Installation Procedure: EVC-E D3 Aquamatic &...

Transcript of Installation Procedure: EVC-E D3 Aquamatic &...

10

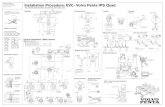

Installation Procedure: EVC-E D3 Aquamatic & InboardInstallation Procedure: EVC-E D3 Aquamatic & Inboard

Document number: 47702217

Release date: 06-2012

To actuator

To powertrim senderTo trim pump motor

Trim pump power supply

2.5” display

Lever connections

Lever

Buzzer

Diagnose connection (VODIA)

Connection for safety lanyard

Rudder angle sender

Fresh water and fuel level senders

Trim relays (up/down)

Engine

FlybridgeAquamatic DPS twin, electronic steering

Typical installation / Main stationDPS twin, electronic steering

Controls

Steering Control Unit

Typical installationSingle engine, Inboard

IMPORTANT! Never cut or modify the Volvo Penta EVC harnesses. For extra power supply, use the Volvo Penta relay for external accessories.

Stand-alone HCU

Use template when making holes in dash-board

Use cable ties to fix cables

Use cable ties to fix cables

SX/DPS connections

Reverse gear connections

A

B

Standard–right hand rotation: Connector A to solenoid A Connector B to solenoid B

Connect shift cable. Lock cable with cotter pin. Power up before connecting shift cable to secure neutral position of actuator.

To ACTUATOR CONNECTION on transmission cable

NOTE! Clamp all cables.

Mount actuator on transom preferably, angled 5˚ downwards.Shift cable bending radius: max. 200 mm (8”).

Clamp steering hoses and cables

To levers, standard EVC bus cable

To engine, ex-tension cable

IMPORTANT! The SCU can be mounted vertically or horizontally. Do NOT mount the SCU with hoses lead-ing up. This will trap air in the hydraulic valve body and cause erratic operation.

Connect power to SCU

Engine starting battery

Main switch

Tightening torque: 5 Nm (3.7 lbf.ft)

Multiple helm stations

To next helm station

To next helm station

Helm station

Helm station

Engine Engine

11 11

7

8 8

11 11

For information on cable lengths etc. please refer to Installation manual.

NOT OK!

OK!

Connecting multiple Multilink hubs

1

10

Fuse

12

OK!

e-Key panel

IMPORTANT! This end of Y-connector must be connect-ed directly, without extension, to levers.

Y-connector

8

7

AUX AUX

Joystick Steering wheel Multilink hub

Multifunction panel(Start/Stop panel)

Buzzer

2.5 displays

Levers

Lever connections

11 11

10

10

10 10

Autopilot 4” display

To NMEA2000 backbone

25

Battery ManagementNegative terminal

Starter motor

Remote frequency reciever with WLAN (RFW)

Continuous output 20 A

B: fused output

A: unfused output

House loads

2.5” Battery Management display

Battery sensor

To engine connector (AUX)

To external switches (optional)

Termination plug

AUX-bus termination

Correct!Termination in the beginning and at the end of the AUX-bus

Incorrect!No end termination of the AUX-bus

5

Termination plug 5

Termination plug

e-Key Remote (optional)

Locking/unlocking the boat system. Controls main circuit breaker and two aux relays

e-Key (standard)

Locking/unlocking the boat system

e-Key System

10

NMEA2000 backbone

Female terminator

Male terminator

ChartplotterEVC AutopilotCompass (CCU)EVC Autopilot

Battery 12 VDC

T-connectorBackbone exten-sion cable

Fuse

Power cable

23 20

202020Use AUX relay

24 20 22 24

5

Joystick

NMEA interface

ADU

Steering wheel

Multilink hub

Levers

Lever connections

Buzzer

Actuator

Battery

Connection for safety lanyard

Steering Control Unit

Steering cylinder

Rudder angle sender (not used)

Fresh water and fuel level senders

Engine

Multilink minimum requirements:

Additional multilink features:

12

16

10

1 1

Diagnose connection (VODIA)

8

9

8

19

Compass (CCU)To NMEA2000backbone

12

Engine

25

7 7

1111

e-Key panel

7

7 7

2.5” displays 4” display

7” display

Autopilot 4” display

To levers, standard EVC bus cable

To engine, extension cable

7

8 8

1010 16

10

10

10

Battery Control Unit (BCU) Battery Control Unit (BCU)

Termination plug5

2.5” Battery Management display

Battery sensor

Battery

Steering cylinderActuator

Steering Control Unit

To engine

2020

NOTE! Minimum two 2.5” displays or one 4” or 7” display.Maximum two 4” or 7” displays on one helm station.

20

10

21 21

Battery sensor

NOTE! Minimum one 2.5” display per driveline or one 4” or 7” display. Maximum two 7” displays on one helm station.

3

Steering wheel non tilt adjuster

Steering

Joystick

Incl. cables 1.5 m (5 ft.)

Steering wheel tilt adjuster Steering wheel hub

Incl. cables 2.5 m (8 ft.)

47

70

22

17 0

6-2

012

Components and Cables

Controls

Twin engine levers

Built-in HCUs

Twin engine levers

Built-in HCUs

Powertrim control

Single engine lever

Built-in HCUs

Single engine lever

Built-in HCU

Powertrim control

Side mounted

Single engine lever

Built-in HCUs

Powertrim control

1b. Wiring harness, Reverse gear, Inboard

Feet Meter Part no.

1.3 0.4 21831016

1. Wiring harness, Stern drive, AQ

Feet Meter Part no.

9.8 3.0 21831018

Components

Sender

Fuel level sender 3–180 ohm

Fuel level sender 240–30 ohm

Sender

Water level sender 3–180 ohm

Stand-alone HCU e-Key panel

Ignition, start/stop and locking/unlocking the boat system

Multilink hub

6 cable sockets

Autopilot interface NMEA 0183 interface NMEA 2000 interface

7” display power supply for 12 V systems

Multisensor

Transom mounted

Multisensor

Hull mounted

SCU

Steering Control Unit

Trim instrument **

Diameter 52 mm (2.05”) analog

Trim instrument **

Diameter 52 mm (2.05”) digital

2.5” display

Not in combination with 4” or 7” display

Multifunction panel

Function configured at startup

7” display

Color display

Autopilot 4” display

Color display

4” display

Color display

Rudder angle sensor

3–180 ohm

Single engine lever

Built-in HCU

Side mounted

Remote frequency reciever

with WLAN (RFW)

Battery Control Unit Battery sensore-KeyCompass (CCU)

Fresh water level **

Diameter 52 mm (2.05”)

EVC system tachometer

Diameter 85 mm (3.35”) 110 mm (4.33”) 0–4000 rpm

Coolant temp **

Diameter 52 mm (2.05”) C°, F°

Speedometer Unitless **

Diameter 85 mm (3.35”) 110 mm (4.33”)

0–40 1/Hour 0–60 1/Hour

Alarm instrument **

Diameter 52 mm (2.05”)

Voltmeter **

Diameter 52 mm (2.05”) 12 V, 24 V

Rudder indicator **

Diameter 52 mm (2.05”)

Front ring kit (nut)

Diameter 52 mm (2.05”) Black/Chrome

Diameter 85 mm (3.25”) Black/Chrome

Diameter 110 mm (4.33”) Black/Chrome

Front ring kit (clamp)

Diameter 52 mm (2.05”) Black/Chrome

Diameter 85 mm (3.25”) Black/Chrome

Fuel level **

Diameter 52 mm (2.05”)

Engine oil pressure **

Diameter 52 mm (2.05”) bar, psi

Turbo pressure **

Diameter 52 mm (2.05”) bar, psi

4-in-1 Gauge **

Diameter 110 mm (4.33”) Coolant temperature Voltage Oil pressure Fuel level

Aux. Dimmer Unit (ADU) **

Instruments**) Only in combination with EVC system tachometer

Not in combination with 2.5” or 7” display

Not in combination with 2.5” or 4” display

Cables

2. Multisensor Y-split*

Feet Meter Part no.

1.9 0.6 21825662

*) Wiring harness AUX-bus.

3. BM-display Y-split*

Feet Meter Part no.

1.9 0.6 21825656

*) Wiring harness AUX-bus.

4. CPM Y-split*

Feet Meter Part no.

1.9 0.6 21825665

*) Wiring harness AUX-bus.

1616 10 10ADU

NMEA interface

24. NMEA2000 Termination plugs

Type Part no.

Male 21812196** Female 21812203**

23. NMEA2000 Powercable

Feet Meter Part no.

6.6 2 21812205**

22. NMEA2000 T-connector

Part no.

21812195**

**) Incl. in Autopilot kit

19. Display cable, 5/6-pin

Feet Meter Part no.

5 1.5 21640400

Incl. in display kit

20. NMEA 2000 Extension cable

Feet Meter Part no.

1 0.3 21812185 6.6 2 21812194 13 4 21867150 19 6 21867151 33 10 21867152

21. Battery sensor cable

Feet Meter Part no.

9.8 3 21840060

17. Steering adapter, 12/6-pin

Feet Meter Part no.

0.6 0.2 21421945

18. Y-split multilink, 6-pin

Feet Meter Part no.

1.6 0.5 3588206

11. Extension cable, 6-pin

Feet Meter Part no.

5 1.5 3889410 10 3.0 3842733 16 5.0 3842734 23 7.0 3842735 30 9.0 3842736 36 11.0 3842737 66 20.0 21172469 131 40.0 21172470

16. Extension cable, 3-pin

Feet Meter Part no.

3 1.0 874759 10 3.0 3807043

12. Sender cable, 6-pin

Feet Meter Part no.

16 5.3 3807229

15. Extension cable, 6-pin

Feet Meter Part no.

5 1.5 21480272

13. Aux. relay cable, 6-pin

Feet Meter Part no.

3.3 1.0 21427463

Kit with cable & relay 12V: 21475508 24V: 21475509

14. Extension cable, 6-pin

Feet Meter Part no.

23 7.0 21166002 30 9.0 21166003 43 13 .0 21166004

7. Standard EVC bus cable, 6-pin*

Feet Meter Part no.

5 1.5 21865234 16 5.0 874789 23 7.0 889550 30 9.0 889551 36 11.0 889552 42 13.0 888013

*) One cable per engine has to be ordered.

8. Y-connector, 6-pin

Feet Meter Part no.

1.6 0.5 3588972

10. Multilink cable, 6-pin

Feet Meter Part no.

5 1.5 3886666

6. Y-split steering, 6-pin

Feet Meter Part no.

1.3 0.4 21421941

9. 7” display cable, 6-pin

Feet Meter Part no.

5.5 1.7 21514712*

*) Incl. in display kit

5. Termination plug

Part no.

21825714

A-CAN

Analog lever interface

e-Key Remote

25. e-Key harness with Safety lanyard

Feet Meter Type Part no.

5 1.5 Single panel 21693202 5 1.5 Twin panel 21693206

26. e-Key harness without Safety lanyard

Feet Meter Type Part no.

5 1.5 Single panel 21693204 5 1.5 Twin panel 21693208

10