Garud 3m Complexity737.Full

Click here to load reader

-

Upload

recep-dogan-pezuekoglu -

Category

Documents

-

view

28 -

download

1

Transcript of Garud 3m Complexity737.Full

http://oss.sagepub.com/Organization Studies

http://oss.sagepub.com/content/32/6/737The online version of this article can be found at:

DOI: 10.1177/0170840611410810

2011 32: 737Organization StudiesRaghu Garud, Joel Gehman and Arun Kumaraswamy

Complexity Arrangements for Sustained Innovation: Lessons from 3M Corporation

Published by:

http://www.sagepublications.com

On behalf of:

European Group for Organizational Studies

can be found at:Organization StudiesAdditional services and information for

http://oss.sagepub.com/cgi/alertsEmail Alerts:

http://oss.sagepub.com/subscriptionsSubscriptions:

http://www.sagepub.com/journalsReprints.navReprints:

http://www.sagepub.com/journalsPermissions.navPermissions:

http://oss.sagepub.com/content/32/6/737.refs.htmlCitations:

What is This?

- Jun 23, 2011Version of Record >>

at RUTGERS UNIV on February 14, 2012oss.sagepub.comDownloaded from

Organization Studies32(6) 737 –767

© The Author(s) 2011Reprints and permission:

sagepub.co.uk/journalsPermissions.navDOI: 10.1177/0170840611410810

www.egosnet.org/os

Complexity Arrangements for Sustained Innovation: Lessons from 3M Corporation

Raghu GarudPennsylvania State University, USA

Joel GehmanPennsylvania State University, USA

Arun KumaraswamyTemple University, Philadephia, USA

AbstractInnovation processes are complex. It is through local interactions among people and technologies that diverse and novel outcomes emerge. Even when governed by simple rules, such interactions can generate nonlinear temporal dynamics. Given such complexities, how might an organization sustain innovation for continued growth and vitality? Drawing on an in-depth study of innovation practices and journeys at 3M Corporation, we identify how combinations of practices – which we conceptualize as complexity arrangements – afford multiple agentic orientations simultaneously for the actors involved and thereby facilitate sustained innovation.

Keywordsagency, complexity, exploration/exploitation, innovation, organizational memory, serendipity, time

In a recent Boston Consulting Group (2009) survey of global corporations, a majority of senior executives reported that innovation is among their top three strategic priorities. Notwithstanding its importance, innovation is difficult to sustain because it is a complex process (Usher 1954; Jelinek & Schoonhoven 1990; Dougherty & Hardy 1996). For instance, innovation involves interactions among networks of people and technologies from different practice domains (Callon 1987; Dougherty 1992; Nonaka & Takeuchi 1995; Hargadon & Sutton 1997) and across micro and macro

Corresponding author:Raghu Garud, Pennsylvania State University, Smeal College of Business, 431 Business Building, University Park, PA 16802, USAEmail: [email protected]

at RUTGERS UNIV on February 14, 2012oss.sagepub.comDownloaded from

738 Organization Studies 32(6)

levels of an organization (Burgelman 1983; Van de Ven 1986). The innovation process is nonlinear, full of ups and downs, false-starts and dead-ends (Van de Ven, Polley, Garud & Venkataraman 1999). Even when governed by simple rules, these interactions and innovation processes can gen-erate a variety of outcomes (Davis, Eisenhardt & Bingham 2009).

How might organizations sustain innovation for continued growth, given the complexities involved? To address this question, we explored practices at 3M Corporation, a company that has been able to sustain innovation for over a century. We found that 3M’s practices encouraged employees to cultivate events driven by serendipity and opportune moments (i.e., kairos)1 even as they paid attention to events driven by schedules and clock time (i.e., chronos). Possibilities for creating opportune moments were enhanced by practices that fostered ongoing interactions between employees who could use the company’s diverse resources to further their initiatives. 3M realized that ideas that emerged during opportune moments could be lost amid daily routines. Consequently, there were mechanisms in place to keep such ideas alive. These practices were facilitated by innovation narratives, which served as memories linking the company’s past, present and future.

Some of these observations are consistent with the extant literature on innovation – for instance, the need to develop structures that foster interactions and allow for the cross-fertilization of ideas, or the need to pay attention to temporal dynamics. Where we extend the literature is in proposing a practice perspective that considers the interplay between relational and temporal aspects associ-ated with innovation. Specifically, we theorize that combinations of relational and temporal prac-tices represent interwoven complexity arrangements.2 These interwoven complexity arrangements afford organizational actors multiple agentic orientations as innovation journeys unfold. We dis-cuss these insights and the implications that emerge when one applies a complexity lens to the challenge of sustaining innovation within organizations.

Innovation and Complexity

Given the importance of sustained innovation for the growth and vitality of firms, organizational scholars have long been interested in understanding the processes by which innovation occurs. Studies on innovation have yielded a number of insights. For instance, we know that innovation implicates actors across multiple levels of the organization (Van de Ven 1986), who interact with one another (Dougherty 1992; Nonaka & Takeuchi 1995; Brown & Eisenhardt 1997) across net-works of practice communities (Hargadon & Sutton 1997).

These observations suggest that innovation processes are complex. Although there are multiple meanings associated with the term ‘complexity’ (for reviews of complexity theories in organiza-tion studies, see Anderson 1999; Burnes 2005; Maguire, McKelvey, Mirabeau & Öztas 2006), most definitions attribute its emergence to combinations or interactions among heterogeneous ele-ments; for instance, between molecules in physics (see Gell-Mann 1994), between proteins in molecular biology (see Meyerguz, Kleinberg & Elber 2007), or between humans and artifacts in social settings (see Dooley 1997; Latour 2005). Such relational complexity (see Boisot & Child 1999) can be understood by the use of a metaphor: the mixing of ingredients together into a stew. The ingredients that make up the stew are far from homogeneous, diversity being essential to ongo-ing adaptation (Axelrod & Cohen 1999). Nor is this stew the work of an omniscient master chef (Stacey 2001). Instead, relational complexity emerges from ‘micro-level’ interactions that occur in response to local conditions (Weick 1979; Drazin & Sandelands 1992; Tsoukas 2008). Each actor is limited to discerning the local actions of a few disaggregated individuals, never glimpsing the entire system (Stacey 2001). It is through such local interactions that innovation emerges as a distributed process (Garud & Karnøe 2001; see also Loasby 2007, who discusses emergence through the combination of a limited number of organizational elements).

at RUTGERS UNIV on February 14, 2012oss.sagepub.comDownloaded from

Garud et al. 739

The term ‘complexity’ also is used to describe the inherently dynamic nature of nonlinear processes (Maruyama 1963; Senge 1990). This temporal complexity is readily apparent in the phase shifts (Chiles, Meyer & Hench 2004; Lichtenstein, Cater, Dooley & Gartner 2007; Plowman et al. 2007) that can occur as a result of deviation-amplifying feedback loops (Maruyama 1963; Masuch 1985). Other dynamics are also implicated in temporal complexity. For instance, what may be considered a solution in real time (e.g., subsidies for corn-based ethanol fuel) may generate unintended problems over time (e.g., worldwide corn shortages and rising food prices). These diachronies are well illustrated by the ‘beer game’ in which temporal complexity invariably leads to suboptimal inventory procurement decisions (Sterman 1989).

Innovation journeys are similarly complex. For instance, the notion of phase shifts can be seen in the work of scholars who have noted the importance of momentum in the emergence of techno-logical trajectories (Hughes 1969). Temporal asynchronies are evident in the need to develop co-specialized assets around an innovative idea (Teece 1986; Ansari & Garud 2009) or in the evolution of technological systems (Rosenberg 1982). It is for this reason that scholars have drawn our atten-tion to the importance of establishing temporal co-ordination (Ancona & Chong 1996) and time pacing (Brown & Eisenhardt 1997). Diachronies are less obvious, but nevertheless important. For instance, in his theory of creative destruction, Schumpeter noted that:

A system – any system, economic or other – that at every given point of time fully utilizes its possibilities to the best advantage may yet in the long run be inferior to a system that does so at no given point of time, because the latter’s failure to do so may be a condition for the level or speed of long-run performance (Schumpeter 2004 [1934]: 84).

