L2 - Phase Diagram

-

Upload

ricardo-villagomez-gro -

Category

Documents

-

view

228 -

download

0

Transcript of L2 - Phase Diagram

-

8/17/2019 L2 - Phase Diagram

1/153

1) Phase Diagram

2) Phase Transformation Under

Thermal Equilibrium3) Microstructural Constituents

4) Alloying Elements Effects

TOPICS

1

-

8/17/2019 L2 - Phase Diagram

2/153

Goals of this lecture

• Learn definitions and basic concepts of phase equilibria and

phase diagrams

• Interpret equilibrium phase diagrams

–Binary isomorphous

– Binary eutectic

– Intermediate compounds/phases

– Phases present

– Their compositions and amounts

– Development of Microstructure and their Mechanical

Properties

2

-

8/17/2019 L2 - Phase Diagram

3/153

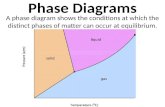

Phase Diagrams

• Many materials systems can exist in a varietyof forms depending on the temperature,pressure and overall composition

• A “phase diagram” is a graphicalrepresentation which details the form(s) thematerial takes under specific conditions

• Assumes the system has achieved chemicalequilibrium

3

-

8/17/2019 L2 - Phase Diagram

4/153

4

-

8/17/2019 L2 - Phase Diagram

5/153

• Changing T can change the

phases: path A to B.

• Changing Co can change thephases: path B to D.

Example: water-sugar system

5

-

8/17/2019 L2 - Phase Diagram

6/153

Definitions and Basic Concepts

• Equilibrium

– Thermodynamic definition: a system is at equilibrium

if its free energy is at a minimum, given a specified

combination of temperature, pressure and

composition.

– Characteristics of the system do not change with time,

i.e., the system is stable

– A change in T, P or C for the system will result in an

increase in the free energy and possible changes to

another state whereby the free energy is lowered.6

-

8/17/2019 L2 - Phase Diagram

7/153

• Sometimes (usually) the kinetics (rate of reaction) of the

system will not allow a phase change to take place

completely, or instantly, under certain conditions – Example: glass of ice water in the sun when 36

• Components:

– Pure Substances (s) required to express composition

of phases in the system

or

–The elements or compounds that are mixed initially(eg. Al and Cu)

7

-

8/17/2019 L2 - Phase Diagram

8/153

8

• Phases:

• Homogenous portion of a system

•Uniform chemical and physical properties

• Several phases may be present simultaneously

• In principal, phases are recognizable and separable

Aluminum-

Copper

Alloy

-

8/17/2019 L2 - Phase Diagram

9/153

Solubility

1. Unlimited Solubility

2. Limited Solubility

• Condition for unlimited solid solution

– Size Factor: similar size (±15%)

–Crystal Structure: Same crystal structure

– Valance: Same valence

– Electronegativity: Similar electronegativity

9

-

8/17/2019 L2 - Phase Diagram

10/153

Solubility Limit

• Solute and solvent

Solvent (component present in greatest amount) Solute (present in minor concentration)

• Solubility Limit:

• Maximum allowed concentration of solute in solvent• Depends on species, temperature and pressure

• Solution and mixture

• A mixture is heterogeneous (more than 1 phasepresent)

• A solution is a single homogeneous phase of variable

composition

10

-

8/17/2019 L2 - Phase Diagram

11/153

•Solidus Line- Temperature where alloy is completely

solid. Above this line, liquefaction begins.

•Liquidus Line - Temperature where alloy is completely

liquid. Below this line, solidification begins.

11

-

8/17/2019 L2 - Phase Diagram

12/153

12

-

8/17/2019 L2 - Phase Diagram

13/153

13

-

8/17/2019 L2 - Phase Diagram

14/153

Example :

Question:

a) What are the phases in this

system?

b) What is the solubility limit for

sugar in water at 20°C?

65

Sugar/Water Phase Diagram

S u g a r

T e m p e r a t u r e

( ° C )

0

20

40

60

80

100

C = Composition (wt% sugar)

L

(liquid solution

i.e., syrup)

Solubility

Limit

L

(liquid)

+S

(solid

sugar) 20

4 0

6

0

8 0

10 0

W a t e r

This is a phase diagram of a two-component system, sugar and

water.

14

-

8/17/2019 L2 - Phase Diagram

15/153

Answer

a) Liquid (“syrup” or sugar in water) and a solid

(sugar)

b) 65 wt% sugar.At 20°C, if C < 65 wt% sugar: syrup

At 20°C, if C > 65 wt% sugar: syrup + sugar

15

-

8/17/2019 L2 - Phase Diagram

16/153

• Indicate phases relation as a function of temperature,

component and pressure.

• However, many useful diagrams are constructed for

constant pressure of 1 atm, so only composition and

temperature are variables

• It provides us with information needed for the control

of phase and microstructure in the materials we make

Phase Diagrams of Materials

16

-

8/17/2019 L2 - Phase Diagram

17/153

One Component Phase Diagram

17

Variable: Pressure and temperature

-

8/17/2019 L2 - Phase Diagram

18/153

18

• Melting point of the system changes with wt% of Ni

• 2 phases present

• L (liquid)

• (FCC solid solution)

• 3 different phase fields

• L

• L +

•

Cu-Ni system

wt% Ni 20 40 60 80 100 0 1000

1100

1200

1300

1400

1500

1600

T(°C)

L (liquid)

(FCC solid

solution)

Two Component Phase Diagram

-

8/17/2019 L2 - Phase Diagram

19/153

19

• Changing T can change # of phases: path A to B.

• Changing Co can change # of phases: path B to D.

