Curtain Wall 50 Mm

Click here to load reader

-

Upload

jacob-priyadharshan -

Category

Documents

-

view

1.103 -

download

121

description

Transcript of Curtain Wall 50 Mm

-

CURTAIN WALL 50MM

-

All rights reserved.No part of this publication maybe reproduced, stored in a retrieval system or transmitted in any form or by any

means electronic, mechanical, photocopying, recording or otherwise, without prior permission of Gulf Extrusions.

04-2012-V.01

-

CURTAIN WALL 50MM

50 - C INTRODUCTION TO THE SYSTEM

50 - B QUALITY AND CERTIFICATIONS

50 - D PROFILES

50 - E PROFILE LIST

50 - F ACCESSORIES

50 - G ASSEMBLY DRAWINGS

50 - H 3D SECTIONS

50 - A GULF EXTRUSIONS

10

04 - 09

11 - 36

37 - 49

51 - 53

55 - 79

81 - 84

03

-

Gulf Extrusions Co. LLC, the flagship company of the Al Ghurair Group of Companies, was founded in 1978, Dubai, UAE where it has over the years earned the reputation known as one of the most innovative and reliable companies in the Middle East.

Located close to its raw material supplier Dubai Aluminium Company Ltd (DUBAL), the worlds largest single smelter site, Gulf Extrusions has become one of the largest extrusion plants in the region.

Gulf Extrusions quality products can be seen in many of todays progressive structures. The company was formed with the sole purpose to meet the increasing demands for aluminium extrusions in domestic, regional and international markets.

Gulf Extrusions six presses and highly skilled workforce are able to produce 65,000 metric tonnes per annum with a rated capacity of 24,000 tonnes for powder coated finish, 6,000 tonnes for anodized finish and can offer more than 10,000 profile designs. These extrusions cover numerous industries ranging from architectural to transportation, engineering to structural sections, components for household items, HVAC and customized products.

During the progressive stages of Gulf Extrusions, from its inception to expansion, the company not only has acquired a majority share in the local market, it has also made its presence felt globally throughout the GCC countries, Indian sub -continent, South East Asia, Australia, Africa, Europe and Canada.

Our commitment and utmost priority is to provide customers with the finest quality of aluminium extrusions.

Gulf Extrusions looks ahead to inevitable challenges and product advancements of the new era.

GULFEXTRUSIONS

03

GULF EXTRUSIONS 50-A

-

QUALITY STANDARD & CERTIFICATIONS50-B

04

Quality is an inseparable element of all activities carried out at Gulf Extrusions. Gulf Extrusions is dedicated to respond and deliver on time, high quality, tailor-made and cost effective products. The management and staff are committed to implement a comprehensive and integrated Quality Management System in accordance with the International Quality Standards of ISO 9001 and ISO 14001.

PRODUCT QUALITY CERTIFICATES

Qualicoat (European Powder Coaters Association): A quality label for coating on metal for Architectural Applications A product license under the control of EWAA (European Wrought Aluminium Association) in Zurich Switzerland

Qualanod (European Anodizers Association): A quality label organization to guarantee high quality Aluminium Anodizing. A product license under the control of EWAA (European Wrought Aluminum Association) in Zurich Switzerland

SASO

ESMA

Management: ISO 9001 (Quality Management System)

Environment: ISO 14001 (Environment Management System)

Membership in International Organization: AAC member (Aluminium Anodizers Council - USA) AEC member (Aluminum Extruders Council - USA) DIN EN 15088

Anodizing Finish:

BS EN 12373-1 2001 Clause 7 (BS:6161 Part 6) BS:3987 Clause 2, 3, 5, 6 Appendix- A, B, C, D, E, F, G, H, J, K, L Minimum Film Thickness- 16 Microns

Powder Coated Finish:

BS:6496 Clause: 10.4, 10.5, 10.6, 10.7 & 10.8 ISO 2360 / 2813 / 2409 / 2931 Minimum Film Thickness 60 Microns

Extrusions Dimensions Tolerances:

