Increase Cone Crusher Productivity by as much as 40% and ... · A typical 500 HP Cone Crusher will...

Transcript of Increase Cone Crusher Productivity by as much as 40% and ... · A typical 500 HP Cone Crusher will...

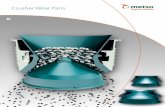

Increase Cone Crusher Productivity by as much as 40%

and lower your operating cost with the SYNTRO-FLO Loading Feeder

by Syntron Material Handling.

• Reduce the amperage by 85% utilizing PWM technology and a rectifier

• Design reduces KW consumption by 50%

• Reduced power grid installation cost

• Eliminates the reactive power losses - resulting in a reduction of up to 80% KVA requirement

Return on Investment – Pays for itself upon installation

Savings after startup include:• Over a 50% reduction in energy

consumed

• Better diagnostic capabilities to reduce maintenance time

• 100% voltage regulation for consistent production rates

Heavy-Duty Electromagnetic Feeder Controls

Return on InvestmentA typical 500 HP Cone Crusher will achieve increases in the amount of net finished product it crushes by as much as 40% when automated and fed by a SYNTRO-FLO cone crusher Loading Feeder by Syntron®.

Increases productivity. Lowers operating costs. At an average price of $9.75/ton for -3/8” rock, an additional 100 tons/hour of net finished product will return an additional $975 per hour in rock production, generating solid returns for your investment in crusher automation.

800.356.4898 | [email protected] | www.syntronmh.com

Composite Idler Roll Advantages• Excellent Strength• 50% lighter weight than

traditional steel rolls• Superior Toughness• High Corrosion Resistance• High Abrasion Resistance• Reduced Material Build-Up• Low Coefficient of Thermal

Expansion• Environmentally Friendly• 50% less Shipping Cost• Stops Back Injuries• Won’t Rust or Corrode• Increase Belt Life by

avoiding Belt Cuts from worn Steel Rolls

Made in U.S.A.

Composite Idler Rolls are Ideal for replacement

of steel rolls in corrosive environments.

Corrosion Resistant Belt Conveyor Idlers

Truss Frame Idlers• 50% lighter weight

than Steel Frames

• 40% increase in load rating vs / CEMA D angle frame

• Frames available in carbon steel; 304 & 316 Stainless Steel, Galvanized and Bitumastic Coating

• Resist corrosion and material build up

Dimensional specifications match our CEMA C, D and E series steel products.

Assumptions• 2,000 ft belt conveyor system with 5 ft spacing on carry side = 400 troughing

idlers or (1200 rolls) and 200 return idlers or (200 rolls) = 1400 rolls

• Steel Roll = $98.00

• Composite Roll = $132.00

• Life cycle of Belt conveyor system = 15 Year

• Replace Steel Rolls 2x the life of the system

• $50.00 labor cost per roll

Composite Roll Steel Roll Composite Cost Cost Cost Difference

Initial Cost $184,800.00 $137,200.00 $47,600.00

Replacement Roll Cost $- $274,400.00 $(274,400.00)

Labor Replacement Cost $- $140,000.00 $(140,000.00)

Total Savings $184,800.00 $551,600.00 $(366,800.00)

*Pricing for Steel and Composite Rollers are based on list prices and typical distributor level multipliers.