Curtain Wall Engineering

-

Upload

bryan-datiles -

Category

Documents

-

view

205 -

download

10

Transcript of Curtain Wall Engineering

Curtain Wall Engineering

CE426: Final Report Jack Greenberg

May 6, 2011

Jack Greenberg 5/6/2011

Curtain Wall Engineering

The curtain wall is an important development of the 20th century that allowed for taller,

economical and efficient construction of buildings. Concisely, a curtain wall is an exterior non‐

load‐bearing wall supported by the structural formwork of a building.1 A curtain wall, which

connects to the structure of the building, is constructed merely to support its own dead weight,

transferring vertical gravity and horizontal wind loads to the building structure. Curtain walls

have become the norm for building erection, finding application in most buildings that are

constructed today. However, curtain wall construction is not actually a new invention; rather, it

had existed unnamed for centuries. The Greeks and Romans had developed a rudimentary

version of modern curtain walls using nonbearing fills such as brick, stone or concrete inside

post‐and‐lintel constructed frames. Likewise, medieval cathedrals employed similar

construction, with columns supporting arches that contained curtain walls of stained glass.2

On a widespread level, curtain wall systems replaced the conventional building

technology of bearing walls. As opposed to curtain walls, bearing walls are structural elements

of buildings, supporting the actual weight of the building. The invention of steel and concrete

framing allowed for the development of curtain wall technology because building materials

became strong enough to carry the entire load of the building, no longer needing exterior

bearing walls for support. The old masonry bearing walls used to construct older buildings

1 Donaldson, Barry. Exterior Wall Systems: Glass and Concrete Technology, Design, and Construction. 2 Hunt, William Dudley. The Contemporary Curtain Wall.

2

Jack Greenberg 5/6/2011

needed to be enormous to support the loads of the floors above, especially for tall buildings

where some walls could be as wide as six feet or more. Therefore, curtain walls have provided

an important alternative to bearing wall construction because it enabled the reduction of the

size of the exterior wall to a mere three inches, saving time, space and money for developers

and allowing the construction of high‐rise buildings.

This relatively new wall system lends itself very well to modern practices of

prefabrication and mass production allowing for economy and flexibility in the design. The main

drawback of constructing a curtain wall is the difficulty in connecting the wall to the structural

elements of the building which is easily achieved in bearing wall design since the wall is actually

part of the structure. Nevertheless, the curtain wall’s advantages also include a reduced weight,

customizable appearance, and faster, more efficient erection making it the most viable option

for buildings.

The curtain wall functions as a filter for the elements, fire, people, animals, sounds

odors, and anything else that might pass into or out of a building. The difficulty in designing a

curtain wall is integrating the sometimes conflicting individual functions the wall must provide

for the building. For example, controlling the condensation that appears upon the glazing

usually complicates the protection against precipitation. Therefore, throughout the entire

process of design, careful thought and consideration goes into the formation of each element in

the curtain wall.

Curtain walls are generally composed of several basic elements, not limited to but

including the fill or panel, joints, vapor barrier, backing and insulation. However, some curtain

3

Jack Greenberg 5/6/2011

walls don’t contain all of these elements such as aluminum framed curtain walls that don’t

contain a concrete masonry unit backing. Additionally, curtain wall elements are composed of

different materials, varying in shape and size.

Probably the most difficult elements of the curtain wall to design are the joints that

connect the curtain wall. One of the things that a curtain wall is most susceptible to is water

leakage. Porous materials such as stone and masonry, allow water to be siphoned through their

surfaces to the inside.3 Nevertheless, the critical location of water entry though curtain walls is

at the joints of the façade. The design of the joint is complicated for curtain walls since the joint

invariably becomes the flexible link in the wall. It must be weather‐tight, yet free to vary its

dimensions with changes in temperature. It must protect against rain while allowing

condensation to bleed off. There are vast numbers of joints in the façade making it an even

greater design challenge for engineers.

