Heat Engine Design

-

Upload

eamonn-mcstravick -

Category

Documents

-

view

222 -

download

0

Transcript of Heat Engine Design

-

8/3/2019 Heat Engine Design

1/25

Heat Engine Design

ByEamonn Mcstravick

-

8/3/2019 Heat Engine Design

2/25

Design Heat Engine Design

Contents

1.1 INTRODUCTION

1.2 WHATISA HEAT ENGINE?

1.3 EXTERNAL COMBUSTION ENGINES

1.4 INTERNAL COMBUSTION ENGINES

1.5 MARKET RESEARCH

1.6 CALCULATIONS

1.7 ADDITIONAL DESIGN TOOLS

1.8 REFERENCES & APPENDICES

Page 2 of 25

-

8/3/2019 Heat Engine Design

3/25

Design Heat Engine Design

1.1 INTRODUCTION

The aim of this assignment is to design a single cylinder heat

engine, to produce 5HP at 3500RPM.

1.2 WHATISAHEATENGINE?

A heat engine is a physical or theoretical device that converts

thermal energy to mechanical output. The mechanical output is

called work, and the thermal energy input is called heat. Heat

engines typically run on a specific thermodynamic cycle. Heat

engines are often named after the thermodynamic cycle they are

modelled by. They often pick up alternate names, such as

gasoline/petrol, turbine, or steam engines. Heat engines can

generate heat inside the engine itself or it can absorb heat from an

external source. Heat engines can be open to the atmospheric air or

sealed and closed off to the outside (Open or closed cycle).

In engineering and thermodynamics, a heat engine performs the

conversion of heat energy to mechanical work by exploiting the

temperature gradient between a hot "source" and a cold "sink".

Heat is transferred from the source, through the "working body" of

the engine, to the sink, and in this process some of the heat is

converted into work by exploiting the properties of a working

substance (usually a gas or liquid).

The two forms of heat engine we are going to look at in this project

are external combustion engines such as the steam engine and

Stirling engine where combustion takes place outside the

mechanical engine system. And internal combustion engines such

Page 3 of 25

-

8/3/2019 Heat Engine Design

4/25

Design Heat Engine Design

as the diesel engine (Compression Ignition) and the petrol engine

(Spark Plug Ignition).

All of these familiar heat engines are powered by the expansion ofheated gases. The general surroundings are the heat sink, providing

relatively cool gases which, when heated, expand rapidly to drive

the mechanical motion of the engine.

1.3 EXTERNAL COMBUSTION ENGINE

The External Combustion (ECE) Engine is a heat engine which burns

fuel to heat a separate working fluid which then in turn carries out

work.

For the same power, external combustion engines are often less

compact and heavier than internal combustion engines. This is

because they contain a heat exchanger to heat the working fluid.

However, they can be more efficient, and are much less particular

about the type of fuel they burn. They also tend to be cleaner due to

lower combustion temperatures and pressures which create less

exotic exhaust gasses, for example nitrogen oxides.

A steam turbine is a good example of an external-combustion

engine. Heat from burning fuel for example changes water in a

boiler to steam. Pipes then carry the steam into the turbine, which

has a series of bladed wheels attached to a shaft. The high-

temperature steam expands as it moves through the turbine and so

pushes on the blades and causes them to turn the shaft. Resulting

Page 4 of 25

-

8/3/2019 Heat Engine Design

5/25

Design Heat Engine Design

in rotating mechanical energy which, can then be connected to a

transmission or power train for the final desired use.

STEAM ENGINES

Steam engines were the first engine type to see widespread use.

They were first invented by Thomas Newcomen in 1705, and James

Watt made big improvements to steam engines in 1769.

In a high pressure steam engine, steam is raised in a boiler to a high

pressure and temperature; it is then admitted to a working chamber

where it expands and acts upon a piston. In "Cornish engines"

steam pressure and vacuum are applied to the piston

simultaneously. As pressure is applied to the top of the piston, the

steam from the previous cycle is condensed to provide a vacuum

below the piston. At the end of the stroke the equilibrium valve

opens to allow the steam above the piston to be transferred to the

Page 5 of 25

-

8/3/2019 Heat Engine Design

6/25

Design Heat Engine Design

lower part of the cylinder as the piston is lifted by the weight of the

pump end of the beam. The piston consequently reciprocates, much

like in the vacuum engine.

The importance of raising steam under pressure (from a

thermodynamic standpoint) is that it attains a higher temperature.

Thus, any engine using such steam operates at a higher

temperature differential than is possible with a low pressure vacuum

engine. After displacing the vacuum engine, the high pressure

engine became the basis for further development of reciprocating

steam technology.

The next major advance in high pressure steam engines was to

make them double-acting. In the single-acting high pressure engine,

the cylinder is vertical and the piston returns to the start or bottom

of the stroke by the momentum of the flywheel.

In the double-acting engine, steam is admitted alternately to each

side of the piston while the other is exhausting. This requires inlet

and exhaust ports at either end of the cylinder with steam flow

being controlled by valves. This system increases the speed and

smoothness of the reciprocation and allows the cylinder to be

mounted horizontally or at an angle.

Power is transmitted from the piston by a sliding rod sealed to the

cylinder to prevent the escape of steam which in turn drives a

connecting rod via a sliding crosshead. This in combination with the

connecting rod converts the reciprocating motion to rotary motion.

The inlet and exhaust valves have their reciprocating motion

derived from the rotary motion by way of an additional crank

mounted eccentrically from the drive shaft.

Page 6 of 25

-

8/3/2019 Heat Engine Design

7/25

Design Heat Engine Design

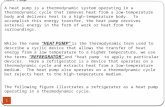

The above shows a labelled diagram of a single cylinder double

acting, high pressure steam engine.

1 Piston

2 Piston rod

3 Crosshead bearing

4 Connecting rod

5 Crank

6 Eccentric valve motion

7 Flywheel

8 Sliding valve

9 Centrifugal governor.

A double-acting piston engine provides as much power as a more

expensive 2-piston single-acting engine, and also allows the use of a

much smaller flywheel than what would be required by a one-pistonsingle-acting engine. Both of these considerations made the double-

acting piston engine smaller and less expensive for a given power

range.

Page 7 of 25

-

8/3/2019 Heat Engine Design

8/25

Design Heat Engine Design

STIRLING ENGINES

A Stirling engine uses the Stirling cycle, the gasses used inside a

Stirling engine never leave the engine. There are no exhaust valvesthat vent high-pressure gasses, as in a petrol or diesel engine, and

there are no explosions taking place. Because of this, Stirling

engines are very quiet.

The Stirling cycle uses an external heat source, which could be

anything from burning fuel to solar energy. No combustion takes

place inside the cylinders of the engine.

Since the Stirling engine is a closed cycle, it contains a fixed mass of

gas called the "working fluid", most commonly air, hydrogen or

helium. In normal operation, the engine is sealed and no gas enters

or leaves the engine. No valves are required, unlike other types of

piston engines. The Stirling engine, like most heat-engines, cycles

through four main processes: cooling, compression, heating and

expansion. This is accomplished by moving the gas back and forth

between hot and cold heat exchangers. The hot heat exchanger is in

thermal contact with an external heat source, e.g. a fuel burner, and

the cold heat exchanger being in thermal contact with an external

heat sink, e.g. air fins. A change in gas temperature will cause a

corresponding change in gas pressure, while the motion of the

piston causes the gas to be alternately expanded and compressed.

The gas follows the behaviour described by the gas laws which

describe how a gas's pressure, temperature and volume are related.

When the gas is heated, because it is in a sealed chamber, the

pressure rises and this then acts on the power piston to produce a

power stroke. When the gas is cooled the pressure drops and this

means that less work needs to be done by the piston to compress

the gas on the return stroke, thus yielding a net power output.

Page 8 of 25

-

8/3/2019 Heat Engine Design

9/25

Design Heat Engine Design

When one side of the piston is open to the atmosphere, the

operation is slightly different. As the sealed volume of working gas

comes in contact with the hot side, it expands, doing work on boththe piston and on the atmosphere. When the working gas contacts

the cold side, the atmosphere does work on the gas and

"compresses" it. Atmospheric pressure, which is greater than the

cooled working gas, pushes on the piston.

To summarize, the Stirling engine uses the temperature difference

between its hot end and cold end to establish a cycle of a fixed

mass of gas expanding and contracting within the engine, thus

converting thermal energy into mechanical power. The greater the

temperature difference between the hot and cold sources, the

greater the potential Carnot cycle efficiency.

Stirling Engines are basically a heat pump in reverse, but instead of

inputting mechanical energy to raise or decrease temperatures, you

can introduce a temperature change to produce mechanical energy.

Page 9 of 25

-

8/3/2019 Heat Engine Design

10/25

Design Heat Engine Design

1.4 INTERNAL COMBUSTION ENGINE

The Internal Combustion (IC) Engine is a heat engine that converts

chemical energy in a fuel into mechanical energy, usually made

available on a rotating output shaft. Chemical energy of the fuel is

first converted to thermal energy by means of combustion or

oxidation with air inside the engine. This thermal energy raises the

temperature and pressure of the gases within the engine and the

high-pressure gas then expands against the mechanical

mechanisms of the engine. This expansion is converted by the

mechanical linkages of the engine to a rotating crankshaft, which is

the output of the engine. The crankshaft, In turn, is connected to a

transmission or power train to transmit the rotating mechanical

energy to the desired final use.

Engine Classification

Internal Combustion Engines can be classified in a number of

different ways:

1) Types of Ignition

Page 10 of 25

-

8/3/2019 Heat Engine Design

11/25

Design Heat Engine Design

a) Spark Ignition (SI). An SI engine starts the combustion

process in each cycle by use of a spark plug. The spark plug

gives a high-voltage electrical discharge between two

electrodes which ignites the air-fuel mixture in the combustionchamber surrounding the plug. In early engine development,

before the invention of the electric spark plug many forms of

torch holes were used to initiate combustion from an external

flame.

b) Compression Ignition (CI). The combustion process in a CI

engine starts when the air fuel mixture self-ignites due to high

temperature in the combustion chamber caused by high

compression

2) Engine Cycle

a) Four-Stroke Cycle. A four-stroke cycle has four piston

movements over two engine revolutions for each cycle.

b) Two-Stroke Cycle. A two-stroke cycle has two piston

movements over one revolution for each cycle.

3) Valve Location

a) Valves in Head

b) Valves in block

c) One Valve in head & one valve in block

4) Basic Design

a) Reciprocating. Engine has one or more cylinders in which

pistons reciprocate back and forth. The combustion chamber

is located in the closed end of each cylinder. Power is

delivered to a rotating output crankshaft by mechanical

linkage with the pistons.

b) Rotary. Engine is made of a block built around a large non-

concentric rotor and crankshaft. The combustion chambers

are built into the non-rotating block.

5) Air Intake Process

a) Naturally Aspirated

Page 11 of 25

-

8/3/2019 Heat Engine Design

12/25

Design Heat Engine Design

b) Supercharged. Intake air pressure increased with the

compressor driven off the engine crankshaft.

c) Turbocharged. Intake air pressure increased with the turbine-

compressor driven by the engine exhaust gases.6) Method of Fuel Input for Spark Ignition Engines

a) Carburetted.

b) Multipoint port fuel injection. One or more injectors at each

cylinder intake

c) Throttle Body Fuel Injection. Injectors upstream in intake

manifold.

d) Petroleum Direct Injection. Injectors mounted in combustion

chambers with injection directly into cylinders.

7) Method of Fuel input for Compression Ignition Engines.

a) Direct Injection. Fuel injected into main combustion chamber.

b) Indirect Injection. Fuel injected into secondary combustion

chamber.

c) Homogenous charge compression ignition. Dome fuel added

during intake stroke.

8) Fuel Used.

a) Petroleum.

b) Diesel Oil or Fuel Oil

c) Gas, Natural Gas, Methane.

d) LPG.

e) Alcohol Ethyl, Methyl.

9) Type of Cooling.

a) Air Cooled

b) Liquid cooled, water cooled.

Basic Engine Cycles

Most internal combustion engines, both spark ignition and

compression ignition; operate on either a four-stroke or a two-stroke

Page 12 of 25

-

8/3/2019 Heat Engine Design

13/25

Design Heat Engine Design

cycle. These basic cycles are fairly standard for all engines, with

only slight differences found in individual designs.

Four-Stroke SI (Spark plug ignition) Engine Cycle.

1. First Stroke: Intake Stroke of Induction The piston travels

from TDC (Top Dead Centre, where the Piston stops at the

furthest point from the crankshaft) to BDC (Bottom Dead

Centre, where the piston stops at the closest point to the

crankshaft) with the intake valve open and exhaust valve

closed. This creates an increasing volume in the combustion

chamber, which in turns creates a vacuum. The resulting

pressure differential through the intake system from

atmospheric pressure on the outside to the vacuum on the

inside causes air to be pushed into the cylinder. As the air

passes through the intake system, fuel is added to it in the

desired amount by means of fuel injectors or a carburettor.

2. Second Stroke: Compression StrokeWhen Piston reaches BDC,

the intake valve closes and the piston travels back to TDC

with all the valves closed. This compresses the air-fuel

mixture, raising both the pressure and the temperature in the

cylinder. The finite time required to close the intake valve

means that actual compression doesnt start until sometime

after BDC. Near the end of the compression stroke, the spark

plug is fired and combustion is initiated.

3. CombustionCombustion of air-fuel mixture occurs in a very

short but finite length of time with the piston near TDC (i.e.

nearly constant-volume combustion). It starts near the end of

the compression stroke slightly before TDC and lasts into the

power stroke slightly after TDC. Combustion changes the

composition of the gas mixture to that of exhaust products the

work output of the engine cycle. As the piston travels from

Page 13 of 25

-

8/3/2019 Heat Engine Design

14/25

Design Heat Engine Design

TDC to BDC, cylinder volume is increased, causing pressure

and temperature to drop.

4. Third Stroke: Expansion Stroke or Power Stroke With all valves

closed, the high pressure created by the combustion processpushes the piston away from TDC. This is the stroke which

produces the work output of the engine cycle. As the piston

travels from TDC to BDC, cylinder volume is increased,

causing pressure and temperature to drop.

5. Exhaust Blowdown Late in the power stroke, the exhaust

valve is opened and exhaust Blowdown occurs. Pressure and

temperature in the cylinder are still high relative to the

surroundings at this point, and a pressure differential is

created through the exhaust system which is open to

atmospheric pressure. This pressure differential causes much

of the hot exhaust gas to be pushed out of the cylinder and

through the exhaust system when the piston is near BDC.

This exhaust gas carries away a high amount of enthalpy,

which lowers the cycle thermal efficiency. Opening the

exhaust valve before BDC reduces the work obtained during

the power stroke but is required because of the finite time

needed for exhaust Blowdown.

6. Fourth Stroke: Exhaust Stroke By the time the piston

reaches BDC, exhaust Blowdown is complete, but the cylinder

is still full of exhaust gases at approximately atmospheric

pressure. With the exhaust valve remaining open, the piston

now travels from BDC to TDC in the exhaust stroke. This

pushes most of the remaining exhaust gases out of the

cylinder into the exhaust system at about atmospheric

pressure, leaving only that trapped in the clearance volume

when the piston reaches TDC. Near the end of the exhaust

stroke before TDC, the intake valve starts to open, so that it is

fully open by TDC when the new intake stroke starts the next

cycle. Near TDC the exhaust valve starts to close and finally

Page 14 of 25

-

8/3/2019 Heat Engine Design

15/25

Design Heat Engine Design

is fully closed sometime after TDC. This period when both the

intake valve and exhaust valve are open is called valve

overlap.

Four-Stroke CI (Compression ignition) Engine Cycle.

1. First Stroke: Intake Stroke The same as the intake stroke in

an SI engine with the one major difference: no fuel is added to

the incoming air.

2. Second Stroke: Compression StrokeThe same as in an SI

engine except that only air is compressed and compression is

to higher pressures and temperature. Late In the compression

stroke fuel is injected directly into the combustion chamber,

where it mixes with the very hot air. This causes the fuel to

evaporate and self-ignite, causing combustion to start.

3. CombustionCombustion is fully developed by TDC and

continues at about constant pressure until fuel injection is

complete and the piston has started towards BDC.

4. Third Stroke: Power Stroke The power stroke continues as

combustion ends and the piston travels towards BDC.

5. Exhaust Blowdown Same as with an SI engine.

6. Fourth Stroke: Exhaust Stroke Same as with an SI engine.

Two-Stroke SI Engine Cycle

1. CombustionWith the piston at TDC combustion occurs very

quickly. Raising the temperature and pressure to peak values,

almost at constant volume.

2. First Stroke: Expansion Stroke or Power Stroke Very high

pressure created by the combustion process forces the piston

down in the power stroke. The expanding volume of the

combustion chamber causes pressure and temperature to

decrease as the piston travels towards BDC.

Page 15 of 25

-

8/3/2019 Heat Engine Design

16/25

Design Heat Engine Design

3. Exhaust Blowdown At about 75C before BDC, the

exhaust valve opens and blowdown occurs. The exhaust

valve may be a poppet valve in the cylinder head, or it may be

a slot in the side of the cylinder which is uncovered as thepiston approaches BDC. After blowdown the cylinder remains

filled with exhaust gas at lower pressure.