BS EN 755 - 9:2008 BS EN 12020 - 2:2008 DIN 1748, DIN 17615 ASTM B221

INTERNATIONAL STANDARD COMPLIANCE

-

QUALITY STANDARD & CERTIFICATIONS

ALLOY 6005A

Element Minimum Maximum

Si 0.50 0.90

Fe - 0.35

Cu - 0.30

Mn - 0.50

Mg 0.40 0.70

Cr - 0.30

Zn - 0.20

Ti - 0.10

Other Each - 0.05

Other Total - 0.15

Aluminium Remainder

ALLOY 6063

Element Minimum Maximum

Si 0.20 0.60

Fe - 0.35

Cu - 0.10

Mn - 0.10

Mg 0.45 0.90

Cr - 0.10

Zn - 0.10

Ti - 0.10

Other Each - 0.05

Other Total - 0.15

Aluminium Remainder

ALLOY 6061

Element Minimum Maximum

Si 0.40 0.80

Fe - 0.70

Cu 0.15 0.40

Mn - 0.15

Mg 0.8 1.20

Cr 0.04 0.35

Zn - 0.25

Ti - 0.15

Other Each - 0.05

Other Total - 0.15

Aluminium Remainder

ALLOY 6060

Element Minimum Maximum

Si 0.30 0.60

Fe 0.10 0.30

Cu - 0.10

Mn - 0.10

Mg 0.35 0.60

Cr - 0.05

Zn - 0.15

Ti - 0.10

Other Each - 0.05

Other Total - 0.15

Aluminium Remainder

ALLOY 6082

Element Minimum Maximum

Si 0.70 1.30

Fe - 0.50

Cu - 0.10

Mn 0.40 1.00

Mg 0.60 1.20

Cr 0.04 0.15

Zn - 0.20

Ti - 0.10

Other Each - 0.05

Other Total - 0.15

Aluminium Remainder

CHEMICAL COMPOSTIONS

05

50-B

-

ANODIZING

A wide range of anodizing treatment options are possible for the aluminium profile sections of this system. The color choices from Gulf Extrusions range from Natural, Gold, and Bronze to Spectro colors (Red, Blue, Green, and Gray).

This surface treatment process involves first pre-treatment with scotch brite brushing for the unfinished profiles, and then subsequently fully immersing the aluminium profiles in an acidic electrolyte solution through which electric current is passed creating an anodic film on the profiles ranging from 5-30MICs.

The process is guaranteed and certified for use by QUALANOD - A quality label Organization to guarantee high quality aluminium anodizing and the companys ISO 9001 certification.

QUALITY STANDARD & CERTIFICATIONS50-B

06

-

Authorization to use the quality sign

QUALITY STANDARD & CERTIFICATIONS

07

50-B

-

POWDER COATING

Horizontal & Vertical Powder coating lines with an Annual Capacity of 24 000 MT Powder Coating BS: 6496 Clause: 10.4, 10.5, 10.6, 10.7, & 10.8 ISO 2360/2813/2409/2931 Minimum Film Thickness - 60 Microns

A wide choice of colors for powder coating can be used for the aluminium profile sections.

From Gulf Extrusions the following powder types are available

Polyester Faade (PE-F) Super Durable Faade (SDF) & Hyper Durable Faade (HDF) (Where SDF & HDF are equivalent to Poly-Vinyldine DiFluoride (PVDF) in terms of corrosion performance) Anti Bacterial (recommended to be used in Hospitals) Anti Static (recommended for laboratories, electronics assembly buildings) and Heat Resistant in nature.

This surface treatment process involves the following pre-treatment

1. Degreasing2. Washing3. Etching4. Washing5. Chromatising6. Double washing in dematerialized water

Once completed, powder is applied using an electrostatic spraying process with charged powder particles, followed by curing in an oven under a controlled temperature of 180-200C for paint polymerization where the paint layer is at least 60mic.

This whole process is certified for use from QUALICOAT - A quality label for coating on metal for Architectural Applications.