Besides for precipitation protection, control against condensation is important for

maintaining clear windows and for maintaining the integrity of the insulation of the wall. A

vapor barrier is constructed to allow the little water that inevitably enters the building to return

the atmosphere. In many curtain wall designs, this provision consists of opening or weeps holes

in the base of the unit. Weep holes are difficult to design because they can actually have

negative effects on the building if it is not designed properly. If the weep holes are not large

enough they can become ineffective since grime and dirt could potentially clog them.

Additionally, if the weep holes are too large or are placed to frequently throughout the façade,

water can enter the building more easily, defeating the purpose of the holes. Similarly, the 3 Hunt, William Dudley.

4

Jack Greenberg 5/6/2011

vapor barrier needs to be wide enough to allow room for the deflection of the panels spanning

across the wall without commandeering too much of the space of the building.4

The panels and glazing that span across the building are elements that cover a majority

of the building envelope. The critical design challenge in these elements is the large surface

area they possess. Probably most importantly, the material chosen for the panel and glazing

greatly influences the thermal properties of the curtain wall. Among the biggest concerns in

curtain wall design is adequate temperature control. The various types of panels and glazing

can have large implications in the money spent on cooling and heating in the building.

Additionally, fire protection is controlled by the effectiveness of the panels and glazing. The wall

must not allow fires to spread from one building to another or allow fires to spread to different

floors of the building. Masonry materials slow down the rate of heat transfer by using a large

amount of heat to evaporate the water contained in their physical or chemical composition,

offering an excellent source of fire protection. Large amounts of heat can be stored in the mass

of masonry, enabling it to withstand exposure to fire for a longer period of time before the

opposite wall face temperature rises appreciably.5

Panels and glazing must also withstand stresses caused by the building movement

resulting from expansion or contraction, or lateral loading from earthquakes and hurricanes.

This is much greater than the dead load of the panels which is usually much smaller in

comparison. Nevertheless, structurally, the design of a curtain wall hinges on the effectiveness

of the sealant and the connection to the structural framing.

4 Hunt, William Dudley. 5 Hunt, William Dudley.

5

Jack Greenberg 5/6/2011

The adhesive used to fix the glass of curtain walls in place is a silicone elastomeric

sealant. Silicone sealants used in structural glazing vary as to type and usage, however the main

properties are generally that they are little affected by ultraviolet light, can bond reliably to

glass and aluminum and have a sufficient elasticity to accommodate thermal expansion and

structural movements. The structural adhesive joint design requires engineering analysis,

considering the strength of the sealant in tensile adhesion, shear adhesion, cohesion and

movement capability, the geometry of the sealant in contact width and thickness and the

imposed loads on the sealant. The silicone adhesive must be sized to carry all forces and

accommodate all movements without over stressing it. Additionally, the system must drain

water from the seals and should be capable of being retrofitted with new glazing for when the

glass breaks. At the start of large scale curtain wall glazing construction, the use of sealant was

an uncertain for many engineers since all of silicone’s material properties had not been fully

researched. Safety factors of greater than six were not uncommon among designs. However, as

the material science and research developed, creative and less overdesigned techniques were

used in the construction using the sealant. Thus, developments such as structural glazing

spacers mitigated the structural progressive collapse failure of the curtain wall.6

All structures whether steel or concrete will transfer movement to the building façade

due to thermal expansion and contraction of the materials supporting a building. Steel

structures are more generally more flexible than concrete and will apply forces to the façade in

its movement. However, concrete structures also impart movement to the exterior wall due to

6 Donaldson, Barry.

6

Jack Greenberg 5/6/2011

long term shrinkage. Therefore, wind, earthquake and other lateral loads imposed on buildings

make it critical for engineers to carefully design exterior walls to handle these dynamic forces.

