DANGJIN STEEL동국제강 영문브로슈어(펼침면)(2)

-

Upload

tienbien2033 -

Category

Documents

-

view

40 -

download

0

Transcript of DANGJIN STEEL동국제강 영문브로슈어(펼침면)(2)

Dangjin Works

steel PlatesCreates New Value of

Head OfficeFerrum Tower, 66 Suha-dong, Jung-gu, Seoul, Korea

Phone : 82-2-317-1114 Fax : 82-2-317-1391

dangjin WOrks400, Hanjin-ri, Songak-eup, Dangjin-gun, Chungnam, Korea

Phone : 82-41-351-4611 Fax : 82-41-351-4691

08 History of Dongkuk Plate

10 About Dangjin Works

12 Overview

14 R&D Center

Create High Quality steel Plate

16 Production Process

18 Facilities

20 Product Supply Standard

Quality Inspection Standard

21 Marketing and Production Plan for Year 2011

2010 Product Specification

22 Standard Certification

23 Delivery

24 Steel Grade Development Plan by Stage

Long Term Steel Grade Development Plan

25 Product Supply Table

27 Business Network

Contents

“tHe CHange anD groWtHFor tHe better Future”We Will beCome a global steel maker

The pride of traditional company in Korean steel industry

The continued effort to create future values

The challenge to be a global company

Donguk Steel strives for the better future

with its continuous change and growth

more first challenges solid technology

The nation’s first 50-ton blast furnace operation [1965]

The first domestic electric arc furnace [1966]

The first domestic production of steel plates [1971]

Now the nation’s first integrated mill in Brazil,

Dongkuk Steel opens up new era of steel with the first spirit.

Dongkuk Steel, with its 40-year-history of steel plate production, is

a strong technology enterprise leading high quality steel industry.

Researchers at its state-of-the-art R&D center are doing their best

to develop high value-added steel products and manufacturing

technologies with their "creating masterpiece" spirit.

First strong

trustworthy products

From needles to vessels, with 56 year of single path in steel

craftsmanship and state-of-the-art facilities, Dangjin Works now

introduces high grade focused steel products being used in offshore

structure, special and mega vessel. Dangjin Works will create new

legend in steel industry with its best products.

HigH “Concentrating on what we do the best”

Dongkuk Steel, a traditional company in Korean steel industry, can do the

best in nothing but steel. It manufactured steel plates first time in Korea

and pioneered steel market. In late 1990s through Pohang Works equipped

with 2.5 million tons of annual steel plate production capacity, Dongkuk

Steel opened up steel plate production system for shipbuilding and has

lead domestic steel plate market. As of year 2010, Dangjin Works, equipped

with 1.5 million tons of annual steel plate production capacity, begins new

operation and opens new era of high grade steel plates.

Dangjin Works enterd into commercialization of its strategic

products with first shipment of steel plates for shipbuilding on

March 18, 2010. Following this success, Dongkuk Steel’s steel

plate business was upgraded from annual 2.9 million tons at

Pohang Works to a total of 4.4 million annual tons of production

system. Combined 40 years of steel plate know-how by Dongkuk

Steel with the latest technology, Dangjin Works is a production

base for next generation strategic products. By constantly sup-

plying the best quality steel plate products proven by the high-

est level customers, Dangjin Works will achieve a win-win with

customers.

dongkuk steel has manufactured steel plates first time

in korea. striving only in the area of steel and getting

ready for global competitiveness, dongkuk steel has

grown itself into a world-class steel manufacturer by

introducing advanced technologies and upgrading pro-

duction facilities.

40 thousand tons produced [1971] >

0.63 million tons produced [1991] >

2.57 million tons produced [2009] >

4.4 million tons production system established [2010] >

1.25 million tons produced [1998] >

0.31 million tons produced [1983] >

The nation’s first production of steel

plates (0.15 million tpy)

completion of no. 2 plate mill in Pohang Works

(1.5 million tpy). Production focused on general

shipbuilding grade.

completion of no. 1 plate mill in Pohang

Works (one million tpy)

completion of dangjin Works(1.5

million tpy). Production focused on

high grade steel plates.

