Chapter 4 Suniya M

-

Upload

ranazikria -

Category

Documents

-

view

215 -

download

0

Transcript of Chapter 4 Suniya M

-

7/25/2019 Chapter 4 Suniya M

1/34

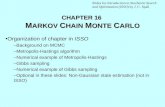

Chapter 4 Results and Discussion

4.1 Introduction

The basic aim of this research work is the preparation of magnesium iron oxide thin films by

electrodeposition route, which is more preferable over the physical methods being a simple,

fast and inexpensive technique !, "#$

%pinel ferrites are very important magnetic materials because of their interesting magnetic

properties combined with chemical and thermal stability$ &agnesium 'ron (xide, also known

as magnesium ferrite whose study has been a motivating sub)ect due to its promising

properties$ &agnesium 'ron (xide *&g+e"(4 has inverse spinel structure$ Displacing of iron

with magnesium *ionic radius of -" fm in cubic inverse spinel structure further enhances the

magnetic properties ., 4#$

'n order to produce oxide/s thin films, 'n0situ oxidation has been carried out$ (xidation time,

an important parameter in electrodeposition technique has been varied to achieve the desired

properties of magnesium iron oxide thin films$ 1 series of six samples has been prepared with!2 minutes deposition and in0situ oxidation was carried out for 2, !3, !2, "3, "2 and .3

minutes, keeping the potential difference " $ 1ll the samples were deposited at room

temperature and without magnetic stirring of electrolyte$ 'n order to investigate the properties

of samples, samples were characteri5ed using various experimental tools$ The structural and

magnetic properties were investigated by 6RD and %& respectively$ The results obtained

are discussed in the following sections$

4.2 X-Ray Diffraction Analysis

60ray diffraction was used for the structural analysis of the thin films, deposited on copper

substrate$ 7ruker D8 1dvance Diffractometer with Cu09: radiation of wavelength !$243;3 values .!$-"A, ."$"8A, 4$82A, 23$!.A, .$"2A and .$8!A,

are corresponding to *4!!, *4"3, * 6 "", *-!! and *

4 .! planes of iron oxide *+e"(.

as matched with BC=D% card no$ !;0;2.$ 1t this oxidation time magnesium ferrite compound

is poorly formed$

&$=hil$ Thesis =age 2-

-

7/25/2019 Chapter 4 Suniya M

4/34

Chapter 4 Results and Discussion

Figure 4.!'ndexed 6RD pattern of as0deposited thin film with !2 minutes oxidation$

The pattern with oxidation time of "3 minutes is shown in +igure 4$4$ 'n this pattern two

peaks of &g+e"(4appeared at "> values of 4.$!;A and -.$82A, corresponding to *433 and

*;"3 planes are matched with BC=D% card no$ !-04;$ Two peaks of iron oxide *+e "(.

appeared at "8$.-A and 23$!.A, corresponding to planes *3.! and *-!! are matched with

BC=D% card no$ !;0;2.$

&$=hil$ Thesis =age 28

-

7/25/2019 Chapter 4 Suniya M

5/34

Chapter 4 Results and Discussion

Figure 4.4'ndexed 6RD pattern of as0deposited thin film with "3 minutes oxidation$

The pattern with "2 minutes oxidation is shown in the +igure 4$2$ The diffraction peaks of

magnesium iron oxide at "> values of 4.$!;A, -.$82A and -4$!.A corresponding to *433, *2..

and *;"3 planes have appeared$ These 7ragg reflections are conspicuous and are correspond

to spinel structure$ The diffraction peaks at "> value of 23$!.A is corresponding to *-!! plane

of iron oxide *+e"(. as matched with BC=D% card no$ !;0;2.$ 1t this oxidation time

magnesium ferrite is richly formed$ The background noise and broadness of the peaks are

characteristic of particles with nanometer dimensions$ This happens because in the nano0

si5ed particles there are insufficient diffraction centers that cause the line broadening 2#$

