Infinity4000 Installation Ref Packet Doc60137

-

Upload

bill-mcfarland -

Category

Documents

-

view

318 -

download

0

description

Transcript of Infinity4000 Installation Ref Packet Doc60137

-

Pool Cover Specialists National, Inc. 8553 South 2940 West West Jordan, Utah 84088 www.poolcovers.com

Infinity 4000 Installation Reference Packet

A quick guide supplying important reference materials for pool builders and Infinity 4000 installers.

800-369-5152

800-568-6955 Fax:

Phone:

-

Table of Contents 1. Infinity 4000 Features

2. Toptrack Styles

3. Deckmount System Enclosure

4. Undertrack Styles

5. PCS Coping Forms

6. Excavation Guides

7. Electrical Requirements

8. Mechanism Housing Options

9. System Clearance Specs

10. Lid Options

11. Infinity 4000 Specifications

Please Note: This document constitutes a quick reference guide to PCS products and methodologies. For full details and instructions, please consult the appropriate

documentation.

- 1 -

2

4

5

6

7

8

10

14

18

19

21

-

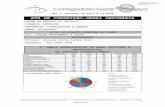

Infinity 4000 Features 1

- 2 -

-

- 3 -

-

Toptrack Styles 2

The original PCS Track. Stands about 3/4 above the deck. Can be used with any pool cover application. For free-form pools, this

and the Snap-down Toptrack are the best options.

An update on the Universal Toptrack. Easy to install and featuring a sleeker look, the patented Snap-down Toptrack has become

the standard Toptrack application.

Standing only 1/8 above the deck, the Horizontal Flush Toptrack is an attractive and less obtrusive style. Because the track must be set below deck, it is only available

on new decks.

The Horizontal Flush Track can be installed without a Retainer. Screw heads will be visible on the track, but will effectively

anchor the track.

Introduced in 2006, the Vertical Flush is a great option for new pools. The Track snaps easily into the Retainer and sits nearly flush

with the deck. The best low-visibility Toptrack on the market.

- 4 -

-

Deckmount System Enclosure 3 For existing pools where recessed systems are not practical, the Infinity 4000 Deckmount System is an affordable and reliable option. To increase the safety and enhance the appearance of Deckmount Systems, Pool Cover Specialists recommends covering the mechanism with our Vinyl Bench Enclosure. The Enclosure is also an effective barrier, protecting the mechanism from harsh weather and other potential interferences.

The Vinyl Bench is custom-built to fit each system. The bench can be constructed for pools with a Track Space of

up to 28 feet.

PCS Part #s DB1002 - DB1009 Vinyl Bench, Exploded Diagram To ease shipment and transport, the Bench is shipped as a modular product. The diagram above shows the separate

pieces included in a Bench of average length.

FIG. A

FIG. B Some notes on installing the Enclosure:

The system is installed and anchored to the deck first.

The Back Panel is assembled and placed in position at the back (non-pool side) of the mechanism. (FIG. A)

The Back Panel is anchored to the deck. (FIG. B)

The Front Panel is assembled and placed in position. Side Panels are secured to the Front and Back Panels.

Specially designed Lid Brackets are then installed to the inside back wall of the Bench.

The Lid panels are then placed over the Bench and secured.

- 5 -

-

Undertrack Styles 4

Installed on 3 sides of the pool, this retainer can be used with PCS Reusable Forms to

create an elegant and sturdy coping. NOTE: It can also be used when a channel

is created in the deck and a raised pool-wall is desired.

This retainer overhangs the pool wall to create the popular cantilevered look.

NOTE: It can also be used with stone coping applications.

Deck-on-Deck retainer raises the track 1/2 above the pool deck. This retainer is ideal

for non-rectangular pools and free-form fiberglass pool-cover applications.

NOTE: Also available in a high-profile configuration.

Our newest retainer is perfect for vinyl liner pools. Built specifically for the new PCS

Housing, available early 2009. This retainer can be used with the easy Snap-in Coping.

The standard gunite Retainer (above) can be modified for use in Raised Wall Pools. In

these applications a pocket is created in the raised wall. The retainer is placed in the pocket and secured to the back wall. It is

then mortared into place.

- 6 -

-

PCS Coping Forms 5 PCS Re-usable Coping Forms come in many styles and can be used in conjunction with any of our retainer options. The images below illustrate how the forms fit in the retainer, held in place by a shim. After the deck is formed, the forms can be removed and re-used for the next application. Below is a sampling of our Coping Form applications.