Effect of Temperature & Composition (Co)

wt% Ni 20 40 60 80 100 0 1000

1100

1200

1300

1400

1500

1600

T(°C)

L (liquid)

(FCC solid solution) A

B D

Cu

Cu-Ni

system

-

8/17/2019 L2 - Phase Diagram

20/153

20

Question:

a) Determine the phase (s) present at point A and Bb) What is the melting points for Cu and Ni

Cu-Ni

phase

diagram

Example :

• Rule 1: If we know T andCo, then we know:

--the phase(s) present

-

8/17/2019 L2 - Phase Diagram

21/153

Answer

(a)At point A (1100, 60) - 1 phase present, α

At point B (1250, 35) – 2 phases presesnt, L + α

(b) Melting points

Cu = 1085°C, Ni = 1453 °C

21

-

8/17/2019 L2 - Phase Diagram

22/153

Example

• Rule 2: If we know T and Co,

then we know:--the composition of each phase.

Cu-Ni

system

Question:

a) Determine the composition of A, B and D

22

-

8/17/2019 L2 - Phase Diagram

23/153

23

Answer

At TA

= 1320°C:

Only Liquid (L) presentCL = C0 ( = 35 wt% Ni)

At TB

= 1250°C:

Both and L present

At TD = 1190°C:Only Solid () present

C = C0 ( = 35 wt% Ni)

CL = C liquidus ( = 32 wt% Ni)

C = C solidus ( = 43 wt% Ni)

-

8/17/2019 L2 - Phase Diagram

24/153

Example

Question:

a) Determine the amount of each phase(s)present at point A, B and D in wt%

• Rule 3: If we know Tand Co, then we know:

--the amount of each

phase (given in wt%).

24

-

8/17/2019 L2 - Phase Diagram

25/153

25

Cu-Ni system

Answer

WL 43 35

43 32 73wt %

= 27wt %W

-

8/17/2019 L2 - Phase Diagram

26/153

• Sum of weight fractions:

9

• Conservation of mass (Ni):

• Combine above equations:

WL W 1

Co WLCL WC

• A geometric interpretation: moment equilibrium:

1W

solving gives Lever Rule

WLR

WS

THE LEVER RULE:

26

-

8/17/2019 L2 - Phase Diagram

27/153

Gibbs Phase Rule

• Phase diagrams and phase equilibria are subject to thelaws of thermodynamics.

• Gibbs phase rule is a criterion that determines howmany phases can coexist within a system atequilibrium.

• It used to predicts the number of phases that willcoexist within a system at Equilibrium

• It does not apply in non-equilibrium situations

P + F = C + N

27

-

8/17/2019 L2 - Phase Diagram

28/153

P + F = C + N

Where,

P: # of phases present

F: degrees of freedom (temperature, pressure, composition)

C: components or compounds

N: noncompositional variables

*N = 1 or 2 for T (temperature) and p (pressure)

N = 1 if p = constant or T = constant

(HINT: p is usually constant so N is usually 1)

28

-

8/17/2019 L2 - Phase Diagram

29/153

29

For the Cu-Ag system @ 1 atm for a

single phase P:

N=1 (temperature), C = 2 (Cu-Ag), P=

1 (, b, L)

F = 2 + 1 – 1= 2

This result tells us that two variables(temperature and composition) canbe varied independently and thesystem will still remain a single

phase)

Example

-

8/17/2019 L2 - Phase Diagram

30/153

• If 2 phases coexist, for example, +L , b+L, b, thenaccording to GPR, we have 1 degree of freedom: F =2 + 1 – 2= 1. Thus, one variable can be changedindependly and still maintain a system with two

coexisting phases.

• If 3 phases exist (for a binary system), there are 0degrees of freedom. This means the composition andTemp are fixed. This condition is met for a eutecticsystem by the eutectic isotherm.

30

-

8/17/2019 L2 - Phase Diagram

31/153

Example

• A

• B• C

Question:

Please determine the value of the degree of freedom for

point A, B and C

31

-

8/17/2019 L2 - Phase Diagram

32/153

Answer

• Point A – C = 2 (A&B), P = 1 (L)

– F = C+1-P = 2+1-1 = 2

• Point B – P = 2

– F = 1

•Point C – P = 3 – F = 0

32

-

8/17/2019 L2 - Phase Diagram

33/153

33

Importance of Phase Diagrams

• There is a strong correlation between microstructureand mechanical properties, and the development of

alloy microstructure is related to the characteristics of

its phase diagram.

• Phase diagrams provide valuable information about

melting, casting, crystallization and other phenomena.

-

8/17/2019 L2 - Phase Diagram

34/153

Concept of Equilibrium

• What phases do we get as we cool off a molten metal?

• This depends very much on the rate of cooling. If we cancool slowly enough, we get phases that are close to whatthermodynamicists would call “equilibrium.”

• This is the basic phase balance that we get if we haveenough time and temperature for diffusion to do itswork.

• Diffusion of key species is essential to being able to getequilibrium.

34

-

8/17/2019 L2 - Phase Diagram

35/153

35

Microstructure

• In metal alloys, microstructure is characterizedby the number of phases, their proportions,and the way they are arranged.

• The microstructure depends on:

– Alloying elements

–Concentration

– Heat treatment (temperature, time, rate of cooling)

-

8/17/2019 L2 - Phase Diagram

36/153

36

Eutectic

• A eutectic or eutectic mixture is a mixture of two or

more phases at a composition that has the lowestmelting point.

• It is where the phases simultaneously crystallize from

molten solution.

• The proper ratios of phases to obtain a eutectic isidentified by the eutectic point on a binary phasediagram.