Conversely, what had been considered trivial at a given time may become a solution to an unantici-pated problem that may arise in the future. All these dynamics point to disequilibrium processes (Lachmann 1976; Chiles, Bluedorn & Gupta 2007) driven by time delays, lags and differences in rhythms (Garud & Nayyar 1994; Brown & Eisenhardt 1997). Equally important, for actors involved in these processes, there are moments of serendipity and flashes of insights (Cunha 2004; Dew 2009). These eureka moments can neither be predicted nor willed a priori, but require prior engage-ment (Usher 1954; Irvine & Martin 1984) – a paradox aptly captured by Pasteur when he observed that ‘chance favors only the prepared mind’.

Complexity is also evident in the proliferation of diverse forms. Actors attempt to make sense of such diversity by placing these forms into categories (Bowker & Star 1991). To the extent that this diversity of forms cannot be placed easily into a parsimonious categorization scheme (Hannan, Pólos & Carroll 2007), it presents itself as complexity to the actors involved, even evoking a cat-egorical discount when organizations deviate from legitimated boundaries (Zuckerman 1999). Building on Drazin and Sandelands (1992), we label this as manifest complexity. In the case of innovation, such manifest complexity is evident in the range of products and services that emerge from research, development and commercialization activities undertaken by organizations. Examples of such complexity include the numerous Walkman versions that Sony generated (Sanderson & Uzumeri 1995) and the sheer breadth of Procter & Gamble’s product lines.

Complexity studies have demonstrated that such a diversity of forms can be generated by apply-ing set of underlying rules or routines (Axelrod & Cohen 1999). We use the term regulative com-plexity to denote this meaning of complexity. Together a collection of such rules or routines constitutes a ‘grammar’ that governs how elements may be combined and used. This grammar may be understood as being more or less complex, and the rules themselves may be context-dependent or subject to their own transformations in use (Cowan, Pines & Meltzer 1994).

In the context of innovation, such regulative complexity is evident in the simple rules that form the basis for the emergence of a variety of products and services (Davis et al. 2009). For

at RUTGERS UNIV on February 14, 2012oss.sagepub.comDownloaded from

740 Organization Studies 32(6)

instance, the many different versions of the Sony Walkman, targeted to satisfy the needs of specific customer segments, emerged through the application of two guidelines: one was to improve audio quality and the second was to improve portability (Sanderson & Uzumeri 1995). Likewise, Procter & Gamble’s diverse product offerings emerged from the repeated application of a limited number of core competencies.

Challenges in Sustaining Innovation

Clearly, innovation implicates different kinds of complexities – relational, temporal, manifest and regulative. Organizations are often unable to deal with such complexities because they have been designed to reduce or suppress them. For instance, organizations may adopt a ‘boxes within boxes’ approach (March & Simon 1958) that reduces interactions and locks people into ‘thought worlds’ (Dougherty 1992). Or, they may institute rules and routines to govern employee interactions and insist on their rigid application (Kanigel 1997) while dampening emergent dialogical processes (Tsoukas 2009). Some organizations continue to rely on short-term performance metrics instead of embracing the longer time horizon required for incipient ideas to mature and yield value. Moreover, they may not have an appropriate culture in place to benefit from their innovation experiences over time (Tushman & O’Reilly 1996).

Innovation processes are dampened in these organizations for several reasons. Given the diffi-culties in fostering relational processes, new ideas may not emerge at all (Dougherty 1992). Even if new ideas were to emerge, they likely would be considered illegitimate, and therefore, selected out (Dougherty & Heller 1994). A lack of appreciation of temporal asynchronies and diachronies may result in intermediary innovation outcomes being perceived as useless mistakes or in products being introduced into the market prematurely (Garud & Karnøe 2001). At an extreme, the diverse outcomes that emerge from product development activities may manifest themselves as a ‘bramble bush’ – a proliferation of technologies, products and patents, without much structure (Van de Ven et al. 1999) – that employees find difficult to understand and, therefore, are unable to benefit from in the pursuit of innovation.

By the same token, innovation processes also can impede current performance. For instance, deviations that are an important part of innovation can easily disrupt firm operations (March 1991). Moreover, the false-starts and dead-ends involved in the complex non-linear innovation journeys from idea conception to commercialization can reduce the efficiency of existing operations given that valuable resources are required (Van de Ven et al. 1999). Even those innovations that survive organizational selection pressures may appear unrelated, thereby distracting the attention of top management, employees and analysts (Ocasio 1997; Zuckerman 1999; Barnett 2008).

Scholars have proposed several approaches to address the tensions that arise between innovation (that implicates complexity) and current performance (that in many organizations is accomplished by structures that reduce complexity). One approach is to attend sequentially to innovation (exploration in March’s (1991) terms) and performance (exploitation in March’s terms), separating them over time (Cyert & March 1963). This approach offers a punctuated equilibrium solution, with the organization undertaking occasional reorientations as it switches between exploration and exploitation (Miller & Friesen 1982; Tushman & Romanelli 1985). Another solution is to carry out exploration and exploita-tion simultaneously, but in separate organizational units (or even outside the organization), with executives at higher levels of the hierarchy resolving the inevitable tensions of managing and inte-grating these units (Tushman & Nadler 1978; Tushman & O’Reilly 1996; Benner & Tushman 2003), a top-down approach that is consistent with Burgelman’s (1983) notion of ‘induced’ innovation.

These approaches may work to the extent that innovations and resultant adaptations occur infre-quently. They start breaking down, however, in dynamic environments within which organizations

at RUTGERS UNIV on February 14, 2012oss.sagepub.comDownloaded from

Garud et al. 741

need to innovate continually to survive. For example, when organizations must reorient themselves frequently, a solution based on sequential attention to goals generates significant disruptions and imposes a heavy cost. Likewise, resolving tensions between exploration and exploitation at a higher level of hierarchy is difficult due to bounded rationality and limits to executive attention, and even-tually exacts a price in terms of lost time and opportunities. Moreover, as environmental changes spawn new stakeholders and new needs, the division of labor and its re-integration through routines and schedules may result in a mismatch between the organization and its ever-changing environ-ment (cf. Henderson & Clark 1990). In fact, organizations may not even recognize the need for change (Tripsas 1997). For all these reasons, many of the prescribed approaches may function effec-tively during times of relative stability, but fail during times of rapid environmental changes.

Recent work on complexity, however, offers clues to organizational practices that may be capa-ble of dealing with and even benefiting from complexity (Tsoukas 2008), thereby reconciling inno-vation with current performance. Some scholars have pointed out the utility of infusing organizational processes with energy and resources to reach a critical threshold above which cas-cading changes emerge (see Lichtenstein et al. 2007). Others underscore the importance of foster-ing interactions among heterogeneous actors that, when shaped by endogenous selection processes, will result in the emergence of novelty (Drazin & Sandelands 1992; Axelrod & Cohen 1999). Going beyond such a ‘complex adaptive systems’ approach (Kauffman 1995) and building upon the work of Elias (1978), Stacey (2001) has emphasized the relational processes by which actors experience and continually respond to complexity through improvisation and spontaneous local interactions. More recently, scholars have taken this argument even further by incorporating tem-poral agency. For instance, Tsoukas and his colleagues describe how dialogical processes and nar-ratives enable the emergence of different temporal and relational agentic orientations as organizational processes unfold (Tsoukas & Hatch 2001; Tsoukas 2009).