&$=hil$ Thesis =age 2

-

7/25/2019 Chapter 4 Suniya M

6/34

Chapter 4 Results and Discussion

Figure 4."'ndexed 6RD pattern of as0deposited thin film with "2 minutes oxidation$

The pattern with oxidation time of .3 minutes is shown in +igure 4$;$ The pattern shows the

7ragg reflections peaks of &g+e"(4, appeared at "> values of 4.$!;A, .3$;3A and -4$!.A,

corresponding to *433, *""3 and *2.. planes of the spinel magnesium ferrite as matched

withBC=D% card no$ !-04;$ The diffraction peaks of iron oxide *+e "(., appeared at ."$2;A,

.$2.A and 23$!.A, corresponding to planes *4"3, * 4

.! and * 6

"" are matched with

BC=D% card no$ !;0;2.$

&$=hil$ Thesis =age ;3

-

7/25/2019 Chapter 4 Suniya M

7/34

Chapter 4 Results and Discussion

Figure 4.#'ndexed 6RD pattern of as0deposited thin film with .3 minutes oxidation$

1ll samples have shown the most preferred orientation *433 of magnesium iron oxide in

addition to its other *""3, *2.. and *;"3 prominent reflections$ ariation in oxidation time

has caused the change in the crystallinity and purity of magnesium iron oxide thin films$

&$=hil$ Thesis =age ;!

-

7/25/2019 Chapter 4 Suniya M

8/34

Chapter 4 Results and Discussion

Ta$le 4.1attice constant *a, unit cell volume *cell, crystalline si5e *D, 60ray density

*dx, dislocation density * and strain of as0deposited thin films with varying the oxidation

time$

%ample

&o.

'(idatio

n Time

)min*

+attice

constan

t

),*

nit cell

olume

),*!

X-ray

density

)g cm-!*

/rystalli

ne si0e

)nm*

Dislocatio

n density

)1(11"

m-2*

%train

)1(1-!*

! 2 8$.8 23$!; 4$23 !8$ "$-- $"4

" !3 8$.8 23$!; 4$23 !8$ "$-- $"4

. !2 8$.2 28"$!8 4$2; ".$-4 !$-- -$.8

4 "3 8$.; 28;$!; 4$2. !8$ "$-- $".

2 "2 8$.; 28;$!; 4$2. "!$3 "$3 -$

; .3 8$.2 28"$!8 4$2; !8$ "$-- $!

4.2.2 ariation in +attice 3arameter ith '(idation Time

attice parameters Ea/ for all electrodeposited thin films of cubic magnesium ferrite are

calculated using 7ragg/s equation *Fq$ 4$!$ The obtained values of lattice parameters *a for

all deposited films are in agreement with BC=D% card no$ !-04;$

a=dhklh2+k2+l2(4.1)

The trend of lattice parameter variations with oxidation time is shown in +igure 4$-$ Gith the

increase in oxidation time lattice parameter decreases$

&$=hil$ Thesis =age ;"

-

7/25/2019 Chapter 4 Suniya M

9/34

Chapter 4 Results and Discussion

Figure 4.5ariations in lattice parameter as a function of oxidation time$

4.2.! ariation in /rystallite %i0e ith '(idation TimeThe average crystallite si5e *D were determined using Debye %cherrer/s formula *Fq$ 4$"$

D= 0.9

cos *4$"

Ghere D is the average crystallite si5e of the phase under investigation, H is the wavelength

of Cu 9:used in 60ray diffraction, I the +ull width at half maxima *+GJ&, contribution to

the diffraction peak width due to small si5e of crystallites and must be taken in radians and >

is the 7ragg/s angle of diffraction 8#$

The average crystallite si5es *D of all the electrodeposited thin films with varying the

oxidation time are listed in Table 4$!$ The trend of crystallite si5e of as0deposited films with

the variation in oxidation time is shown in +igure 4$8$ The film oxidi5ed for !2 minutes has

&$=hil$ Thesis =age ;.

-

7/25/2019 Chapter 4 Suniya M

10/34

Chapter 4 Results and Discussion

shown the highest crystallite si5e, whereas the films oxidi5ed for 2, !3, "3 and .3 minutes

have shown comparatively small crystallite si5es$

Figur

e 4.6ariations in crystallite si5e with oxidation time$

4.2.4 ariation in Dislocation Density ith '(idation Time

The dislocation density indicates the amount of defects in a crystal$ 't is defined as the length

of dislocation lines per unit volume of the crystal$ 't is calculated by using the equation 4$.$

=

1

D2 *4$.

Ghere, D is crystallite si5e$ Jigher value of dislocation density indicates lower crystallinity

levels of the films ;#$ The dislocation density of all deposited thin films with varying

oxidation time is listed in Table 4$!$ The effect of oxidation time on the dislocation density is

&$=hil$ Thesis =age ;4

-

7/25/2019 Chapter 4 Suniya M

11/34

Chapter 4 Results and Discussion

shown in +igure 4$$ The small value of dislocation density and good crystallinity is obtained

in the film oxidi5ed for !2 minutes$ The value of dislocation density for the thin films

oxidi5ed for 2, !3, "3 and .3 minutes has shown the lattice distortion in the structure$ The

presence of dislocations or defects during the deposition process may be due to micro0strain

present in the film -#$

Figure 4.7ariations in dislocation density with oxidation time$

4.2." ariations in nit /ell olume ith '(idation Time

The slightly decreasing trend of unit cell volume of magnesium ferrite with oxidation time is

shown in +igure 4$!3$ &agnesium ferrite has cubic structure so its unit cell volume is )ust

cube of lattice parameter$

&$=hil$ Thesis =age ;2

-

7/25/2019 Chapter 4 Suniya M

12/34

Chapter 4 Results and Discussion

Figure 4.1ariations in unit cell volume as a function of oxidation time$

4.2.# ariation in X-ray Density ith '(idation TimeThe 60ray density of thin films was estimated using Fq$ 4$4$

=1.66042A

V (4.4)

Ghere is unit cell volume and 1 is atomic weigth of number of atoms or ions in a unit cell

8#$ (ne unit cell of magnesium ferrite has ." oxygen ions, !; ferric ions and 8 magnesium

ions$ 60ray density of all the deposited thin films is shown in Table 4$!$ The variation in x0ray

density with oxidation time is shown in +igure 4$!!$ 't approximately remains constant for all

oxidation times$ The synthesi5ed films with !2 and .3 minutes oxidation, exhibit slightly

large x0ray densities$

&$=hil$ Thesis =age ;;

-

7/25/2019 Chapter 4 Suniya M

13/34

Chapter 4 Results and Discussion

Figur

e 4.11=lot between 60ray density and oxidation time$

4.2.5 ariations in %tress8%train ith '(idation Time

The strain of the films was determined using the equation 4$2$

d

d =

2 tan *4$2

Ghere I is +ull width at half maxima *+GJ& of the peak having highest intensity and it is

taken in radians and > is the 7ragg/s angle$ The origin of the strain is also related to the lattice

mis0fit which in turn depends upon the deposition conditions #$ The trend of strain with

varying oxidation time is shown in +igure 4$!"$ The synthesi5ed film with in0situ oxidation

time of !2 minutes has shown lowest strain as compared to all the other films$ %tressKstrain

plot shows decreasing trend with increasing oxidation time$

&$=hil$ Thesis =age ;-

-

7/25/2019 Chapter 4 Suniya M

14/34

Chapter 4 Results and Discussion

Figure 4.12=lot of stressKstrain as a function of oxidation time$

4.! %9 Results of :lectrodeposited Thin Films

The magnetic properties of &g+e"(4 thin films were analy5ed using vibrating sample

magnetometer$ 1nalysis was carried out at room temperature and &0J curves of the thin

films were obtained$

&$=hil$ Thesis =age ;8

-

7/25/2019 Chapter 4 Suniya M

15/34

Chapter 4 Results and Discussion

4.!.1 9agnetic Analysis of As-deposited 9agnesium Iron '(ide Thin Films

'n0plane room temperature &0J curves for as0deposited magnesium iron oxide thin films

with varying oxygen time are shown in +igure 4$!.$ 1s0deposited films have shown a mixed

behavior i$e paramagnetic and ferromagnetic$ +erromagnetic contribution is indicated by

open loop at low field strength while paramagnetic behavior is indicated by close loop at

relatively high field$ The mixed behavior of &0J curves indicates that grains are not fully

developed as shown in 6RD patterns of as0deposited thin films$ The mixed behavior

indicates that the films require further heat treatment$

&$=hil$ Thesis =age ;