L(CE) (CE) + b(CbE)

-

8/17/2019 L2 - Phase Diagram

37/153

Eutectic Reaction and Microstucture

2#1# Solid Solid Liquid

b Liquid

On cooling

On cooling

Eutectic Temperature

Two solids have to form side by

side. They do so in layers. This

microstructure is calledlamellar.

Eutectic Microstructure

37

-

8/17/2019 L2 - Phase Diagram

38/153

f14_09_pg279 38

-

8/17/2019 L2 - Phase Diagram

39/153

39

• Where is the eutectic point?

-

8/17/2019 L2 - Phase Diagram

40/153

•The eutectic point is the point where the liquid phase bordersdirectly on the solid α + β phase; it represents the minimum meltingtemperature of any possible A B alloy.

•The temperature that corresponds to this point is known as theeutectic temperature.

•Not all binary system alloys have a eutectic point: those that forma solid solution at all concentrations, such as the gold-silver system,have no eutectic. An alloy system that has a eutectic is often referredto as a eutectic system, or eutectic alloy.

•Solid products of a eutectic transformation can often be identified bytheir lamellar structure, as opposed to the dendritic structurescommonly seen in non-eutectic solidification.

40/100

-

8/17/2019 L2 - Phase Diagram

41/153

41

• Eutectoid – one solid phase transforms to two other solid

phases

Solid1 ↔ Solid2 + Solid3

+ Fe3C (For Fe-C, 727C, 0.76 wt% C)

Eutectic, Eutectoid, & Peritectic

• Eutectic - liquid transforms to two solid phasesL + b (For Pb-Sn, 183C, 61.9 wt% Sn)

cool

heat

• Peritectic - liquid and one solid phase transform to a 2nd solid

phase

Solid1 + Liquid ↔ Solid2

+ L ε (For Cu-Zn, 598°C, 78.6 wt% Zn)

cool

heat

cool

heat

-

8/17/2019 L2 - Phase Diagram

42/153

42

Eutectoid & PeritecticA

B

-

8/17/2019 L2 - Phase Diagram

43/153

Limited Solubility

43

Cooling Curves

-

8/17/2019 L2 - Phase Diagram

44/153

Cooling Curves• Used to determine phase transition temperature.

• Temperature and time data of cooling molten metal is recorded andplotted.

• Thermal arrest : heat lost = heat supplied by solidifying metal

• Thermal arrest is defined as a region of the cooling curve for a pure metalwhere temperature does not change with time representing the freezingtemperature.

• Alloys solidify over a range of temperature (no thermal arrest)

Pure Metal

Iron

44

-

8/17/2019 L2 - Phase Diagram

45/153

45

Cooling Curves for Iron

• Pure iron when heated

experiences 2 changes incrystal structure before itmelts.

• At room temperature thestable form, ferrite ( iron)has a BCC crystal structure.

• Ferrite experiences apolymorphic transformationto FCC austenite ( iron) at912 ˚C (1674 ˚F).

-

8/17/2019 L2 - Phase Diagram

46/153

Cooling Curve of Pure Iron

• At temperature above

1540 ˚C, iron is in liquidform.

•At 1540 ˚C, iron start to

solidified.

•Delta (BCC) phase start

to form and stable within

the temperature of 1395

- 1540˚C.

•Delta change to gamma

(FCC) phase at around

1395 ˚C. 46

-

8/17/2019 L2 - Phase Diagram

47/153

• Next is the phase change at 910 ˚C, gamma tobeta/alpha (BCC).

• Beta phase is a non-magnetic version of alphairon, is identical to alpha iron in crystal structure,and exists from 910 ˚C to 768 ˚C.

•The temperature at which paramagnetic beta irontransform to ferromagnetic alpha iron is termedas Curie Temperature.

47

Iron Iron Carbon Phase Diagram

-

8/17/2019 L2 - Phase Diagram

48/153

Iron – Iron Carbon Phase Diagram

48

-

8/17/2019 L2 - Phase Diagram

49/153

• Iron carbide (cementite or Fe3C) an intermediate

compound is formed at 6.7 wt% C.

• Typically, all steels and cast irons have carboncontents less than 6.7 wt% C.

• Carbon is an interstitial impurity in iron and forms asolid solution with the , , phases.

49

Transformation Temperature

-

8/17/2019 L2 - Phase Diagram

50/153

Transformation Temperature

The following symbols are used for iron and steel

Acm – In hypereutectoid steel, the temperature at which thesolution of cementite in austenite is completed duringheating.

Ac1 – The temperature at which austenite begins to form

during heating.Ac2 – The temperature at which the α-iron changes to non-

magnetic β-iron. (This is not important for heat treatmentstudies).

Ac3 – The temperature at which transformation of α-iron to

austenite is completed during heatingAc4 – the temperature at which austenite transforms to delta

ferrite during heating.

50

Example:

-

8/17/2019 L2 - Phase Diagram

51/153

pQuestion: Define all the transformation temperature

51

Answer

-

8/17/2019 L2 - Phase Diagram

52/153

Answer

52

-

8/17/2019 L2 - Phase Diagram

53/153

Delta region of Fe-Fe carbide diagram

Liquid + ↔ austenite

53

-

8/17/2019 L2 - Phase Diagram

54/153

Ferrite region of

Fe-Fe Carbide

diagram

54

-

8/17/2019 L2 - Phase Diagram

55/153

IRON IRON-CARBON DIAGRAM

• A map of the temperature at which different phase

changes occur on very slow heating and cooling in

relation to Carbon, is called Iron- Carbon Diagram.