There are several types of curtain wall systems that are currently employed in the

construction of buildings. The most common include conventional masonry, panelized wall

systems and aluminum framed curtain walls. However, there are many more and different

types of exterior wall systems that are used in buildings because curtain walls by definition

include any type of non‐bearing wall. The different techniques used to clad a building are

usually architecturally driven, each giving a different look and feel to the building. Nevertheless,

as the economy, energy and functionality of buildings becomes a dominating role in design,

exterior systems are more engineering driven, with each type of façade having unique qualities

that is advantageous for different design criteria.

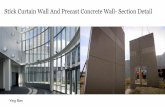

Conventional masonry exterior wall systems consist of a brick or stone façade,

supported by concrete masonry unit backing. These types of wall systems are typically well

suited for buildings that require various non‐uniform wall openings throughout the facade.

Therefore its application is most resonant with residential design methods since residential

buildings are typically not repetitive horizontally. The usage of the floor space in residential

buildings varies much more than floor space in office buildings requiring varied window

openings in the façade. Masonry is ideal for this type of building because its small elemental

size can adapt easily, enabling these openings better than aluminum or glass systems.

7

Jack Greenberg 5/6/2011

Panelized exterior wall systems consist of prefabricated or factory‐manufactured panels

that form a structural envelope.7 The building panels are best and economically manufactured

uniformly; therefore, unlike the conventional masonry façade, they are unsuitable for small

varied openings in the façade. However, panelized wall systems are typically well suited for

large buildings with a repetitive façade design because they can be systematically installed for

quick construction of a building.

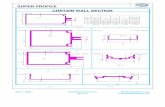

Similar to panelized systems, the aluminum framed curtain wall is a system which

contains panels. In this scheme, the mullions are installed first, and then the panels, usually

made of glass, are inserted into the mullion framing in the field.8 This exterior cladding is well

suited for large uniform buildings because it too is prefabricated and can be systematically

installed into buildings. However, it is economically more flexible than panelized systems and is

even suitable for smaller construction projects as well.

In addition to the function of the building, other qualities of a building that are

important in determining an appropriate façade include the structural framing of the building.

Since the façade of a curtain wall is not a bearing member, it must be attached to the framing

of the building for support. The connection between the façade and the structure can vary

based on the type of façade and structural system used. Concrete structural systems generally

lend themselves to simple connections between all types of curtain walls because of its

customizable shapes and sizes; whereas, steel framing’s less customizable form can at times

make it difficult to join with the exterior curtain wall. This is the most important implication of

7 NAHB Research Center. "Design, Fabrication, and Installation of Engineered Panelized Walls: Two Case Studies." 8 Stuart, Matthew, P.E., S.E., F.ASCE. "Curtainwall Primer for Design Professionals ‐ An Online Course for Engineers and Architects."

8

Jack Greenberg 5/6/2011

choosing an appropriate curtain wall because the detailing of the connection usually dictates an

enormous portion of the cost of the curtain wall.9

The general properties of structural system integration with the exterior wall are

apparent in the construction of conventional masonry. Concrete structural systems typically

integrate very well with conventional masonry facades. The attachment of the masonry wall to

the concrete structure is easy because horizontal masonry ties can be fitted easily into dovetail

slots that are embedded in concrete and can also easily be cast into concrete beams or

columns. Additionally, concrete’s intrinsic ability to be formed into a variety of profiles makes it

an ideal material for interaction with masonry cladding. Steel framing, on the other hand, is not

ideal for conventional masonry cladding because the connection to the masonry wall is very

difficult.

