.00 B dia

Midpoint, (C) = (A+B)/2: (m bgl) 16.75 C

Gauge height, G

Groundwater

Depth, (SWL): (m bgl) 5.34 SWL W

SWL Date: DD-MM 2/05/2017 SWL D

SWL Time: HH:mm 7:30:00 AM

Static Head

Gauge Height, (GH): (m agl) 0.5 GH Test Section

Static Head, SH=(SWL+GH) x g kPa 57.29 SH

Hose length from Gauge to packer head m (needed for head loss calculations back in office - high flow rates only)

Height to gasket at top of rods (RH): (m agl( 1.72 RH

Max Allowable Gauge Pressure

Maximum allowable pressure (MAP) = 11.3kPa x (A) kPa 135.6 MAP

Pump max pressure (from driller) kPa ok CHECK: pump capability >= MAP prior to starting test

Hose length pump to gauge m (needed for head loss calculations back in office - high flow rates only)

Maximum allowable gauge pressure (MAGP) = MAP - SH kPa 78.31 MAGP

Test Pressures

Number of increments (N_Stage); (typically use 3) n 3 N_STAGE

Gauge pressure increment, = MAGP / N_Stage kPa 35 P_INC

Stage duration (consists of 3 equal duration sub-stages) min 15 stage duration (typically 15min, consisting of three 5min substages)

Packer seated in landing ring test

Water drop noted in broken rods either (Y or N)

Drop below top of rods mm NOTE: Fill rods to overflowing prior to test

Test duration min Time taken to drop

Pressure disipation test

Bypass backflow pressure (intantaneous) kPa bypass flow immediately after last test cycle and record instanteous back pressure

Duration to dissipation to zero gauge pressure min Recovery period

(1) If fuild returns via casing during test (indicating bypass /poor seal) , record flow rate during each corresponding test substage. For example: 2min:45secs to fill 22.5L bucket(2) No need to carry out rod leakage tests L2 and L3 if L1 shows no flow (ie. No rod leakage)(3) 1 psi = 6.8948 kPa = 0.06895 bar; use kPa if possible(4)

v7.1 - 20170602JME

System leakage from gasket recorded when notedand has been substracted from water take from gauge to give total water take for each recording interval (refer to tabulated data sheet)

Comments:

BH01

Time:

Date: 02/05/2017

Tested by: BGW

PACKER TEST - SINGLE

Test Method British Standard 5930: 1981 "Code of Practice for Site Investigations" Part 21.5 Packer Test Depth: 12.5 to 21.0

Job No. 255303

Stag

e Target Duration (min) Pressure Increment

Target Gauge Pressure (kPa / psi)

Actual Gauge Pressure (kPa / psi) Duration (min) Gauge Start (Litres) Gauge End (Litres) Leakage Adjustment

L1 5 3 P_INC x 3Rod leakage test at P_INC x 3

L2 5 2 P_INC x 2Rod leakage test at P_INC x 2

L3 5 1 P_INC x 1Rod leakage test at P_INC x 1

1a 5 1 5 5 5 min 8693.3 8728.0 0.8

1b 5 1 5 5 5 min 8728.0 8842.5 0.8

1c 5 1 5 5 5 min 8842.5 8967.0 0.8

2a 5 2 10 10 5 min 9010.0 9159.3 1.0

2b 5 2 10 10 5 min 9159.3 9319.6 1.0

2c 5 2 10 10 5 min 9319.6 9469.8 1.0

3a 5 3 15 15 5 min 9515.5 9795.1 1.5

3b 5 3 15 15 5 min 9795.1 9876.8 1.5

3c 5 3 15 15 5 min 9876.8 10056.9 1.5

4a 5 2 10 10 5 min 10100.0 10254.9 1.0

4b 5 2 10 10 5 min 10254.9 10408.3 1.0

4c 5 2 10 10 5 min 10408.3 10562.2 1.0

5a 5 1 5 5 5 min 10600.0 10730.6 0.5

5b 5 1 5 5 5 min 10730.6 10861.7 0.5

5c 5 1 5 5 5 min 10861.7 10992.9 0.5

123.7

BH01

Date / Time:

Test Records

Total Water Take (per 5 mins) Notes

33.9

113.7

150 mL/min leakage from gasket

'

'

130.7

148.3

159.3

149.2

278.1

80.2

178.6

153.9

152.4

152.9

130.1

130.6

200 mL/min leakage from gasket

'

100 mL/min leakage from gasket

'

'

300 mL/min leakage from gasket

'

'

200 mL/min leakage from gasket

'

'

'

PACKER TEST - SINGLE Test Method British Standard 5930: 1981 "Code of Practice for Site Investigations" Part 21.5 Packer Test Depth: 29.15 to 34.5

Client: Auckland Council

Project: Hackett Diversion - St Mary's Bay CSO

Job No. 255303

Hole Packer:Depth, D: (m bgl) 34.50 D Packer Model: Boyart Longyear

Cased to: (m bgl) 5.25 (HW) Packer Type: Pneumatic (USE nitrogen, NO CO2 or oxygen)

Flowmeter calibration No. 879553/13

Test Section Packer Inflation Pressure: 150 (PSI)Diameter (dia): (m bgl) HQ3 (NQ3 / HQ3 / PQ3) (driller to determine inflation pressure according to vendor instructions)From, (A): (m bgl) 29.15 A SKETCH OF TEST ARRANGEMENTTo, (B): (m bgl) 34.50 B dia

Midpoint, (C) = (A+B)/2: (m bgl) 32.00 C

Gauge height, G

Groundwater

Depth, (SWL): (m bgl) 11.94 SWL W

SWL Date: DD-MM 3/05/2017 SWL D

SWL Time: HH:mm 9:40:00 AM

Static Head

Gauge Height, (GH): (m agl) 0.5 GH Test Section

Static Head, SH=(SWL+GH) x g kPa 122.04 SH

Hose length from Gauge to packer head m (needed for head loss calculations back in office - high flow rates only)