• Iron- Carbon diagram shows

– the type of alloys formed under very slow

cooling,

– proper heat-treatment temperature and

–how the properties of steels and cast irons canbe radically changed by heat-treatment.

55

-

8/17/2019 L2 - Phase Diagram

56/153

Steel and Cast Iron in diagram

Ferrite

Austenite

Steel Cast iron

Pearlite

Pearlite and

Cementine

Pearlite and

Carbide

Eutectic

eutectoid

56

Solid Phases in Iron-Carbide Phase

-

8/17/2019 L2 - Phase Diagram

57/153

Solid Phases in Iron Carbide PhaseDiagram

1. ferrite

•Solid Solution of carbon in iron• BCC Structure

• Carbon only slightly soluble in the matrix

• Max solubility of 0.02%C at 723oC to about 0.008%C at

room temperature

2. austenite

• Solid solution of carbon in iron

• FCC structure

• Can accommodate more carbon than ferrite

• Max of 2.08%C at 1148oC decreases to about 0.8%C at

723oC

• Different in C solid solubility between and is the

basis for hardenin of most steels57

-

8/17/2019 L2 - Phase Diagram

58/153

3. ferrite

• Solid Solution of carbon in iron• BCC Structure

• Max solubility of 0.09%C at 1495oC

4. Cementite (Fe3C)

• Intermetallic Fe-C compound

• Fe3C : 6.67%C and 93.3%Fe

• Orthorhombic cryrstal structure : hard and brittle

58

P li

-

8/17/2019 L2 - Phase Diagram

59/153

Pearlite

is often said to be a two-phased, lamellar (or

layered) structure composed of alternating layers of

alpha-ferrite (88 wt%) and cementite (12 wt%) that

occurs in some steels and cast irons.

Ledeburite

a mixture of 4.3% carbon in iron and is a eutectic

mixture of austenite and cementite. Ledeburite isnot a type of steel as the carbon level is too high

although it may occur as a separate constituent in

some high carbon steels, it is mostly found with

cementite or pearlite in a range of cast irons. 59

Iron carbide (Cementite or Fe C)

-

8/17/2019 L2 - Phase Diagram

60/153

Iron carbide (Cementite or Fe3C)

• Forms when the solubility limit of carbon in ferrite is

exceeded at temperatures below 727 ˚C.

• Mechanically, cementite is very hard and brittle.

• For ferrous alloys there are 3 basic types, based on

carbon content:

Iron (ferrite phase):

-

8/17/2019 L2 - Phase Diagram

61/153

Three important horizontal lines

The diagram shows three horizontal lines which indicate

isothermal reactions (on cooling / heating): • First horizontal line is at 1492°C, where peritectic

reaction takes place:

Liquid + ↔ austenite

• Second horizontal line is at 1147°C, where eutecticreaction takes place:

liquid ↔ austenite + cementite

• Third horizontal line is at 727°C, where eutectoid

reaction takes place:

austenite ↔ pearlite (mixture of ferrite &

cementite)

61

R ti i I bid Ph Di

-

8/17/2019 L2 - Phase Diagram

62/153

Reactions in Iron-carbide Phase Diagram

1. Peritectic Reaction

– This alloy containing 0.15% carbon

– The initial crystals of -solid solution and the whole liquid phase iscompletely transformed to ɤ at 1492oC – (almost no engineeringimportance).

+

2. Eutectic Reaction – Carbon content up to 4.33%

– The liquid is transformed into ɤ and cementite at 1147oC

– Cementite contains 6.67wt% carbon.

– The eutectic of austenite and cementite is known as ledeburite.

-- They are cast irons

+ 3

cool

heat

cool

heat

62

-

8/17/2019 L2 - Phase Diagram

63/153

3. Eutectoid reaction

– Iron –carbon alloy with 0.8% carbon

– ɤ is transformed into ferrite and cementite byeutectoid reaction at 723oC

– They are steels. + 3

cool

heat

63

Summary

-

8/17/2019 L2 - Phase Diagram

64/153

Summary

Peritectic L + =

Eutectic L = + Fe3C

Eutectoid = + Fe3C

Phases present

L

Reactions

BCC structure

Paramagnetic

austenite

FCC structure

Non-magnetic

ductile

ferrite

BCC structure

Ferromagnetic

Fairly ductile

Fe3C cementite

Orthorhombic

Hard

brittle

Max. solubility of C in ferrite=0.022%

Max. solubility of C in austenite=2.14%64

Steel

-

8/17/2019 L2 - Phase Diagram

65/153

Steel

Three major categories of steels

1. low carbon steels (carbon up to 0.3%)

2. Medium carbon steels (carbon from 0.3% to

0.6%)

3. High carbon steels (carbon more than 0.6%)

65

-

8/17/2019 L2 - Phase Diagram

66/153

What is steel?

• A vast family of materials

• Usually composed of ferrite + cementite. Thereare some exceptions.

• The way that the cementite is distributed in theferrite is very important. For example,

1. Very coarse roundish cementite particles widelyseparated soft ductile steel.

2. Very fine roundish cementite particles closelyspaced hard strong steel. (Has some ductility)

3. And so on – there are many ways to distributecementite in ferrite.

66

-

8/17/2019 L2 - Phase Diagram

67/153

Phase transformation in steel according to Fe-C diagram

67

l h f l d h h

-

8/17/2019 L2 - Phase Diagram

68/153

Principal phases of steel and their Characteristics

PhaseCrystal

structureCharacteristics

Ferrite BCC Soft, ductile, magnetic

Austenite FCC

Soft, moderate

strength, non-

magnetic

CementiteCompound of Iron

& Carbon Fe3CHard &brittle

68

The Austenite to ferrite / cementite

-

8/17/2019 L2 - Phase Diagram

69/153

The Austenite to ferrite / cementitetransformation in relation to Fe-C diagram

In order to understand the transformationprocesses, consider a steel of the eutectoid

composition. 0.8% carbon, being slow cooled along

line x- x‘

. • At the upper temperatures, only austenite is

present, with the 0.8% carbon being dissolved in

solid solution within the FCC. When the steel coolsthrough 723°C, several changes occur

simultaneously.