In this progression over the years, we see a shift from an objective systems view of complexity to an intersubjective process view, and then to an unfolding practice view. The latter connects with work by scholars outside the domain of complexity studies. For instance, Emirbayer and Mische (1998), building upon Mead (1932), offered what they labeled as the ‘chordal triad of agency’ to suggest ele-ments of agency that are oriented to the past, the future and the present. In a similar vein, Ricoeur (1984) observed that any moment in the present is shaped by anticipations of the future and memories of the past, and it is through such temporal orientations that agency emerges. Indeed Clark (1990: 147) argued that ‘orientations to the past/present/future have been neglected in organization studies’, and that these orientations ‘contain organizationally specific predispositions’.

In this regard, what is most intriguing is the idea that different organizational practices may sup-port or thwart specific agentic possibilities by generating particular ‘packages’ of orientations towards the past, the present and the future. Equally intriguing is the possibility that actors can potentially engage in a variety of activities and events simultaneously, each with its own temporal rhythm (what Bluedorn 2002 calls ‘polychronicity’). Such a nuanced approach would take seri-ously kairos – based on subjective and qualitative notions of time (Whipp 1994; Hassard 1996; Mosakowski & Earley 2000), without ignoring the simultaneous existence of chronos – based on objective and Newtonian approaches to temporality (Hassard 1996; Orlikowski & Yates 2002), thereby allowing exploration and exploitation to unfold simultaneously.

This is what we explore in this paper by studying organizational practices at 3M Corporation, an organization that had sustained itself for over a hundred years through innovation. Our study reveals that 3M had organized itself such that innovation and performance, exploration and exploitation, kairos and chronos, were part and parcel of everyday work. Specifically, the com-pany had in place interwoven complexity arrangements that afforded employees multiple agentic orientations simultaneously. Asynchronies and diachronies inherent in innovation were addressed

at RUTGERS UNIV on February 14, 2012oss.sagepub.comDownloaded from

742 Organization Studies 32(6)

by the creation of a generative organizational memory that allowed the company to cultivate ideas as they emerged and use them when the time was right. Indeed, interconnecting platforms of knowledge made it possible for people to go ‘back to the future’, allowing 3M to harness – rather than limit – the complexity that innovation requires and generates.

Research Setting and Methods

3M was founded in 1902 by five entrepreneurs, each expecting to get rich mining corundum, a mineral used to make high-quality grinding wheels (3M 2002). However, their mine turned out to produce anorthosite, a relatively soft mineral not suitable for such purposes. Desperate, but reluc-tant to give up, the founders hit upon the idea of using the low-grade ore to make sandpaper and, thus, the company survived.

This pattern – a ‘mistake’ which galvanizes actions that eventually leads to innovation – appears to have played out repeatedly at 3M; sandpaper was merely the first of many such ‘accidental’ innovations. Our research revealed narratives of many innovations, ranging from early successes such as masking tape and reflective traffic signs to later breakthroughs in fiberoptics and medical creams. As we absorbed the details in these narratives, we noticed patterns emerging even though the specific path through which each innovation unfolded was different (see Dooley & Van de Ven 1999). Indeed, as Sandy Cobb, a 3M scientist whom we interviewed observed, 3M had grown in a ‘fractal manner’, expanding little by little from a core set of technology assets.

We decided to focus our attention on the longitudinal processes through which one of 3M’s technology platforms developed and subsequently spawned two innovations. Given our interest in understanding the innovation processes involved in their emergence, our study followed a narra-tive approach (Bruner 1986; Weick 1995; Czarniawska 1998; Pentland 1999). Such an approach not only provides the contextual details of the unfolding processes, but, in addition, the underlying forces driving the outcomes (see Tsoukas 1989, Pettigrew 1990 and Van de Ven & Poole 1995 for details on elements of the process approach we have adopted here). In adopting such an approach, our objective is to spawn a process of narrative generalization. Specifically, readers who are attracted to the details of a narrative can abstract inferences that are relevant to their specific con-texts through a process of abduction (Peirce 1934; see Bartel & Garud 2003; Garud, Dunbar & Bartel 2010 for further details). Indeed, narratives serve as boundary objects (Star & Griesemer 1989) that modulate the complexity with which readers may abstract insights and apply the find-ings to their own contexts (Tsoukas & Hatch 2001; Bartel & Garud 2003).

Data Collection

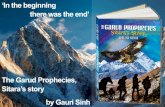

One of the authors has had a longstanding relationship with 3M. At the time this project began in 1998, he already had spent more than five years researching other innovation journeys at the com-pany. It was because of this prior relationship that 3M agreed to a study on how it had sustained innovation for nearly a century. The project began with a kick-off meeting at which Dr. William Coyne, 3M’s senior vice president of research and development (SVP of R&D), and representa-tives from the knowledge management and legal departments, the microreplication technology center and the multimedia technology center were present. By the end of the meeting, we had reached agreement on the scope of the research project and the high level of site access that would be provided. Given 3M’s multitude of technology platforms, products and patents, everyone agreed that this study should focus in detail on a few exemplars. Specifically, we decided to study the microreplication (MR) technology platform, and two innovations it had spawned – brightness enhancement films (BEF) and Trizact abrasives (see Figure 1).

at RUTGERS UNIV on February 14, 2012oss.sagepub.comDownloaded from

Garud et al. 743

MIC

RO

RE

PLI

CAT

ION

: ON

E L

ITTL

E T

EC

HN

OLO

GY

AN

D H

OW

IT G

RE

W

1964

1970

1980

1990

2000

Ligh

ted

Gui

danc

eTu

be

1983

Opt

ics

Tech

nolo

gyC

ente

r (O

TC)

Form

ed

1998

OTC

Ren

amed

Mic

rore

plic

atio

n Te

chno

logy

C

ente

r (M

TC)

1964

Ove

rhea

dP

roje

ctor

Lens

Beg

inni

ng w

ith a

Fre

snel

lens

for

over

head

pro

ject

ors,

mic

rore

plic

atio

n ha

s sp

awne

da

mul

ti-hu

ndre

d m

illio

n -d

olla

rfa

mily

of p

rodu

cts

that

ran

gefr

om s

truc

ture

d ab

rasi

ves

tom

echa

nica

l fas

tene

rs a

nd fr

omre

tror

efle

ctiv

eshe

etin

g fo

rhi

ghw

ay s

igns

to b

righ

tnes

sen

hanc

emen

t film

for

lapt

opco

mpu

ter d

ispl

ays.

0

400

800

1200

1964

1976

1988

1998

SALES (in $ millions)

Traf

fic

Rad

ial S

olar

P

ress

-On

Kal

eido

scop

e

Hig

h V

isib

ility

Sig

nals

C

once

ntra

tor

Lens

Fi

lm

Traf

fic L

ens

Sys

tem

Pri

sm

Cub

e C

orne

r

Wid

e

Lane

Fl

uore

scen

tR

efle

ctiv

ityD

iam

ond

Gra

deA

ngle

Mar

kers

DG

SS

heet

ing

DG

SS

igns

Dyn

amic

Ret

rore

flect

ion

Sco

tchl

iteIn

tern

ally

L

ight

DG

S

L

it S

igns

Pol

e

LEN

SE

S

FLAT

PA

NE

LD

ISP

LAY

S

Lens

Film

Tota

lIn

tern

al

Ref

lect

ion

Opt

ical

Ligh

ting

Film

ILLU

MIN

ATIO

N

Bri

ghtn

ess

Enh

ance

men

tFi

lm I

and

II

TRA

NS

PO

R-

TATI

ON

SA

FETY

AB

RA

SIV

ES

Rig

htA

ngle

Film

FAS

TEN

ER

S

AD

HE

SIV

ES

TRIB

OLO

GY

BIO

AP

PLI

CAT

ION

S

Ste

m W

ebTa

peC

ontr

olTa

cP

lus

Com

ply

Adh

esiv

es

Dra

g R

educ

tion

Film

Pre

cise

Mou

sing

Sur

face

Isop

orou

sM

embr

anes

Mic

roC

hann

elC

oolin

g

Flui

d Tr

ansp

ort

Film

Flui

dics

CS

600

Fast

ener

sC

S 2

00Fa

sten

ers

Sha

ped

Par

ticle

sTr

izac

tA

bras

ives

Gla

ssP

olis

hing

Sem

icon

duct

orW

afer

Pla

nari

zatio

n

Gri

plet

s Pla

sma

Dis

play

Pan

elB

arri

er R

ibs

Filtr

atio

n M

edia

FILT

RAT

ION

Mat

ing

Sur

face

Fast

ener

s

Ligh

tP

ipe

Ligh

tFi

bre

FAS

TEN

ER

S

FRE

EG

LAR

E

OV

ER

HE

AD

PR

OJE

CTO

RLE

NS

Fig

ure

1. I

nnov

atio

ns fr

om t

he M

icro

repl

icat

ion

Tech

nolo

gy P

latfo

rm O

ver T

ime.

