Baixie forging hammers

-

Upload

forginghammer -

Category

Documents

-

view

557 -

download

4

description

Transcript of Baixie forging hammers

Jiangsu Baixie Precision Forging Machinery Co.,Ltd Gillian Ge Mob: +86 (0) 137 7368 3540Tel: +86 513 8883 8848 Fax: +86 513 8889 1498MSN: [email protected]:kunkunh00E-mail: [email protected] ; [email protected]: www.forginghammer.cn

Brief introduce of Baixie Company

In 2002, Baixie developed a first set CNC fully hydraulic die forging hammer in China;In 2004, Baixie finished refitting 80kJ pneumatic hammer with 100% hydraulic driving;In 2006, Baixie developed 100kJ hydraulic counterblow hammer with micro-motion;In 2008, Baixie finished refitting 125kJ pneumatic hammer with 100% hydraulic driving;In 2009, Baixie finished refitting 250kJ pneumatic hammer with 100% hydraulic driving;In 2010, Baixie finished refitting 320kJ pneumatic hammer with 100% hydraulic driving;In 2011, Baixie developed China first set 125kJ CNC fully hydraulic die forging hammer;In 2012, Baixie developed China first set 400kJ CNCfully hydraulic counterblow hammer was in developing.

Baixie , a member of original Haian National Machinery Factory , is the most professional manufacturer of CNC closed die forging hammers in China and more popular company in the world.More than 300 sets Baixie’s hammers have been sold to China and abroad.

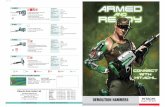

Main Products

1. CHK CNC fully hydraulic die forging hammer

2. CTKA CNC fully hydraulic die forging hammer

3. CTK CNC fully hydraulic die forging hammer (hydraulic drive systems be applied on all types hammers)

4. CDKA CNC hydraulic counterblow hammer

1. CHK series CNC fully hydraulic forging hammers

Baixie’s hammers are suitable for forging automobile part, surgical instrument, and tableware, hardware, and also for spaceflight and ship industry.

Features:

Baixie use U-shape framework and X - configured wide guide rail to ensure high forging accuracy; Adopt short striking stroke structure and hydraulic driving structure to get huge striking energy in short time to ensure high forging frequency; Equipped with Siemens control system to ensure precise energy control; Step the feet pedal switches according to the pre-set programs to simplify

operation; Use safety valve and safety pin to ensure safety operation; Equipped with Vibration control system of GERB to reduce the vibration to surrounding environment. Short die connecting time and short reversal of stroke reduces the die stress, so optimum die life is achieved. Equipped with robots to realize automatic forging line. Equipped with hydraulic ejector according to the customer’s requirement.

CHK series CNC fully hydraulic forging hammers

Main parts

CHK series CNC fully hydraulic forging hammers

Technical parameters

Unit 16 25 31.5 50 63 80 100 125

Striking energy kJ 16 25 31.5 50 63 80 100 125

Striking frequency at normal capacity 1/min 100 90 90 90 80 80 75 70Max. ram stroke mm 630 680 720 720 800 800 840 840

Max. die height without dovetails (upper and lower die)

mm 245 360 400 420 440 460 550 550

Min. die height without dovetails (upper and lower die)

mm 110 200 240 260 280 300 350 350

Daylight between guides mm 500 600 660 770 830 890 960 960

Frame base width mm 1800 2160 2320 2720 2950 3150 3400 3400

Frame base depth mm 1200 1380 1500 1760 1880 2050 2400 2540

Overall weight T 26 41 51 85 100 125 150 195

Main motor capacity kW 30 55 55 2×55 2×55 2×90 2×90 2×110

CHK series CNC fully hydraulic forging hammers

Typical Customers in China

CHK16kJ tableware automatic forging lines in Suzhou, an American company(2 lines)

CHK16kJ-25kJ Surgical instrument forging lines in Shanghai (4 lines)

CHK series CNC fully hydraulic forging hammers

Baixie’s CNC forging hammers are very popular. Here are the customers in China. One of Baixie’s customer who produces hardware tools bought 12 hammers from 2007.