- 7 -

-

Excavation Guides 6 Excavation Instructions For Rectangular Undertrack Pools

Note: It is very important that the pool be formed square providing a true rectangle. To be sure the pool is square check these dimensions:

width AB = width CD length AC = length BD

diagonal AD = diagonal BC

Provisions: 1. Dig the trench at the cover housing end of the pool a minimum of one foot beyond the pool. 2. Extend the trench 36 past each side wall. Trench must be dug 18 - 20 inches deep and 18 inches wide

(front to back). 3. Do not dig out for skimmers along the cover housing end. 4. Determine which side of the trench will house the motor. 5. Form a vault inside the trench. The motor side of the vault will extend 36 beyond the track. The opposite (non-motor) side will extend 12 beyond the track. 6. The finished vault should be dug at least 14 below bond beam height (not deck height). Vault width (front to back) is determined by the track length: Track Lengths up to 65 require a 14 inside dimension. Track Lengths above 65 require a 16 inside dimension. NOTE: If using gravel, form vault 4 - 6 inches deeper. Inside dimensions of vault should be 4 feet longer than Track Space. 7. Make sure the vault has adequate drainage.

- 8 -

-

Excavation Instructions For Freeform / Toptrack Pools Note: It is very important that the pool cover tracks be laid squarely providing a true rectangle around the pool. To be sure the tracks are placed correctly, check these dimensions:

width AB = width CD length AC = length BD

diagonal AD = diagonal BC

Provisions: 1. Dig the trench at the cover housing end of the pool a minimum of one foot beyond the pool. 2. Extend the trench 36 past each side wall. Trench must be dug 18 - 20 inches deep and 18inches wide

(front to back). 3. Do not dig out for skimmers along the cover housing end. 4. Determine which side of the trench will house the motor. 5. Form a vault inside the trench. The motor side of the vault will extend 36 beyond the track. The

opposite (non-motor) side will extend 12 beyond the track. 6. The finished vault should be dug at least 14 deep. Vault width (front to back) is determined by the track length: Track Lengths up to 65 require a 14 inside dimension. Track Lengths above 65 require a 16 inside dimension. NOTE: If using gravel, form vault 4 - 6 inches deeper. Inside dimensions of vault should be 4 feet longer than Track Space. 7. Make sure the vault has adequate drainage.

- 9 -

-

- 10 -

WIRING A 110 VOLT UNIT: The electrician should bring 110VAC to the motor end of the housing. Pull a hot wire, a neutral wire, and an unbroken ground wire (green) to the housing and terminate them in a UL rated J box. The 7/8 Horsepower Motor is the standard motor as of 2003. It draws 13 amps under normal running conditions. Wire to the motor should be no smaller than 12 AWG.

KEY SWITCH: (NOTE: When ordering your Infinity system you have an option for cover controller: Key Switch or Touchpad. As of 2009, the Key Switch is standard.) Run a separate conduit to the desired location and mount a water-tight single gang extra deep junction box. (NOTE: ASTM safety requirements mandate that the key switch be in full view of the pool not more than thirty feet away and 5 above ground level out of reach of small children.) The Key Switch requires three wires, 16 - 22 AWG, however, PCS recommends pulling five wires to simplify any future replacements or upgrades. The Key Switch operates on 5 VDC.

NOTE: PCS recommends using a stranded wire instead of data cable. Data cable is not reliable for pool cover applications.

Electrical Requirements 7

-

BONDING: All INFINITY 4000 systems require bonding. The electrician should provide an 8 AWG (American Wire Gauge) solid copper ground wire from the pool equipment pad to a ground clamp on the electrical conduit inside the housing, with a six foot long tail that will be attached to the mechanism ground lug. Be sure to follow local codes in all instances. (NOTE: Place bonding wires at each end of the housing.)

TOUCHPAD: Run a separate conduit to the desired location. A custom Touchpad enclosure will be provided with the mechanism. This enclosure has been drilled for a NPT (National Pipe Thread) connector in the bottom side. NOTE: ASTM safety requirements mandate that the touchpad be in full view of the pool not more than thirty feet away and 5 above ground level out of reach of small children. Pull five wires, 16-22 AWG, for the Touchpad. The Touchpad operates on 5 VDC.

GROUND FAULT CIRCUIT INTERRUPTER: A 20 Amp dedicated GFCI must be provided in the electrical supply line for the motor.

MOTOR CONTROLLER CIRCUIT BOARD: The INFINITY 4000 control board is either mounted in a water-tight box which is placed inside the cover housing next to the motor or it is mounted inside the casing of the flood-proof motor itself. It changes motor rotation from forward to reverse and has limit switch capabilities for added safety, stopping the cover in the fully opened and fully closed positions. The control is operated by a momentary Key Switch or Touchpad.

TECHNICAL INFORMATION:

In most areas, high and low voltage wires can be run in the same conduit, if they are rated at a voltage of 600 or greater.

Controller Options

- 11 -

-

Wiring Diagrams

- 12 -

Hall Effect Sensor Baldor Motor

Keyswitch or Touchpad

-

- 13 -

-

Mechanism Housing Options 8 Recessed Redwood* Housing - Undertrack

SIDE VIEW Redwood Housing - Undertrack D = 11 min. W = 14 for TLs** up to 65 16 for TLs over 65

The diagrams that follow show cross-sections of the different housing options available. These diagrams are meant to give the technician an idea of how the different housings work. For more detailed information, refer to the appropriate documents or call the PCS Customer Service Department at 1-800-369-5152.

*The Housing can be constructed with many wood types. We recommend redwood for its durability. **TL = TRACK LENGTH

Provisions: 1. 2 x 12 redwood or pressure treated lumber should be used to build the housing. 16P box nails or 3 deck screws should be used to assemble. 2. Inside housing dimensions are determined by the track length: Track lengths up to 65 require a 14 inside dimension Track lengths 65 to 85 require a 16 inside dimension 3. Motor end of cover housing must have a minimum of 36 from pool wall inside measurement and opposite end must have a minimum of 12 from pool wall inside measurement. 4. Temporary bracing should be nailed to the top inside of housing to provide support until bond beam and pool deck have been completed around housing. Spacing should be 2 to 3 apart.

- 14 -

-

Recessed Redwood Housing - Toptrack

SIDE VIEW Redwood Housing - Toptrack D = 11 min. W = 14 for TLs up to 65 16 for TLs over 65

IMPORTANT NOTE: The inside measurements of the cover housing are determined by the width and length of the pool. To determine the length of the cover housing for an Undertrack installation, the width of the pool from water line to water line must be acquired. To this measurement add 36 for the motor end and 12 for the opposite end. (See Diagram A). The inside width of the cover housing is determined by the length of the pool. For standard pool lengths, PCS recommends an inside housing width of 14. (See Diagram C). Use 2 x 12 redwood or pressure-treated lumber to construct the box. Temporary bracing should be nailed to the top inside of the Housing, spaced about 2 to 3 apart. Base boards are used to maintain Housing dimensions, spaced about 3 to 4 apart.

Recessed Redwood Housing - Construction

36 Motor End 12 Opposite End

-

Recessed Gunite Housing - Undertrack

SIDE VIEW Gunite Housing - Undertrack D = 14 min. W = 14 for TLs up to 65 16 for TLs over 65

Recessed Concrete Housing - Toptrack

SIDE VIEW Concrete Housing - Toptrack D = 14 min. W = 14 for TLs up to 65 16 for TLs over 65

36 Motor End 12 Opposite End

36 Motor End 12 Opposite End

- 16 -

-

(2009) Vacuum Formed Housing for Vinyl Liner Pools

SIDE VIEW (2009) Vacuum Formed Housing

The (2009) Vacuum Formed Housing offers a great improvement over Vinyl Liner Pool Housings of the past. Some notes about the Housing:

Modular Design - the Housing is shipped in 6 sections. This makes transport and installation easier.

Compatibility - works with the new and improved PCS Vinyl Liner Retainer (PCS Part #52001).

New Lid - adds a sleeker look to the mechanism cover.

Mounting - can be mounted to polymer and steel wall pools.

T Slot Mechanism Mounting System - allows for easier installation and position adjustment

12 Opposite End 36 Motor End

- 17 -

-

System Clearance Specs 9

- 18 -

Standard System (110v AC, 220v AC, 24v DC)

Single Gang Junction Box

Brushless DC System (110v AC)

Hydraulic System (110v AC, 220v AC)

3 - 4 Open Conduit

Mini Infinity System, using Mounting Plates (all motor options available)

-

Lid Options 10

Our standard lid in an Undertrack application. The installation is made easy with the PCS Drop-In Lid Bracket

Brace. These Braces are installed to the back wall of the Housing, approximately one every 2 - 3 feet. The Lid

Brackets slide into the Braces and sit flush with the deck.

This is the standard lid in a Toptrack application. Drop-In Lid Braces are used here as well. The Toptrack Lid Bracket is formed with an angle to elevate the lid over the Toptrack.

Undertrack Lid Bracket Toptrack Lid Bracket Drop-In Lid Bracket Brace

Lid Bracket w/ Mounting Holes (22742)

Side View

Standard Lids:

- 19 -

-

Adjustable Lids:

11 Adjustable Lid Bracket

(LB2100)

14 Adjustable Lid Bracket -for flush lids-

(VL2100)

15 Adjustable Lid Bracket (LB2300)

Front View (dimensions are for all Adjustable

Lid Bracket models)

PCS Adjustable Lid Brackets can be adjusted 5 degrees up or down. These Brackets are extremely sturdy and can hold up

to 1200 pounds when properly installed. The Bracket is secured directly to the Housing wall.

Made for larger lids, the 24 Bracket is ideal for Vanishing Leading Edge applications, as illustrated above. This

Bracket, when installed properly, can hold up to 600 pounds.

24 Adjustable Lid Bracket (LB2400)

- 20 -

-

Infinity 4000 Specifications 11 Pool Cover Fabric 7-Year Manufacturers Limited Prorated Warranty Low shrink, non-wicking yarns Specially-formulated vinyl for chlorine resistance, UV resistance, abrasion resistance, and mildew

resistance 10 color options Custom cover colors and designs available

Economic Specs The U.S. Dept. of Energy has established that heating costs can be reduced 60 to 80 percent by

covering a pool when it is not in use. A PCS pool cover can increase the daytime water temperature by 10 - 15 degrees. Night-time heat loss

is reduced by 70%. A covered pool allows much less chemical evaporation; this means less chlorine and other chemicals

are needed, thereby reducing pool care costs.

Mechanism Manufacturers Lifetime Limited Warranty Machined and Hard-anodized End-castings Hard-anodized aluminum brackets Powder-coated, anodized reel system

Electrical 3-Year Manufacturers Limited Warranty on all electrical components Standard IDEC Keyswitch Controller Standard .84 horsepower, 34 rpm Gearmotor Optional - Touch-sensitive Touchpad; Backlit Touchpad Optional Hydraulic Motor Optional water-feature shutoff

Safety Credentials Meets or exceeds all ASTM F 1346 - 91 requirements Electrical bonding included with all systems to ensure electrical grounding Full UL listing

- 21 -

-

Notes:

-

POOL COVER SPECIALISTS NATIONAL, INC.

VISIT US ON THE WEB:

www.poolcovers.com

116 West Morgan Knightstown, IN 46149

765-345-9000

8553 South 2940 West West Jordan, Utah 84088

801-255-6124

1-800-369-5152

Excavation Instructions For Rectangular Undertrack PoolsExcavation Instructions For Freeform / Toptrack PoolsTECHNICAL INFORMATION: Recessed Redwood* Housing - UndertrackRecessed Redwood Housing - ToptrackRecessed Redwood Housing - ConstructionRecessed Gunite Housing - UndertrackRecessed Concrete Housing - Toptrack(2009) Vacuum Formed Housing for Vinyl Liner PoolsStandard System (110v AC, 220v AC, 24v DC)Brushless DC System (110v AC)Hydraulic System (110v AC, 220v AC)Mini Infinity System, using Mounting Plates (all motor options available)Standard Lids:Adjustable Lids:

/ColorImageDict > /JPEG2000ColorACSImageDict > /JPEG2000ColorImageDict > /AntiAliasGrayImages false /CropGrayImages true /GrayImageMinResolution 300 /GrayImageMinResolutionPolicy /OK /DownsampleGrayImages true /GrayImageDownsampleType /Bicubic /GrayImageResolution 300 /GrayImageDepth -1 /GrayImageMinDownsampleDepth 2 /GrayImageDownsampleThreshold 1.50000 /EncodeGrayImages true /GrayImageFilter /DCTEncode /AutoFilterGrayImages true /GrayImageAutoFilterStrategy /JPEG /GrayACSImageDict > /GrayImageDict > /JPEG2000GrayACSImageDict > /JPEG2000GrayImageDict > /AntiAliasMonoImages false /CropMonoImages true /MonoImageMinResolution 1200 /MonoImageMinResolutionPolicy /OK /DownsampleMonoImages true /MonoImageDownsampleType /Bicubic /MonoImageResolution 1200 /MonoImageDepth -1 /MonoImageDownsampleThreshold 1.50000 /EncodeMonoImages true /MonoImageFilter /CCITTFaxEncode /MonoImageDict > /AllowPSXObjects false /CheckCompliance [ /None ] /PDFX1aCheck false /PDFX3Check false /PDFXCompliantPDFOnly false /PDFXNoTrimBoxError true /PDFXTrimBoxToMediaBoxOffset [ 0.00000 0.00000 0.00000 0.00000 ] /PDFXSetBleedBoxToMediaBox true /PDFXBleedBoxToTrimBoxOffset [ 0.00000 0.00000 0.00000 0.00000 ] /PDFXOutputIntentProfile () /PDFXOutputConditionIdentifier () /PDFXOutputCondition () /PDFXRegistryName () /PDFXTrapped /False

/CreateJDFFile false /Description > /Namespace [ (Adobe) (Common) (1.0) ] /OtherNamespaces [ > /FormElements false /GenerateStructure false /IncludeBookmarks false /IncludeHyperlinks false /IncludeInteractive false /IncludeLayers false /IncludeProfiles false /MultimediaHandling /UseObjectSettings /Namespace [ (Adobe) (CreativeSuite) (2.0) ] /PDFXOutputIntentProfileSelector /DocumentCMYK /PreserveEditing true /UntaggedCMYKHandling /LeaveUntagged /UntaggedRGBHandling /UseDocumentProfile /UseDocumentBleed false >> ]>> setdistillerparams> setpagedevice