Height to gasket at top of rods (RH): (m agl( 1.60 RH

Max Allowable Gauge Pressure

Maximum allowable pressure (MAP) = 11.3kPa x (A) kPa 333.4 MAP

Pump max pressure (from driller) kPa ok CHECK: pump capability >= MAP prior to starting test

Hose length pump to gauge m (needed for head loss calculations back in office - high flow rates only)

Maximum allowable gauge pressure (MAGP) = MAP - SH kPa 211.31 MAGP 30 PSI

Test Pressures

Number of increments (N_Stage); (typically use 3) n 3 N_STAGE

Gauge pressure increment, = MAGP / N_Stage kPa 70 P_INC 10 PSIStage duration (consists of 3 equal duration sub-stages) min 5 stage duration (typically 15min, consisting of three 5min substages)

Packer seated in landing ring test

Water drop noted in broken rods either (Y or N)

Drop below top of rods mm NOTE: Fill rods to overflowing prior to test

Test duration min Time taken to drop

Pressure disipation test

Bypass backflow pressure (intantaneous) kPa bypass flow immediately after last test cycle and record instanteous back pressure

Duration to dissipation to zero gauge pressure min Recovery period

(1) If fuild returns via casing during test (indicating bypass /poor seal) , record flow rate during each corresponding test substage. For example: 2min:45secs to fill 22.5L bucket(2) No need to carry out rod leakage tests L2 and L3 if L1 shows no flow (ie. No rod leakage)(3) 1 psi = 6.8948 kPa = 0.06895 bar; use kPa if possible(4)

(5) Groundwater recorded during drilling when hole depth 25.5m

Test pressures 10/20/30/20/10 PSI

v7.1 - 20170602JME

System leakage from gasket recorded when notedand has been substracted from water take from gauge to give total water take for each recording interval (refer to tabulated data sheet)

Comments:

BH01

Time:

Date: 02/05/2017

Tested by: BGW

PACKER TEST - SINGLE

Test Method British Standard 5930: 1981 "Code of Practice for Site Investigations" Part 21.5 Packer Test Depth: 29.15 to 34.5

Job No. 255303

Stag

e Target Duration (min) Pressure Increment

Target Gauge Pressure (kPa / psi)

Actual Gauge Pressure (kPa / psi) Duration (min) Gauge Start (Litres) Gauge End (Litres) Leakage Adjustment

L1 5 3 P_INC x 3Rod leakage test at P_INC x 3

L2 5 2 P_INC x 2Rod leakage test at P_INC x 2

L3 5 1 P_INC x 1Rod leakage test at P_INC x 1

1a 5 1 P_INC x 1 10 5 min 11038.3 11047.6 0.5

1b 5 1 P_INC x 1 10 5 min 11047.6 11056.7 0.5

1c 5 1 P_INC x 1 10 5 min 11056.7 11065.7 0.5

2a 5 2 P_INC x 2 20 5 min 11068.0 11081.9 1.0

2b 5 2 P_INC x 2 20 5 min 11081.9 11095.5 1.0

2c 5 2 P_INC x 2 20 5 min 11095.5 11108.8 1.0

3a 5 3 P_INC x 3 30 5 min 11115.5 11134.5 1.5

3b 5 3 P_INC x 3 30 5 min 11134.5 11153.2 1.5

3c 5 3 P_INC x 3 30 5 min 11153.2 11171.7 1.5

4a 5 2 P_INC x 2 20 5 min 11174.5 11187.6 1.0

4b 5 2 P_INC x 2 20 5 min 11187.6 11200.7 1.0

4c 5 2 P_INC x 2 20 5 min 11200.7 11214.2 1.0

5a 5 1 P_INC x 1 10 5 min 11215.5 11223.8

5b 5 1 P_INC x 1 10 5 min 11223.8 11232.6

5c 5 1 P_INC x 1 10 5 min 11232.6 11241.1

8.5

BH01

Date / Time: 03/05/2017 09:40am

Test Records

Total Water Take (per 5 mins) Notes

8.8

8.6

100 mL/min leakage from gasket

'

'

12.9

12.6

12.3

17.5

17.2

17.0

12.1

12.1

12.5

200 mL/min leakage from gasket

'

leakage not recorded

'

'

'

'

'

200 mL/min leakage from gasket

'

'

300 mL/min leakage from gasket

PACKER TEST - SINGLE Test Method British Standard 5930: 1981 "Code of Practice for Site Investigations" Part 21.5 Packer Test Depth: 9.75 to 15.0

Client: Auckland Council

Project: Hackett Diversion - St Mary's Bay CSO

Job No. 255303

Hole Packer:Depth, D: (m bgl) 15.00 D Packer Model: Boyart Longyear

Cased to: (m bgl) 3.70 (HW) Packer Type: Pneumatic (USE nitrogen, NO CO2 or oxygen)

Flowmeter calibration No. 879553/13

Test Section Packer Inflation Pressure: 150 (PSI)Diameter (dia): (m bgl) HQ3 (NQ3 / HQ3 / PQ3) (driller to determine inflation pressure according to vendor instructions)From, (A): (m bgl) 9.75 A SKETCH OF TEST ARRANGEMENTTo, (B): (m bgl) 15.00 B dia

Midpoint, (C) = (A+B)/2: (m bgl) 12.375 C

Gauge height, G

Groundwater

Depth, (SWL): (m bgl) SWL W

SWL Date: DD-MM 9/05/2017 SWL D

SWL Time: HH:mm

Static Head

Gauge Height, (GH): (m agl) 0.5 GH Test Section

Static Head, SH=(SWL+GH) x g kPa 15.00 SH

Hose length from Gauge to packer head m (needed for head loss calculations back in office - high flow rates only)