-

7/25/2019 Chapter 4 Suniya M

16/34

Chapter 4 Results and Discussion

&$=hil$ Thesis =age -3

-

7/25/2019 Chapter 4 Suniya M

17/34

Chapter 4 Results and Discussion

&$=hil$ Thesis =age -!

-

7/25/2019 Chapter 4 Suniya M

18/34

Chapter 4 Results and Discussion

Figure 4.1!&0J plots for as0deposited &agnesium 'ron oxide thin films with oxidation

time for *a 2mins *b !3mins *c !2mins *d "3mins *e "2mins *f .3mins

Fffect of oxidation time on the coercive field EJc/, saturation magneti5ation E&s/, remenant

magneti5ation E&r/ and squareness E&rK&s/ *the ratio of remenant magneti5ation to saturation

magneti5ation of as0deposited magnesium iron oxide thin films are listed in Table 4$"$ 't is

clear that the magnetic properties are changed by changing the oxidation time$

Ta$le 4.2 The variation of the Coercivity *Jc, saturation magneti5ation *&s, remanance

*&r and squareness *%L of as0deposited thin films with oxidation time$

%ample Depositio '(idation /oerciity 9agneti0atio Remananc %;uarenes

&$=hil$ Thesis =age -"

-

7/25/2019 Chapter 4 Suniya M

19/34

Chapter 4 Results and Discussion

&o. n time)min*

time)min*

1(1-!

! !2 2 ""3$2- 3$8.4-; 3$3"48 "$"8" !2 !3 44-$8! 3$-4-; 3$3";84 .2$33. !2 !2 22;$28 3$;".! 3$3";2! 4"$48;4 !2 "3 $".. 3$;!32 3$34.!2 -3$;";2 !2 "2 !.4$8 3$;"". 3$3." ;4$!4; !2 .3 !-$84; 3$;3"83 3$34;!" -;$23.

4.!.2 :ffect of '(idation on %aturation 9agneti0ation of As-Deposited

Thin Films

%aturation magneti5ation E&s/ of as0deposited &g+e"(4thin films as a function of oxidation

time is shown in +igure 4$!4$ Gith increasing oxidation time a decrease in saturation

magneti5ation is observed$ 1 maximum saturation magneti5ation E& s/ is observed at 2

minutes oxidation time$ The magneti5ation in the magnesium ferrite was derived from the site

occupancy difference of +e.Mbetween tetrahedral and octahedral sites !3#$ (n the other hand,

the presence of the iron oxide species *+e"(. may be the responsible for a retardation of the

magnetic properties$ 'n this case saturation magneti5ation is not showing increasing trend

with the increase of the crystallite si5e$

&$=hil$ Thesis =age -.

-

7/25/2019 Chapter 4 Suniya M

20/34

Chapter 4 Results and Discussion

Figure 4.14=lot of %aturation magneti5ation as a function of oxidation time$

4.!.! :ffect of '(idation on Retentiity of As-Deposited Thin Films

The effect of oxidation time on retentivity E& r/ of as0deposited thin films is shown in +igure