Sou

rce:

3M

Cor

pora

tion

at RUTGERS UNIV on February 14, 2012oss.sagepub.comDownloaded from

744 Organization Studies 32(6)

Our analysis drew on multiple data sources. Immediately following our kick-off meeting, we were given a variety of private archival materials, including technical documents, marketing bro-chures, books chronicling 3M’s history, company compilations of innovation narratives, details of 3M’s technology platforms, in-house magazines, interviews of 3M employees conducted by oth-ers, and internal promotional videos. We also developed our own database of public archival mate-rials, including relevant articles and interviews published in the popular business press, case studies and reports written by academics and financial analysts, and videos about 3M (e.g., In Search of Excellence).

Although these materials offered rich third-person perspectives on innovation practices at 3M, they stopped short of offering an insider’s perspective on how 3M employees both experienced and enacted these practices. To this end, we engaged in a series of semi-structured interviews with 3M employees intimately involved in the development of the MR platform, BEF and Trizact. For instance, given his corporate role, we asked the SVP of R&D questions about innovation practices across 3M Corporation as a whole. By comparison, we asked scientists and technology managers to describe their roles and experiences during the development of the MR platform and the two specific innovation journeys related to it. In all, we conducted interviews with 18 people represent-ing the corporation (such as the SVP of R&D), the MR platform (such as the director of the MR technology center), and the two innovation journeys that we studied (such as the division heads, project leaders and scientists involved), as well as employees who themselves had been studying the process of innovation at 3M (such as those from 3M’s knowledge management group). Each of these interviews lasted for about 1 hour, and most interviews were taped and transcribed. On those occasions when we were not able to record our conversations, we took copious notes, which we used as the basis for our analysis.

Throughout the data collection process, we were guided by a ‘purposive sampling’ strategy (Lincoln & Guba 1985). Given the emergent nature of our research design, we also engaged in a variety of informal data collection activities. For example, we maintained regular telephone and email contact with our informants. We also visited 3M multiple times over a period of 12 months. During these visits, we observed team meetings, reconnected with our informants and other key project stakeholders, and took advantage of chance encounters. Both during and after these interac-tions, we took detailed notes, recording the particular content discussed as well as our own thoughts and insights. We continued data collection until new observations no longer offered additional information (Lincoln & Guba 1985).

Data Analysis

To make sense of these rich data, our analysis unfolded in stages. First, we asked stakeholders to ‘member check’ (Lincoln & Guba 1985) our interview transcripts and notes to ensure that we had faithfully captured what they said. During this initial step, we did not share what we had heard from one person with the others (what Locke & Velamuri 2009 refer to as ‘restricted transparency’). Next, triangulating across all our data sources – private and public archival documents, stakeholder interviews and informal observations – we generated a chronology of events as a way of under-standing the processes by which the two innovations (BEF and Trizact) had emerged. In places where there were ambiguities with respect to dates or gaps in our understanding of the data, we requested and were readily supplied with supplementary information.

Satisfied with our broad understanding of the development of the MR platform and the two innovation journeys, we finished coding the data for thematic content (Miles & Huberman 1994). We did this by abstracting raw quotations and text segments from the interviews and other

at RUTGERS UNIV on February 14, 2012oss.sagepub.comDownloaded from

Garud et al. 745

materials, and then generating a Microsoft Access database of quotations indexed by person and by theme (see Table 1 for illustrative quotes from 3M employees offering their perspectives on innovation, based on their experiences). Of note, the accounts offered to us by 3M employees included not only successes and achievements, but also missteps and aborted efforts during the course of the two journeys. In other words, we could not detect any overt attempts to mask the failed attempts and false-starts endemic to innovation journeys. This suggests that these data possess strong face validity.

Our reading of the data was accompanied by ‘a head full of theories’ (Weick 2007: 16). Specifically, our analysis was shaped by the fact that 3M employees themselves thought of inno-vation processes as being complex. For instance, Dr. Coyne (1996), in his talk during the United Kingdom innovation lecture series, noted that:

Innovation at 3M is anything but orderly. It is sensible, in that our efforts are all directed at reaching our goals, but the organization ... and the process ... and sometimes the people can be chaotic. We are managing in chaos, and this is the right way to manage if you want innovation.

Sandy Cobb, a scientist, also spoke about fractal growth at 3M. We also were influenced by work on complexity and interactive emergence (Sims 1991) which showed how art can emerge through the application of simple rules and through the interactions of intermediary outcomes with humans.

During this process of iterating between the data, existing theories and our own emergent understandings, we developed a series of lists, sketches, diagrams and short presentations (Weick 1995), which we shared with several stakeholders from 3M. An overall gestalt emerged from this dialogical process (Tsoukas 2009), one that Langley (1999: 691) refers to as ‘an

Table 1. 3M Employees’ Perspectives on Innovation

‘Our vision is that we would like to be the most innovative enterprise in the world….To be recognized by our customers as the most innovative enterprise….We think that it is very important for an organization to have foresight and the way we describe foresight is to understand the future before it gets here….Then, we have to see how we can connect with that future. These are critical first steps in creating a tradition of innovation.’ (Coyne)

‘My definition of innovation is taking what a customer may need or not even perceive that they need and identifying it with a technology to answer that need.’ (Guehler)

‘Innovation is probably the sum total and integration of your experiences. And it’s also keeping your eyes open to the world to see where and how you can take what you’ve learned in all of the different areas that you’ve been in and apply it to a specific thing, an idea. But then doing it, selling other people on the idea, gathering them in so that they become part of and supportive of what you’re doing.’ (Cobb)

‘I think innovation is the ability to take the product from concept to market place. So my definition is taking the concept, putting a concept together, building in the capability to manufacture, to understand, and then delivering it to a customer.’ (Jones)

‘I believe there are moments of not necessarily a flash of lightning, but that all of a sudden, something becomes clear to you that wasn’t clear before. You wait for it to happen and, for some people, it happens more frequently, for other people it never happens.’ (Hoopman)

‘Innovation is a messy process. It is being able to allow people time on their own and time to make mistakes and pursue their own dreams. I think it’s a matter of having creative people in the company and letting them work on things that they think will be important for the future.’ (Dippon)

at RUTGERS UNIV on February 14, 2012oss.sagepub.comDownloaded from

746 Organization Studies 32(6)

uncodifiable creative leap’. The process of zigzagging across this ‘hodgepodge of events, actions and talks’ (Czarniawska 2008: 33) culminated in the creation of a ‘narrative account’ (Langley 1999) summarizing the practices at 3M, and tracing the history of the MR platform and the emergence of BEF and Trizact. As with the raw interviews and our provisional theoriza-tions, we again gave 3M an opportunity to review our conclusions. Although 3M requested that we remove a few statements that were sensitive and confidential, these elisions proved immate-rial to our analysis.