Height to gasket at top of rods (RH): (m agl( 1.45 RH

Max Allowable Gauge Pressure

Maximum allowable pressure (MAP) = 11.3kPa x (A) kPa 110.0 MAP

Pump max pressure (from driller) kPa ok CHECK: pump capability >= MAP prior to starting test

Hose length pump to gauge m (needed for head loss calculations back in office - high flow rates only)

Maximum allowable gauge pressure (MAGP) = MAP - SH kPa 95.00 MAGP 15 PSI

Test Pressures

Number of increments (N_Stage); (typically use 3) n 3 N_STAGE

Gauge pressure increment, = MAGP / N_Stage kPa P_INC 5 PSIStage duration (consists of 3 equal duration sub-stages) min 15 stage duration (typically 15min, consisting of three 5min substages)

Packer seated in landing ring test

Water drop noted in broken rods either (Y or N)

Drop below top of rods mm NOTE: Fill rods to overflowing prior to test

Test duration min Time taken to drop

Pressure disipation test

Bypass backflow pressure (intantaneous) kPa bypass flow immediately after last test cycle and record instanteous back pressure

Duration to dissipation to zero gauge pressure min Recovery period

(1) If fuild returns via casing during test (indicating bypass /poor seal) , record flow rate during each corresponding test substage. For example: 2min:45secs to fill 22.5L bucket(2) No need to carry out rod leakage tests L2 and L3 if L1 shows no flow (ie. No rod leakage)(3) 1 psi = 6.8948 kPa = 0.06895 bar; use kPa if possible(4)

(5)

Test pressures 10/20/30/20/10 PSI

v7.1 - 20170602JME

Noted groundwater of 0.1m agl; used conservative groundwater level of 1m bgl for pressure calculation.

System leakage from gasket recorded when notedand has been substracted from water take from gauge to give total water take for each recording interval (refer to tabulated data sheet)

Comments:

BH04

Time: 09:30am

Date: 09/05/2017

Tested by: JME / Justin

PACKER TEST - SINGLE

Test Method British Standard 5930: 1981 "Code of Practice for Site Investigations" Part 21.5 Packer Test Depth: 9.75 to 15.0 EOBH

Job No. 255303

Stag

e Target Duration (min) Pressure Increment

Target Gauge Pressure (kPa / psi)

Actual Gauge Pressure (kPa / psi) Duration (min) Gauge Start (Litres) Gauge End (Litres) Leakage Adjustment

L1 5 3 P_INC x 3Rod leakage test at P_INC x 3

L2 5 2 P_INC x 2Rod leakage test at P_INC x 2

L3 5 1 P_INC x 1Rod leakage test at P_INC x 1

1a 5 1 5 5 5 min 12773.0 12782.3 1.0

1b 5 1 5 5 5 min 12782.3 12790.4 1.0

1c 5 1 5 5 5 min 12790.4 12798.1 1.0

2a 5 2 10 10 5 min 12802.5 12817.7 1.5

2b 5 2 10 10 5 min 12817.7 12832.3 1.5

2c 5 2 10 10 5 min 12832.3 12846.3 1.5

3a 5 3 15 15 5 min 12853.0 12878.9 6.0

3b 5 3 15 15 5 min 12878.9 12904.0 6.0

3c 5 3 15 15 5 min 12904.0 12925.8 6.0

4a 5 2 10 10 5 min 12926.1 12938.4 6.0

4b 5 2 10 10 5 min 12938.4 12956.4 6.0

4c 5 2 10 10 5 min 12956.4 12965.3 6.0

5a 5 1 5 5 5 min 12968.5 12977.8 6.0

5b 5 1 5 5 5 min 12977.8 12987.2 6.0

5c 5 1 5 5 5 min 12987.2 12996.4 6.0 3.2

13.7

13.1

12.5

19.9

19.1

15.8

6.3

12.0

2.9

3.3

3.4

6.7

BH04

Date / Time: 09/05/2017 09:30am

Test Records

Total Water Take (per 5 mins) Notes

200 mL/min leakage from gasket

'

'

8.3

7.1

300 mL/min leakage from gasket

'

'

1.2 L/min leakage from gasket

'

'

'

'

'

'

'

'

PACKER TEST - SINGLE Test Method British Standard 5930: 1981 "Code of Practice for Site Investigations" Part 21.5 Packer Test Depth: 18.85 to 25.15

Client: Auckland Council

Project: Hackett Diversion - St Mary's Bay CSO

Job No. 255303

Hole Packer:Depth, D: (m bgl) 25.15 D Packer Model: Boyart Longyear

Cased to: (m bgl) 2.30 (HW) Packer Type: Pneumatic (USE nitrogen, NO CO2 or oxygen)

Flowmeter calibration No. 879553/13

Test Section Packer Inflation Pressure: 150 (PSI)Diameter (dia): (m bgl) HQ3 (NQ3 / HQ3 / PQ3) (driller to determine inflation pressure according to vendor instructions)From, (A): (m bgl) 18.85 A SKETCH OF TEST ARRANGEMENTTo, (B): (m bgl) 25.15 B dia

Midpoint, (C) = (A+B)/2: (m bgl) 22.00 C

Gauge height, G

Groundwater

Depth, (SWL): (m bgl) 3.11 SWL W

SWL Date: DD-MM 28/04/2017 SWL D

SWL Time: HH:mm 8:00:00 AM

Static Head

Gauge Height, (GH): (m agl) 0.515 GH Test Section

Static Head, SH=(SWL+GH) x g kPa 36.00 SH

Hose length from Gauge to packer head m (needed for head loss calculations back in office - high flow rates only)

Height to gasket at top of rods (RH): (m agl( 1.35 RH

Max Allowable Gauge Pressure

Maximum allowable pressure (MAP) = 11.3kPa x (A) kPa 210.0 MAP

Pump max pressure (from driller) kPa ok CHECK: pump capability >= MAP prior to starting test

Hose length pump to gauge m (needed for head loss calculations back in office - high flow rates only)