Paving new path of steel plates

History oF Dongkuk Plate

History oF Dongkuk Plate History oF Dongkuk PlateDongkuk steel CatalogueDangjin Works

08 09

Construction Site Control Room Finishing Mill Shipping

steel Plate Production capacity (unit:ton)

0.15

0.3

1

2.5

2.9

4.4

million

million

million

million

million

million

Dangjin Works is a 1.5 million tons of annual capacity production

base for Dongkuk Steel’s next generation strategic products

with the latest and the best steel plate production infrastruc-

ture.

Dangjin Works will produce high grade steels such as wide

width steel plates for shipbuilding, TMCP (Thermo Mechanical

Controlled Process) steel plates, heat treated steel plates, high

tensile steel plates, which will account for over 50% of its total

production, thus leading the upgrade of steel plate market.

1,500,000 Tons

Dangjin Works is equipped with an exclusive pier capable of

berthing 50 thousand ton vessel. Production facilities from raw

materials placement to product shipping at Dangjin Works are

arranged in straight line of 1.2 km to improve efficiency. Dangjin

Works is also the most up-to-date with environment friendly ap-

proach by using natural gas.

Dangjin Works produces high grade oriented steel plates be-

ing used in special vessel, offshore structure, mega vessel and

building. For steel plates used in mega vessel, it is crucial how

uniformly the plates are produced with desired thickness. Dan-

gjin Works’ plate mill is one and only place where steel plates of

4,800 mm width, the largest standard in Korea, and of 4.5 to 150

mm thickness size can be manufactured.

4,800mm1.2km

50% >dangjin, home for dongkuk steel’s new plate mill, is a

place where a number of steel manufacturers and dis-

tributors are located and with its advantage in traffic

convenience, is fast emerging as a steel mecca. dangjin

Works has established a high grade oriented production

system and has started manufacturing high grade steel

plate for shipbuilding. dangjin Works, as a next genera-

tion production base for dongkuk steel, will do a leading

role in establishing a steel belt connecting korea and

Brazil with the construction of an integrated mill in Bra-

zil first time in korea.

Driving force of steel belt connecting Dangjinand brazil

aboutDangjin Works

aboutDangjin Works

Dongkuk steel CatalogueDangjin Works

10 11

about Dangjin Works

View of Dangjin Works Finishing Mill View of pier

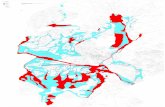

Location of dangjin Works

january 2007 Dangjin Construction Headquarters established

march Construction of shipping yard started

February 2008 Construction of main plant started

may “Prayer for safety” and steel frame erection ceremony

may 2009 Completion of FerrumVille, apartment for employee housing

august Completion of one berth for 50 thousand ton vessel

september Ignition ceremony for reheating furnace First slab imported to Dongkuk Steel pier

october Passed trial product test

november First shipment of steel plates

march 2010 First shipment of steel plates for shipbuilding

may Opening of Dangjin Works

Overview of dangjin Works

construction Progress

overvieW overvieWDongkuk steel CatalogueDangjin Works

12 13

dangjin Works is equipped with state-of-the-art facility

lines focused on high grade steel production, environ-

ment friendly facilities, and an exclusive pier capable

of berthing 50 thousand ton vessel. Together with r&d

center, dangjin Works is spurring its efforts to obtain a

variety of quality certifications and to mass produce high

value added strategic products.

Dangjin Works will create top quality steel plate

overvieW

( establishing customer oriented production & supply network )

• The newest production base for next generation strategic products • 1.5 million tons of wide width high strength steel plates, TMCP, and heat treated plates • Secured an exclusive pier for 50 thousand ton vessel

• The most optimized primary steel plate production base • 2.9 million tons of steel plates for structure and shipbuilding • Secured 3 exclusive piers

• Technical support and providing data to customers • Developing new steel grade and technology • Technical cooperation with JFE Steel and other partners

Dangjin no. 3 Plate mill

Pohang no.1 and no.2 Plate mill

r&D Center

Head Office

Incheon Works

Pohang Works

Busan Works

● Establishing 4.4 million tons steel plate system

● Guaranteeing the shortest delivery period service

● Guaranteeing the highest quality

● Environment friendly production system

Dongkuk Steel Dangjin Works

Hanjin Inlet Pyeongtaek Harbor

15

SongakiC

West Coast Expressway

West Pyeongtaek iC

Asan Bay

38

address 400, Hanjin-ri Songak-eup, Dangjin-gun, Chungnam, Korea

main products Wide width steel plates for shipbuilding, TMCP steel plates, Heat-treated steel plates, etc.