This paper itself was inspired by recent events at 3M. 3M’s approach to innovation changed when James McNerney was hired as the CEO in 2000, a time when the company’s revenues and profits showed signs of stagnation. During his tenure between 2000 and 2004, McNerney sought to improve operational efficiency by establishing central control, introducing Six Sigma3 initia-tives and standard routines, and placing an emphasis on projects with the potential to yield quick results. Even though 3M’s profits improved, these changes appear to have had an adverse impact on 3M’s culture of innovation. For instance, 3M’s rank among the most innovative companies in corporate America began to slip during this time (Buderi 2000; Technology Review 2004; Boston Consulting Group 2009). Under its current CEO George Buckley, however, 3M appears to be going back to its earlier approach to innovation. In support of his initiatives after taking over from McNerney, Buckley noted:

Invention is, by its very nature, a disorderly process. You can’t put a Six Sigma process into that area and say, ‘Well, I’m getting behind on invention, so I’m going to schedule myself for three good ideas on Wednesday and two on Friday.’ That’s not how creativity works. (Hindo 2007)

Indeed, recent results indicate that 3M’s renewed emphasis on innovation under Buckley has been paying off both in terms of resilient performance during recessionary times and a slew of new product announcements, such as 3D optical films for mobile devices, abrasives that self-sharpen for long life, and low-cost respirator masks for use in developing countries (Daley 2009; Black 2010; Mattioli & Maher 2010).

Given these developments, we decided to re-examine innovation practices at 3M prior to the introduction of Six Sigma initiatives. Three researchers (including one who had been involved in the collection and analysis of the original data collected in 1998 and 1999) reviewed the data and analysis in light of recent advances in our knowledge of complexity. We sought a more nuanced understanding of the innovation practices at 3M to identify the generative nature of underlying rules and the products that emerged through nonlinear processes. We also sought to identify how temporal and relational dynamics were implicated in the process. Once again, we followed the iterative steps described earlier to generate the insights that we present in this paper.

Innovation Practices and Processes at 3M

What struck us about 3M were the thousands of different products that the company had gener-ated over its history. Such a proliferation of products, often daunting and confusing to outsiders, can readily be explained from a complex adaptive systems perspective. Specifically, from this perspective, heterogeneity of actors and a few simple rules can give rise to system emergence and a diversity of outcomes (Simon 1962; Kauffman 1995; Axelrod & Cohen 1999). This held true for 3M, where interactions among a limited number of technology platforms (each a cluster of intellectual assets) had spawned a diverse array of products. In addition, the application of a

at RUTGERS UNIV on February 14, 2012oss.sagepub.comDownloaded from

Garud et al. 747

few simple rules to shape interactions within the organization had contributed to this diversity. These included the much-discussed ‘15% exploration’ option that allowed employees to work on their own ideas and projects for up to 15% of their time, the ‘30% stretch’ goal requiring that 30% of annual revenues come from new products introduced within the past four years, and mechanisms such as Genesis Grants to fund nascent ideas or the Pacing Plus program to acceler-ate the development of high-potential products (see Table 2 for an insider’s definitions of some of these practices).

The 15% option had, over time, also become an opportunity for 3M employees to ‘bootleg,’ a 3M term that referred to the utilization of company-wide resources – especially those within its many technology platforms – to explore creative ideas. When we studied 3M, there were 30 such technology platforms ranging from adhesives and ceramics to imaging and medical devices. As many documents and employees informed us, 3M had a principle governing ownership and use of these platforms: ‘The technology belongs to the corporation and the products to the businesses.’

At 3M, it was typical for technology platforms to be housed in their own technology centers. For instance, the microreplication (MR) technology platform that we studied in detail was housed in the MR Technology Center (see Table 3 for 3M employees’ perspectives on these technology plat-forms). Dr. Robert Finochiarro, then the Technical Director of the MR Technology Center,

Table 2. 3M Practices. Source: Coyne (1996)

‘I’ll now make a confession: the 15% part of the 15% rule is essentially meaningless. Some of our technical people use much more than 15% of their time on projects of their own choosing. Some use less than that; some use none at all… The number is not so important as the message, which is this: the system has some slack in it. If you have a good idea, and the commitment to squirrel away time to work on it, and the raw nerve to skirt your lab manager’s expressed desires, then go for it.’

‘We have the Genesis Grants, which is another way that we support innovation in the company. People can apply for a $50,000 grant to work on something that they think might be a new technology in the company.’

‘We had a new product objective that 25% of our sales in any one year should come from products that are less than five years on the marketplace. That was a stretch objective. Now stretch objectives have to change as environments change, and so, we changed that objective in 1992 to an objective that 30% of our sales should come from products that are less than four years on the marketplace.’

‘We felt we needed to add another stretch objective and that was called Pacing Plus and it was identifying products that changed the basis of competition. And then making sure we allocated resources towards those kinds of products.’

‘My view is that valuable short-term results come from things that have been under way for some time…what you did two or three years ago. So when an organization gets to a point where we have to emphasize short-term results, what you need to do is to reach back on the things that are close-to-market, and accelerate those to market and put more resources on bringing those things that have already started down that path toward the market.’

‘The best description I’ve heard of 3M is that you never know what 3M is going to come up with next, but neither do they. Another way to describe 3M is we’re like a living organism.’

‘We’ll always win as long as we are able to leverage on the culture of innovation and the people we have in the company. What management has to do is to provide that environment and then get out of the way. We don’t want to change this company because the fundamentals are going to be sustainable no matter what and if we focus on those we’re going to be successful.’

at RUTGERS UNIV on February 14, 2012oss.sagepub.comDownloaded from

748 Organization Studies 32(6)

explained that the center not only nurtured the basic technologies of MR and optics, but it also partnered with business units to develop innovative products, and provided manufacturing services to customers. In other words, the center served as a focal resource for 3M employees, businesses and customers, thereby enabling them to make sense of the MR platform and its potential applications.

We also found another mechanism – narratives – that enabled employees to make sense of the assets in these platforms. As several 3M executives wrote: ‘Stories are a habit of mind at 3M, and it’s through them – through the way they make us see ourselves and our business operations in complex, multi-dimensional forms – that we’re able to discover opportunities for strategic change’ (Shaw, Brown & Bromiley 1998: 42). Indeed, we were able to read a number

Table 3. The Microreplication Platform in 3M Employees’ Words

‘One key ingredient that has allowed 3M to be innovative, not in one year or in two years but over a sustained period of time, has been its selectivity and aggressiveness in identifying and investing in significant technology platforms that are applicable to many markets. The microreplication technology platform is a very notable example of this strategy. We have been continually developing and investing into our capability in the microreplication platform for at least 10 or 15 years.’ (Wong)

‘One of the first things we used that (microreplication) for was making the Fresnel lens for the overhead projector, and that led into a series of other products in the optics area. But, this technology has also found its way into a host of other applications.’ (Appeldorn)

‘The technology platform involves efforts in two areas. One is developing a basic understanding on the intellectual property position to protect that technology platform. The other which is very critical to any success is having the ability to deliver the product to the customer, which means developing the manufacturing base for implementing that technology platform.’ (Jones)

‘Our advantage is probably the diversity of methods we have for generating microstructures. Although our patents are on the products themselves, we also have a toolbox full of all kinds of methods for making structures. Thus, when people within the company come up with product ideas, we can respond relatively quickly to get them onto the market.’ (Hoopman)

‘The idea of a technology center is to utilize our technology platforms to support what we have and create new products. By creating a technology center, we have been able to gather critical resources, both in people and in equipment, to ensure that we have the best capability in the world…Our mission is first to nurture and develop the basic technologies of microreplication and optics. Second is to partner with business units in the development of new, innovative products and services. Third is to provide manufacturing services to our customers.’ (Finocchiaro)

‘An idea can come from anywhere. So, our center works closely with many laboratories and business units within 3M. Communication is key to this close working arrangement… We have annual events where many laboratories will present their technologies in almost a mini-trade-show kind of forum. Within our technology center, we sponsor a symposium every other year [where] we review all the current programs based on microreplication. We regularly exchange personnel with other technology centers. The main objective of all this is the cross-fertilization of ideas . . . And, looking at our success stories, in each case, we have combined our microreplication technology with another core competency or technology platform.’ (Finocchiaro).