69

h i f i / i

-

8/17/2019 L2 - Phase Diagram

70/153

The Austenite to ferrite / cementite

transformation in relation to Fe-C diagram

• The iron wants to change crystal structure

from the FCC austenite to the BCC ferrite,

but the ferrite can only contain 0.02%carbon in solid solution.

• The excess carbon is rejected and forms

the carbon-rich intermetallic known as

cementite.

70

P liti t t

-

8/17/2019 L2 - Phase Diagram

71/153

Pearlitic structure

•The net reaction at theeutectoid is the formation of

pearlitic structure.

• Since the chemicalseparation occurs entirely

within crystalline solids, the

resultant structure is a finemixture of ferrite and

cementite.

71

-

8/17/2019 L2 - Phase Diagram

72/153

Schematic picture of the formation and

growth of pearlite

Ferr ite

Cementite

Austeniteboundary

72

-

8/17/2019 L2 - Phase Diagram

73/153

Nucleation & growth of pearlite

73

Transformations in Hypoeutectoid Steels

-

8/17/2019 L2 - Phase Diagram

74/153

Transformations in Hypoeutectoid Steels

74

• Line GS shows the temperatures where transformation of ɤ to

-

8/17/2019 L2 - Phase Diagram

75/153

• Line GS shows the temperatures where transformation of ɤ to

starts.

• Line ES shows the temperatures where transformation of ɤ toFe3C starts.

• Point S is called eutectoid point, where degree of freedom,F = 0

• When point S is reached during cooling, the ɤ decomposes to

100% lamellar pearlite at 723oC.

• Line PQ shows the variation in solubility of carbon in iron with

the temperature. It corresponding to starting of precipitation ofsurplus cementite out of ferrite.

• The limiting composition for getting pearlite is 0.025% carbon.

With carbon content less than this, no pearlite will be formed.75

Case Study – Point X

-

8/17/2019 L2 - Phase Diagram

76/153

Case Study Point X1• At temperature T1 , it cuts the GS line, (proeutectoid

) starts to form.

• The composition of the ɤ moves along line GS.

• At T2

, the composition of ferrite is indicated by point Mand austenite by point O.

• At eutectoid temperature, the carbon content in theferrite is 0.025% and that of austenite 0.8%.

(0.8) →

0.025+

(6.67)

Pearlite 76

-

8/17/2019 L2 - Phase Diagram

77/153

77

-

8/17/2019 L2 - Phase Diagram

78/153

78

Example Problem

-

8/17/2019 L2 - Phase Diagram

79/153

79

Example Problem

For a 99.6 wt% Fe-0.40

wt% C steel at atemperature just belowthe eutectoid,determine the

following:a) The compositions of

Fe3C and ferrite ().

b) The amount of

cementite (in grams)that forms in 100 g ofsteel.

Answer

-

8/17/2019 L2 - Phase Diagram

80/153

80

Answer

W Fe3C

R

R S C

0 C

C Fe3C

C

0.40 0.022

6.70 0.022 0.057

b) Using the lever rule with

the tie line shown

a) Using the RS tie line just below the eutectoid

C = 0.022 wt% C CFe3C = 6.70 wt% C

F e 3

C ( c e m e n t i t e )

1600

1400

1200

1000

800

600

4000 1 2 3 4 5 6 6.7

L

(austenite)

+L

+ Fe3C

+ Fe3C

L+Fe3C

C , wt% C

1148°C

T(°C)

727°C

C0

R S

CFe C 3C

Amount of Fe3C in 100 g

= (100 g)WFe3C

= (100 g)(0.057) = 5.7 g

Transformation in a Steel Containing

-

8/17/2019 L2 - Phase Diagram

81/153

less than 0.025% Carbon – X2

• Carbon content is less than 0.025%.

• Austenite transform to at T3 and transformation iscompleted at T4

• No change in this structure between T4 and T5

• At T5, the vertical composition cuts the solvus line PQ.Excess carbon will be separates our as Fe3C.

• If cooling rate is higher than the equilibrium rate, themicrostructure is 100% ferrite, this is a ferrite which issupersaturated as its carbon-content

81

Transformation in Hypereutectoid Steel

-

8/17/2019 L2 - Phase Diagram

82/153

– X3• Cooled from T6 to T7, no phase changes occurs.

• Below T7 , cementite begins to separate out.

• At T8 the composition are ɤ and cementite.

• Further cooling, the entire amount of austenite willtransform to pearlite.

• Final microstructure consists of pearlite andproeutectoid cementite.

82

-

8/17/2019 L2 - Phase Diagram

83/153

83

-

8/17/2019 L2 - Phase Diagram

84/153

84

-

8/17/2019 L2 - Phase Diagram

85/153

85

-

8/17/2019 L2 - Phase Diagram

86/153

86

E l

-

8/17/2019 L2 - Phase Diagram

87/153

Example:

• Consider 1.0kg of austenite contanining1.15wt% C. cooled to below 727oC,

a) What is the proeutectoid phase?

b) How many kilograms each of total ferrite andcementite form?

c) How many kilograms each of pearlite and the

proeutectoid phase form?

d) Schematically sketch and label the resulting

misrostucture.