4. Intake and Scavenging When blowdown is nearly complete, at

about 50C before BDC, the intake slot on the side of the

cylinder is uncovered and intake air-fuel enters under

pressure. Fuel is added to the air with either a carburettor or

fuel injection. This incoming mixture pushes much of the

remaining exhaust gases out the open exhaust valve and fills

the cylinder with a combustible air-fuel mixture, a process

called scavenging. The piston passes BDC and very quickly

covers the intake port and then the exhaust port (or the

exhaust valve closes). The higher pressure at which the air

enters the cylinder is established in one of the two ways.

Large two-stroke cycle engines generally have a supercharger,

while small engines will intake the air through the crankcase.

On these engines the crankcase is designed to serve as a

compressor in addition to serving its normal function.

5. Second Stroke: Compression StrokeWith all valves (or ports)

closed, the piston travels towards TDC and compresses the

air-fuel mixture to a higher pressure and temperature. Near

the end of the compression stroke, the spark plug is fired; by

the time the piston gets to TDC, combustion occurs and the

next engine cycle begins.

Two-Stroke CI Engine Cycle

Page 16 of 25

-

8/3/2019 Heat Engine Design

17/25

Design Heat Engine Design

The two-stroke cycle for a CI (compression ignition) engine is similar

to that of the SI (spark plug ignition) engine, except for two

changes. No fuel is added to the incoming air, so that compression

is done on air only. Instead of a spark plug, a fuel injector is locatedin the cylinder. Near the end of the compression stroke, fuel is

injected into the hot compressed air and combustion is initiated by

self ignition.

I am going to base my design on an internal combustion, single

cylinder, four-stoke, spark plug ignition engine.

Page 17 of 25

-

8/3/2019 Heat Engine Design

18/25

Design Heat Engine Design

1.5 MARKET RESEARCH

As a starting point I have done a little bit of research into what is

already out there on the market. Honda a well known engine

manufacturer produces a single cylinder four-stroke engine which

delivers 5.2HP at 3600RPM. Since I am looking to design an engine

which produces 5HP at 3500RPM, it is maybes worth taking a look.

The model is a Honda GC190, it is a 190cc displacement air cooled

single cylinder engine applications for this engine include Go-Karts,

Pressure washers, Reel mowers, Generators, Water pumps,

Blower/Vac, Air compressors.

Specifications as follows:

Engine Type Air-cooled 4-stroke OHC single

cylinder

Bore x Stroke 69 x 50 mm

Displacement 187 cm3

Compression Ratio 8.5: 1

Net Horse Power Output 3.9kW (5.2HP) at 3,600 rpm

Net Torque 11.2 Nm at 2,500 rpm

PTO Shaft Rotation Anticlockwise (from PTO shaft

side)

Ignition System Transistorized Magneto

Starting System Recoil or Electric Starter

Carburettor Horizontal type butterfly valve

Lubrication System Forced Splash

Governor System Centrifugal Mechanical

Air Cleaner Dry (paper) type

Oil Capacity 0.58 l

Page 18 of 25

-

8/3/2019 Heat Engine Design

19/25

Design Heat Engine Design

Fuel Tank Capacity (litre) 1.8l

Dimensions (L x W x H) 345mm x 369mm x

331mm

Dry Weight 13.2 kg

So based on the above specification I will carry out a full

thermodynamic analysis based on the above specification

1.6 CALCULATIONS

See attached thermodynamic analysis for the Honda GC190 @

3600RPM

Page 19 of 25

-

8/3/2019 Heat Engine Design

20/25

Design Heat Engine Design

By adjusting the mathematics of the calculation we can work out

what the power output will be for a speed of 3500RPM.

See attached thermodynamic analysis for the Honda GC190 @

3500RPM

Page 20 of 25

-

8/3/2019 Heat Engine Design

21/25

Design Heat Engine Design

As it turns out the power output calculation for the Honda GC190 at

3500RPM, turns out to be 5HP or 3.8kW. This means that design

could be based around the GC190s specification i.e. Bore, Stroke

(which determines the displacement) & Compression Ratio.

So from these parameters I can model a basic engine design, but

the thermo-dynamic analysis I did for the design used a lot of

assumptions without actual certainty of the conditions involved.

What other tools could I use to help create a more accurate,

realisation to what is happening during the combustion process and

how well the design will perform?