Production capacity 1.5 million tpy

total investment 840 million US dollars

size Total area of 687,600㎡

Total plant length of 1.2㎞

(1.4㎞ up to fence)

Dangjin Works

The R&D Center, with land area of 53,600㎡ and total floor space

of 12,903㎡, has one research and two laboratory units. No. 1

lab is a huge laboratory with testing ground for melting such as

vacuum induction melting and casting furnace and pilot testing

ground for hot rolling. The R&D Center is equipped with various

kinds of testing equipment such as testing ground for material

quality and property with tensile and fatigue testing machine,

common milling machine, and welding testing ground. Under

the banner of "A passionate and innovative research institute

creating new technologies and values", the R&D Center will ex-

pand the work force to over 100 researchers in a few years. The

R&D Center will maximize the synergy effect by combining Dan-

gjin Works with integrated mill business in Brazil, expand into

machinery and information technology and will develop into an

integrated technology research institute.

● address440, Songdong-ri, Daesong-myun, Nam-gu, Pohang, Korea

Phone : 82-54-271-2710~14

Fax. 82-54-271-5759

Technical support for internal & external customers

Introduction of new products and

technologies

Developing new steel grades

r&D CenterDongkuk steel CatalogueDangjin Works

14

r&D Center

The r&d center of dongkuk steel was relocated to a

large high technology r&d center building in daesong-

myun, nam-gu, Pohang and was newly opened in Octo-

ber 2009.

The r&d center will integrate steel related knowledge

and information around the world, accelerate r&d activ-

ities for product development and creating new technol-

ogy, thus reinforcing dongkuk steel’s competitiveness.

The key for dongkuk steel towards the era of endless

global competition is "technology"and "globalization".

r&d center will play a pivotal role to secure the best

world-leading technological competitiveness.

r&D Center at the heart of future core growth power

Create HigH Quality steel Plate

dangjin Works, with investment of 840 million Us dollars for 3 years, is equipped with the latest precision controlled

casting and heat treatment facilities and is capable of producing 1.5 million tons of steel plates. The operation of dan-

gjin Works enables dongkuk steel to fortify its competitiveness in high grade steel market by producing wide width,

high tensile steel plates, TMcP steel plates, and heat treated steel plates.

SLAB

PLATE ULTRASONIC TEST

SHOT BLASTPRESS LEVELER

HEAT TREATMENTFURNACE

HEAT TREATMENTLEVELER

DESCALER

COOLING BED No.1 & No.2(T≤50mm)

COOLING BED No.3 (T≻�50mm)

SOFT COOLING PRE - LEVELER MULPIC(ACC+DQ)

CROP SHEARDSTS & SLITTERDIVIDING SHEARNo.1 MARKING

No.2 FINAL INSPECTION No.2 MARKING GAS CUTTING

No.1 FINAL INSPECTION

HOT LEVELERFINISHING MILL & EDGERREHEATING FURNACE

COLD LEVELER

ProDuCtion ProCess ProDuCtion ProCessDongkuk steel CatalogueDangjin Works

16 17

upgrading the value of steel plate with all new equipment and process

ProDuCtion ProCess

Finishing Mill rolls products with size required by cus-

tomers. The Finishing Mill at Dangjin Works is the latest

facility with Work Roll Shift as work rolls move to the left

and the right which is capable of producing ultra thin, wide

width steel plates

This facility is for leveling plates after heat treatment with

temperature of 400–700˚C. Leveling after heat treatment

creates fine-grain and improves product quality along with

leveling. This facility is frequently utilized for leveling es-

pecially medium thick steel plates and capable of leveling

up to 5,400 tons.

finishing Mill Heat Treatment Leveler

Mulpic is a facility to produce high grade steels such as

TMCP products. It executes accelerated cooling or direct

quenching treatment to rolled products through which

much stronger high quality products can be produced.

Press Leveler is to level thick steel plates and capable of

enhancing shape quality and precisely measuring product

size such as thickness. Press Leveler at Dangjin Works

has leveling capacity of approximately 2,500 tons.

Mulpic Press Leveler

This is the state-of-the-art facility necessary for the pro-

duction of high quality heat treated steel products such

as pressure vessel, pressure boiler, wind tower, and API.

Heat treatment furnace at Dangjin Works has annual ca-

pacity of producing 200 thousand tons.