87

Answer

-

8/17/2019 L2 - Phase Diagram

88/153

This problem asks us to consider various aspects of 1.0 kg of

austenite containing 1.15 wt% C that is cooled to below theeutectoid.

(a)The proeutectoid phase will be Fe3C since 1.15 wt% C is

greater than the eutectoid composition (0.76 wt% C).

(b) Application of the appropriate lever rule expression yields

0.83(1.0kg) = 0.83kg for total ferrite

88

6.7 - 1.150.83

1.150 17

-

8/17/2019 L2 - Phase Diagram

89/153

0.17 (1.0kg) = 0.17kg

(c)

0.93 (1.0kg) = 0.93kg

Proeutectoid

0.07 (1.0kg) = 0.07kg

89

0.17

1.150.93

1.150.07

-

8/17/2019 L2 - Phase Diagram

90/153

Eutectoid

(e) Schematically, the microstructure would appear as:

90

0.17 0.07 0.10 kg

Transformation in Eutectoid Steel –X4

-

8/17/2019 L2 - Phase Diagram

91/153

4

• On cooling a eutectoid point S, all austenite

will transform into 100% pearlite.

• Microstructure at room temperature will be

pearlite.

91

• Below eutectoid temperature,

-

8/17/2019 L2 - Phase Diagram

92/153

p ,

layers of ferrite and cementite

are formed. Pearlite.

92

PearliteEutectoid reaction:

F C

-

8/17/2019 L2 - Phase Diagram

93/153

↔ + Fe3C

Austenite – 0.76 wt% C

Ferrite - 0.022 wt% C

Cementite - 6.70 wt% C

Redistribution of carbon by diffusion

93

-

8/17/2019 L2 - Phase Diagram

94/153

Attention !!!

• It should be noted that the transitions as

discussed, are for equilibrium conditions,

as a result of slow cooling.

• Upon slow heating the transitions will

occur in the reverse manner.

94

Attention !!!

-

8/17/2019 L2 - Phase Diagram

95/153

Attention !!!

•When the alloys are cooled rapidly, entirelydifferent results are obtained, since sufficient time

may not be provided for the normal phase

reactions to occur.

• In these cases, the equilibrium phase diagram is no

longer a valid tool for engineering analysis.

•Rapid-cool processes are important in the heattreatment of steels and other metals (to be

discussed later in H/T of steels).

95

Alloying Steel with more Elements

-

8/17/2019 L2 - Phase Diagram

96/153

• Teutectoid changes: • Ceutectoid changes:

Alloying Steel with more Elements

96

Cast Irons

-

8/17/2019 L2 - Phase Diagram

97/153

Cast Irons-Iron-Carbon alloys of 2.11%C

or more are cast irons.

-Typical composition: 2.0-

4.0%C,0.5-3.0% Si, less than

1.0% Mn and less than 0.2%

S.

-Si-substitutes partially for C

and promotes formation of

graphite as the carbon richcomponent instead Fe3C.

**Formation of graphite or cementite

(iron carbide) is depends on cooling rate

97

Cooling rate dependent of cast irons

-

8/17/2019 L2 - Phase Diagram

98/153

microstructures

98

Cast Irons

-

8/17/2019 L2 - Phase Diagram

99/153

• Can be divided into two main groups, depends on thecarbon content. There are white and grey cast irons.

• In white cast irons, carbon is present in the combined formas cementite.

•In grey cast irons, it is present in free form as graphite.

• Under very slow cooling rate, carbon atoms get sufficienttime to separate out in pure form as graphite, or add ingraphitizing element (Si).

• 3 groups of cast irons in iron carbide phase diagram – Eutectic, Hypoeutectic and hypereutectic.

99

Gray Cast Iron

-

8/17/2019 L2 - Phase Diagram

100/153

Gray Cast Iron

•Composition of 2.5% to 4% carbon and 1% to 3%) silicon.

•Graphite exists largely in the form of flakes.

•Properties of gray iron :

o Low (negligible) ductility

o Weak in tension

o Strong in compression

o Good vibration damping

•Products from gray iron include automotive engine blocks and heads,

motor housings, and machine tool bases.

Nodular Cast Iron (Ductile Iron)

-

8/17/2019 L2 - Phase Diagram

101/153

• This is an iron with the composition of gray iron in which the molten metal

is chemically( added with magnesium) treated before pouring to cause the

formation of graphite spheroids rather than flakes.

• shock resistant , stronger

and more ductile iron.

• Applications include machinery components requiring high strength and

good wear resistance.

White Cast Iron

-

8/17/2019 L2 - Phase Diagram

102/153

•Due to large amounts of iron carbide presence, the structure of

white iron is very hard, wear resistance and brittle.

•It is obtained either by cooling gray iron rapidly or by adjusting the

composition by keeping the carbon and silicon content low.

•Products from white iron include railway brake shoes.

Malleable Iron

-

8/17/2019 L2 - Phase Diagram

103/153

•Obtained by annealing white iron in an atmosphere of carbon monoxide and

carbon dioxide, between 800oC~900oC, for several hours.

•2 types of malleable iron :

•Pearlite malleable(white malleable) – upon fast cooling of white iron

•Ferrite malleable (black malleable) – upon slow cooling of white iron

•The structure has good ductility, strength and shock resistance.

•Typical products include pipe fittings and flanges, railroad equipment parts.

Transformation in Hypoeutectic Cast

-

8/17/2019 L2 - Phase Diagram

104/153

Iron -

• A structure just below 1147 ˚C consist ofproeutecitc austenite and ledeburite (eutecticmixture consisting of austenite and cementite).