Page 21 of 25

-

8/3/2019 Heat Engine Design

22/25

Design Heat Engine Design

1.7 ADDITIONAL DESIGN TOOLS

There are lots of different engineering software tools available to

designers which allow them to simulate their designs prior to

physical prototypes and testing. Hence saving a lot of time and

money at the prototype stages by providing a more accurate

representation of what will happen in reality, mainly by means of

finite numerical methods.

In the case of this single cylinder four stroke SI engine, what tools

could we use to improve and validate our design calculated from

empirical calculations?

AIR PRESSURES & THERMO-FLUID FLOW

Firstly, it would help if I had a tool which could tell me the actual

pressures at the start of the compression stroke, and also the flow

of the air-fuel mixture at the intake stroke. Also how much exhaust

Page 22 of 25

-

8/3/2019 Heat Engine Design

23/25

Design Heat Engine Design

residual was left over from previous strokes, instead of relying on

assumptions.

A CFD (Computational Fluid Dynamics Package) could be used to

compute these uncertainties, and if the results are not good enoughthe engines design model could either be altered and then

reanalyzed or make use of the softwares optimizers which would

alter the model to attain the required flows & or pressures required.

Some packages tie in the thermal effects of fluids by analysing

convection currents etc. this would also allow us to identify what

thermal effects the burning gases have on the components inside

the combustion chamber, and how much heat is exhausted and how

much needs to dissipated by the components. Again optimizers can

be used on the components so that enough heat can be dissipated

from the engine components, without causing damage; i.e. optimize

to the required steady state temperature.

MECHANICAL EFFICIENCY AND MOVING INTERFERENCE DETECTION AND INTERACTION

Also the mechanical efficiency is another assumption made in the

empirical calculations, how do we know what the actual mechanical

efficiency of the engine is? If we had our basic design model we

could run it through an ADAMS (AUTOMATICDYNAMICANALYSISOFMECHANICAL

SYSTEM)

Software package to determine how much energy is lost through

friction and it will also check for any component clashes, and how

the components interact with each other. The software wills also

feedback the loads and forces exerted on the components that we

could use for further analysis.

NATURAL FREQUENCY ANDDYNAMIC RESPONSE

Other tools which would help validate the design include dynamic

analysis software packages which numerically determine the natural

and transient frequencies; this allows you to optimize the

Page 23 of 25

-

8/3/2019 Heat Engine Design

24/25

Design Heat Engine Design

components so that there natural frequencies dont coincide with

the operating frequencies of the engine.

FATIGUE

ANALYSIS

Fatigue analysis packages allow you to calculate the fatigue life of

all the components under dynamic loading, determined by the

ADAMS package.

STRESS ANALYSIS

By taking the values from the motion simulation package, you can

apply these as static and dynamic loads to the components and

optimize there designs for desired stresses.

ACOUSTICS

Acoustics is another issue that could possibly be considered in the

design of the heat engine, where you want the machine to run

under a certain sound limit. This could be done with a computer

software acoustics package.

All the above software design tools would help you to greater

understand your design to how it would operate in reality. Also with

the ability to optimize your design so that it meets your desired

criteria is of great benefit, but there will come a point where some of

your analysis may play off against each other. For example you

may optimize your crankshaft in a stress analysis package, and find

that its natural frequency has now changed into your operating

range, and then following further dynamic analysis your design fails.

So you are sort of stuck back in the loop playing off which

characteristics are more important to you.

MULTIPHYSICS

Multiphysics software tools however take theses different analyses

and run them together, so it can combine structural, thermal,

Page 24 of 25

-

8/3/2019 Heat Engine Design

25/25

Design Heat Engine Design

computational fluid dynamics (CFD), acoustics, dynamics and

fatigue. This gives you a full simulation of what is happening within

the operation of the engine from all angles.

1.8 REFERENCES & APPENDICES

The following references and attached appendices were used during

the compilation of this report.

Engineering Fundamentals of the Internal Combustion Engine

Second Edition. By Willard. W. Pulkrabek. ISBN. 81-203-

3031-5

IDEAS Tutorials - Analyzing Thermal Performance of an Engine

Block,Response Analysis,Optimization Parameter Studies,

Optimization Redesign

www.wikipedia.org

www.bsonline.com

http://www.wikipedia.org/http://www.bsonline.com/http://www.wikipedia.org/http://www.bsonline.com/