4$!2$ The values of retentivity vary randomly with oxidation time$ The film with 2 minute

oxidation time has shown the lowest value of remenant magneti5ation E&r/$

Figure 4.1"=lot of Retentivity as a function of oxidation time$

&$=hil$ Thesis =age -4

-

7/25/2019 Chapter 4 Suniya M

21/34

Chapter 4 Results and Discussion

4.!.4 :ffect of '(idation on /oerciity of As-Deposited Thin Films

The coercivity EJc/ of a magnetic material is usually a measure of its magneto0crystalline

anisotropy !!#$ The coercivity of as0deposited thin films as a function of oxidation time is

shown in +igure 4$!;$ Coercive field of the films was increased up to the oxidation time of !2

minute and after that trend of coercivity was decreased$ 1 large increase in the coercivity for

the sample with oxidation time 2 minute could be attributed to a high intrinsic coercive force

of iron oxide *+e"(. solid !"#$ The value of coercivity varies randomly$ This change may be

due to the low crystalline anisotropy, which arises from crystal imperfection and the high

degree of aggregation !!#$

Figure 4.1#=lot of Coercivity as a function of oxidation time$

&$=hil$ Thesis =age -2

-

7/25/2019 Chapter 4 Suniya M

22/34

Chapter 4 Results and Discussion

4.!." :ffect of '(idation on %;uareness of As-deposited Thin Films

The squareness also known as remanant ratio RN &rK&s shows the ease with which the

direction of magneti5ation reorients to the nearest easy axis direction after the field is

removed$ The small value of R indicates the isotropic nature of the sample !.#$ The

squareness of as0deposited thin films has shown almost increasing trend with increasing

oxidation time as shown in +igure 4$!-$

Figure 4.15=lot of %quareness as a function of oxidation time$

4.4 9agnetic Analysis of 9agnetically Annealed 9agnesium Iron '(ide

Thin Films

The deposited thin films of magnesium iron oxide were annealed at .33 C *in presence of

magnetic field for one hour$ &0J loops of annealed thin films were observed to show the

ferromagnetic behavior that might be expected due to the change in crystalline state of films$

&$=hil$ Thesis =age -;

-

7/25/2019 Chapter 4 Suniya M

23/34

Chapter 4 Results and Discussion

7y annealing the film with 2 minutes in0situ oxidation, still a mixed behavior wit dominant

ferromagnetic behavior was observed$ Thin film with 2 minutes oxidation showed very

different behavior than other samples, as easy axis was observed along the out0plane field as

shown in +igure 4$!8$ The difference between the &0J curves for in and out0plane field was

observed describing the uniaxial magnetic anisotropy$ The magnetic anisotropy is a factor

which strongly affects the shape of the hysteresis loop$ The magnetic properties are direction

dependent$ +or an anisotropic material the magnetic moments line up in the direction of easy

axis of magneti5ation, while in an isotropic material the magnetic moments have no preferred

direction for orientation$ Fasy axis is an energetically favorable direction of spontaneous

magneti5ation and depends on the cause to raise magnetic anisotropy$ 1nisotropy can be

magneto0crystalline anisotropy, shape anisotropy, exchange anisotropy and magneto0elastic

anisotropy$ The annealed films have shown strong ferromagnetic behavior with relatively

high value of coercivity$

&0J plot for the electrodeposited magnetically annealed thin film of in0situ oxidation of !3

minutes at potential of " is shown in +igure 4$!$ The hysteresis curves for both applied

fields perpendicular *out0plane and parallel *in0plane are not symmetric about the axis and

showed a shift on the magneti5ation axis that is because of anisotropy$ The &0J curve has

shown coercivity of 4."$.! and ;.$-. O for in0plane and out0plane respectively$

&$=hil$ Thesis =age --

-

7/25/2019 Chapter 4 Suniya M

24/34

Chapter 4 Results and Discussion

&$=hil$ Thesis =age -8

-

7/25/2019 Chapter 4 Suniya M

25/34

Chapter 4 Results and Discussion

Figure 4.16&0J curve of magnetically annealed thin film of 2 minutes oxidation$

Figure 4.17&0J curve for magnetically annealed thin film of !3 minutes oxidation$