‘Our Abrasives division has used many different technologies to reinvent itself several times. But the reinvention that’s going on today is far more dramatic. And it comes from the 15% time, of a person taking initiative to explore new technologies for abrasives. One person in the abrasive division laboratory looked at many different new technologies within 3M, started to work with microreplication which is an optical technology, and found that, if he combined that technology with abrasives technology, he could create an abrasive material that was far superior to anything in the marketplace.’ (Coyne)

at RUTGERS UNIV on February 14, 2012oss.sagepub.comDownloaded from

Garud et al. 749

of 3M innovation narratives during our engagement with the company. From these narratives, we learned how top management had circumscribed its own ‘destructive’ potential when it came to innovation. For instance, one narrative titled ‘Back to the future’ had in it the following quote (also repeated in many other narratives of innovation at 3M) from 3M’s legendary chairman, William McKnight:

Those men and women to whom we delegate authority and responsibility... are going to want to do their jobs in their own way... Mistakes will be made, but if a person is essentially right, the mistakes he or she makes are not as serious in the long run as the mistakes management will make if it is dictatorial and undertakes to tell those under its authority exactly how they must do their job. Management that is destructively critical when mistakes are made kills initiative, and it is essential that we have many people with initiative if we are to continue to grow.

This particular quote was brought to our attention most frequently during our discussions with 3M employees and we can understand why it is such an important part of 3M’s culture. In tradi-tional hierarchies, top managers can indeed become dictatorial. Implicit in this quote, we see a culture that places limits on top management’s dysfunctional micro-management of the work per-formed by engaged employees. The message contained in this quote and expressed in different ways in other 3M narratives of innovation suggests an organizational culture that affords its employees the psychological safety (Edmondson 1999) required to make exploration the sine qua non of organizing.

Indeed, through a combination of our own interviews and compilations of innovation narratives, we learned how the MR technology platform itself originated, not as a result of a top management directive or initiative but from the discovery of a new thermofax imaging technology in the late 1950s by Roger Appeldorn, using his 15% time. Similarly, we learned how, during the early 1960s, Appeldorn and his colleagues drew inspiration from an old 3M product and applied this discovery to create a new product line. Appeldorn used purchase requisitions for materials to hire people dur-ing a hiring freeze and, along with colleagues, even made sales calls on public school teachers when 3M’s own marketing people expressed reservations about the market potential of the new product line. We also learned about the linguistic origins of the term ‘microreplication’. Appeldorn and his colleagues had originally named the technology ‘structured surfaces’ after seeing fine pat-terns on the plastic Fresnel lens they had developed. They then changed the name to ‘microreplica-tion’ to more evocatively convey the process of replicating precise microscopic patterns on any material’s surface to alter its physical properties.

Our engagement with 3M gave us the opportunity to explore in greater depth how employees experienced and navigated through complexities associated with the innovation process. Employees whom we interviewed offered us their own narratives of two innovation journeys that culminated in the emergence of brightness enhancement films (BEF) and the Trizact abrasive (see Tables 4 and 5 for illustrative comments). BEF is a thin plastic film that is applied to a laptop computer’s LCD display to enhance its brightness, whereas Trizact is a new abrasive that cuts faster, finishes finer and lasts longer than traditional abrasives. BEF was the end result of a journey that languished for decades as researchers attempted to identify viable commercial applications for the optical film they had developed. Conversely, those involved with Trizact thought that the disruptive nature (see Christensen 1997) of the product would have an immediate impact on the market. Surprisingly, the technology was not adopted for over three years by customers. Underlying the two seemingly unrelated products and the journeys that led to their emergence were the MR technology platform and other practices at 3M. In order to gain a deeper understanding of these practices, we first sum-marize the journeys.

at RUTGERS UNIV on February 14, 2012oss.sagepub.comDownloaded from

750 Organization Studies 32(6)

Table 4. The BEF Innovation Journey in 3M Employees’ Words

Illustrative quotes Practices/Comments

‘We started making some linear Fresnel lenses that were magnifiers for the LED watches but that market went down as fast as it went up. We’d find a lot of small applications as component parts, but selling just hundreds and even thousands of these is not a viable business. We struggled for a good 15 years. Still, we learned a lot about tooling, a lot about converting the parts and selling them.’ (Cobb)

False-starts and partial wins still add to knowledge in 3M’s technology platforms.

‘I came across a distribution system for light (patented by Loren Whitehead) that conducted light within a rectangular or square tube by total internal reflection. Earlier, we had made arrays of solar-concentrating lenses and learned a lot about how to do that. We also had tried to make decorative materials that looked like they were not flat, called optically-shaped film. When I saw what Whitehead was doing, I was able to visualize our capability of making tooling that, by his standard, would be considered exquisite, and also a process to make the film 30-some-odd inches wide and very thin. I began to realize that the efficiency of the thin film in a round tube would actually be greater than in the square tube. It took quite a bit of work, but we also were able to receive patents on the thin, flexible film itself.’ (Cobb)

Collision of people, ideas and technologies combined with prior several disparate products enables a 3M scientists to visualize a new future.

‘Between Christmas and New Year’s when things were pretty quiet, I talked our machinist in the Optics Technology Center into making the tool for putting up a roll (of film). We ‘bootlegged’ it, since we never did get the authorization to do it. Once we made the tool, [my boss] suggested that I apply for a Genesis Grant. And, I was fortunate enough to be awarded one of the grants, which allowed me to take that first tool and turn it into pilot plant production.’ (Cobb)

15% option, bootlegging, Genesis Grant, pilot plant experimentation, technology platform.

‘Within six months, we laid out a business plan with a vision, some pricing, and some markets that we wanted to go in. The plan also stated that we wanted to obsolete our products and develop alternative technology. We put a small team together. It included a laboratory person from the microreplication technology center. We hired some people out of school. We had a process engineer developing an alternative manufacturing process. And, one of the keys to our success was our ability to use other divisions’ facilities. So, we didn’t have to invest into significant infrastructure to start delivering products to customers.’ (Jones)

Use expertise and facilities all over 3M to experiment.

‘In view of the rapid changes in the electronic display market, if we were to just meet 3M’s internal new-product-to-sales ratio objective, we would not be able to stay in the business very long. That is because the industry and the markets and the technologies are changing a lot faster than a goal of 30% new products over four years could support. So we had to learn how to grow this business based on new technologies, new products, and based on a new-product-to-sales ratio substantially higher than the aggregate corporate objective for all divisions in 3M.’ (Wong)

Performativity of 30% ostensive rule.

‘We’re not a machine tool because everything doesn’t work smoothly. We’re not totally chaotic either. We’re somewhere in between, like organized chaos. Specifically, we are soft on some of the rules. We try to follow an introduction plan, but we’re dynamic enough to skip steps when necessary. One of our goals is to get products to market rapidly and have a number of hits in the marketplace so that we can be successful. If we were rigidly organized with step 1, step 2, step 3, then I think we would fail.’ (Jones)

Performativity of ostensive rules.

