Cgf 6 2 final

-

Upload

kmi-media-group -

Category

Documents

-

view

236 -

download

4

description

Transcript of Cgf 6 2 final

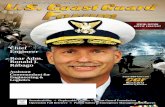

March 2014Volume 6, Issue 2

www.CGF-kmi.com

Dedicated to Those Who Are Always Ready

Cutter Review O Dry Dock & Cutter Maintenance O AIS Radar Modernization O FY15 Budget Initiatives O eLog

Idea Developer

Capt. Alan Arsenault

CommanderCoast Guard Research and Development Center

AnnuAl DryDock & Ship repAir Directory

Powering the US Coast Guard since 1966.

www.rolls-royce.com

Integrated power and propulsion systems

Trusted to deliver excellence

Since delivering the propeller system for USCGC Dependable in 1966, Rolls-Royce has been a trusted supplier to the US Coast Guard’s increasingly advanced ship building programs for nearly half a century. Delivering the best performance and reliability for the OPC means using the most proven and effi cient integrated power and propulsion systems available in the world today. It’s what Rolls-Royce does best; combining the most reliable offshore technology with a proven high performance naval pedigree, to deliver the most cost effective and reliable ship power and propulsion solutions for the US Coast Guard and over 4,000 customers worldwide.

NasscoIndustry_Marine_040214_v2.indd 1 05/02/2014 18:08

Cover / Q&AFeatures

Captain alan arsenaultCommander

Coast Guard Research and Development Center

16

Departments Industry Interview2 editor’s perspeCtive3 nav notes14 on the horizon27 resourCe Center

Benjamin r. stonePresident and CEOAlenia Aermacchi North America

March 2014Volume 6, Issue 2U.S. CoaSt gUard forUm

28

“Our biggest asset is

our people, the subject

matter experts that

we have here—the scientists, engineers,

both civilians and

military.”

- Capt. Alan Arsenault

identifying optionsAutomatic identification systems (AISs) are playing an increasing role in the management, tracking and surveillance of many military platforms, in the air, on the seas and even on land. AIS is much more precise, clear, complete and efficient than traditional voice communications and pre-GPS location techniques.By Henry Canaday

Drydock and Ship repair Directory

Coast Guard Forum’s annual sampling of the facilities around the country where Coast Guard cutters and boats have or could have work done to ensure safety and operational readiness.

high and dryPulling a ship out of the water is the most effective—and sometimes only—way to manage repair orders. While Coast Guard vessels that are brought in for maintenance or repairs go to commercial shipyards 80 percent of the time, they perform 20 percent of the work themselves.By Peter BuxBaum

1210

7usCg’s fy 2015 Budget requestCoast Guard Commandant Admiral Robert Papp Jr. recently testified before the House Appropriations Subcommittee in Homeland Security on next year’s budget request.

20strengthening the fleetRebuilding the fleet while maintaining operational capabilities is fundamental to the Coast Guard’s modernization plan. While reducing the numbers of cutters, it hopes to increase its performance.By Peter BuxBaum

24radar modernizationBringing better capabilities to the Coast Guard by upgrading, modernizing and in some cases replacing aging systems to improve radar.By SCott nanCe

26elog 3.0eLog is a software tool that revolutionizes the Coast Guard’s ability to plan its fleet, while simplifying maintenance routines for crewmembers. By marlowe CHurCHill and Petty offiCer firSt ClaSS CHriStoPHer okula

4

After seeing an increase to more than $10.2 billion in FY14, the Coast Guard’s budget again takes a whack, losing about $418 million and falling below FY13 levels.

Losing about $142 million, the acquisition, construction and improve-ments elements line items account for about one-third of the budget reduc-tion. Personnel and management, and shore and aids to navigation are two areas that do see some increase in their budgets, but vessels, aircraft and other areas all see declines. Vessels alone drops to about $803 million from about $999 million, while aircraft funding drops from $175.3 million in FY14 to $68 million in FY15.

Several members of Congress were quick on the mark voicing concern, and in some cases outrage, at the budget request. Rep. Duncan Hunter (R-Calif.), chairman of the House Subcommittee on Coast Guard and Maritime Transportation, in his opening remarks at a recent hearing with Admiral Papp, said, “Once again, Congress is being forced to come up with hundreds of millions of dollars just to sustain Coast Guard front-line operations. The administration needs to understand that the Coast Guard cannot continue to do more with less. If the president is going to continue to propose these cuts year after year, he needs to tell us how he intends to rescope the missions of the Coast Guard to reflect his reduced budgets.”

In his remarks, Papp said, “We now sit at a critical point in time where the vital necessity to recapitalize our aging offshore fleet connects with the expertise and strong competition to do so affordably. To lose this opportunity would affect the very shape of our service and impact our ability to conduct our missions for the next 40 years. All we need now is stable and predictable funding.”

Even with the increase the Coast Guard budget saw in FY14—and welcomed it was—it was so small in relation to the needs that the additional funding made little difference.

The Coast Guard has done herculean work in managing its missions with its budget to date, but the day of reckoning is coming if the gaps are not addressed. Dedicated people are the founda-tion of the Coast Guard and the reason it can do what it does. It’s not a matter of rewarding those people for their work, but of properly resourcing them for the mission.

Dedicated to Those Who Are Always Ready

Editorial

Editor-In-ChiefJeff McKaughan [email protected] EditorHarrison Donnelly [email protected]

Online Editorial ManagerLaura McNulty [email protected] EditorSean Carmichael [email protected]. Bissell • Peter Buxbaum • Henry Canaday Kelly Fodel Cheryl Gerber • Steve Hirsh Nora McGann • William Murray • Scott Nance

art & dEsign

Art DirectorJennifer Owers [email protected]

Ads and Materials ManagerJittima Saiwongnuan [email protected] Graphic DesignerScott Morris [email protected] Designers Andrea Herrera [email protected] Paquette [email protected] ExecutiveRena Pensky [email protected]

KMi MEdia groupChief Executive OfficerJack Kerrigan [email protected] and Chief Financial OfficerConstance Kerrigan [email protected] McKaughan [email protected] Castro [email protected] Show CoordinatorHolly Foster [email protected]

opErations, CirCulation & produCtion

Operations AdministratorBob Lesser [email protected] & Marketing AdministratorDuane Ebanks [email protected] Gill [email protected] Woods [email protected] SpecialistRaymer Villanueva [email protected]

a proud MEMbEr of:

subsCription inforMation

U.S. Coast Guard ForumISSN 2152-6990

is published six times a year by KMI Media Group. All Rights Reserved.

Reproduction without permission is strictly forbidden. © Copyright 2014.

U.S. Coast Guard Forum is free to qualified members of the U.S. military, employees of the U.S. government and

non-U.S. foreign service based in the U.S.All others: $75 per year.Foreign: $159 per year.

CorporatE offiCEs

KMI Media Group 15800 Crabbs Branch Way, Suite 300

Rockville, MD 20855-2604 USA Telephone: (301) 670-5700

Fax: (301) 670-5701 Web: www.CGF-kmi.com

u.s. Coast guardforuM

Volume 6, Issue 2 • March 2014

EdItor’S PErSPECtIVE

Jeffrey D. McKaughaneditor-in-CHief

www.GIF-kmi.com

Geospatial Intelligence

Forum

www.BCD-kmi.com

June 2012Volume 1, Issue 1

www.BCD-kmi.com

Border Threat Prevention and CBRNE Response

Border Protector

Michael J. Fisher

ChiefU.S. Border PatrolU.S. Customs and Border Protection

Wide Area Aerial Surveillance O Hazmat Disaster ResponseTactical Communications O P-3 Program

Integrated Fixed Towers

Leadership Insight:Robert S. BrayAssistant Administrator for Law EnforcementDirector of the Federal Air Marshal Service Transportation Security Administration

SPECIAL SECTION:

Border & CBRNE Defense

www.MAE-kmi.com

Military AdvancedEducation

www.MIT-kmi.com

Military Information Technology

www.GCT-kmi.com

Ground Combat

Technology

www.MLF-kmi.com

Reverse Auctions O Defense Transportation O Afghanistan RetrogradeILS O Supply Chain Efficiencies O DMSMS O Senior Logisticians

The Publication of Record for the Military Logistics Community

Resource Aligner

Vice Adm. William A. “Andy” Brown Deputy CommanderU.S. Transportation Command

SPECIAL PULL-OUT SUPPLEMENTUSTRANSCOM

www.MLF-kmi.com

November/December 2013Volume 7, Issue 10

Exclusive Interview with:

GAIL JORGENSONAcquisition Director USTRANSCOM

Military Logistics Forum

www.M2VA-kmi.com

Military Medical & Veterans

Affairs Forum

www.MT2-kmi.com www.NPEO-kmi.com

Military Training Technology

Navy Air/Sea PEO Forum

www.SOTECH-kmi.com

Special Operations Technology

www.TISR-kmi.com

Tactical ISR Technology

www.CGF-kmi.com

U.S. Coast Guard Forum

KMI MedIa Group LeadershIp MaGazInes and WebsItes

www.CGF-kmi.com2 | CGF 6.2

Compiled by kmi media Group staffNaV NotES

Latest FRC CommissionedCoast Guard Cutter Charles Sexton was

commissioned into service March 8 at Coast Guard Sector Key West, Fla. Sexton is the second of six fast response cutters to be homeported in Key West, and the eighth vessel to be delivered through the Coast Guard’s Sentinel-class FRC recapitalization project.