Maximum allowable gauge pressure (MAGP) = MAP - SH kPa 180.00 MAGP

Test Pressures

Number of increments (N_Stage); (typically use 3) n 3 N_STAGE

Gauge pressure increment, = MAGP / N_Stage kPa 70 P_INC 10 PSIStage duration (consists of 3 equal duration sub-stages) min 15 stage duration (typically 15min, consisting of three 5min substages)

Packer seated in landing ring test

Water drop noted in broken rods either (Y or N)

Drop below top of rods mm 17mm NOTE: Fill rods to overflowing prior to test

Test duration min 6 min 45 sec Time taken to drop

Pressure disipation test

Bypass backflow pressure (intantaneous) kPa bypass flow immediately after last test cycle and record instanteous back pressure

Duration to dissipation to zero gauge pressure min Recovery period

(1) If fuild returns via casing during test (indicating bypass /poor seal) , record flow rate during each corresponding test substage. For example: 2min:45secs to fill 22.5L bucket(2) No need to carry out rod leakage tests L2 and L3 if L1 shows no flow (ie. No rod leakage)(3) 1 psi = 6.8948 kPa = 0.06895 bar; use kPa if possible(4)

(5)

v7.1 - 20170602JME

Hammering occurred between 10-40 kPa on 3rd pressure increment; pressure reduced from target 30 PSI to 25 PSI to compensate.

System leakage from gasket recorded when notedand has been substracted from water take from gauge to give total water take for each recording interval (refer to tabulated data sheet)

Comments:

BH06

Time: 10:30am

Date: 28/04/2017

Tested by: BGW

PACKER TEST - SINGLE

Test Method British Standard 5930: 1981 "Code of Practice for Site Investigations" Part 21.5 Packer Test Depth: 18.85 to 25.15

Job No. 255303

Stag

e Target Duration (min) Pressure Increment

Target Gauge Pressure (kPa / psi)

Actual Gauge Pressure (kPa / psi) Duration (min) Gauge Start (Litres) Gauge End (Litres) Leakage Adjustment

L1 5 3 P_INC x 3Rod leakage test at P_INC x 3

L2 5 2 P_INC x 2Rod leakage test at P_INC x 2

L3 5 1 P_INC x 1Rod leakage test at P_INC x 1

1a 5 1 10 10 5 min 8074.9 8076.0

1b 5 1 10 10 5 min 8076.0 8077.1

1c 5 1 10 10 5 min 8077.1 8079.1

2a 5 2 20 20 5 min 8080.1 8083.1

2b 5 2 20 20 5 min 8083.1 8086.4

2c 5 2 20 20 5 min 8086.4 8089.3

3a 5 3 30 25 5 min 8090.3 8101.2 1.0

3b 5 3 30 25 5 min 8101.2 8112.3 1.0

3c 5 3 30 25 5 min 8112.3 8124.5 1.0

4a 5 2 20 20 5 min 8124.9 8130.6 1.0

4b 5 2 20 20 5 min 8130.6 8136.3 1.0

4c 5 2 20 20 5 min 8136.3 8141.7 1.0

5a 5 1 10 10 5 min 8142.5 8145.6 1.0

5b 5 1 10 10 5 min 8145.6 8149.9 1.0

5c 5 1 10 10 5 min 8149.9 8152.2 1.0

'

'

'

c. 200 mL/min gasket leakage

'

'

'

'

'

1.3

9.9

10.1

11.2

4.7

4.7

4.4

2.1

3.3

BH06

Date / Time: 28/04/2017 10:30am

Test Records

Total Water Take (per 5 mins) Notes

PACKER TEST - SINGLE Test Method British Standard 5930: 1981 "Code of Practice for Site Investigations" Part 21.5 Packer Test Depth: 9.85 to 15.10

Client: Auckland Council

Project: Hackett Diversion - St Mary's Bay CSO

Job No. 255303

Hole Packer:Depth, D: (m bgl) 15.10 D Packer Model: Boyart Longyear

Cased to: (m bgl) 4.00 (HW) Packer Type: Pneumatic (USE nitrogen, NO CO2 or oxygen)

Flowmeter calibratio 12024.6 879553/13

Test Section Packer Inflation Pressure: 150 (PSI)Diameter (dia): (m bgl) HQ3 (NQ3 / HQ3 / PQ3) (driller to determine inflation pressure according to vendor instructions)From, (A): (m bgl) 9.85 A SKETCH OF TEST ARRANGEMENTTo, (B): (m bgl) 15.10 B dia

Midpoint, (C) = (A+B)/2: (m bgl) 12.48 C

Gauge height, G

Groundwater

Depth, (SWL): (m bgl) 1.45 SWL W

SWL Date: DD-MM 11/05/2017 SWL D

SWL Time: HH:mm 8:00:00 AM

Static Head

Gauge Height, (GH): (m agl) 1.000 GH Test Section

Static Head, SH=(SWL+GH) x g kPa 24.10 SH

Hose length from Gauge to packer head m (needed for head loss calculations back in office - high flow rates only)

Height to gasket at top of rods (RH): (m agl( 1.35 RH

Max Allowable Gauge Pressure

Maximum allowable pressure (MAP) = 11.3kPa x (A) kPa 111.3 MAP

Pump max pressure (from driller) kPa ok CHECK: pump capability >= MAP prior to starting test

Hose length pump to gauge m (needed for head loss calculations back in office - high flow rates only)

Maximum allowable gauge pressure (MAGP) = MAP - SH kPa 87.20 MAGP

Test Pressures

Number of increments (N_Stage); (typically use 3) n 3 N_STAGE

Gauge pressure increment, = MAGP / N_Stage kPa 29 P_INC (use 5 PSI)

Stage duration (consists of 3 equal duration sub-stages) min 15 stage duration (typically 15min, consisting of three 5min substages)

Packer seated in landing ring test

Water drop noted in broken rods either (Y or N)