‘Now, we also have 3M Dual Brightness Enhancement Film (DBEF). DBEF was introduced a year ago and is now growing rapidly. It is based upon a new technology platform beyond microreplication. So the innovation and the renewal process continues.’ (Wong)

Spin-offs, a new platform, a whole new cycle of innovation.

at RUTGERS UNIV on February 14, 2012oss.sagepub.comDownloaded from

Garud et al. 751

Table 5. The Trizact Innovation Journey in 3M Employees’ Words

Illustrative quotes Practices/Comments

‘Back in 1988, one of the people in tech service started having this notion that, perhaps, microreplicated rivet material that helped make yachts a little bit faster could be applied to aircraft to reduce fuel consumption. He started talking around to different people involved in the rivet project or people who understood microreplication. And so they got involved, using their 15% time. And the deeper they got into it, the more they realized that maybe this just wasn’t something for aircraft alone. Maybe it was a new way to make a coated abrasive.’ (Dippon)

15% exploration option and support of assets in the technology platform.

‘In 1991, the project became a Pacing Program for the Abrasives Division -- that meant getting corporate funding, and it helped bring in additional people to the project. And now they could start to make steps more quickly, they could afford more equipment to do testing on a small pilot plant. Usually, at this stage pilot plant is equipment that’s kind of been … take this old piece of equipment from this line that’s not used anymore, maybe add a new winder to it, but it’s a conglomeration of materials of equipment to be able to do it as easily as we can with as little money as possible.’ (Dippon)

Pacing Program and bricolaging of equipment and facilities.

‘After the Pacing Program was initiated, we held an off campus kick off meeting. At that meeting there were about two dozen people representing nine different laboratories around the corporation. Some of the operating divisions were also involved in the program, so we had representatives from marketing. We also had engineering representatives and most of the disciplines that you’d think would be needed in order to start a successful business were on board from that time. Many of the key people in the program either were brand new to the Abrasives division or outsiders who didn’t know any better. Part of our success was we didn’t know it couldn’t be done and went ahead and just did it.’ (Collins)

Relational complexities afforded because of the Pacing Program status.

‘In about 1993 or thereabouts, we had our first pilot plant within the Abrasives buildings themselves, so we weren’t depending upon or sharing time on somebody else’s equipment. Now we could run experiments every day of the week. And again, the more you can experiment, the faster the progress that you can make.’ (Dippon)

Experimentation and prototyping with dedicated pilot plant facilities.

‘And what we found was that the team would get very excited by what they had created but, when they tested it with the customer, it didn’t perform nearly as well. Well, soon, the tech service engineer who was involved learned that he could do most of the testing in simulated customer conditions in one of our centers. The team started to see positive results out in the field and the next step was to have customers use it on a continuing basis and tell us how it performed and what value it offered. This also allowed us to produce more materials through our pilot plant and understand the whole process of manufacture as well.’ (Dippon)

3M guideline in practice – customer testing.

‘The new abrasive we made doesn’t look the same and cannot be used in the same manner as a conventional abrasive. You have to reduce the pressure when pushing on the abrasive or you’ll wear it out very quickly and will not experience the value it provides when you use it properly. It required quite an effort to convince the customer to change the way they use sandpaper. This was a case where we thought we had invented a better mousetrap and the world would beat a path to our door. But, it didn’t. We were a bit surprised by the kind of market resistance or inertia that we had to overcome.’ (Collins)

Asynchronies and diachronies in the innovation journey.

(Continued)

at RUTGERS UNIV on February 14, 2012oss.sagepub.comDownloaded from

752 Organization Studies 32(6)

The Brightness Enhancement Film Innovation Journey

The BEF innovation journey dates back to the very origins of the MR technology. In the late 1950s, efforts to improve 3M’s thermofax photocopying technique led Roger Appeldorn and his col-leagues to discover a new imaging technology during their 15% exploration time. They thought that this discovery could be the basis for a new line of products such as overhead transparencies and overhead projectors, but they were unsuccessful in convincing corporate staff because of the high manufacturing costs involved. Appeldorn and his colleagues then bootlegged resources and were successful in developing a new plastic Fresnel lens that was far cheaper and superior to other lenses available at that time. And when they noticed the microscopic pattern on the plastic surface of the Fresnel lens, they came to realize that changing the surface of a material would enable them to radically change its other physical properties. This insight laid the foundation for what later developed into the MR technology platform.

After making the new Fresnel lenses for its own overhead projector product line for nearly a decade, 3M created a new division called Industrial Optics to develop and sell applications based on the Fresnel lenses. The first opportunity that emerged was to make a magnifier for LED watches. However, when the popularity of LED watches declined, so did the business opportunity for this product. Many subsequent applications followed, but most had very limited markets. Nonetheless, each of these experiments and niche applications resulted in people at the division accumulating expertise in the technology and developing a toolkit of manufacturing techniques that later became the basis for the Optics Technology Center. However, the Industrial Optics division itself lan-guished for the next 15 years, with only the support of Appeldorn and a few other executives keep-ing the division (and the idea of microreplication) alive.

While working on a project at the University of Minnesota, Sandy Cobb, a scientist in the Optics division, became aware of an invention patented by Loren Whitehead at the University of British Columbia to transport and distribute light using rectangular tubes through total internal reflection. Cobb immediately thought of a way to improve on Whitehead’s invention by employing the optically shaped film that their division had developed for use in decorative applications. Cobb recounted:

Illustrative quotes Practices/Comments

‘One of the things that you often find about innovation is that it will spin off into something that you didn’t necessarily expect at the time, and which 10 years later, will be a bigger business than the original idea…. Since 1996, we have spun off another Pacing Plus program directed at the silicon wafer industry. We learned that our microreplicated product could perform a similar function more efficiently, in less time, and with superior quality. This has the potential to be much bigger than the initial project that was applied only to conventional abrasive applications.’ (Dippon).

Spin-offs and Pacing Plus.

‘Early on, we were primarily a technically based program, so it made sense to have someone with a technical background leading it. Later, it became more of a business development program, so I stepped down and turned it over to a business manager-type person. Today a sales manager leads the program, since sales and marketing have become so important. So the program’s leadership has evolved to reflect the true challenges.’ (Collins)

Distributed program leadership as a journey unfolds.

Table 5. (Continued)

at RUTGERS UNIV on February 14, 2012oss.sagepub.comDownloaded from

Garud et al. 753

When I saw what Whitehead was doing, I was able to visualize our capability of making tooling that by his standard would be considered exquisite, and also a process that would make the film wide and very thin. I also began to realize that the efficiency of the thin film in a round tube would actually be greater than in the square tube.

To explore whether his idea had any merit, Cobb resorted to bootlegging, just as his boss Appeldorn had done during the early 1960s. Cobb recounted:

Between Christmas and New Year’s when things were pretty quiet, I talked our machinist in the Optics Technology Center into making the tool for putting up a roll [of film]. We ‘bootlegged’ it since we never did get the authorization to do it.

When the idea worked and became the basis for several patents, Appeldorn suggested that Cobb apply for a grant under the new Genesis Grants program that 3M had established to fund such exploratory work. On obtaining a Genesis Grant, Cobb and his colleagues improved upon that first bootlegged tool and built a pilot plant to make small batches of film for testing new applications. However, they faced a problem because an appropriate light source for their appli-cation was not available. The metal halide lamps being developed at that time were too large, too hot, and did not come on instantly. Therefore, they could only apply their newly developed film to a few niche applications, such as traffic signs and guidance tubes that could be used in con-struction zones on highways.

In 1986, Rich Dryer, a scientist at the Optics Technology Center, noticed that a piece of paper looked brighter when the plastic film was placed on it. Though this discovery was interesting and gave rise to many ideas, none formed the basis for a viable business. Other experiments and ‘fail-ures’ followed with each adding to the MR technologies, tooling and processes. But the division itself languished from a business standpoint for want of commercially viable applications.