The cutter is named after Machinery Technician 1st Class Charles W. Sexton, who drowned during a rescue operation conducted off the coast of Washington. On January 11, 1991, Sexton was aboard a motor lifeboat dispatched to

assist the 75-foot fishing vessel Sea King, which was taking on water off the Columbia River bar. After boarding the Sea King, he helped stabilize an injured crew member and dewatered flooded compartments of the ship for six hours to keep the Sea King afloat.

While being towed toward port, the Sea King capsized without warning. Sexton and two of the Sea King’s crew were trapped inside and could not be rescued. For his extraordinary heroism and self-less actions, Sexton was posthumously awarded the Coast Guard Medal.

The 154-foot FRC class has a flank speed of 28 knots, state-of-the-art command, control, commu-nications and computer technology, and a stern launch system for the vessel’s 26-foot cutter boat. Sexton will join the seven fast response cutters delivered to date in performing operations in the Seventh Coast Guard District, an area comprised of 1.8 million square nautical miles of ocean ranging from the South Carolina coast to the Caribbean.

Delivery of the ninth FRC, to be commissioned the Coast Guard Cutter Kathleen Moore, is sched-uled for later this month.

Coast Guard Coxswain of the Year

A Coast Guardsman was honored in Corpus Christi as the Coast Guard coxswain of the year for his efforts during a law enforcement case in which he intercepted a Mexican boat after its crew was suspected of fatally wounding a Coast Guardsman while attempting to smuggle narcotics, December 2, 2012.

Petty Officer 1st Class Travis Connick was recognized for sustained superior performance, skill and leadership during the interdiction. Captain Samuel R. Creech Jr., the commanding officer of Sector Corpus Christi, awarded the coxswain of the year the Commander Ray Evans Outstanding Coxswain Trophy.

“He inspires me and the entire Coast Guard who protect our U.S. waterways,” said Creech. During the ceremony, Creech refer-enced Connick’s “warrior spirit.”

“My crew and I were just doing what we were trained to do,” said Connick.

When approached, the Mexican boat fled and rammed the Coast Guard Cutter Halibut’s 16-foot response boat, killing one of its crew-members, Senior Chief Petty Officer Terrell Horne III.

Coast Guard assets immediately responded, along with U.S. Customs and Border Protection, to intercept the suspected vessel.

At 3 a.m., Coast Guard Station Los Angeles-Long Beach launched a boatcrew aboard a 45-foot Response Boat-Medium, with Connick as the coxswain. Connick and his crew relentlessly pursued the boat in heavy seas and complete darkness, maxi-mizing crew endurance and vessel limita-tions, to intercept the Mexican boat before

it reached Mexican territorial waters. Connick and his crew were more than 90 miles offshore when they intercepted the boat.

Jose Meija-Leyva of Ensenada, Mexico, who was operating the boat intercepted by Connick, was convicted of murdering Horne and is facing up to life in prison. Also in the Mexican boat was Manuel Beltran-Higuera, who was convicted of assault and failure to yield, and is facing up to 60 years in prison.

The Commander Ray Evans outstanding coxswain trophy is a Coast Guard-wide competition awarded annually and recognizes a coxswain who demonstrates sustained superior performance, exceptional boat handling skills, and exemplary leadership.

Connick received this award while serving on active duty at Coast Guard Station Los Angeles-Long Beach. He is currently attached to Coast Guard Sector Corpus Christi and drills at Coast Guard Station Port O’Connor as a reservist. He works full time with United Services Automobile Association.

www.CGF-kmi.com CGF 6.2 | 3

www.CGF-kmi.com4 | CGF 6.2

Improved technology means better trackIng and IdentIfIcatIon on the water.by henry canaday, cgf correspondent

Automatic identification systems (AISs) are playing an increasing role in the man-agement, tracking and surveillance of many military platforms, in the air, on the seas and even on land. AIS is much more precise, clear, complete and efficient than traditional voice communications and pre-GPS location techniques.

Maritime AIS is now required of many commercial and other vessels. It is crucial for operations in the Coast Guard and U.S. Navy.

But AIS comes in many types and with a variety of associated functions and applica-tions. For example, Class A AIS is for large vessels that must receive and transmit posi-tions almost constantly. Class B AIS is for light commercial or recreational vessels that

transmit data frequently, but not constantly, and at lower power.

In addition, Navy and Coast Guard need Class A AIS that can share data with friendly ships, but keep it secret from others.

Finally, AIS technology continues to evolve rapidly, with new capabilities added in ever smaller packages.

The Coast Guard has selected L-3’s Pro-tech-M AIS for installation on all of its ves-sels. According to Pete Besio, senior sales manager and L-3 Marine Systems, “The Protec-M has been deployed on U.S. Coast Guard vessels for more than eight years and supports standard and restricted modes of operation.”

In standard mode, Protec-M works as a standard Class A transponder, compliant with

International Maritime Organization require-ments. In restricted mode the unit receives all AIS transmissions from AIS-equipped vessels, but transmits only encrypted position reports in accordance with NATO Standardization Agreement (STANAG) 4.0 requirements. Thus, in restricted mode, vessels with Protec-M can communicate with similarly equipped ships, and all of these vessels are able to track each other while remaining unseen by vessels without restricted Mode AIS.

Besio said Protec-M is standard fit on all U.S. Coast Guard vessels as well as many vessels of the Coast Guard’s port partners. In addition, similar L-3 AIS products are installed in Coast Guard land-based installa-tions, on Coast Guard aircraft and on aids to navigation.

www.CGF-kmi.com4 | CGF 6.2

www.CGF-kmi.com CGF 6.2 | 5

Besio said L-3 leads the AIS industry in technology and is actively participating in industry groups that work on future prod-uct requirements. “We continue to develop products that meet and exceed current and projected market needs.”

The L-3 marketer emphasized that Protec-M is the only AIS product today that complies with Sensitive but Unclas-sified Tactical Information Exchange and Display System (STEDS) 4.0 requirements. “L-3 developed and delivers a protocol that increases security beyond current require-ments as part of our offering to the U.S. Coast Guard. Additionally, our products are manufactured in the United States, which we believe is significant, considering the role of our equipment in our nation’s homeland security strategy.”

But other OEMs are also active in AIS development and are continually improving their offerings. “The story of AIS is deep and continues to evolve,” said Furuno Sales Manager Matt Wood. The technology began to become available in the mid- to late-1990s,

and requirements for marine uses were in place by the middle of 2002.

Wood said shipboard AIS usually includes a receiver and a transponder for receiv-ing and sending two kinds of data. Static data includes the name of the vessel, its unique Maritime Mobile Service Identity (MMSI) number, length, breadth and similar unchanging characteristics. Dynamic data includes such items as speed on course, heading and rate of turn. To report these dynamic data the AIS must be connected to other vessel systems, such as the gyrocom-pass and GPS.

After 9/11 there was a controversy over AIS. The technology eliminated confusion and errors that could arise in voice com-munication of identification, position and movement. But might it not also aid pirates or other malefactors? “This remains a legiti-mate concern,” Wood observed.

And there have been layers, applications and enhancements added to the original AIS concept. Systems have been miniaturized. AIS has been virtualized. For example, in addition to ships and lighthouses, any point on earth can be assigned an AIS number.

“So there are different subjects and micro-subjects in AIS,” Wood explained.

One example is the fusion of AIS and automatic radar plotting aid (ARPA) data, a fusion that was first offered by Furuno. The combination of the AIS ‘blip’ with the ARPA ‘blip’ can be very useful, Wood said. “Lots of organizations use those every day.”

Coast Guard AIS has a set of very spe-cific requirements, some of which Furuno systems have met and some of which they have not. Both the Coast Guard and the Navy require Blue Force Tracking (BFT), with friendly targets colored blue, enemies colored red and unknown targets in other colors. “BFT is a whole other art and science,” Wood said. He said the Navy and Coast Guard chose an early model of BFT AIS, made by L-3.

Later in 2014, Furuno expects to release its own full BFT AIS. At present it makes three AIS systems. The first is the Class A FA150, which meets all civilian AIS require-ments.