Typical Customers in China

CHK16kJ-CHK31.5kJ automobile, forklift and machinery parts forging lines in Jingxian (5 lines)

CHK25kJ-CHK100kJ hardware tools forging lines in Shandong (12 lines)

CHK series CNC fully hydraulic forging hammers

CHK series CNC fully hydraulic forging hammers

Typical Customers in China

CHK31.5-CHK80kJ rigging forging lines in Shandong (4 lines)

CHK31.5kJ-CHK100kJ automobile forging lines in Fuzhou (5 lines)

CHK series CNC fully hydraulic forging hammers

Typical Customers in China

CHK80kJ steering knuckle forging line in Anhui

CHK80kJ-CTK125kJ vane forging lines in Deyang Dongfang Turbine Co.,Ltd (2

lines)

CHK series CNC fully hydraulic forging hammers

Typical Customers in China

China first set 125kJ forging hammer with U-frame (in 2011) CHK16kJ-CHK125kJ anchor chain

forging lines in Jiangsu (4 lines)

CHK series CNC fully hydraulic forging hammersTypical Customers out of China

The forging hammers are not only welcomed in China, but also popular in abroad. We exported the hammers to Germany, Brazil, Russia, Syria, Turkey, India, Vitenam and so on.

CHK25 hand tool forging line in Russia CHK25 hand tools forging lines in Vietnam (2 lines)

CHK series CNC fully hydraulic forging hammers

Typical Customers out of China

CHK25kJ hand tool forging line in Brazil CHK31.5kJ automobile parts forging line in Turkey.

2. CTKA Series CNC Fully Hydraulic forging hammer

In order to easy to ship, Baixie developed CTKA CNC fully hydraulic die forging hammers. These series forging hammers have the same hydraulic system with CHK, but the frames are composed by two uprights with one anvil. They have below features:1.High integrated fully hydraulic driving system, no need pump chamber and hydraulic station;2.Programmable striking control and digital inputting;3. Long hammer tup enhancing working accuracy;4. Striking energy and striking sequence be set optionally; no surplus striking energy avoiding noise problem and increasing the die life.5. Man-machine interface and automatically malfunction diagnosis, Chinese and

English display.

Spec. CTKA 160 200 250 320 400

Striking energy kJ 160 200 250 320 400

Daylight of guiderails mm 1000 1000 1000 1200

Max. striking stroke mm 1000 1050 1100 1200 1300

Min. striking stroke mm 800 780 800 900 950

Max. die height (without wedge)

mm 650 700 750 750 800

Min. die height(without wedges) mm 450 430 450 450 500

Striking frequency Min-1 55 50 45 45

Dropping weight kgs 11000 12500 15000 17000 22500

Main motor kW 4×75 4×90 4×90 4×110 4×110

CTKA Series CNC Fully Hydraulic forging hammer

Technical parameters

In order to save investing costs as lower as possible, we can keep using of frames (including uprights, anvil), only change the driving system and control system, as well as the ram.

Baixie supplies this kind of refitting, that is CTK series. More than twenty sets hammers in the range of 75kJ to 400kJ were conversed.

There has many advantages to use the new hydraulic system:

Controlling striking energyWith controlling exact striking energy, it not only improves the die life, but also saves the energy, as well as keep the stable products quality..

High speed striking 100% hydraulic driving to make the system get huge energy in a short time.Lower space cost Don’t need the hydraulic station any more, just two oil tanks are on the two sides of the hammer.

3. CTK CNC fully hydraulic die forging hammer (hydraulic drive systems be applied on all types hammers)

Technical parameters:

Unit 25 50 75 125 250 400

Striking energy kJ 25 50 75 125 250 400

Striking frequency at normal capacity 1/min 90 80 70 60 50 40

Max. ram stroke mm 720 850 900 1000 1100 1200

Ram depth mm 400 700 800 850 1200 2000

Max. die height without dovetails (upper and lower die)

mm 500 500 550 600 750 800

Min. die height without dovetails (upper and lower die)

mm 300 320 350 400 450 500

Daylight between guides mm 450 600 680 730 1000 1200

Frame base width mm 2380 2960 2700 3700 4000 4400

Frame base depth mm 1100 1500 1800 2000 2400 2700

Total height mm 6400 6800 7600 9200 9200 11000

Overall weight T 33 64 100 165 320 440

Main motor capacity kW 55 2×55 2×90 4×55 4×90 4×132

CTK series CNC fully hydraulic forging hammers(hydraulic drive systems be applied on all types hammers)