Drop below top of rods mm NOTE: Fill rods to overflowing prior to test

Test duration min Time taken to drop

Pressure disipation test

Bypass backflow pressure (intantaneous) kPa bypass flow immediately after last test cycle and record instanteous back pressure

Duration to dissipation to zero gauge pressure min Recovery period

(1) If fuild returns via casing during test (indicating bypass /poor seal) , record flow rate during each corresponding test substage. For example: 2min:45secs to fill 22.5L bucket(2) No need to carry out rod leakage tests L2 and L3 if L1 shows no flow (ie. No rod leakage) (not applicable for pneumatic packer)(3) 1 psi = 6.8948 kPa = 0.06895 bar; use kPa if possible(4)

v7.1 - 20170602JME

System leakage from gasket recorded when notedand has been substracted from water take from gauge to give total water take for each recording interval (refer to tabulated data sheet)

Comments:

BH08

Time:

Date: 11/05/2017

Tested by: JME

PACKER TEST - SINGLE

Test Method British Standard 5930: 1981 "Code of Practice for Site Investigations" Part 21.5 Packer Test Depth: 9.85 to 15.10

Job No. 255303

Stag

e Target Duration (min) Pressure Increment

Target Gauge Pressure (kPa / psi)

Actual Gauge Pressure (kPa / psi) Duration (min) Gauge Start (Litres) Gauge End (Litres) Leakage Adjustment

L1 5 3 P_INC x 3Rod leakage test at P_INC x 3

L2 5 2 P_INC x 2Rod leakage test at P_INC x 2

L3 5 1 P_INC x 1Rod leakage test at P_INC x 1

1a 5 1 5 5 5 12020.6 12024.6 1.0

1b 5 1 5 5 5 12024.6 12028.8 1.0

1c 5 1 5 5 5 12028.8 12033.5 1.0

2a 5 2 10 10 5 12035.4 12041.2 1.9

2b 5 2 10 10 5 12041.2 12046.9 1.9

2c 5 2 10 10 5 12046.9 12052.7 1.9

3a 5 3 15 15 5 12056.0 12064.5 3.1

3b 5 3 15 15 5 12064.5 12073.6 3.1

3c 5 3 15 15 5 12073.6 12082.9 3.1

4a 5 2 10 10 5 12084.5 12092.8 1.7

4b 5 2 10 10 5 12092.8 12101.1 1.7

4c 5 2 10 10 5 12101.1 12109.8 1.7

5a 5 1 5 5 5 12114.5 12121.5 1.2

5b 5 1 5 5 5 12121.5 12130.6 1.2

5c 5 1 5 5 5 12130.6 12137.7 1.2

3.7

BH08

Date / Time: 11/05/2017

Test Records

Total Water Take (per 5 mins) Notes

3.0

3.2

c. 208 mL/min gasket leakage

'

'

5.9

3.9

3.8

3.9

5.4

6.0

6.2

6.6

6.6

7.0

5.8

7.9

c. 374 mL/min gasket leakage

'

c. 234 mL/min gasket leakage

'

'

c. 623 mL/min gasket leakage

'

'

c. 340 mL/min gasket leakage

'

'

'

u2

cm² cm² 150 10

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_20 1/15

Cone resistance (qc) in MPa Friction ratio (Rf) in %

Sleeve friction (fs) in MPa Inclination (I) in degrx

Dep

th in

m to

refe

renc

e le

vel (

)

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

2 4 6 8 10 12 14 16 18 20 246810

0.10 0.20 0.30 0.40 0.50

1.45

0.4

1.4

1.0

0.9

0.7

1.1

2.4

3.6

4.5

4.6

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.5M

qc = 20.80fs = 0.43 I = 5.38Final depth = 10.44

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_20 2/15

Dynamic pore pressure (u2) in MPa

Equilibirum pore pressure (u0) in MPa Inclination (I) in degrx

Dep

th in

m to

refe

renc

e le

vel (

)

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

-0.1 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3

0.00 0.20 0.40 0.60 0.80 1.00 1.20

1.45

2.27 ->

0.4

1.4

1.0

0.9

0.7

1.1

2.4

3.6

4.5

4.6

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.5M

u = 2.34 I = 5.38

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_20 3/15

Corrected cone resistance (qt) in MPaD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.5M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_20 4/15

Excess pore pressure (du) in MPa Dynamic pore pressure ratio (u/qc) in MPaD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

-0.1 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 01234

1.45

2.25 ->

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.5M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_20 5/15

Effective cone resistance (qe) in MPaD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.5M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_20 6/15

Total vertical stress (rov;z) in kPa

Effective vertical stress (rov;z̀ ) in kPa

Dep

th in

m to

refe

renc

e le

vel (

)

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

50 100 150 200 250 300 350 400 450 500 550 600 650 700 750

100 200 300 400 500 600 700

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.5M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_20 7/15

Net cone resistance (qn) in MPa Pore pressure ratio (Bq)D

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

2 4 6 8 10 12 14 16 18 20 0.00.20.40.60.8

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.5M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_20 8/15

Normalised cone resistance (qnorm) [Qt] Normalised friction ratio (fnorm) in %D

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

50 100 150 200 250 300 350 400 450 500 246810

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.5M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_20 9/15

Soil behaviour type index (Ic)D

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5

1.45

7 6 5 4 3 2

(2) Organic soils(3) Clay(4) Silt mixtures(5) Sand mixtures(6) Sand clean to silty(7) Gravelly sand

G.L. : 0.00 m

1.50 m Predrilled

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_20 10/15

Undrained shear strength (Su) in kPaD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.5M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_20 11/15

Relative density (consolidated) in %

Relative density (over-consolidated) in %

Dep

th in

m to

refe

renc

e le

vel (

)

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

20 40 60 80 100 120 140

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.5M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_20 12/15

Equivalent SPT N60 ValueD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.5M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_20 13/15

Sounding speed in cm/sD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.5M

u2

cm² cm² 150 10

Dep

th in

m to

refe

renc

e le

vel (

)

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_20 14/15

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

1.45

(3)

(0)

(5)

(5)

(4)(3)

(3)

(5)

(3)

(3)

(3)

(4)(4)

(5)

(4)(5)

Soil (Qt, Fr) Soil (Qt, Bq) Soil (Average)

Soil behaviour type classification after Robertson 1990

(0) Not defined(1) Sensitive, fine grained(2) Organic soils-peats(3) Clays-clay to silty clay(4) Clayey silt to silty clay(5) Sand mixtures(6) Sands(7) Gravelly sand to sand(8) Very stiff sand to clayey sand(9) Very stiff fine grained

(3)

(0)

(5)

(4)

(5)

(5)

(4)(3)

(5)

(5)

(5)(5)

(6)

Soil (Qt, Fr) Soil (Qt, Bq) Soil (Average)

Soil behaviour type classification after Robertson 1990

(0) Not defined(1) Sensitive, fine grained(2) Organic soils-peats(3) Clays-clay to silty clay(4) Clayey silt to silty clay(5) Sand mixtures(6) Sands(7) Gravelly sand to sand(8) Very stiff sand to clayey sand(9) Very stiff fine grained

(3)

(0)

(6)(0)

(4)(0)

(4)

(5)

(4)(3)

(4)

(5)(5)(4)(6)

Soil (Qt, Fr) Soil (Qt, Bq) Soil (Average)

Soil behaviour type classification after Robertson 1990

(0) Not defined(1) Sensitive, fine grained(2) Organic soils-peats(3) Clays-clay to silty clay(4) Clayey silt to silty clay(5) Sand mixtures(6) Sands(7) Gravelly sand to sand(8) Very stiff sand to clayey sand(9) Very stiff fine grained

G.L. : 0.00 m

1.50 m Predrilled

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_20 15/15

Internal friction angle in degreesD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.5M

u2

cm² cm² 150 10

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_21 1/15

Cone resistance (qc) in MPa Friction ratio (Rf) in %

Sleeve friction (fs) in MPa Inclination (I) in degrx

Dep

th in

m to

refe

renc

e le

vel (

)

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

2 4 6 8 10 12 14 16 18 20 246810

0.10 0.20 0.30 0.40 0.50

1.45

0.8

2.0

2.6

3.5

3.7

3.6

3.7

3.0

2.7

3.5

3.4

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL:-1.61M

qc = 26.58fs = 0.16 I = 3.64Final depth = 11.47

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_21 2/15

Dynamic pore pressure (u2) in MPa

Equilibirum pore pressure (u0) in MPa Inclination (I) in degrx

Dep

th in

m to

refe

renc

e le

vel (

)

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

-0.1 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3

0.00 0.20 0.40 0.60 0.80 1.00 1.20

1.45

2.95 ->1.22 ->

2.6 ->

1.57 ->

1.59 ->

0.8

2.0

2.6

3.5

3.7

3.6

3.7

3.0

2.7

3.5

3.4

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL:-1.61M

u = -0.02 I = 3.64

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_21 3/15

Corrected cone resistance (qt) in MPaD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL:-1.61M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_21 4/15

Excess pore pressure (du) in MPa Dynamic pore pressure ratio (u/qc) in MPaD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

-0.1 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 01234

1.45

2.93 ->1.19 ->

2.57 ->

1.49 ->

1.53 ->

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL:-1.61M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_21 5/15

Effective cone resistance (qe) in MPaD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL:-1.61M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_21 6/15

Total vertical stress (rov;z) in kPa

Effective vertical stress (rov;z̀ ) in kPa

Dep

th in

m to

refe

renc

e le

vel (

)

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

50 100 150 200 250 300 350 400 450 500 550 600 650 700 750

100 200 300 400 500 600 700

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL:-1.61M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_21 7/15

Net cone resistance (qn) in MPa Pore pressure ratio (Bq)D

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

2 4 6 8 10 12 14 16 18 20 0.00.20.40.60.8

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL:-1.61M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_21 8/15

Normalised cone resistance (qnorm) [Qt] Normalised friction ratio (fnorm) in %D

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

50 100 150 200 250 300 350 400 450 500 246810

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL:-1.61M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_21 9/15

Soil behaviour type index (Ic)D

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5

1.45

7 6 5 4 3 2

(2) Organic soils(3) Clay(4) Silt mixtures(5) Sand mixtures(6) Sand clean to silty(7) Gravelly sand

G.L. : 0.00 m

1.50 m Predrilled

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_21 10/15

Undrained shear strength (Su) in kPaD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL:-1.61M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_21 11/15

Relative density (consolidated) in %

Relative density (over-consolidated) in %

Dep

th in

m to

refe

renc

e le

vel (

)

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

20 40 60 80 100 120 140

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL:-1.61M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_21 12/15

Equivalent SPT N60 ValueD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL:-1.61M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_21 13/15

Sounding speed in cm/sD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL:-1.61M

u2

cm² cm² 150 10

Dep

th in

m to

refe

renc

e le

vel (

)

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_21 14/15

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

1.45

(0)

(3)(6)

(5)

(5)

(5)

(4)(4)

(5)

(4)

(3)

(3)

(4)

Soil (Qt, Fr) Soil (Qt, Bq) Soil (Average)

Soil behaviour type classification after Robertson 1990

(0) Not defined(1) Sensitive, fine grained(2) Organic soils-peats(3) Clays-clay to silty clay(4) Clayey silt to silty clay(5) Sand mixtures(6) Sands(7) Gravelly sand to sand(8) Very stiff sand to clayey sand(9) Very stiff fine grained

(3)

(3)

(0)

(0)

(5)

(4)

(3)

(4)

(5)

(3)

(4)

(3)

Soil (Qt, Fr) Soil (Qt, Bq) Soil (Average)