The second, the FA50, is a Class B system with lower power and less frequent transmis-sion of dynamic data. For purposes of avoid-ing collisions, the FA50 is equivalent to using radar at two revolutions per minute. “No one does that,” Wood said. “Radar is generally

www.CGF-kmi.com CGF 6.2 | 5

24 rpm.” Nevertheless, FA50 is a full, dual-channel AIS and compares favorably with other Class B systems that have sim-pler send and receive circuitry and less target sensitivity. Wood said the FA50 can suit some light commercial vessels.

The third Furuno AIS, the FA30, is a receive-only system for recreational vessels, especially sailboats that might not have the battery power to transmit for long periods.

Wood said his company’s FA150 fits most Coast Guard requirements now and will meet all requirements, includ-ing encryption and BFT, in the future. He said the Coast Guard is very active in AIS development and works on it constantly. Along with efforts by other maritime orga-nizations, such as the U.K.’s Maritime and Coastguard Agency, that interest should keep AIS manufacturers “on their toes” and continue to drive the technology forward.

Wood stressed that Furuno “is one of the largest OEMs of maritime electronics, our support is second to none, we offer the most meaningful bells and whistles for any fleet, and we make devices that last much longer that anyone will own their boats.”

Sweden’s Saab makes military AIS, the R5. The R5 has its own encryption, BFT and also encryption according to STEDS European requirements, noted Stuart Tol-man, sales manager for the Americas. “It’s fifth-generation; it came out last year, a totally new technology, a true software radio,” Tolman said. “We have the capabil-ity of manipulating the radio so that it can use any frequency in the 30-megahertz range. The Coast Guard could use its own frequency if it wanted to.”

The R5 has three channels, so it can use the third channel for encryption without interfering with IMO requirements that the first two channels be used only for life sav-ing at sea.

The Saab AIS can operate in silent mode or full encryption mode. The Coast Guard could thus use it to see only commercial vessels or in a secure mode to see both commercial vessels and U.S. assets, without letting commercial vessels see the latter.

Tolman said the R5 is used all over the world and is used by U.S. Navy submarines in secure mode, where it interacts with a competitor’s AIS solution for BFT.

Saab also makes AIS base stations that can operate in encrypted mode and an airborne AIS, the R4. “It’s the perfect solu-tion for search and rescue and airborne surveillance,” Tolman said. “It could get

data to Coast Guard vessels without others seeing it.”

The Saab exec believes the new Saab AIS would be an improvement over AIS currently used by most Coast Guard ves-sels. “It’s a lot more flexible. We can also integrate navigation into AIS. With sensors we can offer both AIS functionalities and navigation functionalities.”

Only a few firms make AIS products that currently meet Coast Guard requirements for encryption and BFT. But there are more than a dozen firms that continue to improve AIS tools for commercial and recreational vessels.

For example, Icom America makes two AIS products now and will shortly introduce a third, according to David McLain, national sales manager marine and avionics.

The first, the MXA 5000, is a black box receiver for Class A and B AIS. It receives on both 161.975MHz and 162.025MHz chan-nels simultaneously, allowing it to obtain-ing AIS data from transponders that operate on only one channel. A built-in antenna splitter allows it to receive both a VHF radio signal and AIS data. The MXA 5000 is com-pact, weighing only 400 grams.

The second product is Icom’s Class B MA500-TR Transponder. The transponder can be turned off if, for example, pirates are a worry. It has its own special display for visualizing targets. The MA-500TR is suited for workboats and small vessels. It receives both Class A and Class B AIS data and transmits MMSI number, name, type of ship, position, speed and other data.

The system’s display looks like a marine radar and shows AIS-equipped vessels and targets within specified distances. A danger list can be sorted by distance, and when a vessel comes within a specified distance an icon blinks, and the system can alert crew with a collision alarm even when they are away from the system. When connected to an Icom radio, the MA-500TR enables a call to another vessel by selecting a vessel with cursor keys, rather than typing in an MMSI number.

McLain said both these systems are built to mil-spec standards and might suit the Coast Guard. The Mexican Navy and Brazilian government have purchased the MA-500TR.

Icom is now launching another product, the M506 VHF fixed mount marine radio, that has a built-in AIS receiver that will work with the new National Marine Elec-tronics Association (NMEA) 2000 standard.

“This is huge,” McLain said. “It is one of the very few radios that do that.” The radio has a last call feature to automatically save the last two minutes of an incoming call.

Transas Marine makes Class A and Class B commercial AIS, explained Sales Manager Paul Welling. Its Class A AIS is designed for larger ships and works constantly, while its Class B device works only intermittently for smaller ships.

The company also makes AIS base sta-tions that can track ships and send mes-sages. These stations can also use Transas’ Vessel Traffic System (VTS) to monitor all the traffic in a port.

The company has yet not made military-grade AIS, which requires encryption. How-ever, Welling said, “We could can deliver them if needed. If the Coast Guard came to us and needed a hundred systems, we could access them through different manufactur-ers.”

Transas’ VTSs are extensively used by coastal agencies around the world, but not in the U.S., where the Coast Guard has a national system built be a large defense manufacturer.

Welling said Transas’ commercial AIS technology meets all the specifications and certification standards for civilian uses, as does the AIS equipment of about a dozen manufacturers.

For example, Vesper produces Class B AIS transponders for the recreational market, according to spokesman Andrew Golden. And Simrad provides a suite of AIS systems, including the MX535B Class A-AIS, the AI50 Class B AIS, NAIS 400 AIS and the MX512 navigation system.

Simrad’s Class A MX535B is competi-tively priced and offers both standalone and expanded configuration. The expanded ver-sions offers eight input or output ports for connection to shipboard systems.

The Class B AI50 transponder shows ship name and MMSI, vessel type, time to closest point of approach, course, speed, heading and rate of turn.

Simrad’s Class B NAIS 400 offers mul-tiple network connections, is waterproof and lightweight and is low on power con-sumption. O

For more information, contact Editor-in-Chief Jeff McKaughan [email protected]

or search our online archives for related stories at www.cgf-kmi.com.

www.CGF-kmi.com6 | CGF 6.2

coast guard commandant admIral robert papp Jr. recently testIfIed before the house approprIatIons subcommIttee In homeland securIty on next year’s budget request.

Invest In long-term operatIonal capacIty

The Coast Guard’s FY 2015 budget preserves today’s critical front-line operations and invests in tomorrow’s Coast Guard by continuing recapitalization efforts for new cutters, boats, aircraft, systems and infrastructure. In 2015, the Coast Guard will implement risk-based operational efficiencies and business practices, overlaid with a near- and long-term operational assessment, to strategically allocate resources to optimize mis-sion performance. This approach sustains the balance between today’s operational requirements and continued investment in recapitalization.

The Coast Guard’s FY 2015 strategic and budget priorities are to:

Surface Assets: $803 millionThe budget provides $803 million for the following surface

asset recapitalization and sustainment initiatives:

• National Security Cutter (NSC) – Provides funding for the eighth NSC, completing the recapitalization of the Coast Guard’s high endurance cutter fleet. The acquisition of NSC 8 is vital for performing DHS missions in the far off-shore regions, including the harsh operating environment of the Pacific Ocean, Bering Sea and Arctic. The NSC also provides a robust command and control platform for homeland security contingency operations.

• Fast Response Cutter (FRC) – Provides production funding to procure two FRCs. These assets replace the aging fleet of 110-foot patrol boats that provide the coastal capability to conduct search and rescue operations, enforce border security, interdict drugs, uphold immigration laws, prevent terrorism and enhance resiliency to disasters.

• Offshore Patrol Cutter (OPC) – Supports review of the preliminary design work for the OPC. The OPC will replace the medium endurance cutter classes that conduct

missions on the high seas and coastal approaches. • Polar Icebreaker – Continues pre-acquisition activities for

a new polar icebreaker. • Cutter Boats – Continues funding for production of multi-

mission cutter small boats that will be fielded on the Coast Guard’s major cutter fleet beginning with the NSC.

• In-Service Vessel Sustainment – Continues funding for sustainment projects on 140-foot icebreaking tugs, 225-foot seagoing buoy tenders, the training Barque Eagle, and initial sustainment on the 47-foot motor lifeboats.

• Survey and Design – Continues funding for multi-year engineering and design work for multiple cutter classes in support of future sustainment and acquisition projects.

Air Assets: $68 millionThe budget provides $68 million for the following air asset

recapitalization or enhancement initiatives:

• HC-144A – Funds spare parts required to maintain the operational availability of the HC-144A Ocean Sentry aircraft.

Invest in Long-term Operational Capacity Dedicated investment to build boats,

cutters, aircraft and corresponding infra-structure capable of meeting today’s threats and those of the future is essential to the Coast Guard’s continued role as America’s maritime first responder. The current condition and serviceability of the Coast Guard’s legacy surface fleet and air-craft and the projected timelines to com-plete replacement of these assets require continued investment in surface and air recapitalization programs to maintain the capability to operate.