GUARANTEE PERIOD:10 years for PE-F Quality25 years for PE-SDF

QUALITY STANDARD & CERTIFICATIONS50-B

08

-

Authorization to use the quality sign

QUALITY STANDARD & CERTIFICATIONS

09

50-B

-

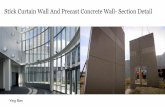

CW 50 is a unique curtain wall structure that combines multi-structural grid to create various aspects, starting by the conventional curtain wall system passing through the two way horizontal capping curtain wall systems to the four way structural curtain wall systems.

CW 50 has proven to be a curtain wall solution perfectly tailored to the Middle East market requirement.

FEATURES:

The CW 50 system consists of 50mm width structure components allowing several external appearances. It is fast to manufacture and to install. With the wide range of profile selection, the system can provide the possibility of large glass panels, maintaining the stiffness and rigidity of the curtain wall structure. Mullions can be reinforced by Aluminium or Steel tubes to enhance the free span area, making it possible to be used in high structures. In CW 50 system, Casements are Italian openings with selected stay arms to ensure the tightness and stability of the opening.

CW 50 uses the same structures for multifunctional applications: Conventional application is obtained by applying horizontal and vertical caps, clipped to horizontal and vertical pressure plates screwed to the structure holding the glass panels. Two EPDM gaskets, one to the inside fixed on the structure, the second to the outside fixed on the pressure plate; provide the grip on the glass panels. Glass thickness ranges between 6mm 32 mm

Two way or horizontal capping application is obtained by applying horizontal caps only, clipped to a horizontal pressure plate screwed to the structure and holding the glass panels. Two EPDM gaskets applied horizontally one to the inside fixed to the structure; the second to the outside fixed to the pressure plate provide the grip on the glass panels. Vertically only a vertical sealant is applied between the glass panels for aesthetic and water tightness Glass thickness ranges between 6mm 32mm

Four way structural aspects is a curtain wall aspect which conceals that conceals the aluminium structure from the outside making it completely invisible. Concealed openings are designed in order to keep the external appearance of the structure uniform even in the presence of the opening. The four way structural applications is obtained by fixing a glass toggle to the glass holding the panel by a specially designed aluminium spacer, well sealed by a structural sealant to ensure the rigidity of panel. The space between glass panels is sealed by a neutral sealant for aesthetic and water tightness purposes; this application is the most common application in the MENA region. Glass thickness is of 32 mm if panel is composed of Xmm inside- 20 mm airspace-8 mm outside the glass thickness can vary if we change the outer glass thickness uniformly on the faade.