This facility is capable of producing narrow width products

on-line and has significantly improved production capacity

of narrow width products at Dangjin Works. Slitting Shear

is installed together with Double Side Trimming Shear.

Heat Treatment furnace slitting shear

Edger or Edge Mill is installed at the rear of Finishing Mill

and is the newest facility to improve quality and productiv-

ity by maintaining uniform width and minimizing width de-

viation during finish rolling. It enables rolling of minimum

1,200 mm up to maximum 4,900 mm thickness

This facility is for leveling thin plates which can maximize

plate flatness and product shape quality. Cold leveler at

Dangjin Works has leveling capacity of up to 3,600 tons.

edger cold Leveler

dangjin Works produces high grade oriented steel plates used for special vessel, offshore structure, mega ves-

sel and structures. Producing steel plates as widely and uniformly as possible with desired thickness is the key

factor for steel plate products used for mega vessel. dangjin plate mill is the one and only plant in the world ca-

pable of producing steel plates with 4.5 to 150㎜ thickness and 4,800㎜ width.

FaCilities FaCilitiesDongkuk steel CatalogueDangjin Works

18 19

FaCilities

responding to customers’ trust with the best quality and service

21

Thickness

Width

Length

Max. piece weight

classification

Annual capacity

Supply range

Selling price

Quality assurance thickness

Shipbuilding class

Non-shipping class

Breakdown

Min. 1.5 million tons

4.5~150㎜

Product basis 900~4,800㎜(Mill Edge 4,900㎜)

3,000~25,000㎜

Max. 20Ton

general 83㎜

High tensile 83㎜

general 100㎜

High tensile 80㎜

Product price [Base+Extra(Inspection fee for shipbuilding class, Material, Measurement, Per size, Additional quality items)] + Transportation cost [Base+Extra] + Value added tax (10%)

Within the range of 10 shipbuilding certifications including AR, NR, N and TMCP

✽VAT : 0 percent for local sales✽Inspection fee for shipbuilding class : Excluding non-shipbuilding class

remarks

ProDuCt suPPly stanDarD

Thickness

Managed by lower standard limit+over 0.1㎜

Width

Managed within Min. +3㎜, Max. +30㎜ Managed within Min. +5㎜, Max. +100㎜

(Unit:㎜)

Length

Bow standard (lateral)

standard

Max. 5㎜

Max. 6㎜

Max. 7㎜

Width

0‹W≤2,500

2,500‹W≤3,500

3,500‹W

flatness standard (longitudinal)

thickness

※ Products with 3 or more waves within random length of 4,000㎜ go through cold leveling or treated as failed

Classification

Number of waves (random length of 4,000㎜)

6≤T‹10

10≤T‹15

15≤T‹38

38≤T

shipbuilding class

1 wave 2 waves

8 4

7 4

6 3

5 3

non-shipbuilding class

1 wave 2waves

10 5

9 5

8 4

5 3

Quality insPeCtion stanDarD

20

● normalizing

● TMcP

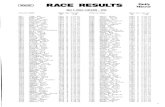

marketing anD ProDuCtion Plan For year 2011

2010 ProDuCt sPeCiFiCation

classification

classification

Shipbuilding

Shipbuilding

Welding structure

Bridge

Pressurevessel

API

Offshorestructure

SN

API 2H-50

400A/B/C, 490B/C

Test &evaluation

Rolling &Property test

PWHT &Welding test

Property test

Welding property test report

Welding property evaluation

JIS

2W50

ASTM

X 60, 65

X 70

Property test

Property test Welding test

Property test

Property test PWHT test

PWHT test

Property test DWTT test

Property test

DWTT test

PWHTtest

Customerevaluation

Additionaltest

Property test

Securing basic property &Optional test

PWHT &Welding test

Property testCustomerevaluation

Evaluation by major shipbuilders(Approval for supply)

Customerevaluation

Welding propertyevaluation

Customerevaluation

Customerevaluation

Customerevaluation

PQR report (DNV, ABS)

nov

nov

2010

2010

2011

2011

Dec

Dec

jan

jan

Feb

Feb

mar

mar

apr

apr

may

may

jun

jun

AH/DH/EH36-N

EH40

EN S355N

A516 series (50T )

HSB 600/600L

● normalizing ● TMcP

•shipbuilding class : A/D/E (83T), AH/DH32 (70T)