However, panelized systems and aluminum framed curtain walls generally work well

with either system. Panelized systems as compared with conventional masonry have a vastly

different influence on the perimeter of the building structure. Generally spanning from column

to column, the points of attachment to the building structure are limited with few connections

necessary to the structure. This quality, though limiting the location of where the attachments

must be made, actually makes the number of connections much more manageable and easily

attachable to both concrete and steel framing alike. Similarly, aluminum framed curtain walls

are easily attachable to both concrete and steel systems since the aluminum shape that holds

9 Donaldson, Barry.

9

Jack Greenberg 5/6/2011

the system in place can be manufactured into complex shapes that fit into the steel and

concrete structure.10

Another important consideration in determining the type of building envelope to use is

the structural implications imposed on the building. Conventional masonry walls with concrete

masonry backing usually distribute loads evenly over the beams at the edge of the building;

however, they are usually much heavier than other types of curtain walls and can have a large

influence in the sizes of these beam members. However, gravity loads of panel systems are

generally much smaller than conventional systems and are generally self‐supporting. In

addition, the panels usually work well with buildings that contain columns at the edge of the

building. Attaching to the edge eliminates the need for the spandrel beam to resist the vertical

loads of the wall. However, when the panel is required to be tied back to the lower flange or

web of the spandrel beam, torsional loads must be factored into the structural design.11

As opposed to the plethora of types of curtain walls, there are generally two methods of

curtain wall installation, stick and unitized systems. Today, the vast majority of curtain walls

employ the use of stick system installation. Framing members, the “sticks”, are either

prefabricated or assembled on site and are first installed into the structural framing of the

building. Glazing or panels are then attached to the stick faming, completing the construction of

the wall. Although not as popular as the stick system, unitized system is an effective method of

installation that is usually most effective for large building projects. The curtain walls are

factory fabricated to include the glazing and all elements of the wall, installing only the wall in

10 Donaldson, Barry. 11 Donaldson, Barry.

10

Jack Greenberg 5/6/2011

one step into the structural framing of the buildings. Because of the control exercised in

prefabrication as opposed to field construction, unitized systems generally provide a better

quality building envelope. Although the fabrication costs are higher than stick system

installation, this method entails a lower field installation cost and are usually less expensive in

locations with high labor rates.

With the design and of construction of new buildings in the past century, curtain wall

engineering has extended to become its own field of engineering with many engineers starting

specialty firms to address the complexity of curtain wall design. Nevertheless, curtain wall

construction is still in its infancy as curtain wall systems are being developed to mitigate the

effects of temperature on heating and cooling costs of the buildings. Similarly, the

improvement of construction techniques and material installation will change the way curtain

walls are design and erected in the future.

11

Jack Greenberg 5/6/2011

12

Bibliography

Donaldson, Barry. Exterior Wall Systems: Glass and Concrete Technology, Design, and

Construction. Philadelphia, PA: ASTM, 1991. Print.

Hunt, William Dudley. The Contemporary Curtain Wall. New York: Dodge, 1958. Print.

Marshall, Richard D., and H. C. S. Thom. Proceedings of Technical Meeting Concerning Wind

Loads on Buildings and Structures: Held at National Bureau of Standards, Gaithersburg,

Maryland, January 27‐28, 1969. Washington, D.C.: U.S. Dept. of Commerce, National

Bureau of Standards, 1970. Print.

NAHB Research Center. "Design, Fabrication, and Installation of Engineered Panelized Walls:

Two Case Studies." ToolBase Services by NAHB Research Center | Home Building

Technical Information Resources Builders Construction Remodeling Innovations. U.S.

Department of Housing and Urban Development Office of Policy Development and

Research Washington, DC, Jan. 2002. Web. <http://www.toolbase.org/>.

Stuart, Matthew, P.E., S.E., F.ASCE. "Curtainwall Primer for Design Professionals ‐ An Online

Course for Engineers and Architects." Engineering Continuing Education PDH CEU for PE

LS AIA License Renewal. Web. <http://www.pdhonline.org/courses/s119/s119.htm>.

Zhou, Y. S. An Introduction to the Design of Curtain Walls, Aluminum Windows, Glass Walls,

Skylights and Canopies. Hong Kong: Wilson Curtain Wall Consultant (HK), 2002. Print.