&$=hil$ Thesis =age -

-

7/25/2019 Chapter 4 Suniya M

26/34

Chapter 4 Results and Discussion

&0J loop for the electrodeposited magnetically annealed thin film of in0situ oxidation for !2

minutes is shown in +igure 4$"3$ The &0J curve for in and out0plane has shown that & sis

larger in case of in0plane as compared to out0plane$ The in0plane &0J curve has shown

coercivity of .!;$42 O and out0plane curve shows 433$!" O$

Figure 4.2 &0J curve for magnetically annealed thin film of !2 minutes oxidation$

&$=hil$ Thesis =age 83

-

7/25/2019 Chapter 4 Suniya M

27/34

Chapter 4 Results and Discussion

Figure 4.21 &0J curve for magnetically annealed thin film of "3 minutes oxidation.

Figure 4.22 &0J curve for magnetically annealed thin film of "2 minutes oxidation.

&$=hil$ Thesis =age 8!

-

7/25/2019 Chapter 4 Suniya M

28/34

Chapter 4 Results and Discussion

&0J curves for the magnetically annealed thin film of in0situ oxidation of "3, "2 and .3

minutes have shown an enhanced ferromagnetic behavior as shown in +igure 4$"!04$".$ This

modified magnetic behavior as compared to that of as0deposited thin films have pointed out

the existence of a metastable cation distribution which results in different exchange

interactions between themselves$The different exchange interactions have caused modified

magnetic properties !4#$ The &0J curves for in and out0plane has shown that &sin case of

in0plane was larger than that of out0plane$ &agnetic properties of magnetically annealed thin

films are summari5ed in Table 4$.$

Figure 4.2!&0J curve for magnetically annealed thin film of .3 minutes oxidation$

Ta$le 4.! The variation of the Coercivity *Jc, saturation magneti5ation *&s, remanance

*&r and squareness *%L of magnetically annealed thin films with oxidation time *t$

&$=hil$ Thesis =age 8"

-

7/25/2019 Chapter 4 Suniya M

29/34

Chapter 4 Results and Discussion

%ampl

e &o.

t

)min*

In-

plane

'ut-

plane

In-

plane

'ut-

plane

In-

plane

'ut-

plane

In-

plane

'ut-

plane! 2 84$-

"

4"8$!

8

3$43 3$-8; 3$38! 3$!.! 3$!8

2

3$!;;

;" !3 4."$.

!

;.$-

.

!$-2- 3$.3- 3$284 3$!38 3$.."

-

3$.23

;. !2 .!;$4

2

433$!

"

2$2 3$22 !$384 3$3. 3$!83

8

3$!;;

-4 "3 4!8$-

8

23.$8

2

4$;!2 "$-.2 !$.-4 3$2-8 3$"-

-

3$"!!;

2 "2 4--$;

"

2!4$!

2

!;$. ;$28" 4$--- !$-38 3$"8"

"

3$"2

2; .3 4"8$"

4-3$2

"

.$"-- !$.2 3$-;!

3$4.; 3$"."

2

3$""2

8

4.4.1 ariations in /oerciity of Annealed Thin Films ith '(idation Time

Ghen the samples were placed in0plane to magnetic field, coercivity *J c decreased with the

increasing oxidation time as shown in +igure 4$"4 but when oxidation rate was increased

from !2 minutes samples have shown again increasing trend in coercivity$ The films which

were oxidi5ed for 2 minutes have shown higher value of coercivity for in0plane, while same

samples were placed out0plane in external magnetic field have shown lower value of

coercivity$ The variation in coercivity would be due to change in crystalline state of the films

after annealing$

&$=hil$ Thesis =age 8.

-

7/25/2019 Chapter 4 Suniya M

30/34

Chapter 4 Results and Discussion

The coercivity of the films strongly depends on grain si5e, microstructure of films and

residual magnetic induction along with other complex factors$ The coercivity of the films is

also strongly dependent on magneto0crystalline anisotropy !;#$

Figure 4.24Jcplot of annealed films with oxidation time

4.4.2 ariations in %aturation 9agneti0ation of Annealed Thin Films ith

'(idation Time

%aturation magneti5ation *&s of annealed films has shown an increasing trend with oxidation

time$ %aturation magneti5ation in case of in0plane is larger than out0plane as shown in +igure

4$"2$ The value of saturation magneti5ation depends upon crystallite si5e, oxidation time and

annealed temperature$

&$=hil$ Thesis =age 84

-

7/25/2019 Chapter 4 Suniya M

31/34

Chapter 4 Results and Discussion

Figure 4.2" &s plot of annealed films with oxidation time$

4.4.! ariations in Retentiity of Annealed Thin Films ith '(idation Time

Retentivity E&r/ of annealed films has shown an increasing trend with increasing oxidation

time$ Retentivity in case of in0plane was observed to be larger than out0plane as shown in

+igure 4$";$

Figure 4.2# &r=lot of annealed films as a function of oxidation time$

&$=hil$ Thesis =age 82

-

7/25/2019 Chapter 4 Suniya M

32/34

Chapter 4 Results and Discussion

References

!# T$ Panai, T$ shimokawa, y$ Gatanabe, &$ Qakano, 9$ %u5uki and J$ +ukunaga,

Transactions on &agnetics, ", 4.8-04.!, *"3!4$

"# C$ %check, =$ Fvans, R$ %chad and O$ angari, Bournal of 1pplied =hysics, 7!,

-;.40-;.;, *"33.$

.# 1$ Ooldman, S&odern +errite Technology, %pringer %cience U 7usiness &edia,

*"33;$

4# Q$ Tian, B$ G$ Gang, +$ i, $ &ei, $ 6$ u, $ $ Oe and C$ P$ Pou, Bournal of

&agnetism and &agnetic &aterials, !24, 4!-204!-8, *"3!"$

2# T$ 9$ =athak, Q$ J$ asoya, $ 9$ akhani and 9$ 7, &odi, Ceramics 'nternational,!#,

"-20"8!, *"3!3$

;# 9$ Vsharani, 1$ R$ 7alu, O$ %hanmugaval, &$ %uganya and $ %$ Qagarethinam,

'nternational Bournal of %cientific Research and Reviews, 2, 2.0;8, *"3!.$

-# B$ &$ 'wata, R$ $ Chopdekar, +$ Grong, F$ 1rehol5 and P$ %u5uki, 1pplied =hysics

etters, 1", 320!!, *"33$

8# 7$ D$ Cullity, SFlements of 60ray Diffraction, 1ddison0Gesley =ublishing Company,

V%1, *!-8$

# =$ 9$ 9alita, 7$ 9$ %harma and J$ $ Das, 7ull$ &ater$ %ci$, 2!, .!.0.!-, *"333$

!3# 9$ %$ 9im, =$ &uralidharan, %$ J$ Jan, B$ %$ 9im, J$ O$ 9im and C$ '$ Cheon, Bournal

of 1lloys and Compounds, "!, 4;304;., *"3!3$

!!# $ %epelak, '$ 7ergmann, D$ &en5el, 1$ +eldhoff, =$ Jeit)ans, +$ B$ itterst and 9$ D$

7ecker, Bournal of &agnetism and &agnetic &aterials, !1#, -;40-;, *"33-$

!"# &$ %ugimoto, Bournal of the 1merican Ceramic %ociety, 62, ";0"-4, *!$

&$=hil$ Thesis =age 8;

-

7/25/2019 Chapter 4 Suniya M

33/34

Chapter 4 Results and Discussion

!.# P$ Chen, &icroelectronic Fngineering, 6", !!2"0!!2-, *"338$

!4# %$ F$ %hirsath, 7$O$ Toksha and 9$&$ Bournal of &aterial =hysics, 115, !;.0!;,

*"33$

!2# %$ Thankachan, 7$ =$ Bacob, %$ 6avier and F$&$ &ohammed, =hysica %cripta, 65,

4.4!04.4-, *"3!.$

!;# C$ 7ean, Bournal of 1pplied =hysics, 2#, !.8!0!.8., *!22$

&$=hil$ Thesis =age 8-

-

7/25/2019 Chapter 4 Suniya M

34/34