•ks : SB410 (83T) SB450, 480 (25T)

•astm : A516-60, 65, 70 (83T)

•jis : SPV 235, 315, 355 (83T)

•en : S275N/NL, S355N/NL (70T)

•shipbuilding class : A/D/E (83T), AH/DH/EH32 (83T),

AH/DH/EH36 (83T)

•Welding structure : A572-50/60, A709-50, A573-70,

S355M/ML (83T)

•bridge : HSB 500/500L, SM520B,C-TMC (83T)

•aPi : X52, 56 (35T)

A537-Cl.1

SPV355

Dongkuk steel CatalogueDangjin Works

Dongkuk steel CatalogueDangjin Works

22 23

2010-03-25

1) 2010-02-012) 2010-03-023) 2010-08-234) 2010-09-29

1) 2010-01-292) 2010-02-223) 2010-07-024) 2010-09-29

1), 2) 2010-04-063) 2010-07-07

2010-03-15

1), 2) 2010-02-023) 2010-03-03

1) 2010-01-222) 2010-03-093) 2010-07-084) 2010-10-07

1) 2010-04-142) 2010-04-263) 2010-08-25

1) 2010-03-052) 2010-03-253) 2010-08-11

class certificate

ABS

CCS

BV

DNV

GL

RS

RINA

KR

LR

NK

Ordinary and Higher strength Hull Structural Steel Plates

Normal and Higher strength Hull Structural Steel

Normal and Higher strengthHull Steel Rolled Products

Rolled Steel Products

Normal and Higher strengthHull Structural Steels

Hull Structural Steel

Normal and Higher strengthHull steel plates

Rolled Steel Plates for Hull

Steel Plates

Rolled Steels for Hull

GEN50003/961145

FS09W00040T

22703/A3 BV22704/A3 BV

1) AMM-45692) AMM-46123) AMM-47824) AMM-4915

WZ 2170 HH1

10.00026.294

FAB178210PU

TJN25394-SP001

1) MD00/3773/0001/12) MD00/3773/0002/1

1) NKR-415ROL2) NKR-421ROL3) NKR-449ROL

ARCR(NR)TMCPNormalizing

A, B, D, E, AH32/36DH32/36, EH32/36

A, B, D, E, A32/36D32/36, E32/36

KA, KB, KD, KE, KAH32/36, KDH32/36KEH32/36

certification no.1) ar, 2) Cr3) tMCP, 4) Nor.

Process grade date1) ar, 2) Cr3) tMCP, 4) Nor.

● shipbuilding class

2010-02-10

1) 2010-05-042) 2011-03-09

1) 2010-02-102) 2010-03-243) 2011-03-09

class certificate

KoreanIndustrialStandards

Rolled steel forgeneral structures

Rolled Steels for bridge structures

Rolled steel forwelded structures

KS D 3503

KS D 3868

KS D 3515

10-0066

10-0253

10-0067

SS400, SS490

HSB500, HSB500LHSB600, HSB600L

SM400A, SM400B, SM400C, SM490A, SM490B, SM490CSM490YA, SM490YBSM520B, SM520C, SM570

certification no. grade date

● ks

stanDarD CertiFiCation

•Production period for heavy loaded plate

Delivery

● Production Lead Time

•Production period for general plate (Land transportatin basis for general plate)

Material design standby

12

Production control

3Rolling/Shearing

9Shipping

328 days

(4 weeks)Transportation

1

(unit : day)

2010-05-20

class certificate

JapanIndustrialStandards

Rolled steel forgeneral structures

Rolled steel forwelded structures

JIS G 3101

JIS G 3106

KSKR10005

KSKR10006

SS330, SS400, SS490, SS540

SM400A, SM400B, SM400CSM490A, SM490B, SM490CSM490YA, SM490YBSM520B, SM520C, SM570

certification no. grade date

● jis

class certificate

LRQAManufacture of hot rolledplates, sections and bars

ISO9001:2008 SEO 0938902 2010-01-15

certification no. date

● isO9001

classification

Heavy plate, CR 28 3 31

Normalizing 28 15 43

additional periodProduction period Total

U=not treated, as-rolled(+AR)N=normalized or normalized rolled(+N)CR=temperarure controlled rolled(+N)

N=normalized or normalized rolled(+N)

TM=thermo-mechanically treated(+M)

4.5~1002010-04-08

2010- 03-30

class certificate

TUVRheinland

Hot Rolled Products of Structural Steels

Quality Assurance System For Manufacturer of Materials

EN 10025-1:2004

EN 764-5, para. 4.2

0035-CPD-A254

01 202 ROK/Q-10 0044

-

EN 10025-2:2004

EN 10025-3:2004

EN 10025-3:2004

S235JR, S235JO, S235J2, S275JR, S275JO, S275J2S355JR, S355JO, S355J2, S355K2

S275N, S275NLS355N, S355NL

S275M, S275MLS355M, S355ML

certification no. standard grade Process Thickness date

● en

Thin plate, TMCP Narrow & Short plate 28 6 34

● Order of priority

●TMCP●TMCP/N●Normalizing

classification

Construction

Plant

Line pipe

Offshore

Wind power

Shipbuilding

Welding structure

Bridge structure

Weatherable steel

Boiler

Pressure vessel (low temp)

Pressure vessel (Ni steel)

Pressure vessel (med & high temp)

API 5L (general)

API 5L (anti-corrosion)

API 2H (N)

API 2W (TMCP)

2010

HSB500/500L

SB410/450/480

SPV235/315/355A516-60,65,70A537 Cl.1

X52/56/60/65/70

2H-50

S275N,NLS355N,NLS355M,ML

A/D/EAH/DH/EH32AH/DH/EH36

SM520B/CA572-50,60A709-50, A573-70

2011

EH40

SM570TMC

HSB600

SPV410

2W-50

S420M

2012

EH47

SB480M

SLA325A

SPV490

X80

2W-60

2013

FH32/36

SMA490C

SL3N

X65

Yield strength

Tensile strength

Tensile strength

Yield strength

1st stage 2nd stagestrengths

Heavy plate High strengthLow temperature

ToughnessWeatherability/anti-corrosion

steel graDe DeveloPment Plan by stage

•Shipbuilding : E, AH/DH/EH36•Building (bridge) structure : SM520-TMC, HSB500•Pressure vessel : A516•API : 5L X52/56

•Shipbuilding : EH40, FH32/36•Building (bridge) structure : SM570-TMC, HSB600•API : 5L X70/X80, 2W-50/60•Weatherability : SMA490C, etc.

•Shipbuilding : FH40 •API : X100, X70 (Anti-corrosion) •Offshore structure: S500, YS460MPa class, etc.

1st stage2009~2010

2nd stage

2011~2013

3rd stage

2014~2016

long term steel grade Development Plan

Dongkuk steel CatalogueDangjin Works

24 25

● steel grade producible with current technology● steel grade with high demand● steel grade to be immediately replaced with tmCP. new production method at Dongkuk steel : tmCP/Heat treatment grade

● steel grade requiring intermediate technology level● steel grade requiring core strategic development

● steel grade requiring high technology level● steel grade with best technology by japanese integrated mill

A~DH36 �

A �

B �

D �

E �

AH/DH/EH32 �

AH/DH/EH36 �

EH40

A �

B �

D �

E �

AH/DH/EH32

AH/DH/EH36

SS400, 490 �

A36 �

A283-C,D �

S235JR,J0,J2 �

S275JR,J0,J2 �

S275N,NL �

S355JR,J0,J2,K2 �

S355N,NL �

SN400A,B,C, 490B,C

S420M

S355N/NL

SM400A,B,C �

SM490A,B,C �

SM490YA,YB �

SM520B,C �

SM570

A572-50/60 �

A709-50 �

A573-70 �

HSB500,500L �

HSB600,600L

ProDuCt suPPly table

● steel grade Table Ⅰ �Order placed■As-Rolled■TMCP■Normalizing

•EH40(TMCP) :

from 3Q

•AH32~EH36(Nor.) :

from 2Q

•HSB600, 600L :

from 2Q

•SN400 series :

from 3Q

steel grade '10.4Q '11.1Q '11.2Q

�

�

�

�

�

�

'11.3Q

�

'11.4Q

�

remarks

Ship-building

Structure

Nor.

General

Welding

TMCP

As-Rolled

ProDuCt suPPly table

A285-C �

A516-55 �

A516-60 �

A516-65 �

A516-70 �

SPV235 �

SPV315 �

SPV355 �

SPV410

A516-55-N �

A516-60-N �

A516-65-N �

A516-70-N �

A537Cl.1

SB410 �

SB450

SB480 �

API-5L-A �

API-5L-B �

API-5L-X42 �

API-5L-X46 �

API-5L-X52 �

API-5L-X56

API-5L-X60

API-5L-X65

API-5L-X70

API 2W-50

API 2H-50

ASG 250 �

ASG 300 �

ASG 350 �

CSA300W �

26

● steel grade Table Ⅱ �Order placed■As-Rolled■TMCP■Normalizing

•A537 Cl.1 (Nor.) :

from 2Q

•API 2W/2H 50 :

from 2Q

•API 5L X60/65 :

from 2Q

•API 5L X70 :

from 3Q

steel grade '10.4Q '11.1Q

�

'11.2Q

�

�

�

�

�

�

'11.3Q

�

�

'11.4Q remarks

Dongkuk steel CatalogueDangjin Works

Pressurevessel

API

Offshorestructure

Aus.

Can.

As-Rolled

TMCP

TMCP

Nor.

General

Boiler

business netWork

27

● domestic ● Overseas ● sales department

www.dongkuksteel.com/eng

overseas sales team 1Phone : 82-2-317-1280

Fax: 82-2-317-1397

e-mail: [email protected]

overseas sales team 2Phone : 82-2-317-1262

Fax: 82-2-317-1397

e-mail: [email protected]

overseas sales team 3Phone : 82-2-317-1060

Fax: 82-2-317-1397

e-mail: [email protected]

overseas business teamPhone : 82-2-317-1181

Fax: 82-2-317-1397

e-mail: [email protected]

Plate sales team kim ju-Ho

Phone : 82-2-317-1321

Fax: 82-2-317-1398

e-mail: [email protected]

sHiPbuilDing anD marine engineering Plate sales team jeoung Tae-Un

Phone : 82-2-317-1241

Fax: 82-2-317-1398

e-mail: [email protected]

Plate sales strategy team Lee Yun-ro

Phone : 82-2-317-1270

Fax: 82-2-317-1398

e-mail: [email protected]

DemanD generation team kim seon-Hoi

Phone : 82-2-317-1361

Fax: 82-2-317-1398

e-mail: [email protected]

HeaD oFFiCeFerrum Tower, 66 Suha-dong, Jung-gu,

Seoul, Korea

Phone : 82-2-317-1114

Fax : 82-2-317-1391

inCHeon Works1 Songhyeon-dong, Dong-gu,

Incheon, Korea

Phone : 82-32-830-6216

Fax : 82-32-830-6902

Dangjin Works400, Hanjin-ri, Songak-eup,

Dangjin-gun, Chungnam, Korea

Phone : 82-41-351-4611

Fax : 82-41-351-4691

PoHang Works880, Songdong-ri, Daesong-myun, Nam-gu,

Pohang, Korea

Phone : 82-54-278-6111

Fax : 82-54-271-5301

busan Works370-97 Shinpyeong-dong, Saha-gu,

Busan, Korea

Phone: 82-51-294-2133

Fax : 82-51-220-3010

los angeles branCH DONGKUK INTERNATIONAL, INC.

19750 Magellan Drive Torrance, CA.

90502, U.S.A.

Phone: 1-310-523-9595

FAX : 1-310-523-9599

neW york oFFiCe DONGKUK INTERNATIONAL, INC.

400 Kelby Street, 11th Floor, Fort Lee,

NJ 07024, U.S.A

Phone : 1-201-592-8600

FAX : 1-201-947-3999

tokyo branCHDONGKUK CORPORATION

7Floor, Seika Building 2-7-6,

Kayaba-cho, Nihonbashi Chuo-Ku,

Tokyo 103-0025, Japan

Phone : 81-3-5623-5723

FAX : 81-3-5623-5722

sHangHai rePresentative oFFiCeDONGKUK STEEL MILL CO., Ltd.

SHANGHAI REPRESENTATIVE OFFICE

Rm.2306, Sheng Gao International

Building, No.137, Xian Xia Road,

Shanghai, China

Phone : 86-21-6229-0114

FAX : 86-6229-0221

rio De janeiro oFFiCeCSP(Companhia Siderúrgica do Pecém)

Praia de Botafogo - 440 - 21º Andar-

Botafogo - Rio de Janeiro - Brazil

Phone : 55-21-2169-8988

FAX : 55-21-2169-8951