Bare Metal Stents

-

Upload

justin-eng -

Category

Documents

-

view

227 -

download

0

Transcript of Bare Metal Stents

Endovascular StentsMark DeAngelis, Hector Baez, Amanda

Johnston, Justin Eng

Background● Developed in late 1980s.● Hold open blood vessels at sites of percutaneous

transluminal coronary angioplasty (PCTA) or vascular injury.

● PCTA is a form of percutaneous cardiovascular intervention (PCI), used for patients with atherosclerotic plaque or thrombotic deposits (Ratner et al, 2013).

Diagram of PCTA

Figure 1. A diagram of PCTA: A) the location of the coronary arteries, B) the artery before the balloon is expanded, C) the artery as the balloon is expanding, D) the stent in place. (NIH)

Background (cont.)● Can be balloon inflated or self-inflated.● Three main types:

○ Coil■ Circular tubes of metallic wire or strips in coil

shape.○ Tubular mesh

■ Wires wound together in a mesh network.○ Slotted tube

■ Metal tubes that have a laser-cut design (Butany et al, 2005).

Materials● Metals are ideal for stents.

○ Many choices for grades and alloys.■ Allows tailoring to different needs.

○ Excellent mechanical properties.○ Typically bioinert.○ Fairly inexpensive and easy to fabricate.○ Can be coated with polymeric coatings

(Ratner et al, 2013; Stent Manufacturing).

Fabrication● Can be laser fabricated using computer

numerical control (CNC).● Produces slotted tube type.● Laser cuts pattern from metal tube.● “Mask” is applied to allow different heat

treatment for bands and connectors.● “Mask” is removed after heat treatment

(Gregorich).

Fabrication (cont.)● Alternative method:

○ Liquid or powder stent material is poured into female mold.

○ Mold is rotated with forces of at least 1G as stent solidifies (Mirizzi).

● Argon furnaces allow annealing temps of 11oo °C for 316L stainless steel.

● Stents can be electropolished after heat treatment.

● Inspected for quality control and packaged in clean rooms (Stent Manufacturing).

316L Stainless Steel● Low carbon grade of 316 stainless steel.

○ Unaffected by sensitization, the precipitation of carbides at grain boundaries.

● Contains molybdenum.○ Provides corrosion resistance in chloride

environments.● Austenitic structure.

○ Provides excellent strength (Stainless Steel).

316L Stainless Steel Element Percent

Composition

Iron Balance

Carbon <0.03%

Chromium 16-18.5%

Nickel 10-14%

Molybdenum 2-3%

Manganese <2%

Silicon <1%

Phosphorus <0.045%

Sulphur <0.03

Figure 2. A table of the chemical composition of 316L stainless steel (Stainless Steel).

Figure 3. The Medtronic beStent2, a balloon expandable, slotted tube stent made of 316L stainless steel. The arrow is pointing to gold radiopaque marker. (Butany et al, 2005)

UNIMET L-605 Cobalt Chromium● Super-alloy

○ Can withstand high temps and mechanical stress.● Solid strengthened.● Excellent resistance to:

○ Oxidation○ Sulfidation○ Wear○ Galling

● Stronger than steel, better radiopacity (AZoM, Kereiakes et al, 2003).

UNIMET L-605 Cobalt Chromium

Element Percent Composition

Cobalt 46.38-56.95%

Chromium 19-21%

Tungsten 14-16%

Nickel 9-11%

Iron <3%

Other Balance

Figure 4. A table of UNIMET L-605’s chemical composition (AZoM).

Comparison of Metals

Metal

Elastic modulus (GPa)

Yield strength (MPa)

Tensile strength (MPa)

Density (g/cm3)

316L stainless steel (ASTM F138 and F139; annealed) 190 331 586 7.9Cobalt chromium 210 448-648 951-1220 9.2Pure iron 211.4 120-150 180-210 7.87Mg alloy (WE43) 44 162 250 1.84

Figure 4. A comparison of the mechanical properties of metals, including 316L and cobalt chromium (Mani et al, 2007).

Optimizing the Device● Desirable characteristics:

○ Low cross sectional area○ High flexibility○ High biocompatibility○ High radial strength○ Low metallic surface area○ Favorable radiographic properties○ Easy deployment (Butany et al, 2005)

Figure 5. Features of a commercial cobalt chromium stent (Sahajanand Medical Technologies Pvt. Ltd.).