Strengthen Resource and Operational Stewardship

The FY 2015 budget reflects sound, risk-based allocation of resources. In 2015, Coast Guard will decommission two 1960s era high endurance cutters (WHECs) that are being replaced by more capable national security cutters. The Coast Guard will also decommission eight 110-foot patrol boats, three HC-130 aircraft, and corresponding shore-side support personnel while accept-ing the delivery of new, more capable fast response cutters, HC-144 aircraft and C-27J aircraft to the fleet.

Preserve Critical Front-Line Operations The FY 2015 budget sustains critical

frontline operations, including maintain-ing search and rescue coverage, protecting critical infrastructure and key resources, and preserving operational hours dedicated to proficiency. Field commanders will con-tinue to optimize operational capacity to support safe navigation, safeguard natural resources, protect the environment, detect and interdict drugs and individuals attempt-ing to enter the United States illegally, and support the nation’s foreign policy objec-tives and defense operations.

www.CGF-kmi.com CGF 6.2 | 7

• HC-27J – Funds continued activities of the C-27J Acquisition Program Office (APO). The APO (new in 2014) will organize logistics, training, maintenance support and ensure these newly acquired aircraft are ready for induction into the operational fleet.

• HH-65 – Continues modernization and sustainment of the Coast Guard’s fleet of HH-65 helicopters, converting them to MH-65 short range recovery helicopters. The modernization effort includes reliability and sustainability improvements, where obsolete components are replaced with modernized sub-systems, including an integrated cockpit and sensor suite.

• C-130J – Funds spare parts required to maintain the operational availability of the HC-130J long range surveillance aircraft.

Other Acquisition, Construction and Improvements (AC&I) Initiatives: $57.3 million

The budget provides $57.3 million for other initiatives funded under the AC&I account, including the following equipment and services:

• Program Oversight and Management – Funds activities associated with the transition of the Coast Guard’s assets from acquisition to operations, including delivery, provision of logistics, training and other services necessary to ensure seamless integration into the operational fleet.

• Command, Control, Communications, Computers, Intelligence, Surveillance and Reconnaissance (C4ISR) – Provides design, development, upgrades and assistance on C4ISR hardware and software of new and in-service assets.

• CG-Logistics Information Management System – Continues development and deployment of this system to Coast Guard operational assets.

Shore Units and Aids to Navigation (ATON): $40.6 millionThe budget provides $40.6 million to recapitalize shore infra-

structure for safe, functional and modern facilities that support Coast Guard assets and personnel:

• Specific Project – Funds construction of a new small arms firing range at Coast Guard Training Center in Yorktown, Va.; completes the second phase of renovations to facilities at Coast Guard Station Woods Hole, Mass.; funds renovation of existing facilities and construction of a new maintenance and engineering building at Coast Guard Station Morro Bay, Calif.

• ATON Infrastructure – Maintains transportation safety on federal waterways through construction and improvements to short-range aids and infrastructure to improve the safety of maritime transportation.

Personnel and Management: $115.3 millionThe budget provides $115.3 million for pay and benefits of the

Coast Guard’s acquisition workforce.

Operational Adjustments In FY 2015, the Coast Guard will make sound, risk-based opera-

tional reductions while investing in critical recapitalization initiatives. These reductions include:

• Vessel Board and Search Teams (VBST): -$1.4 million Eliminates four VBSTs: one team each from Sector Boston, Sector Southeast New England, Sector San Diego and Sector San Francisco. VBSTs consist of law enforcement personnel dedicated to ports, waterways and coastal security enforcement activities. The types of boardings accomplished by these teams will be conducted by sector response and station personnel or from cutter-based crews.

• HC-144A Programmed Flight Hours: -$4.9 million Adjusts the Coast Guard’s HC-144A annual programmed flight hours from 1,200 to 1,000 hours per aircraft to align with mission demands.

• Fixed Wing Aircraft Bravo-0 Response: -$2.2 million Removes the fixed wing Bravo-Zero readiness requirement from Coast Guard air stations, with the exception of Air Station Kodiak, Alaska, and Air Station Barbers Point, Hawaii. This initiative includes a commensurate reduction to staffing of fixed wing aircrew personnel.

• Aids to Navigation (ATON): -$3.5 million Consolidates funding for coastal and western river aids to navigation, enabled by modernization and efficiencies in servicing aids to navigation, policy modifications and logistics.

Billets at associated aids to navigation teams (ANTs) will be reduced and ANT Eufaula, Ala., will be closed, with remaining maintenance responsibilities distributed to other ANTs.

• Operational Efficiencies: -$15.0 million Operational commanders, using risk-based prioritization of patrols and operational activities, are able to adjust operations and balance emerging mission demands with daily operations. Additionally, new Coast Guard assets are equipped with enhanced intelligence and communication tools that enable field staff to target threats and prosecute them more efficiently. As a result, operational efficiencies that scale cutter, boat and aircraft hours will reduce resources required for fuel and variable maintenance with no anticipated impact to operations. Safety of life, urgent security activities and operational hours dedicated to meet minimum proficiency standards will be preserved.

Asset Decommissioning and RetirementAs the Coast Guard recapitalizes its cutter and aircraft fleets and

brings new assets into service, the older assets that are being replaced will be decommissioned or retired.

• High Endurance Cutter (WHEC): -$14.9 million Decommissions the sixth and seventh WHECs. National security cutters are replacing the aging WHEC fleet.

• Patrol Boat (WPB): -$6.1 million Decommissions eight 110-foot WPB patrol boats. These assets

strengthen resource and operatIonal stewardshIp

www.CGF-kmi.com8 | CGF 6.2

© 2014 Trijicon, Inc. Wixom, MI USA 1-800-338-0563 www.trijicon.com

TRIJICON ACOG®

No other magnified optic is more battle proven than the Trijicon ACOG. It’s utilized worldwide by many of the world’s finest fighting forces. With easy to use features and a nearly bomb-proof design, the ACOG proves to be the world’s finest combat optic.

PML7020-4 Rev(13.0)

battleproven.

SEE THE LINK

Trijicon_USCoastGuard_PML7020-4Rev(13.0).indd 1 3/25/2014 8:36:19 AM

will be replaced with FRCs in the Seventh and Eighth Coast Guard Districts.

• HC-130 Aircraft Retirement: -$11.6 million Eliminates funding and personnel associated with the

retirement of three HC-130H to the Air Force for transfer to the U.S. Forest Service as outlined in the FY 2014 National Defense Authorization Act. Newly acquired HC-130J aircraft will provide increased operational reliability.

For more information, contact Editor-In-Chief Jeff McKaughan [email protected] or

search our online archives for related stories at www.cgf-kmi.com.

Pay & Allowances: $83.1 millionMaintains parity with DoD for military pay, allowances and

health care, and for civilian pay raise and retirement contributions. As a branch of the armed forces of the United States, the Coast Guard is subject to the provisions of the National Defense Authori-zation Act, which include pay and personnel benefits for the military workforce.

Operating and Maintenance Funds for New Assets: $72.1 million Provides funding for operations and maintenance of shore facili-

ties, as well as cutters, boats, aircraft and associated C4ISR subsys-tems delivered through acquisition efforts.

• Shore Facilities – Funds operation and maintenance of shore facility projects scheduled for completion prior to FY 2015.

• Response Boat-Medium – Funds operation, maintenance and support of 15 RB-Ms as well as adjustments for the standard support level for the 155 RB-Ms currently in service.

• Rescue 21 (R21) –Provides additional funds for the R21 System for maintenance of Coast Guard leased and owned towers, and Alaska communications sites.

• FRC – Funds operation and maintenance of FRCs #13-17 and provides funding for personnel to operate and maintain hulls #15-18, including the shore-side support personnel.

• NSC – Funds personnel, operations and maintenance for NSC #5, including costs for shore-side support personnel. Provides new funding for operation of the NSC baseline mock-up laboratory at the Maritime Domain Awareness Center in Moorestown, N.J.

• HC-144A MPA – Funds operations, maintenance and personnel funding for aircraft #18 that will be assigned to Air Station Miami, Fla. O

preserve crItIcal front-lIne operatIons

www.CGF-kmi.com CGF 6.2 | 9

pullIng a shIp out of the water Is the most effectIve—and sometImes only—way to manage repaIr orders.by peter buxbaum, cgf correspondent

Coast Guard vessels that are brought in for maintenance or repairs go to commercial shipyards 80 percent of the time. But the 20 percent that go to the Coast Guard Yard in Baltimore, Md., include some of the most challenging jobs.