Typical Customer

CTK250kJ railway parts forging line in Shandong

CTK320kJ crank shafts forging line in Qinghai

CTK series CNC fully hydraulic forging hammers(hydraulic drive systems be applied on all types hammers)

Typical Customer

CTK80kJ-125kJ automobile forging lines in Faw-Brahat (4 lines)

CTK75kJ-125kJ automobile parts forging lines in Changzhou (2 lines)

CTK series CNC fully hydraulic forging hammers(hydraulic drive systems be applied on all types hammers)

Compare Baixie 100% hydraulic hammer with hydro-pneumatic forging hammer

ItemFully hydraulic forging hammer Hydro-pneumatic forging hammer

Basis principlesThe upper and lower chamber of working cylinder is full of hydraulic oil.

Upper chamber is full of high-pressure Nitrogen, and lower chamber is hydraulic oil

How to control the striking energyBy controlling the close time of striking valve By controlling the striking stroke of ram

Normal striking energyIt can realize max. striking energy in every place in the die closed height

It can realize max. striking energy only when the ram has max. stroke.

Striking stroke small large

Striking speed slow fast

Return speed fast speed

Dies be closed and striking continuously no has

Mix of oil and gas No has

Pressure keeping property of hydraulic system

good bad

Item Fully hydraulic forging hammer Hydro-pneumatic forging hammer

Power system Be installed on the frame with high integration

Hydraulic station is separated, and power system is installed in pump room.

The space be needed No additional beside the hammer body Need the pump room and pipeline

main valve structure and longevity Cone valve with long longevity Combination sliding valve with short longevity

Hydraulic pipeline No additional high pressure pipeline With additional high pressure pipeline

Dropping weight big small

control way of striking energy PLC worker

performance of large hammer good bad

worker requirement Low( semi-skilled) High( skilled)

PLC of striking energy and steps yes no

accuracy high low

Realize automatic It can It can not

Compare Baixie 100% hydraulic hammer with hydro-pneumatic forging hammer

hydraulic die forging hammer Hydro-pneumatic forging hammer

Cost for purchasing hammers 1.5 1

Cost for constructing pump room no Should take into consideration

Hydraulic oil usage 1 3

Pipe system noShould have the pipe system with large flow

Safety propety good worse

Leakge of Nitrogen No often

cooling machine ( heating exchange) 1 twice

Energy saving good normal

Stable quality of forging parts good normal

Reliability of forging hammer good normal

Maintenance cost lower higher

Compare Baixie 100% hydraulic hammer with hydro-pneumatic forging hammer

4. CDKA series Fully Hydraulic Counterblow Hammer

CDKA’s basic structures : The mass ratio of the upper to the lower ram is

1:1; Fully hydraulic driving system; Siemens’s PLC control; Multiple element cast steel and welded

construction frame; X-configured wide guide rail; Hydraulic ejectors; Automatic lubrication and oil temperature control

system; GERB vibration control system.

Just as the name implies, counterblow hammer is a kind of equipment that the upper ram and lower ram strike with each other with equal energy.

Technical parameter:

Unit 160 250 320 400

Striking energy kJ 160 250 320 400

Blow frequency at normal working capacity 1/min 50 45 40 38

Upper ram stroke mm 630 700 700 700

Ram depth mm 1450 1700 1800 2000

Max. die height without dovetails (upper and lower die)

mm 700 820 900 950

Min. die height without dovetails (upper and lower die)

mm 400 500 550 600

Daylight between guides mm 1100 1300 1350 1500

Frame base width mm 3600 4200 4500 5000

Frame base depth mm 1650 1900 2000 2400

Total height mm 10800 11500 12000 13000

Overall weight T 125 180 240 320

Main motor capacity kW 220 360 440 530

CDKA series Fully Hydraulic Counterblow Hammer

CDKA series Fully Hydraulic Counterblow Hammer

Picture showes 400kJ CNC fully hydraulic driving counterblow hammer was finished by Baixie and passed the inspection by China authoritative department.

It is first set 100% hydraulic driving counterblow hammer in China and the advanced in the world.

Machining workshop

Assembly workshop

Thanks for your watch!

Welcome to visit our company!

www.forginghammer.cn