Interaction● Minimal interaction with the host

tissue (blood)● Withstand corrosion

○ Cobalt Chromium○ 316L Stainless Steel

Engineering Solutions● Drug-Eluting stents

○ anti-proliferative drug (Maisel)○ prevents neointima

● Biodegradable stents○ short term support○ absorbed or dissolved○ match the radial strength of traditional

materials

Why Stents?● Treats stenosis,

improving blood flow● High complication rate

(Biomaterials Science 775)○ ~21% within the first

9 months ● Room for improvement

Figure 6. Increase in carotid stenting (Nallamothu)

FDA Approval● First coronary stent 1994● Classification

○ nature of expansion○ stent design

Commercialization● As late as 2004, 16 models were

approved○ 9 different manufacturers

● Prefered treatment for Coronary Artery Disease

● $2.5 billion spent on stents in 2003 (Butany)

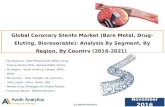

Competition● Currently 13

approved coronary stents by FDA

● Growing Market● Overuse debate

Figure 7. Market size and growth for coronary stent devices (Ruchika BBC)

Work Cited● AZoM.com Staff Writers. "UDIMET Alloy L-605 (UNS R30605)." UDIMET Alloy L-605 (UNS R30605).

AZoM, 29 June 2013. Web. 08 Apr. 2014. <http://www.azom.com/article.aspx?ArticleID=9458>.● Butany, J., K. Carmichael, S. W. Leong, and M. J. Collins. "Coronary Artery Stents: Identification and

Evaluation." Journal of Clinical Pathology 58.8 (n.d.): 795-804. US National Library of Medicine. Web.<http://www.ncbi.nlm.nih.gov/pmc/articles/PMC1770873/>.

Gregorich, Daniel, and Jonathan Stinson. Medical Devices and Methods of Making the Same. Boston Scientific Scimed, Inc., assignee. Patent US 20080114449 A1. 23 Jan. 2008. Print. "How Is Coronary Angioplasty Done?" - NHLBI, NIH. NIH, 01 Feb. 2012. Web. 08 Apr. 2014. <http://www.nhlbi.nih.gov/health/health-topics/topics/angioplasty/howdone.html>.Kereiakes, Dean J. "Usefulness of a Cobalt Chromium Coronary Stent Alloy." ScienceDirect. The American Journal of Cardiology, Aug.-Sept. 2003. Web. 8 Apr. 2014.

● Maisel, William H., Dr. "Drug-Eluting Stents." American Heart Association Journals. Circulation, 2017. Web. 30 Apr. 2014.

● Mani, Gopinath, Marc D. Feldman, Devang Patel, and C. Mauli Agrawal. "Coronary Stents: A Materials Perspective." Coronary Stents: A Materials Perspective. Biomaterials Volume 28, Issue 9, Mar. 2007. Web. 08 Apr. 2014. <http://www.sciencedirect.com/science/article/pii/S0142961206010076>.

● Mirizzi, Michael S. Stent Made by Rotational Molding or Centrifugal Casting and Method for Making the Same. Advanced Cardiovascular Systems, Inc., assignee. Patent US 6574851 B1. 31 July 2000. Print.

● Nallamothu, Brahmajee K., Dr., Mingrui Lu, Dr., Mary A. Rogers, Dr., Hitinder S. Gurm, Dr., and John D. Birkmeyer, Dr.

● "Physician Speciality No Effect on Carotid Stenting Outcomes | HeartZine." Physician Speciality No Effect on Carotid Stenting Outcomes | HeartZine. Archives of Internal Medicine, Aug. 2008. Web. 30 Apr. 2014.

● Ratner, Buddy D. Hoffman, Allan S. Schoen, Frederick J. Lemons, Jack E. (2013). Biomaterials Science - An Introduction to Materials in Medicine (3rd Edition). (pp. 773-776). Elsevier.

● Sahajanand Medical Technologies Pvt. Ltd. Design Features of Coronnium. Digital image. SMTPL - Coronnium - Cobalt Chromium Alloy Coronary Stent. Sahajanand Medical Technologies Pvt. Ltd, n.d. Web. 30 Apr. 2014. <http://www.smtpl.com/coronnium.html>.

● "Stainless Steel - Grade 316L - Properties, Fabrication and Applications (UNSS31603)." Stainless Steel - Grade 316L - Properties, Fabrication and Applications (UNS S31603). AZoM, 18 Feb. 2004. Web. 08 Apr. 2014. <http://www.azom.com/article.aspx?ArticleID=2382>.

● "Stent Manufacturing." Stent Manufacturing - Nitinol Stents. Norman Noble, Inc, n.d. Web. 08 Apr. 2014. <http://www.nnoble.com/Stent/Stents.htm>.

Questions?