The Yard, which has been around since 1899, is the Coast Guard’s organic ship repair and maintenance capability. Its stable and veteran workforce encompasses a level of expertise that is hard to find elsewhere. Some of the most experienced workers who helped build cutters in the 1960s and 1970s are now repairing and maintaining those same vessels. The deep institutional knowledge to be found at the Coast Guard Yard, as well as the facility’s capacity to fabricate discontinued parts, is what attracts the toughest assignments.

The Coast Guard is currently in the process of replacing some of its aging cutters. But it also must count on some of those same older vessels to perform to expectations while they are still in service.

“The Coast Guard tends to keep ships around a lot longer than anyone else,” said Commander Matt Lake, the yard’s industrial manager. “If we are to keep our vessels in service for 30 or 40 or more years, we must do major structural repairs and replace obsolete and difficult to support equipment.”

www.CGF-kmi.com10 | CGF 6.2

For more information, contact Editor-In-Chief Jeff McKaughan [email protected] or

search our online archives for related stories at www.cgf-kmi.com.

A good deal of the Coast Guard Yard’s efforts in recent years have been directed toward maintaining the mission effectiveness of the older fleet. Seventeen 110-foot patrol boats were overhauled in a Mission Effectiveness Project (MEP) that ended in 2012. An MEP focused on medium endurance cut-ters that began eight years ago will be ending this year after 27 of the vessels have been serviced. A new program that started this year, dubbed the In Service Vessel Sustainment Project, will be maintaining nine icebreaking tugboats, 16 225-foot seagoing buoy tenders, one training ship, and a number of 47-foot motor life boats over an eight-year period. The White House budget for fiscal year 2015 requested $24.5 million for this sustainment project.

The Coast Guard Yard’s total budget amounts to around $100 million annually. Its dry dock facilities include a ship lift that pulls vessels out of the water and places it on a rail system where it is pushed around by giant pusher tugs. The ship lift facility has the capacity to dry dock four vessels at any one time. The yard also has an old, World War II-era floating dry dock that it inherited from U.S. Navy. This dock can lift ships weighing up to 6,000 tons. The yard can also dock up to four small vessels of 110 feet and less on specially designed cradles on concrete piers. The yard is capable of handling vessels that measure up to 378 feet.

Performing major maintenance work on a cutter typically requires that the vessel be pulled out of the water and into the dry dock. “Our cutters are generally dry docked once every four years on a routine basis to do inspections of propeller shafts, steel plating, the hull structure and fin stabilizers,” said Lake. “We clean and paint the tanks and do other things that can’t be done while the ship is in the water.”

In its earlier days, and through the 1970s, the yard was devoted primarily to shipbuilding. Since that time the focus has shifted toward major renovation work. In contrast to commercial shipyards that contract with Coast Guard, which tend to do routine repair work, the Yard gets the lion’s share of the higher risk technical work.

“For example,” Lake explained, “perhaps the Coast Guard doesn’t understand all of the interface issues involved in installing a piece of equipment on a ship. The place that gets to try it out first is the yard because of the lower risk of cost increases and schedule impacts.”

The Coast Guard Yard also performs the normal repairs that are consigned to commercial shipyards; they constitute about half its workload. The other half involves performing major service life extension and midlife availability projects. The MEPs, an example of a midlife availability project, are designed to maintain mission effectiveness until a vessel is decommissioned. The 110-foot patrol boats will eventually be replaced by the 154-foot fast response cutter. The 210- and 270-foot medium endurance cutters are to be replaced by the offshore patrol cutter.

MEPs and midlife maintenance availabilities are put in place to manage subsystem obsolescence and reliability issues, such as hull integrity, without which a vessel would be vulnerable to engineer-ing casualties and reduced operational mission hours. A service life extension program (SLEP) involves updating a vessel with the latest systems and technologies and affecting other upgrades and structural work in order to keep the ship up to standard for another 10 years or more. The In Service Vessel Sustainment Project will involve midlife availability work as well as SLEPs.

The MEP eliminates problems associated with obsolete and unsupportable equipment and systems. In addition to the standard dry docking work, including underwater body paint and freeboard

and superstructure painting, the cutters undergoing an MEP receive a new over-the-horizon boat davit; reverse osmosis water maker; main diesel engine electronic governor control; engine room fire protec-tion system; oily water separator; tank level indicator; Mark 39 gyro compass; air conditioning upgrades, and renovated crew berthing areas.

The 110-foot MEP also included hull renewal, structural repairs, new equipment such as switch-boards and generator sets, new electric cabling, and rehabilitated berthing spaces.

Many of the icebreaking tugs coming in as part of the In Service Vessel Sustainment Project now have

over 30 years of service. “We intend to bring them in to do a substan-tial amount of work to increase their service life for something more than a decade,” said Lake. “We specifically look at what we know will be problematic to support and replace those. We also make sure that the hull structure is sound.”

SLEPs will also be performed on the training ship, the Eagle, which was built in 1936, and the 47-foot motor life boats. The work on the buoy tenders will be midlife availability work.

The Coast Guard Yard is also called upon to do emergency repair work. The 210-foot medium endurance cutter Confidence arrived at the Yard last November for a 26-day emergency dry dock availability. The Coast Guard had identified excessive corrosion and wastage in the engine room bilge prior to deployment on an operational patrol from its homeport in Cape Canaveral, Fla.

Naval architects determined that the Confidence was unsafe to sail without significant repairs, and that an emergency dry docking was required. Fixing Confidence was given top priority at the yard, and nearly continuous work occurred on Confidence over three weeks.

The work involved a collaboration among the yard’s structural, pipe, rigging and paint shops. The work included inspections of wasted metal, fuel tank cleaning and repair, piping repairs, ballast removal and reinstallation, structural and welding repairs, and pres-ervation of engine room bilges. Iron work by the yard’s structural shop totaled over 175 square feet in plating and over 40 feet of T-bar stiffener replacement and repair.

“The Yard completed Confidence’s emergency repair in 26 days, one day ahead of schedule, and under budget,” said Lake.

The Coast Guard Yard has been around for well over 100 years, and Lake anticipates that its services will be required for many years to come. “We are in a growth industry,” he said. “The average age of Coast Guard vessels seems to increase every year, so the yard will be here for a very long time.

“We provide a unique organic capability that doesn’t exist else-where in the Coast Guard and is hard to find elsewhere in the federal government,” Lake added. “Our expertise in the renovation of ships occupies a unique niche. Our infrastructure and our workforce are optimized for that sort of work and there is a lot of it to be done.” O

Cmdr. Matt Lake

www.CGF-kmi.com CGF 6.2 | 11

ALABAMA

BAE Systems Southeast Shipyards – MobileMain Gate, Dunlap Dr.Mobile, AL 36652

Austal1 Dunlap Dr.Mobile, AL 36602

C & G Boat Works Inc.401 Cochran Bridge Causeway, Hwy 98Mobile, AL 36603

Harrison Brothers Dry Dock & Repair Yard Inc.P.O. Box 1843Mobile, AL 36633-1843

Steiner Shipyard8640 Hemley St.Bayou La Batre, AL 36509

Horizon Shipbuilding Inc.13980 Shell Belt Rd.Bayou La Batre, AL 36509

Master Marine 14284 Shell Belt Rd., Ste. ABayou La Batre, AL 36509

ALASkA

Vigor Industrial – Ketchikan3801 N. Tongassketchikan, Ak 99901

CALifORNiA

Al Larson Boat ShopSan Pedro, CA 90731

BAE Systems San Diego Ship Repair2205 East Belt St.San Diego, CA 92113

BAE Systems San Francisco Ship RepairPO Box 7644San francisco, CA 94120

Bay Marine Boatworks310 W. Cutting Blvd.Richmond, CA 94804

Bay Ship & YachtAlameda, CA 94501

Gulf Copper Ship Repair – San Diego1428 Mckinley Ave.National City, CA 91950

EMD Marine 6418 Hayward WaySan Diego, CA 92139-1144

fLORiDA

BAE Systems Southeast Shipyards – Jacksonville8500 Heckscher Dr.Jacksonville, fL 32226

BAE Systems Southeast Shipyards – Mayport1936 Bailey Ave.Jacksonville, fL 32228

Bradford Marine3051 W. State Rd.fort Lauderdale, fL 33312

Derecktor Florida775 Taylor Ln.Dania, fL 33004

Eastern Shipbuilding2200 Nelson St.Panama City, fL 32401

Eastern Shipbuilding13300 Allanton Rd.Panama City, fL 32404

Gulf Marine1800 Grant St.Tampa, fL 33605

Hendry Shipyard Venture1650 Hemlock St.Tampa, fL 33605-6042

Ind-Mar Services1317 Elk Ct.Orange Park, fL 32073

International Ship Repair & Marine Services 1616 Penny St.Tampa, fL 33605

Janco Enterprises200 N. Wilson Ave. Cocoa, fL 32922

Miller Marine Yacht Services7141 Grassy Point Rd.Panama City, fL 32409

North Florida Shipyards2060 East Adams St.Jacksonville, fL 32202-1212

Standard Marine and Ship Repair4120 N. Courtenay Pkwy.Merritt island, florida 32953

GEORGiA

Savannah Marine301 N Lathrop Ave.Savannah, GA 31415

GuAM

Gulf Copper Ship Repair – Guam1034 E. Lanchero St.Agat, Guam 96915

HAWAii

BAE Systems Hawaii Shipyards3049 ualena St., Ste. 915Honolulu, Hi 96819

iOWA

Sunflower Enterprises 5 Jones St., Ste. 2Dubuque, iA 52001

LOuiSANA

Conrad Shipyard LLC1501 front St.Morgan City, LA 70380

Leevac Shipyards Houma LLC3201 Earhart Blvd.Houma, LA 70363

in 2014, through about the middle of March, the Coast Guard had more than 70 contract solicitations, awards and modifications that involved drydock or dockside repair to its floating assets.Coast Guard Forum has put together just a sampling of the facilities around the country where Coast Guard cutters and boats have or could have work done to ensure safety and operational readiness.

Drydock and Ship repair Directory

www.CGF-kmi.com12 | CGF 6.2

Leevac Shipyards Jennings LLC111 Bunge St. Jennings, LA 70546

Leevac Shipyards Lake Charles LLC8200 Big Lake Rd.Lake Charles, LA 70605-0301

Thoma-Sea Marine Constructors1874 industrial Blvd.Houma, LA 70363

Bollinger Shipyards65 Hwy. 308 SouthLockport, LA 70374

MAiNE

Rockland Marine79 Mechanic St.Rockland, ME 04841

MASSACHuSETTS

Fairhaven Shipyard50 fort St.fairhaven, MA 02719

MiSSiSSiPPi

VT Halter Marine Inc.900 Bayou Casotte Pkwy.Pascagoula, MS 39581

NEW JERSEy

Yank Marine Services487 Main St.Dorchester, NJ 08316

NEW yORk

Derecktor New York311 East Boston Post Rd.Mamaroneck, Ny 10543

Muller Boat Works2214 E. 69th St.Brooklyn, Ny 11234

NORTH CAROLiNA

Jarret Bay Boatworks530 Sensation WeighBeaufort, NC 28516

OHiO

The Great Lakes Group 4500 Division Ave.Cleveland, OH 44102-2228

OREGON

Reedsport Machine and Fabrication170 Bay front LoopWinchester Bay, OR 97467

Vigor Industrial – Portland5555 N. Channel Ave.Portland, OR 97217

PENNSyLvANiA

Donjon Shipbuilding & Repair220 E. Bayfront Pkwy.Erie, PA 16507

RHODE iSLAND

Blount Boats Inc.461 Water St.Warren, Ri 02885

J. Goodison Co. 7 india St.Providence, Ri 02903

Senesco Marine10 MacNaught St.North kingstown, Ri 02852

SOuTH CAROLiNA

Detyens Shipyards Inc.1670 Drydock Ave., Bldg. 236, Ste. 200North Charleston, SC 29405-2121

TENNESSEE

Wepfer Marine2661 Channel Ave.Memphis, TN 38113

TExAS

Bludworth Marine Channelview Shipyard & Ship Repair411 Lakeside Dr.Channelview, Tx 77530

Bludworth Marine Galveston City Pier 38Galveston Pier 38 Dock Office, 3901 Wharf Galveston, Tx 77550

Bludworth Marine Galveston Shipyard6200 Harborside Dr.Galveston, Tx 77017

Bludworth Marine Orange Shipyard2599 S Childers Rd.Orange, Tx 77630

Gulf Copper – Central Yard5700 Procter St. ExtensionPort Arthur, Tx 77642

Gulf Copper – South Yard2020 Gulfway Dr.Port Arthur, Tx 77640

Gulf Copper Ship Repair4721 E. Navigation Rd.Corpus Christi, Tx 78402

Gulf Copper – North Yard7200 Hwy 87 EastPort Arthur, Tx 77642

Gulf Copper Dry Dock & Rig Repair2920 Todd Rd.Galveston, Tx 77554

Kirby Marina202 Pasadena Blvd.Pasadena, Tx 77506

Malin International320 77th Street, Pier 40/41Galveston, Tx 77554

Marine Technicians Unlimited512 Holly St.Huntington, Tx 75949

Sneed Shipbuilding17112 Market St.Channelview, Tx 77630

viRGiNiA

BAE Systems Norfolk Ship Repair750 West Berkley Ave.Norfolk, vA 23523-1032

Colonna’s Shipyard 400 East indian River Rd.Norfolk, vA 2352

WASHiNGTON

Gold Star Marine Inc.2900 Washington St.Port Townsend, WA 98368

Everett Shipyard2730 federal Ave. Everett, WA 98201-3411

Lake Union Drydock Company1515 fairview Ave. ESeattle, WA 98102

Nichols Brothers Boat Builders5400 South Cameron Rd.freeland, WA 98249

Platypus Marine02 North Cedar St.Port Angeles, WA 98363

Puglia Engineering201 Harris Ave.Bellingham, WA 98225

Vigor Industrial – Bremerton500 Pacific Ave., Ste. 700Bremerton, WA 98337

Vigor Industrial – Everett2730 federal Ave.Everett, WA 98201

Vigor Industrial – Port Angeles202 N. Cedar St. Ste.1Port Angeles, WA 98363

Vigor Industrial – Seattle1801 16th Ave. SWSeattle, WA 98134-1017

Vigor Industrial – Tacoma313 East f. St.Tacoma, WA 98421

WiSCONSiN

Burger Boat Company1811 Spring St.Manitowoc, Wi 54220

Fraser Shipyards1 Clough Ave.Superior, Wi 54880

Marinette Marine1600 Ely St.Marinette, Wi 54143

www.CGF-kmi.com CGF 6.2 | 13

New Coast Guard Master ChiefThe Coast Guard recently announced the selection for master chief petty

officer of the service.Master Chief Petty Officer Steven Cantrell is the current Atlantic Area

Master Chief and will relieve the current master chief, Michael P. Leavitt, during a change of watch ceremony in May in Cape May, N.J.

Cantrell hails from Memphis, Tenn., and joined the Coast Guard in 1983. During his career, he has served in various afloat and ashore assignments, including as a Gold Badge command master chief to the vice commandant

of the 8th District, the 1st District, officer in charge of Station Panama City Beach, Fla., Station Wrightsville Beach, N.C., Station Alexandria Bay, N.Y., and Station Harbor Beach, Mich. Cantrell’s afloat assignments included officer in charge of the Coast Guard Cutters Ridley and Point Wells.

Cantrell has earned a permanent cutterman’s insignia, coxswain insignia, boat forces insignia and command afloat and ashore insignia, as well as the Command Master Chief insignia. Cantrell holds a Master of Science degree in business administration.

Polar Star Makes Her ReturnThe Coast Guard Cutter Polar Star has returned to their

homeport of Coast Guard Base Seattle following a 108-day deploy-ment of Operation Deep Freeze 2014.

Polar Star departed Seattle December 3, 2013, and made port calls in Honolulu, Sydney, Australia, McMurdo Station, Antarctica ,and Tahiti, French Polynesia.

Having completed a reactivation that began four years ago, this deployment marks the first time in six years that a U.S. icebreaker has supported Operation Deep Freeze, the U.S. Antarctic Program’s resupply efforts of McMurdo Station.

In January, Polar Star departed Sydney to assist in the rescue effort of two ships, the Russian vessel Akademik Shokalsiky and the Chinese vessel Xue Long. These vessels were beset (or stuck) in 15 feet of thick sea ice near Commonwealth Bay, Antarctica. While Polar Star was en route, the shifting ice conditions allowed the two ships to break free from the ice prior to the Coast Guard icebreaker’s arrival.

In Antarctica, Polar Star broke a navigable shipping lane through 12 miles of ice in McMurdo Sound, encountering ice up to 10 feet in thickness. The shipping channel was used by the tanker ship Maersk Peary to deliver approximately 3.5 million gallons of fuel to McMurdo residents, allowing the station to remain operational during the freezing winter months. The channel was also used by the cargo ship Maersk Illinois to deliver more than 500 containers of supplies to operate McMurdo and South Pole stations for the next 12 months.

The crew of the Polar Star also delivered and deployed nearly one mile of fuel hose to Marble Point, an air station 20 miles west of McMurdo. The new hose replaced a worn-out one, and allows the air station to be refueled for the next 15 years.

In February, prior to departing Antarctica, Polar Star hosted Coast Guard Vice Admiral Peter Neffenger, the deputy comman-dant for operations, who visited Antarctica to observe the opera-tions of the U.S. Antarctic Program. For more than 50 years, the U.S. Coast Guard has deployed to Antarctica in support of Operation Deep Freeze.

Polar Star, a 399-foot polar class icebreaker with a 140-person crew, is recently out of a three-year, $90 million overhaul by Vigor Shipyards based in Seattle. The icebreaker was commissioned in January 1976.

Optimizing WMSL 753The Coast Guard has been experi-

encing excessive cylinder temperatures on the WMSL Class as the ship tries to increase to top speed. Ships have also witnessed excessive carbon buildup and increased maintenance on the MDPEs. To correct the temperature, low loading, speed and load balancing issues, several highly sensitive systems will need to be analyzed and adjusted. This will require strict oversight and highly skilled tech-nicians from the OEM. The size and scope of the work correcting these issues are tied directly to the proprietary control software and are very specific to 418-foot WMSL main propulsion equip-ment and software.

The MPDEs have overcome many design issues, but optimization due to the weight of the ship after delivery has yet to be performed. The adjustments being made through this optimiza-tion study will potentially increase cost savings in maintenance and fuel saving by re-calibrating the complete propul-sion system.

By not executing optimization to the current ship profile, the WMSL Program is susceptible to increases in cost and failures.

To that end, the NSC Program Office by way of Surface Forces Logistics Center, Long Range Enforcement Product Line has proposed to enter into a contract on the basis of other than full and open competition with MTU America to perform optimiza-tion analysis and remediation to support the ability to meet program speed requirements and lower total ownership costs for USCGC Hamilton. Tognum America/MTU was used as the main propulsion integrator for the national security cutters during acquisition. According to the Coast Guard, “Tognum America/MTU’s experience is critical to the safe and accurate execution of the sensitive work required to modify the MDPE propulsion system and software.” The total estimated value of this acquisi-tion is $250,000.

www.CGF-kmi.com14 | CGF 6.2

oN tHE HorIZoN

MH-65E Radar Sensor SystemRockwell Collins has been selected by the U.S. Coast Guard to provide

the MH-65E Radar Sensor System (RSS) for 102 MH-65E aircraft. Rockwell Collins’ RTA-4114 multiScan weather radar with enhanced ground/shoreline mapping and a new maritime surface search mode will provide the Coast Guard with a lightweight, flexible and supportable solution.

“Coast Guard pilots will benefit from MultiScan’s broad array of capa-bilities that provide reduced workload and enhanced situational awareness,” said Troy Brunk, vice president and general manager of airborne solutions for Rockwell Collins. “MultiScan’s solid state design provides high reliability and reduced life cycle costs that are vital in a cost-constrained budget envi-ronment.”

Under the Coast Guard contract, Rockwell Collins will provide an enhanced RTA-4114 radar with a new maritime surface search mode and advanced ground clutter rejection algorithms expanding the radar’s ground mapping capability for shoreline and over water use.

The RTA-4114 system represents a major step forward in automation for helicopter flight crews. The radar automatically scans ahead of the aircraft

and combines the returns through advanced digital processing and analysis algorithms to display not just precipitation rates, but the actual weather threats. It features automated tilt, clutter removal and gain management, as well as automatic compensation for many predictable atmospheric and climatic conditions.

Next 10 FRCs NamedThe Coast Guard recently announced the names of 10 Sentinel-Class fast

response cutters (WPCs 1116-1125). Like the first 15 ships in the class, each ship will honor a Coast Guard enlisted hero.

The selected namesakes include recipients of the Silver Star, the Navy and Marine Corps Medal, the Coast Guard Medal, the Bronze Star, and the Gold Lifesaving Medal. Several heroes of the U.S. Lifesaving Service are honored for their actions prior to the formation of the current U.S. Coast Guard, two heroes are recognized for valor during service in World War II and two others for service in Vietnam. Two namesakes died in the course of their duties and were recognized for their actions posthumously.

The 10 namesakes and cutter names are:

• Winslow W. Griesser – (WPC 1116 – USCGC Winslow Griesser) Recipient of the Gold Lifesaving Medal for heroic actions to rescue the crewmembers of two large scows that had broken loose from their moorings in Buffalo, N.Y., in 1900.

• Richard H. Patterson – (WPC 1117 – USCGC Richard Patterson) Awarded the Bronze Star with combat “V” device for actions to take command of the Cutter Point Welcome and maintain the safety of the crew while under attack from North Vietnamese forces in 1966.

• Joseph Tezanos – (WPC 1118 – USCGC Joseph Tezanos) Awarded the Navy and Marine Corps medal for distinguished heroism while leading the rescue of more than 40 injured servicemembers following the explosion of a Navy LST in Pearl Harbor in 1944.

• Rollin A. Fritch – (WPC 1119 – USCGC Rollin Fritch) Posthumously awarded the Silver Star for his selfless and heroic action to remain on station in defense of his ship and crewmembers while under heavy enemy fire during an attack on transport ship USS Callaway off the coast of Luzon, Philippines, in 1945.

• Lawrence O. Lawson – (WPC 1120 – USCGC Lawrence Lawson) Recipient of the Gold Lifesaving Medal for his leadership of a successful rescue of 18 members of the steam vessel Calumet that

became distressed in icy conditions off Evanston, Ill., on Thanksgiving Day 1889.

• John F. McCormick – (WPC 1121 – USCGC John McCormick) Awarded the Gold Lifesaving Medal in 1938 for his exceptional skill in maintaining control of the 52-foot motor lifeboat Triumph while responding to a vessel in need near the Columbia River Bar under treacherous conditions, allowing the crew to recover a crewmember that had been washed overseas.

• Bailey T. Barco – (WPC 1122 – USCGC Bailey Barco) Recipient of the Gold Lifesaving Medal for his heroic and selfless action to rescue the crew of a schooner that had been grounded during a severe winter storm off the coast of Virginia Beach, Va., in 1900.

• Benjamin B. Dailey (WPC 1123 – USCGC Benjamin Dailey) Awarded the Gold Lifesaving Medal for his actions to rescue nine men from a foundering ship off the Outer Banks in 1885.

• Donald H. Horsley - (WPC 1124 – USCGC Donald Horsley) Recipient of the Bronze Star with combat “V” device for his leadership of Division 13 of Coast Guard Squadron One, which was tasked with interdicting reinforcement and re-supply shipments for North Vietnamese forces during the Vietnam War.

• Jacob L. A. Poroo – (WPC 1125 – USCGC Jacob Poroo) Posthumously awarded the Coast Guard Medal after suffering fatal burns received during his efforts to attempt a rescue and respond to a building fire at the LORAN station in Adak, Alaska, in 1968.

Seven FRCs are currently performing operations in Miami and Key West, Fla., and the eighth cutter will be commissioned into service in March 2014. The FRCs named after the above list of Coast Guard heroes will be delivered to San Juan, Puerto Rico (WPCs 1116-1118), Pascagoula, Miss. (WPCs 1119-1120), and Ketchikan, Alaska (WPCs 1121-1122). Homeports for WPCs 1123-1125 will be named at a later date. All of the newly-named cutters are scheduled to be delivered to the Coast Guard by 2017.

www.CGF-kmi.com CGF 6.2 | 15

Compiled by kmi media Group staff

Captain Alan Arsenault received his Bachelor of Science degree in electrical engineering from the U.S. Coast Guard Academy, New London, Conn., in 1988. Following graduation, he completed an assignment as operations officer aboard the USCGC Bramble in Port Huron, Michigan. From 1990 to 1992 he was assigned to the Electronics Technology Division at Coast Guard Headquarters in Washington, D.C.

In 1992 he attended graduate school at the University of New Hampshire and received his Master of Science degree in electrical engineering in 1994. Following graduate school, he served as a proj-ect manager in the Long Range Navigation (Loran) Branch at the Coast Guard Electronics Engineering Center in Wildwood, N.J. When that command was decommissioned in 1997, Arsenault became the first executive officer of the newly commissioned Loran Support Unit located on a portion of property once occupied by the Engineering Center. In 1999, he assumed the duties of chief of engineering at the Loran Support Unit. From 2001 to 2003 he served as the equipment branch chief in the Electronic Systems Division at Maintenance Logistics Command Atlantic in Norfolk, Va. From 2003 to 2006 he served as commanding officer of the Electronics Systems Support Unit in Seattle, Wash. From 2006 to 2011 he completed coursework at the Defense Acquisition University and served as the assistant project manager for the Rescue-21 project and as project manager for the Interagency Operations Centers Project in the Acquisition Directorate at Coast Guard Headquarters.

Currently, Arsenault is serving as the commanding officer of the Coast Guard Research and Development Center in New London. He is a Department of Homeland Security Level III certified Program Manager and a certified Project Management Professional with the Project Management Institute.

Personal awards include the Coast Guard Meritorious Service Medal (five awards), the Coast Guard Commendation Medal (two awards), the Coast Guard Achievement Medal, Commandant’s Let-ter of Commendation and numerous unit, team and service awards.