INTRODUCTION TO THE SYSTEM50-C

10

INTRODUCTION TO THE SYSTEM

-

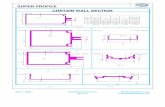

PROFILES

PROFILES

11

50-D

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES50-D

12

Mullion / Transom Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES

13

50-D

Mullion / Transom Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES50-D

14

Complementary Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES

15

50-D

Complementary Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES50-D

16

Frame & Sash Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES

17

50-D

Frame & Sash Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES50-D

18

Mullion / Transom Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES

19

50-D

Mullion / Transom Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES50-D

20

Mullion / Transom Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES

21

50-D

Mullion / Transom Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES50-D

22

Mullion / Transom Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES

23

50-D

Mullion / Transom Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES50-D

24

Complementary Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES

25

50-D

Frame & Sash Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES50-D

26

Corner Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES

27

50-D

Corner Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES50-D

28

Mullion / Transom Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES

29

50-D

Mullion / Transom Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES50-D

30

Mullion / Transom Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES

31

50-D

Mullion / Transom Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES50-D

32

Mullion / Transom Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES

33

50-D

Complementary Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES50-D

34

Complementary Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES

35

50-D

Complementary Profiles

-

All dimensions in mm _ _ _ _ _Visible area

PROFILES50-D

36

Complementary Profiles

-

PROFILE LIST

PROFILE LIST

37

50-E

-

ProfileReference

Profile Section Page WeightKG/MIX

cm4IY

cm4WXcm3

WYcm3

PROFILE LIST50-E

38

1.485

1.976

2.387

2.990

1.705

2.091

0.278

24.082

73.03

147.08

231.35

58.295

118.21

0.098

17.332

26.872

34.591

45.895

9.723

12.461

3.204

7.303

15.145

23.636

33.462

12.511

19.645

0.101

6.933

10.749

13.837

18.358

5.797

7.536

1.281

13795

13794

13940

16441

15125

15126

11069

12

12

12

13

13

13

14

-

ProfileReference

Profile Section Page WeightKG/MIX

cm4IY

cm4WXcm3

WYcm3

PROFILE LIST

39

50-E

0.297

0.438

0.421

0.364

0.386

1.503

0.365

0.176

0.091

0.989

0.441

0.725

7.341

0.371

3.834

3.604

6.066

4.951

5.164

15.465

0.337

0.149

0.126

0.537

0.294

0.436

2.991

0.349

1.533

1.476

2.426

1.980

1.953

6.951

0.435

11525

11388

11581

11872

11582

11359

11472

14

14

14

14

14

12

15

-

ProfileReference

Profile Section Page WeightKG/MIX

cm4IY

cm4WXcm3

WYcm3

PROFILE LIST50-E

40

0.213

0.257

0.386

0.456

0.519

0.331

0.454

0.314

0.181

0.726

0.180

0.284

0.070

0.234

0.197

0.812

1.368

0.811

0.802

0.695

0.775

0.255

0.215

0.735

0.197

0.281

0.102

0.249

0.303

0.459

0.676

0.531

0.500

0.483

0.483

10529

11618

24372

21926

23389

21074

11434

15

15

16

15

15

15

15

-

ProfileReference

Profile Section Page WeightKG/MIX

cm4IY

cm4WXcm3

WYcm3

PROFILE LIST

41

50-E

0.541

0.167

1.763

2.005

2.656

0.752

1.226

0.572

0.130

54.465

76.781

122.01

16.516

21.987

2.583

0.187

17.939

22.899

31.553

1.945

8.809

0.649

0.185

11.926

14.347

20.75

4.489

6.218

1.244

0.170

7.175

9.160

12.621

0.809

3.238

11956

21073

13547

14496

15625

10744

13213

15

15

18

18

18

17

17

-

ProfileReference

Profile Section Page WeightKG/MIX

cm4IY

cm4WXcm3

WYcm3

PROFILE LIST50-E

42

1.242

1.323

0.560

0.740

3.642

2.470

0.436

24.125

31.25

4.926

5.962

434.51

139.1

0.084

9.744

11.10

1.563

2.059

53.26

31.381

3.463

5.157

6.417

1.895

2.451

47.42

21.688

0.124

3.663

4.391

0.665

0.859

21.303

12.552

1.486

13913

13212

22405

15907

13938

13939

11414

17

17

16

16

19

19

24

-

ProfileReference

Profile Section Page WeightKG/MIX

cm4IY

cm4WXcm3

WYcm3

PROFILE LIST

43

50-E

0.433

2.604

2.315

3.322

1.567

3.042

2.646

0.974

75.164

67.253

150.51

35.182

143.10

123.71

6.349

25.136

22.159

32.953

14.509

32.482

28.184

0.560

16.525

14.516

25.634

9.031

25.547

22.111

2.537

10.055

8.863

13.181

6.671

12.993

11.274

11415

12388

13674

12748

12785

13255

13661

24

20

20

21

21

22

22

-

ProfileReference

Profile Section Page WeightKG/MIX

cm4IY

cm4WXcm3

WYcm3

PROFILE LIST50-E

44

3.651

2.067

0.389

0.344

0.642

0.239

0.259

295.39

104.79

0.531

0.228

0.225

0.243

0.382

43.146

22.29

5.580

4.575

4.999

0.253

0.289

41.195

18.5

0.366

0.198

0.311

0.209

0.288

17.258

10.25

2.232

1.830

2.127

0.335

0.382

12387

12665

09719

10178

09718

09723

10260

23

23

24

24

24

24

24

-

ProfileReference

Profile Section Page WeightKG/MIX

cm4IY

cm4WXcm3

WYcm3

PROFILE LIST

45

50-E

1.615

0.944

1.241

0.311

0.834

11.193

3.120

8.642

30.965

24.499

1.321

2.781

1.061

140.96

15.887

2.530

8.933

0.409

43.287

58.296

59.582

3.603

6.147

5.023

0.575

1.177

0.848

22.211

7.476

0.982

3.643

0.274

7.016

10.378

13.397

09724

11218

13640

11219

11383

11982

13824

24

25

25

25

26

26

26

-

ProfileReference

Profile Section Page WeightKG/MIX

cm4IY

cm4WXcm3

WYcm3

PROFILE LIST50-E

46

5.191

2.368

1.911

2.709

2.526

2.662

2.448

256.13

100.506

85.755

221.85

231.97

233.13

135.22

256.13

29.378

26.523

37.915

36.391

34.8

29.222

36.711

18.516

16.171

30.67

29.66

29.528

20.807

36.711

11.351

10.605

15.166

14.556

13.919

11.685

13823

13880

13881

13871

13872

13785

13788

27

28

28

29

29

30

30

-

ProfileReference

Profile Section Page WeightKG/MIX

cm4IY

cm4WXcm3

WYcm3

PROFILE LIST

47

50-E

3.006

3.671

2.489

2.462

2.055

2.028

0.423

375.91

313.34

146.94

140.34

109.51

104.45

0.115

41.678

42.754

34.316

33.752

10.947

10.757

3.746

41.466

38.306

21.034

20.376

15.861

15.347

0.149

16.671

17.102

13.727

13.501

6.976

6.851

1.608

13784

13787

14168

14171

14169

14170

11407

31

31

32

32

32

32

33

-

ProfileReference

Profile Section Page WeightKG/MIX

cm4IY

cm4WXcm3

WYcm3

PROFILE LIST50-E

48

0.391

0.523

0.315

1.523

2.313

2.777

1.123

0.602

0.138

0.200

12.280

65.674

46.122

8.022

5.557

4.227

3.903

14.268

26.89

59.212

13.765

0.433

0.168

0.182

5.626

11.615

10.188

3.119

2.223

1.691

1.561

6.341

6.172

12.464

3.494

11408

11346

11347

13786

11348

11349

11350

33

33

33

33

34

34

35

-

ProfileReference

Profile Section Page WeightKG/MIX

cm4IY

cm4WXcm3

WYcm3

PROFILE LIST

49

50-E

1.004

4.655

4.312

1.768

1.133

2.516

97.529

--

--

--

18.922

295.477

--

--

--

1.285

17.859

--

--

--

4.850

35.815

--

--

--

11354

11274

10296

09458

10682

35

36

36

36

36

-

ACCESSORIES

ACCESSORIES

51

50-F

-

Gasket / Accessories Reference

Section Description Unit

ACCESSORIES50-F

52

Linear Meter

Linear Meter

Linear Meter

Linear Meter

Linear Meter

Linear Meter

Linear Meter

Linear Meter

GE-G-034

GE-G-021

GE-G-048

GE-G-047

GE-G-055

GE-G-033

GE-G-039

GE-G-015

EPDM RUBBERUSED WITH SASH

13212

EPDM RUBBERUSED WITH FRAME

EPDM RUBBERUSED WITH FRAME

EPDM RUBBER USEDWITH

MULLION / TRANSOM

EPDM RUBBERUSED WITH

PRESSURE 801203

EPDM RUBBER USEDWITH

MULLION / TRANSOM

EPDM RUBBERUSED WITH FRAME

& SASH

EPDM RUBBER USED WITH

MULLION / TRANSOM

-

Gasket / Accessories Reference

Section Description Unit

Linear Meter

Linear Meter

Piece

Piece

GE-G-056

GE-G-060

GE-LOCKING SYSTEM

GE-STAY ARM

EPDM RUBBER FOROPENING USED WITHMULLION / TRANSOM

LOCKING SYSTEM

FRICTION STAY ARM

EPDM RUBBER FORTRANSOM COVER CLIP

ACCESSORIES

53

50-F

-

ASSEMBLY DRAWINGS

ASSEMBLY DRAWINGS

55

50-G

-

ASSEMBLY DRAWINGS50-G

56

All dimensions in cross sections are shown in mmProfile are not necessarily shown to scale

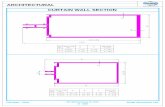

50mm 4-way Structural Glazing

-

Detail - 1

ASSEMBLY DRAWINGS

57

50-G

50mm 4-way Structural Glazing

All dimensions in mm

-

ASSEMBLY DRAWINGS50-G

58

Detail - 250mm 4-way Structural Glazing

All dimensions in mm

-

Detail - 3

ASSEMBLY DRAWINGS

59

50-G

50mm 4-way Structural Glazing

All dimensions in mm

-

ASSEMBLY DRAWINGS50-G

60

Detail - 450mm 4-way Structural Glazing

All dimensions in mm

-

Detail - 5

ASSEMBLY DRAWINGS

61

50-G

50mm 4-way Structural Glazing

All dimensions in mm

-

ASSEMBLY DRAWINGS50-G

62

Detail - 650mm 4-way Structural Glazing

All dimensions in mm

-

ASSEMBLY DRAWINGS

63

50-G

50mm 4-way Structural Glazing

All dimensions in mm

-

ASSEMBLY DRAWINGS50-G

64

50mm 2-way Structural Glazing

All dimensions in cross sections are shown in mmProfile are not necessarily shown to scale

-

Detail - 1

ASSEMBLY DRAWINGS

65

50-G

50mm 2-way Structural Glazing

All dimensions in mm

-

ASSEMBLY DRAWINGS50-G

66

Detail - 250mm 2-way Structural Glazing

All dimensions in mm

-

Detail - 3

ASSEMBLY DRAWINGS

67

50-G

50mm 2-way Structural Glazing

All dimensions in mm

-

ASSEMBLY DRAWINGS50-G

68

Detail - 450mm 2-way Structural Glazing

All dimensions in mm

-

Detail - 5

ASSEMBLY DRAWINGS

69

50-G

50mm 2-way Structural Glazing

All dimensions in mm

-

ASSEMBLY DRAWINGS50-G

70

Detail - 650mm 2-way Structural Glazing

All dimensions in mm

-

ASSEMBLY DRAWINGS

71

50-G

50mm 2-way Structural Glazing

All dimensions in mm

-

ASSEMBLY DRAWINGS50-G

72

50mm Conventional

All dimensions in cross sections are shown in mmProfile are not necessarily shown to scale

-

Detail - 1

ASSEMBLY DRAWINGS

73

50-G

50mm Conventional

All dimensions in mm

-

ASSEMBLY DRAWINGS50-G

74

Detail - 250mm Conventional

All dimensions in mm

-

Detail - 3

ASSEMBLY DRAWINGS

75

50-G

50mm Conventional

All dimensions in mm

-

ASSEMBLY DRAWINGS50-G

76

Detail - 450mm Conventional

All dimensions in mm

-

Detail - 5

ASSEMBLY DRAWINGS

77

50-G

50mm Conventional

All dimensions in mm

-

ASSEMBLY DRAWINGS50-G

78

Detail - 650mm Conventional

All dimensions in mm

-

ASSEMBLY DRAWINGS

79

50-G

50mm Conventional

All dimensions in mm

-

3D SECTIONS

3D SECTIONS

81

50-H

-

50mm Mullion / Transom

3D SECTIONS50-H

82

-

50mm Curtain Wall

3D SECTIONS

83

50-H

-

50mm Curtain Wall

3D SECTIONS50-H

84

-

All rights reserved.No part of this publication maybe reproduced, stored in a retrieval system or transmitted in any form or by any

means electronic, mechanical, photocopying, recording or otherwise, without prior permission of Gulf Extrusions.

-

P.O.Box-5598, Dubai, United Arab Emirates Tel: +971 4 884 6830 Email: [email protected] Visit us at www.gulfex.com