• Further cooling, the excess carbon comes out ascementite from proeutectic and eutecticaustenite.

• Both will contain 0.8% carbon and woulddecompose by the eutectoid reaction to pearlite.

104

Problem 1

-

8/17/2019 L2 - Phase Diagram

105/153

Problem 1

105

Answer

-

8/17/2019 L2 - Phase Diagram

106/153

106

Answer

-

8/17/2019 L2 - Phase Diagram

107/153

107

Answer

-

8/17/2019 L2 - Phase Diagram

108/153

108

Problem 2

-

8/17/2019 L2 - Phase Diagram

109/153

109

Answer

-

8/17/2019 L2 - Phase Diagram

110/153

110

Answer

-

8/17/2019 L2 - Phase Diagram

111/153

111

Answer

-

8/17/2019 L2 - Phase Diagram

112/153

Formation of graphite or

cementite (iron carbide) is

depends on cooling rate

112

-

8/17/2019 L2 - Phase Diagram

113/153

113

-

8/17/2019 L2 - Phase Diagram

114/153

114

Iron- Iron

Carbide system

Iron-Graphite

system

-

8/17/2019 L2 - Phase Diagram

115/153

115

Problem 3

-

8/17/2019 L2 - Phase Diagram

116/153

116

Answer

-

8/17/2019 L2 - Phase Diagram

117/153

117

Answer

-

8/17/2019 L2 - Phase Diagram

118/153

118

Answer

-

8/17/2019 L2 - Phase Diagram

119/153

119

Answer

-

8/17/2019 L2 - Phase Diagram

120/153

120

Answer

-

8/17/2019 L2 - Phase Diagram

121/153

121

Transformation in Hypereutectic Cast Iron

-

8/17/2019 L2 - Phase Diagram

122/153

• A structure just below 1147 ˚C consist of proeutectic cementite andledeburite.

• Further cooling, the excess carbon comes out as cementite fromeutectic austenite.

• Proeutectic cementite will remain as it is since it does not

undergoes any further change on cooling.

• the excess carbon comes out as cementite from eutectic austenite.

• At 723 ˚C, eutectic austenite transforms into pearlite

• Final microstructure will reveal proeutectic cementite present asplate and transformed eutectic consisting of pearlite pluscementite.

122

-

8/17/2019 L2 - Phase Diagram

123/153

123

Transformations in Eutectic Cast Iron

-

8/17/2019 L2 - Phase Diagram

124/153

• Eutectic cast iron solidifies at 1147 ˚C.

• As the temperature decreases, the solubilityof carbon in austenite iron decreases, as

indicated by the cementite line.

• On further cooling, proeutectoid cementiteseparates out of the austenite at 723˚C.

• Final structure is ledeburite.

124

-

8/17/2019 L2 - Phase Diagram

125/153

125

-

8/17/2019 L2 - Phase Diagram

126/153

126

-

8/17/2019 L2 - Phase Diagram

127/153

127

-

8/17/2019 L2 - Phase Diagram

128/153

128

Element Content in Cast Iron

-

8/17/2019 L2 - Phase Diagram

129/153

Element Function

Carbon Increase graphite content

Silicon Help formation of graphiteSulfur + Manganese Stabilize cementite and combination

of sulfur and manganese form

manganese sulfide.

Phosphorous Lower down melting point

Microstructure of cast irons

-

8/17/2019 L2 - Phase Diagram

130/153

130

Microstructure of cast irons

-

8/17/2019 L2 - Phase Diagram

131/153

131

Microstructure of cast irons

-

8/17/2019 L2 - Phase Diagram

132/153

132

Microstructure of cast irons

-

8/17/2019 L2 - Phase Diagram

133/153

133

Microstructure of cast irons

-

8/17/2019 L2 - Phase Diagram

134/153

134

Microstructure of cast irons

-

8/17/2019 L2 - Phase Diagram

135/153

135

ELEMENTS INFLUENCE IN FERROUS

ALLOYS PROPERTIES

-

8/17/2019 L2 - Phase Diagram

136/153

ALLOYS PROPERTIES

Manganese (Mn) improves hardenability, ductility and wear resistance. Mn,

increasing strength at high temperatures.

Copper (Cu) improves corrosion resistance.

Chromium (Cr) improves hardenability, strength and wear resistance, sharply

increases corrosion resistance at high concentrations (> 12%).

Sulfur improves machinability.

Silicon (Si) improves strength, elasticity, acid resistance and promotes

large grain sizes, which cause increasing magnetic

permeability.

Nickel (Ni) increases strength, impact strength and toughness, impart

corrosion resistance in combination with other elements.

Molybdenum

(Mo)

increases hardenability and strength particularly at high

temperatures.

-

8/17/2019 L2 - Phase Diagram

137/153

Aluminum

(Al)

deoxidizer, limits austenite grains growth.

Vanadium (V) increases strength, hardness, creep resistance and impact

resistance due to formation of hard vanadium carbides,

limits grain size.

Tungsten (W) increases hardness particularly at elevated temperatures due

to stable carbides, refines grain size

Titanium (Ti) improves strength and corrosion resistance, limits austenite

grain size.

From a phase diagram

• We know

-

8/17/2019 L2 - Phase Diagram

138/153

• We know

– Overall Composition

– Solidus line

– Liquidus Line

– Limits of Solid Solubility

– Chemical Composition of Phases at anyTemperature

– Amount of Phases at any Temperature

– Invariance Reaction

– Development of Microstructure

– Chemical Activity

138

Determination of Phase Diagrams

-

8/17/2019 L2 - Phase Diagram

139/153

• Cooling Curves

• Differential Scanning Calorimetry

• Thermomechanical Analysis

• Metallography

• Energy Dispersive X-ray Spectroscopy

• Electron Microprobe Analyzer

•X-ray Diffraction

• Transmission Electron Microscopy

139

Cooling Curves

-

8/17/2019 L2 - Phase Diagram

140/153

140

Usage of Phase Diagrams in

Determining the Heat Treatability

-

8/17/2019 L2 - Phase Diagram

141/153

Determining the Heat Treatability

• Heat Treatment is based on “controlling” thesolid state transformation rate

– Heat treatment of steels control of the eutectoidreaction

–Age hardening (precipitation strengthening) ofaluminium alloys: control of precipitation reaction.

141

Example: Another – A closeup of A

steel

-

8/17/2019 L2 - Phase Diagram

142/153

steel.The darker area is Fe

with small amount of

interstitial carbon.

The lighter standout

areas are the

compound cementite,

Fe3C. (Iron carbide.)

142

What have we seen?

-

8/17/2019 L2 - Phase Diagram

143/153

•Multiphase materials, or alloys. Phases areseparate, they are clearly different materials. Butthey are mixed together, at times very finely.

• We do not always have multiphase alloys. There

are many useful single phase alloys. BUT• The presence of the second phase is very

important to…

BLOCK DISLOCATIONS! INCREASE STRENGTH.

143

Summary

-

8/17/2019 L2 - Phase Diagram

144/153

144

• Phase diagrams are useful tools to determine:

-- the number and types of phases present,

-- the composition of each phase,

-- and the weight fraction of each phase

For a given temperature and composition of the system.

• The microstructure of an alloy depends on-- its composition, and

-- rate of cooling equilibrium

-

8/17/2019 L2 - Phase Diagram

145/153

Additional Information

Effect of Alloys

145

Carbon Content in Steels• Carbon is the most important alloying element in steel.

-

8/17/2019 L2 - Phase Diagram

146/153

146

• Most steels contain less than 1% carbon.

• Plain carbon steel - carbon is the only significant alloying element

• Mild steel , or low carbon steel, are produced in the greatest quantity

because it is cheap, soft, ductile, and readily welded. Caution: it cannot be heat-treated

• Mild steels are used for car bodies, appliances, bridges, tanks, andpipe.

Name Carbon Content Examples

Low carbon (mild) 0.05% - 0.32% Sheet, structural

Medium carbon 0.35% - 0.55% Machinery

High carbon 0.60% - 1.50% Machine tools

Cast iron >2.00% Castings

Carbon Content Cold Working in Steels• Medium carbon steel - used for reinforcing bars in concrete,

-

8/17/2019 L2 - Phase Diagram

147/153

147

farm implements, tool gears and shafts, as well as uses in

the automobile and aircraft industries.

• High carbon steels - used for knives, files, machine tooling,hammers, chisels, axes, etc.

• A small increase in carbon has significant impact onproperties of the steel. As Carbon increases the steel:

–becomes more expensive to produce and less ductile,i.e., more brittle

– becomes harder and less machinable and harder to weld

– has higher tensile strength and a lower melting point

-

8/17/2019 L2 - Phase Diagram

148/153

•Cold working is used to enhance the properties ofsteel

– Reducing thickness by 4% raises the tensilestrength by 50%

– Cold working is plastic deformation at roomtemperature.

– Cold working produces dislocations in the metal’sstructure which block dislocations as they slide

along the slip planes

148

Other Elements in Steels• Alloying elements are added to nullify undesirable

elements

-

8/17/2019 L2 - Phase Diagram

149/153

149

elements

– Carbon

– Manganese

• increases strength, malleability, hardenability, and

hardness• Sulfur reacts with the Mn which reduces the hot short

effect of the iron sulfide accumulating at the grainboundaries and reducing strength at Temp

– Silicon- reduces Oxygen negative effects

– Aluminum-• reacts with Oxygen versus iron (no sparks). Killed

steel

-

8/17/2019 L2 - Phase Diagram

150/153

• promotes smaller grain size which adds toughness

– Boron- increases the hardenability of steel (only withAl added)

– Copper- increases corrosion resistance

– Chromium- increases corrosion resistance andhardenability

– Nickel, Niobium, titanium, tungsten carbide, vanadium

• increase toughness and strength and impactresistance 150

Alloying steel with other elements changes the Eutectoid

Temperature, Position of phase boundaries and relative

A f h h

-

8/17/2019 L2 - Phase Diagram

151/153

151

Amounts of each phase

Stainless Steel• Corrosion of steels can be slowed with addition of Cr and

Ni

-

8/17/2019 L2 - Phase Diagram

152/153

152

Ni.

• Stainless steels have chromium (up to 12%) and Ni(optional)

– ferritic stainless: 12% to 25% Cr and 0.1% to 0.35%

Carbon• ferritic up to melting temp and thus can not form the

hard martensitic steel.

• can be strengthened by work hardening

• very formable makes it good for jewelry, decorations,utensils, trim

– austenitic stainless: 16% to 26% Cr, 6% to 23% Ni,

-

8/17/2019 L2 - Phase Diagram

153/153

0.35% Carbon• machinable and weldable, but not heat-treatable

• used for chemical processing equipment, food utensils,architectural items

– martensitic stainless: 6% to 18% Cr, up to 2% Ni, and 0.1%to 1.5% C•

hardened by rapid cooling (quenching) from austeniticrange.• Corrosion resistance, low machinability/weldability

used for knives, cutlery.

– Marging (high strength) steels: 18% to 25% Ni, 7% Co, with

others• heated and air cooled cycle with cold rolled