Q: The president’s 2015 budget proposal has just come out. If I looked at it correctly, it looked like it was less money this year for RDT&E for the Coast Guard. In general terms, if that turns out to be your working budget, what does that mean for you as far as number of projects, timelines for projects, and so on?

A: With the president’s request, we’re at about $17.9 million, which is about $2 million less than last year. One thing to keep in mind about our budget is that our appropriations cover all of our expenses

including salaries, facilities, support and operations—whether here in New London or our detachment down in Mobile. Most other parts of the Coast Guard have a separate budget for salaries.

As far as the number of projects, if you look in our annual report portfolio, we have about 80 projects at any given time. I think we’re going to have the same number of projects, but with less discretion-ary funding, we will have to significantly scale back the scope on a number of those projects.

Our biggest asset is our people, the subject matter experts that we have here—the scientists, engineers, both civilians and military.

We have a very robust process in place that tracks each of the projects and what their status is.

In early March we conducted our annual Idea Submission Review, which is a process where we review projects that are submitted to us from all across the enterprise and cover the entire gamut of the Coast Guard mission. Just from the most recent review we collected 117 project ideas.

Q: Regardless of budgets, what are your R&D priorities for the next 12 months or so, or the next cycle as you see it?

A: Among our heavy hitters—the Arctic is a big one. Not surprising, based on the Coast Guard’s Arctic strategy and the new national strat-egy. Last year, we participated in Arctic Shield and we’ll also be doing so again this year.

Maximizing R&D Funding Across the Spectrum of Coast Guard Ideas

Idea Developer

Captain Alan ArsenaultCommander

Coast Guard Research and Development Center

Q&AQ&A

www.CGF-kmi.com16 | CGF 6.2

We definitely see unmanned systems—air, surface and subsur-face—as being game-changers for the Coast Guard. We are focused on looking at efficiencies and where we might be able to replace manned systems with unmanned systems. We’re certainly not at the leading edge of developing the actual unmanned system—we’re taking advantage of some of the work done by the other ser-vices. We are evaluating the systems from our cutters and in our operational environment to see how they can best be integrated.

Cybersecurity in the port environment is also very high on our list. We are working with our sector commanders, our port part-ners and industry to determine the vulnerabilities and mitigate the risks involved.

Another area that kind of popped up to the top at our submis-sion review recently was command-and-control communications and mobile applications, how we can tie those into the Coast Guard architecture to take advantage of mobile capabilities.

Modeling and simulation has also become very important to us here at the R&D center.

Q: Is the idea submission review an annual process?

A: Yes, it’s currently in its third year. It’s a way to pull the stake-holders in early into developing project portfolios, and it’s really worked out well. It’s not our portfolio, it’s our stakeholders’ and the operators’ portfolio out in the field, and with them driving the projects, it really helps.

The idea of submission review with its numerous stakeholders will be very important in terms of defining our portfolio for FY15 and FY16. We had a lot of great ideas to work with. For example, aviation laser eye protection, developing an environmentally-friendly mooring system to reduce damage to sensitive areas—like coral reefs—down in District 7, and oil spill research. Another of the interesting ones was the need to look into emergent threats related to shale wastewater, a by-product of hydraulic fracking.

At the end of the review process we have all of these great ideas that we compare against our skill sets, available resources, potential to leverage partnerships with other government agencies and industry, and then develop an execution plan. Then it will go through another layer of review, which would include a portfolio review to see if they fit with our long-term plan and where to go from there.

Q: As far as coordinating and partnering your R&D efforts with other services or other elements of the federal government to maximize dollars, eliminate waste and get to an end game sooner, how do you go about doing that, and are there ways you think you can increase and improve that process in the future?

A: That’s a huge part of what we do before we start executing any projects. Actually at the portfolio review, partnerships represent a key theme in our metrics—how much we can leverage work done by other services or agencies. For example, we score projects on how well they exploit existing technology or research and new or existing partnerships and also on how well projects look for solutions that provide broad applicability with multiple interested customers and mission sets. This maximizes our investments and those of our partners as well.

The bottom line is nobody can afford to do duplicate effort. We need to leverage each other.

One example of that over the last couple of years is our relation-ship with the Office of University Programs, under DHS, Science and Technology Directorate. They run a network of centers of excellence, basically consortiums of different universities, that operate with grant funding—about $20 million per center over the course of several years.

We’re leveraging those by providing input to their funding oppor-tunity announcements. This is a case where we’re not co-funding anything, but using our influence to try to get maritime research done by these universities that help us. It’s not as direct as spending money or relying on contract support, but there are a lot of academic talent and resources that we can draw on.

We put effort into building all of these relationships. Sometimes they may take years to mature, but they’re very important to us because we don’t see our base [funding] growing anytime soon, so relationships are a huge part of our business CONOPS.

Q: How closely do you work with industry? Do you have partner-ships that you draw on their expertise and leverage things that they’ve already done so you don’t have to do them again?

A: Yeah, we have a couple of tools in our toolbox that we use here quite a bit. The first one is the broad agency announcement. That’s typically the way we advertise to industry that we have a mission need. If we see some good proposals come back, we might put one or two—or more—contractors on contract to let them show us what they can do.

A couple of years ago, we did one for an Arctic craft. Basically, there are no port facilities up there and it’s very difficult to launch boats from the beach. We wanted to look for alternatives that could drive up on top of ice, in the water and drive right up onto the beach. We received a number of interesting proposals and put a few of them under contract to do some testing off of Barrow.

One of our other tools is the cooperative research and develop-ment agreement, or CRADA. Our office is the only Coast Guard Labo-ratory authorized to enter into these technology transfer agreements. A CRADA is where we either go to industry, or oftentimes industry comes to us, with a not-fully-mature technology or an idea. We have seven of those in place right now. As an example, we have three in place looking at some alternative fuels; we have one with Honda and Mercury Marine looking at using different blends other than ethanol for our outboard motors—ethanol is a problem in the marine envi-ronment because it attracts water. One other is with Cummins on the diesel side.

So under those CRADAs we actually helped define the biobutanol mixing standards that were recently published.

We have a CRADA with General Dynamics C4 Systems on some mobile asset tracking work; we’re planning on putting another one in place with them relatively soon on Next-Generation 911 systems, as it relates to the Coast Guard’s Rescue-21 command and control system.

We have another one with a company called UrsaNav. We did a little work with them using the old Coast Guard Loran-C infrastruc-ture to test some alternatives to wireless precise time.

We’re also doing some tactical datalink work with Engility, and we have one with the Marine Exchange of Alaska looking at the next-generation Arctic maritime navigation safety system.

These are not contractual relationships, they are based upon a legal agreement with no money exchange—we just provide in-kind services. Typically what we provide are CONOPS and Coast Guard

www.CGF-kmi.com CGF 6.2 | 17

infrastructure and assets, and industry typically supplies their ideas and some of their technologies they use to fill a mission need.

Q: Let’s go back to the national Arctic strategy. Are there R&D efforts that you are involved in, or will be coming to the forefront, that are important steps in developing and executing an Arctic strategy?

A: We’re certainly tied into that. I mentioned earlier that we partici-pated in Arctic Shield last year, and are planning on doing so again this year.

Our primary focus was oil in ice type work, looking at if there is an accident, what capabilities work best in an ice environment? We did a lot of testing with technologies that would work in that kind of an environment.

We used unmanned systems, both air and underwater systems, to monitor work and the cleanup of simulated oil spills. We had a formidable network of partners during that operation, includ-ing Woods Hole Oceanographic Institute, the Bureau of Safety and Environmental Enforcement, University of Alaska Fairbanks, Environment Canada, Swedish Coast Guard, DHS S&T’s Center for Maritime, Island, and Remote and Extreme Environmental Security, the National Oceanic and Atmospheric Administration, and multiple Coast Guard operational units.This year we plan to continue that work but will also spend time on high latitude communications in cooperation with DoD and their MUOS satellite system.

Earlier I mentioned the CRADA with the Marine Exchange of Alaska—we will be working with them testing AIS Transmit. They currently have the infrastructure where they can transmit and receive AIS information, and we want to see if we can use the same system to transmit weather, ice reports and other data. We are also teaming with NOAA on what their needs might be as well. This CRADA, like the others, stresses the importance and value of public-private partnerships. The Marine Exchange is a nonprofit that we already have a relationship with to receive AIS data to put into our common operating picture, and this could just be an extension of that service.

We’re also involved in the pre-acquisition work for the possible future icebreaker, like requirements development. Actually, the high latitude study, the original mission analysis that was done, set the stage for the icebreaker work and everything else was developed by the R&D center.

Q: Do you think the Coast Guard maximizes its use of modeling and simulation for the projects that you use, or is that an area that you can improve?