When Paul Guehler, a 3M vice president, was charged with breathing fresh life into the strug-gling division during the early 1990s, he and the division’s managers carefully assessed the market potential of the division’s various technologies, ideas and applications. They then decided to focus resources and efforts into using the optical film to develop filters for the ergonomic management of computer displays.

Even as the division was building the new filter business, it became apparent that the film could possibly play a role in the emerging market for laptop computers with liquid crystal displays. The emergence of backlit liquid crystal displays solved a key constraint – the lack of a light source – that Cobb and his colleagues had confronted in developing a commercially viable application for their optical film. Reflecting on this development, Cobb remarked:

With our optical lighting film we never found its niche, the niche found us. We didn’t find the right combination of things to make a product that had a very strong appeal or need. The film worked extremely well, but it didn’t have all the ingredients that were necessary, that is, a light source. However, we had a system of people to look at it and find a need for it. Communication was a big part of that.

Within six months, the Optical Systems division laid out a basic business plan with a vision, target markets and a product migration map. Recognizing that the electronics market would move much faster than most of 3M’s traditional product markets, the division planned to make its own products obsolete by developing new products and alternate manufacturing technologies. The divi-sion put together a small team of people including an expert from the MR Technology Center, a manufacturing process engineer, and several new hires. Again, this team bootlegged equipment

at RUTGERS UNIV on February 14, 2012oss.sagepub.comDownloaded from

754 Organization Studies 32(6)

and facilities from other divisions to begin producing and delivering products to customers without investing significantly in infrastructure at the beginning.

These early attempts demonstrated that their product’s design was not optimal for the new application. Sandy Cobb explained the problem they confronted: ‘The film we had was very coarse and there was terrible interference even though it made the display brighter.’ Cobb and his colleagues were able to solve the problem after some experimentation, but it became apparent to them that the cosmetic quality required for the film far exceeded their capability to produce it in high volume. Indeed, by 1994, they were finding it difficult to schedule production at a sister division’s facility. So, with help from the MR Technology Center, they developed a new produc-tion process for the optical film and scaled up their production capabilities. Cobb observed:

What also made it very successful was the fact that we had the accumulated expertise over all these years. We also had the patents and intellectual property. It took a tremendous amount of marketing on our part and it took some very brilliant people along that line, very determined people to sell into a market that was 99% initially in Japan.

The resultant film – BEF – enhanced the brightness of backlit flat panel displays by 50% to 100%, extended the life of laptop batteries, and was rated by Compaq among the top eight innova-tions associated with laptop computers. Even as BEF was transforming into a blockbuster product, the division was already launching a second generation of brightness-enhancing films. As Andy Wong, the division’s General Manager explained, the division would not be satisfied with simply meeting 3M’s 30% stretch goal: ‘Now, we also have the 3M Dual Brightness Enhancement Film (DBEF). It is based upon a new technology platform beyond microreplication. So the innovation and renewal process continues.’

Thus, we see in the BEF journey how the various practices in place at 3M enabled the company to wait, prepare and finally leverage an opportunity when it presented itself. For instance, the 15% exploration time, bootlegging and Genesis Grants made it possible for the scientists to follow up on ideas and to experiment with different applications even when no new products were readily apparent and the division itself was languishing. Even experiments that did not pan out played important roles. They led to intellectual property positions, knowledge on problems and possibili-ties, and the generation of a toolkit of techniques and processes. The Optics Technology Center (later, the MR Technology Center) focused all of these accumulated efforts toward augmenting the MR technology platform until the time was right for leveraging these assets into viable products. These practices enabled the Optical Systems division to ‘stretch time out’ until the market applica-tion materialized.

Aside from the ability to deal with and even benefit from such temporal complexity, we also see the practices that facilitated productive relational dynamics. For instance, the ability to bring together experts from across the corporation enabled cross-fertilization, thereby ensuring the creation of novel processes and techniques. The ability to make use of the resources from other divisions ensured that projects could proceed without investing in new expertise or fresh resources. In fact, Paul Guehler noted that, at times, the Optical Systems division had over 150 people from across 3M working on the BEF and DBEF projects at no cost to the division. Mindful engagement with customers eventually resulted in a match between 3M’s technology capabilities and unarticulated customer needs, manifest in a continuing stream of products. Finally, we see simple rules being adjusted to suit the dynamic context, as when the Optical Systems division planned to outperform 3M’s 30% stretch goal to keep pace with the rapidly evolving markets that it had entered.

at RUTGERS UNIV on February 14, 2012oss.sagepub.comDownloaded from

Garud et al. 755

The Trizact Innovation Journey

In contrast to the BEF journey, the development of the Trizact abrasive owed its origins in the late 1980s not to a scientist or researcher, but to a service technician with a passion for aircraft and flying. This person thought that the microreplicated rivet material used in yachts could potentially reduce fuel consumption if it were used in aircraft. The service technician started discussing his idea with people involved in the microreplicated rivet project and those with expertise in MR technology.

A small team from the Abrasives division, which was exploring whether the MR technology could be used to develop a more flexible manufacturing process for their products, also became involved in this informal project. They began to experiment with various materials, slurries and manufacturing techniques, first using their 15% exploration time and later with the help of two Genesis Grants. It was then that they realized that, in addition to serving as a new material for use in aircrafts, the technology might also be a new way to make high-performance coated abrasives. Their manager, In Sun Hong, recalled:

After they worked a bit (using their 15% time), they told me this was a promising technology. We had a meeting. I looked at it and I said, ‘Yeah’. I had been in the abrasive world long enough to recognize that ‘Hey, this is something we need. Let’s look further at it.’

In 1991, Hong led this small team of researchers, making presentations to corporate executives and securing their support. Due to these efforts, the project secured funding under the Pacing Program, a corporate funding program to increase the pace of development for high potential ideas. Stanley Collins, who was elected the technical leader of this Pacing project recalled:

We held an off-campus meeting to kick off the team. At that meeting, there were 2 dozen people representing 9 different laboratories around the corporation. Some of the operating divisions were also involved in the program, so we had representatives from marketing. We also had engineering representatives, and most of the disciplines that you’d think would be needed to start a successful business were on board and present at the original planning meetings and participated in trying to plan the project.

As new expertise and technologies became salient, the team brought in people from other areas. For instance, microreplication experts from the Optics Technology Center became key advisors and people from other divisions, such as Dental Products, who had expertise in light cur-ing, joined the team. Even as the team experimented with different slurries and curing techniques, they made progress by developing a commercially viable manufacturing process and cataloging their journey to serve as both a shared memory for the team and a socialization tool for new proj-ect hires. A retired manufacturing line from the Traffic Control Materials division became their testing ground. In 1993, they succeeded in building the first pilot plant within the Abrasives divi-sion, allowing them to build prototypes and run experiments more quickly, thereby accelerating their progress.

The emerging team did not know how to test a new product that was radically different from conventional abrasives. This was a challenge. Darrell Dippon, who later took over as the project leader, explained: ‘What we found was that the team would get very excited by what they had cre-ated, but when they tested it with the customer, it didn’t perform nearly as well.’

Soon, a technical service engineer on the team found that he could simulate customer conditions at a customer center within the division, and devised techniques to test the new abrasive. Once reliability and performance of the new abrasive improved, the team began testing the product on-site with potential customers to determine how it performed under real-life conditions. Dippon

at RUTGERS UNIV on February 14, 2012oss.sagepub.comDownloaded from

756 Organization Studies 32(6)

recalled that they used results from these tests to refine the manufacturing process until 1995, when they built a manufacturing plant to produce the new abrasive in quantity.

Simultaneously, they also began developing other new products. Each new product necessitated further innovations. For each innovation, Dippon related how they applied what they had learned from their earlier projects: ‘In most cases, just looking at the past probably completes 80 to 90% of the product design. It’s usually the last 10 to 20% where the innovation comes in.’

Surprisingly, when they launched the new abrasive they encountered resistance from customers. Collins explained: