Micro-Bulk Gas Purifiers -...

Transcript of Micro-Bulk Gas Purifiers -...

www.arminc.com 719-538-5959 [email protected] Advanced Research Manufacturing Colorado Springs, CO USA

Specialty Gas

Industrial Gas

Micro-Bulk Gas Purifiers Solutions that meet your needs Service that exceeds your expectations

www.arminc.com 719-538-5959 [email protected] Advanced Research Manufacturing Colorado Springs, CO USA

Dimensions Flow slpm

Model Units A B Nominal Max FP Max CR

975 mm 202.0 76.0

7.0 60 100 inch 7.94 3.00

977 mm 254.0 76.0

10 120 200 inch 10.00 3.00

05K mm 462.0 76.0

43 200 400 inch 18.20 3.00

07K mm 440.0 102.0

135 500 700 inch 17.30 4.00

08K mm 864.0 102.0

170 650 850 inch 34.00 4.00

50K mm 701.0 152.0

225 1000 1500 inch 27.60 6.00

Nominal flow rates are based on 1 yr service life Max flow rates are at 150 psig gas pressure

Weights range from 1 to 10 lbs based on size and fill material Dimensions

VCRTM

B

A

Vessels Only Many gas/impurity combinations can be effectively purified with an ambient temperature purifier. In these applications it can be very

cost effective to simply have an ambient temperature purifier upstream of the use point. Suitable vessel size is based on the anticipated flow rate of the gas being purified, input impurity load and desired lifetime between regeneration or re-placement. In some cases it is desirable to oversize the vessel to enhance purity or lifetime performance. The chart at right lists nominal flow rates at 150 psi line pressures to achieve specified impurity removal to <1ppb for a nominal 1 year service life. Max flow rates listed are based on filtration option spec-ified, FP=0.003µm, CR=0.1µm.

Vessel Size Nominal flow for 1 year life

Maximum flow FP

Maximum flow CR

975 7 slpm 60 slpm 100 slpm

977 10 slpm 120 slpm 200 slpm

05K 43 slpm 200 slpm 400 slpm

07K 135 slpm 500 slpm 700 slpm

08K 170 slpm 650 slpm 850 slpm

50K 225 slpm 1000 slpm 1500 slpm

Class Gases Purified Impurities removed Removal Efficiency

Regen Capable

C Ar, He, Kr, Ne, Xe, N2, & H2 CO, CO2, H2, H2O, NMHC, O2 <1 ppb Yes

CA Ar, He, Kr, Ne, Xe, N2, & H2 CO, CO2, H2, H2O, NMHC, O2 <1 ppb Yes

F C2F6, C3F8, C4F8, CClF3, CCl2F2, CCl4, CF4, CHClF2, CHF3, & CH3F CO, CO2, H2, H2O, NMHC, O2 <1 ppb No

OX CDA & O2 CO2, H2O, NMHC, Amines, NOx <1 ppb Yes

T BCl3, BF3, CL2, ClF3, F2, HBr, HCl, HF, NF3, SF4, WF6 H2O <1 ppb No

W Ar, He, Kr, Ne, Xe, H2, & N2 H2O <1 ppb Yes

Y AsH3, B2H6, CH4, D.C.S.(SiH2Cl2), Ge2H6, GeH4, H2Se, NH3, PH3, SF6,

SiH2, SiH4, Si2H6, DMHZ, & Hydride/Carrier Gas mix CO2, H2O, O2 <1 ppb Yes

Fill Class Designations for the fill material required to remove specific impurities from specific gas streams are listed in the chart below. This is not a

comprehensive list of every possible impurity that can be removed from every possible gas. If the gas to be purified, or impurities are not listed, contact ARM, Inc. for assistance.

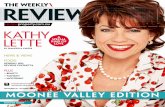

Micro-Bulk Purifiers

Micro-Bulk purifiers typically offer a moderate flow rate serving a lab or production work cell through high purity, permanently installed plumbing to each point-of-use. This brochure outlines the features/benefits/performance of ARM’s Micro-Bulk purifiers.

ARM Inc. purifiers are categorized into 3 groups. The primary distinction is based on flow rate of the gas being purified. The following is offered as a general rule: Category Flow Rate Point-of-Use 0.1-100 slpm Micro-Bulk 100-1200 slpm Bulk 60-5000 nm3/hr Point-of-Use and Bulk Purifiers are described in their own brochures.

www.arminc.com 719-538-5959 [email protected] Advanced Research Manufacturing Colorado Springs, CO USA

Open Frames

With NEMA Enclosures

1. Applicable to heated vessels in Nova and Pro-Panel Series only 2. Dependent on vessel size.

3. Only applicable with air operated valve option. 4. 50 ppm maximum

Specification Common to All

Max Operating Pressure 200 PSIG (17.24 BAR)

Max Operating Temperature1 400°C

Nominal Flow Rate2 0.3 slpm to 20.0 slpm

Maximum Flow Rate2 4.5 slpm to 300 slpm

Pressure Drop2 <1 ATM typical

Filtration 0.1 µm standard, optional 0.003 µm

Wetted Surfaces Electro-polished, <10Ra, 316L stainless steel

Typical Inlet Gas Purity 99.999%4

Outlet Purity <1 ppb

Input Power 100VAC, 120VAC, 230VAC, 50/60Hz, 600W (max)

Inlet/Outlet Fittings VCRTM standard, optional SwagelokTM or tube stub

Operating Air Supply3 60-90 psig CDA

Features Vessel Only Advantage

Series

Heated operation No Yes

Optional inlet/outlet/bypass valves Yes Yes

Optional pneumatic inlet/outlet valves N/A Yes

Power status indication N/A Yes

Ready (for operation) indication N/A Yes

Thermocouple fault indication N/A Yes

Process indication N/A Yes

Alarm indication N/A Yes

Valves open indication No Yes

Inlet/Outlet Connections

The standard inlet/outlet connections are 1/2” VCRTM face seal fittings. Other connection types are optional, contact ARM for quote.

Filtration

All purifiers include an integral filter. Two standard options are available CR-0.1 micron and a FP-0.003 micron, these filter particles down to the size specified to less than 1 particle per cubic foot of gas.

www.arminc.com 719-538-5959 [email protected] Advanced Research Manufacturing Colorado Springs, CO USA

Gases Purified Impurities Removed to <1.0 ppb

O2, CDA CH4, CO, CO2, H2, H2O, THC

N2 CH4, CO, CO2, H2, H2O, O2, THC

X

Purifier Cabinet Optional Components

Heated Getter Vessel

MFM

PX

Relief

MOV AOV

Inlet

Particle Filter

Outlet

AOV

AOV

AOV

AOV

Adsorber Vessels (heated regen)

AOV AOV

AOV AOV

Regen Outlet Inlet

PX AOV MOV

MOV Outlet Sample MOV

AOV MOV

Inlet Sample

MOV

Heated Getter Vessel Hydrogen

Removal Vessel

Particle Filter

MOV

MFM

PX PX

Relief

AOV MOV

AOV MOV

MOV

Inlet Sample

Outlet Sample

Inlet Outlet

MOV AOV

MOV MOV

MFM

Relief

MOV AOV

Inlet

Particle Filter

Outlet

AOV

AOV

AOV

AOV

Adsorber Vessels

(heated regen)

AOV AOV

AOV AOV

Regen Outlet Inlet

PX AOV MOV

MOV

MOV

Outlet Sample MOV

PX

AOV MOV

MOV

Inlet Sample

Purifier Cabinet Optional Components

Purifier Cabinet Optional Components

Gases Purified Impurities Removed to <1.0 ppb

N2, N2/Noble gas mix CH4, CO, CO2, H2, H2O, O2

H2 CO, CO2, H2O, N2, O2

Hydrides CO2 , H2O, O2

Gases Purified Impurities Removed to <1.0 ppb

Ar, He, Kr, Ne, Xe, N2, H2, CO, CO2, H2, H2O, NMHC, O2

CDA, CO2, N2O, O2 CO2, H2O, NMHC, Amines, NOx

Ar, CO, H2, He, Kr, N2, Ne, Xe H2O

www.arminc.com 719-538-5959 [email protected] Advanced Research Manufacturing Colorado Springs, CO USA

Standard Features/Options Hardware Standard Optional

316L stainless steel tubing, fittings, components √

Wetted surfaces electro-polished √

Steel and aluminum enclosures, powder coated √

Manually operated bypass valves √

Pneumatic/electric operated valves √

Industry standard inlet/outlet connections √

Gas-to-gas heat exchangers (as required) √

Air cooled heat exchangers (as required) √

Water cooled heat exchanges √

Flow meter/flow totalizer √

Overpressure relief protection √

Particle filtration √

Instrumentation & Controls Standard Optional

Inlet pressure transducer √

Outlet pressure transducer √

Captured overpressure exhaust √

Emergency shutdown √

PLC control of automatic functions √

Microprocessor control of automatic functions √

Remote Internet access for control, upgrades √

Touchscreen HMI √

Remote Internet access for troubleshooting √

Control & Instrumentation

Specifications Common to All

Specification Range Specification Range

Maximum allowable working pressure 150 to 250 PSI Pressure drop 1 ATM or less

Inlet/outlet tube diameters 1/2” to 1” Outlet purity Down to < 1PPB

Flow rate 100 to 1200 slpm Input power 100 to 240 VAC 50/60 Hz

www.arminc.com 719-538-5959 [email protected] Advanced Research Manufacturing Colorado Springs, CO USA

Enclosures

SF Enclosure

MF Enclosure

LF Enclosure

NEMA Enclosures

www.arminc.com 719-538-5959 [email protected] Advanced Research Manufacturing Colorado Springs, CO USA

Advantage Series, A Different Approach….

….. from initial inquiry to commissioning

www.arminc.com 719-538-5959 [email protected] Advanced Research Manufacturing Colorado Springs, CO USA

For assistance with other gases, customization or

other high purity requirements contact ARM, Inc., or your local rep/distributor.

and note that the gases and impurities, hard-ware descriptions, and options identified in this brochure are only the most common configurations. If you don’t find your gas/impurities or other specifications it does not mean we won’t have a solution. We have the knowledge, experience and willingness to pursue the technology that will work for your application.

Phone: 719-538-5959 E-mail: [email protected]

How to begin….. Its as easy as a phone call. We will discuss your specifics, gas, flow, pressure, duty cycle, etc. Below is a document located on our

website that will assist you in collecting the information we will ask about in order to define the type of technology, level of automation, and any rec-ommended options to meet your particular gas purification requirements.

Each Advantage Series purifier built is assigned a model number identifying the basics about the purifier. As an example, working with the customer, it is determined that the system will be purifying Hydrogen gas at an 85 Nm3/hr. When quoted, the model number would be A-50KC-30-Ar. A indi-cates an Advantage Series purifier, 50KC indicates the vessel size and media used, 30 indicates the rated flow, and Ar indicates Argon gas is being purified. This is not the only way we identify a particular purifier, each system is serialized with documentation tying that particular unit back to engineering drawings, test records, control software, anything that may be unique to that particular purifier, which will assists us in after sales support need it be required.

Purifier Parameters PDF Form

(http://www.arminc.com/assets/arm_psg_form07.pdf)

![MOV Instruction MOV destination,source MOV AX,BX MOV SUM,EAX MOV EDX,ARRAY[EBX][ESI] MOV CL,5 MOV DL,[BX]](https://static.fdocuments.net/doc/165x107/5a4d1b787f8b9ab0599b8123/mov-instruction-mov-destinationsource-mov-axbx-mov-sumeax-mov-edxarrayebxesi.jpg)

![Syntia: Synthesizing the Semantics of Obfuscated Code mov r15, 0x200 xor r15, 0x800 mov rbx, rbp add rbx, 0xc0 mov rbx, qword ptr [rbx] mov r13, 1 mov rcx, 0 mov r15, rbp add r15,](https://static.fdocuments.net/doc/165x107/5b4e1bc67f8b9ab71a8b4e86/syntia-synthesizing-the-semantics-of-obfuscated-code-mov-r15-0x200-xor-r15-0x800.jpg)