Soil behaviour type classification after Robertson 1990

(0) Not defined(1) Sensitive, fine grained(2) Organic soils-peats(3) Clays-clay to silty clay(4) Clayey silt to silty clay(5) Sand mixtures(6) Sands(7) Gravelly sand to sand(8) Very stiff sand to clayey sand(9) Very stiff fine grained

(0)

(3)(6)(0)

(0)

(5)

(4)

(4)

(5)(4)

(3)

(4)

(4)

(4)

Soil (Qt, Fr) Soil (Qt, Bq) Soil (Average)

Soil behaviour type classification after Robertson 1990

(0) Not defined(1) Sensitive, fine grained(2) Organic soils-peats(3) Clays-clay to silty clay(4) Clayey silt to silty clay(5) Sand mixtures(6) Sands(7) Gravelly sand to sand(8) Very stiff sand to clayey sand(9) Very stiff fine grained

G.L. : 0.00 m

1.50 m Predrilled

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_21 15/15

Internal friction angle in degreesD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL:-1.61M

u2

cm² cm² 150 10

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_22 1/15

Cone resistance (qc) in MPa Friction ratio (Rf) in %

Sleeve friction (fs) in MPa Inclination (I) in degrx

Dep

th in

m to

refe

renc

e le

vel (

)

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

2 4 6 8 10 12 14 16 18 20 246810

0.10 0.20 0.30 0.40 0.50

1.45

0.7

0.6

2.5

2.0

1.3

1.0

1.4

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.92M

qc = 18.96fs = 0.26 I = 2.90Final depth = 7.77

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_22 2/15

Dynamic pore pressure (u2) in MPa

Equilibirum pore pressure (u0) in MPa Inclination (I) in degrx

Dep

th in

m to

refe

renc

e le

vel (

)

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

-0.1 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3

0.00 0.20 0.40 0.60 0.80 1.00 1.20

1.45

2.01 ->

0.7

0.6

2.5

2.0

1.3

1.0

1.4

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.92M

u = 3.06 I = 2.90

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_22 3/15

Corrected cone resistance (qt) in MPaD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.92M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_22 4/15

Excess pore pressure (du) in MPa Dynamic pore pressure ratio (u/qc) in MPaD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

-0.1 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 01234

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.92M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_22 5/15

Effective cone resistance (qe) in MPaD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.92M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_22 6/15

Total vertical stress (rov;z) in kPa

Effective vertical stress (rov;z̀ ) in kPa

Dep

th in

m to

refe

renc

e le

vel (

)

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

50 100 150 200 250 300 350 400 450 500 550 600 650 700 750

100 200 300 400 500 600 700

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.92M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_22 7/15

Net cone resistance (qn) in MPa Pore pressure ratio (Bq)D

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

2 4 6 8 10 12 14 16 18 20 0.00.20.40.60.8

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.92M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_22 8/15

Normalised cone resistance (qnorm) [Qt] Normalised friction ratio (fnorm) in %D

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

50 100 150 200 250 300 350 400 450 500 246810

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.92M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_22 9/15

Soil behaviour type index (Ic)D

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5

1.45

7 6 5 4 3 2

(2) Organic soils(3) Clay(4) Silt mixtures(5) Sand mixtures(6) Sand clean to silty(7) Gravelly sand

G.L. : 0.00 m

1.50 m Predrilled

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_22 10/15

Undrained shear strength (Su) in kPaD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.92M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_22 11/15

Relative density (consolidated) in %

Relative density (over-consolidated) in %

Dep

th in

m to

refe

renc

e le

vel (

)

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

20 40 60 80 100 120 140

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.92M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_22 12/15

Equivalent SPT N60 ValueD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.92M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_22 13/15

Sounding speed in cm/sD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.92M

u2

cm² cm² 150 10

Dep

th in

m to

refe

renc

e le

vel (

)

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_22 14/15

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

1.45

(3)

(3)

(6)

(4)

(4)(5)(4)

Soil (Qt, Fr) Soil (Qt, Bq) Soil (Average)

Soil behaviour type classification after Robertson 1990

(0) Not defined(1) Sensitive, fine grained(2) Organic soils-peats(3) Clays-clay to silty clay(4) Clayey silt to silty clay(5) Sand mixtures(6) Sands(7) Gravelly sand to sand(8) Very stiff sand to clayey sand(9) Very stiff fine grained

(6)

(3)

(6)

(6)

(5)

(6)(0)

Soil (Qt, Fr) Soil (Qt, Bq) Soil (Average)

Soil behaviour type classification after Robertson 1990

(0) Not defined(1) Sensitive, fine grained(2) Organic soils-peats(3) Clays-clay to silty clay(4) Clayey silt to silty clay(5) Sand mixtures(6) Sands(7) Gravelly sand to sand(8) Very stiff sand to clayey sand(9) Very stiff fine grained

(6)

(0)(3)

(3)

(6)

(0)

(4)(5)(4)

(0)

(0)(0)

Soil (Qt, Fr) Soil (Qt, Bq) Soil (Average)

Soil behaviour type classification after Robertson 1990

(0) Not defined(1) Sensitive, fine grained(2) Organic soils-peats(3) Clays-clay to silty clay(4) Clayey silt to silty clay(5) Sand mixtures(6) Sands(7) Gravelly sand to sand(8) Very stiff sand to clayey sand(9) Very stiff fine grained

G.L. : 0.00 m

1.50 m Predrilled

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT_22 15/15

Internal friction angle in degreesD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75

1.45

G.L. : 0.00 m

1.50 m Predrilled

EOH: MAX PUSH 8T

SWL: -1.92M

u2

cm² cm² 150 10

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT23 1/15

Cone resistance (qc) in MPa Friction ratio (Rf) in %

Sleeve friction (fs) in MPa Inclination (I) in degrx

Dep

th in

m to

refe

renc

e le

vel (

)

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

2 4 6 8 10 12 14 16 18 20 246810

0.10 0.20 0.30 0.40 0.50

1.45

W.L. = 0.00 m

1.1

1.8

0.9

1.4

1.5

G.L. : 0.00 m

1.80 m Predrilled

EOH: MAX PUSH 8T

SWL: COLLPASED 2.64M

qc = 12.45fs = 0.64 I = 2.07Final depth = 5.88

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT23 2/15

Dynamic pore pressure (u2) in MPa

Equilibirum pore pressure (u0) in MPa Inclination (I) in degrx

Dep

th in

m to

refe

renc

e le

vel (

)

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

-0.1 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3

0.00 0.20 0.40 0.60 0.80 1.00 1.20

1.45

W.L. = 0.00 m

1.1

1.8

0.9

1.4

1.5

G.L. : 0.00 m

1.80 m Predrilled

EOH: MAX PUSH 8T

SWL: COLLPASED 2.64M

u = 0.13 I = 2.07

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT23 3/15

Corrected cone resistance (qt) in MPaD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30

1.45

W.L. = 0.00 mG.L. : 0.00 m

1.80 m Predrilled

EOH: MAX PUSH 8T

SWL: COLLPASED 2.64M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT23 4/15

Excess pore pressure (du) in MPa Dynamic pore pressure ratio (u/qc) in MPaD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

-0.1 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 01234

1.45

W.L. = 0.00 mG.L. : 0.00 m

1.80 m Predrilled

EOH: MAX PUSH 8T

SWL: COLLPASED 2.64M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT23 5/15

Effective cone resistance (qe) in MPaD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

2 4 6 8 10 12 14 16 18 20 22 24 26 28 30

1.45

W.L. = 0.00 mG.L. : 0.00 m

1.80 m Predrilled

EOH: MAX PUSH 8T

SWL: COLLPASED 2.64M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT23 6/15

Total vertical stress (rov;z) in kPa

Effective vertical stress (rov;z̀ ) in kPa

Dep

th in

m to

refe

renc

e le

vel (

)

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

50 100 150 200 250 300 350 400 450 500 550 600 650 700 750

100 200 300 400 500 600 700

1.45

W.L. = 0.00 mG.L. : 0.00 m

1.80 m Predrilled

EOH: MAX PUSH 8T

SWL: COLLPASED 2.64M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT23 7/15

Net cone resistance (qn) in MPa Pore pressure ratio (Bq)D

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

2 4 6 8 10 12 14 16 18 20 0.00.20.40.60.8

1.45

W.L. = 0.00 mG.L. : 0.00 m

1.80 m Predrilled

EOH: MAX PUSH 8T

SWL: COLLPASED 2.64M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT23 8/15

Normalised cone resistance (qnorm) [Qt] Normalised friction ratio (fnorm) in %D

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

50 100 150 200 250 300 350 400 450 500 246810

1.45

W.L. = 0.00 mG.L. : 0.00 m

1.80 m Predrilled

EOH: MAX PUSH 8T

SWL: COLLPASED 2.64M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT23 9/15

Soil behaviour type index (Ic)D

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5

1.45

W.L. = 0.00 m

7 6 5 4 3 2

(2) Organic soils(3) Clay(4) Silt mixtures(5) Sand mixtures(6) Sand clean to silty(7) Gravelly sand

G.L. : 0.00 m

1.80 m Predrilled

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT23 10/15

Undrained shear strength (Su) in kPaD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500

1.45

W.L. = 0.00 mG.L. : 0.00 m

1.80 m Predrilled

EOH: MAX PUSH 8T

SWL: COLLPASED 2.64M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT23 11/15

Relative density (consolidated) in %

Relative density (over-consolidated) in %

Dep

th in

m to

refe

renc

e le

vel (

)

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

20 40 60 80 100 120 140

1.45

W.L. = 0.00 mG.L. : 0.00 m

1.80 m Predrilled

EOH: MAX PUSH 8T

SWL: COLLPASED 2.64M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT23 12/15

Equivalent SPT N60 ValueD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75

1.45

W.L. = 0.00 mG.L. : 0.00 m

1.80 m Predrilled

EOH: MAX PUSH 8T

SWL: COLLPASED 2.64M

u2

cm² cm² 150 10

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT23 13/15

Sounding speed in cm/sD

epth

in m

to re

fere

nce

leve

l ()

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5

1.45

W.L. = 0.00 mG.L. : 0.00 m

1.80 m Predrilled

EOH: MAX PUSH 8T

SWL: COLLPASED 2.64M

u2

cm² cm² 150 10

Dep

th in

m to

refe

renc

e le

vel (

)

Date :Cone no. :Project no. :

CPT no. :

Test according NEN 5140 class 1Project :Location:Position:

St Mary's BaySt Mary's Bay Road Reserve0, 0 RD

11/12/2017S10CFIIP.S16083

DF17GE038CPT23 14/15

0

-1

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

-12

-13

-14

-15

-16

-17

-18

-19

-20

-21

-22

-23

-24

1.45

(5)

(5)

(8)

Soil (Qt, Fr) Soil (Qt, Bq) Soil (Average)

Soil behaviour type classification after Robertson 1990

(0) Not defined(1) Sensitive, fine grained(2) Organic soils-peats(3) Clays-clay to silty clay(4) Clayey silt to silty clay(5) Sand mixtures(6) Sands(7) Gravelly sand to sand(8) Very stiff sand to clayey sand(9) Very stiff fine grained

(6)

(7)(6)

(6)

(6)

(6)(7)

Soil (Qt, Fr) Soil (Qt, Bq) Soil (Average)

Soil behaviour type classification after Robertson 1990

(0) Not defined(1) Sensitive, fine grained(2) Organic soils-peats(3) Clays-clay to silty clay(4) Clayey silt to silty clay(5) Sand mixtures(6) Sands(7) Gravelly sand to sand(8) Very stiff sand to clayey sand(9) Very stiff fine grained

(6)

(6)

(0)(6)