6 Phase Diagram

-

Upload

adiyat-adi -

Category

Documents

-

view

236 -

download

0

Transcript of 6 Phase Diagram

-

8/12/2019 6 Phase Diagram

1/22

Phase Diagram BKTK-2011

Phase Diagram

-

8/12/2019 6 Phase Diagram

2/22

Phase Diagram BKTK-2011

An Introduction

To have better properties, materials can be fabricated and be

composed of different compounds / atoms alloys material.

The properties of the alloys is strongly dependent on the

characteristic of microstructure of the alloys.

The characteristic on the alloys can be described using Phase

Diagram of the alloys. The characteristic is determined by elements

present, composition, heat treatment.

Valuable informations of alloys are often explainable from their PhaseDiagram

-

8/12/2019 6 Phase Diagram

3/22

Phase Diagram BKTK-2011

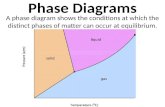

Some definitions

Component : pure/stable compounds (metals or oxides) of which an

alloy is composed

System : material under consideration or possible alloys consisting of

the same components.

Solid solution : a solution that consists of at least two different

components.

Solubility limit: maximum concentration of solute can be dissolved in the

solvent in a solid solution.

Phase : homogeneous portion of a system that has uniform physical and

chemical charateristics

-

8/12/2019 6 Phase Diagram

4/22

Phase Diagram BKTK-2011

Some definitions (2)

Equilibrium : a state or condition where free energy of the system is

minimum (time independent property) a function of temperature,

pressure and composition.

Phase equillibrium: equillibrium state when it applies to a systemconsists of more than one phase.

Metastable state: a non equilibrium condition of a system since the

equilibrium state is very slowly to reach.

-

8/12/2019 6 Phase Diagram

5/22

Phase Diagram BKTK-2011

The Gibbs phase rule*

P + F = C + N

Number of phases

Number of

noncompositional variables(temperature, pressure)Number of

components

Number of degrees of freedom

external controlled variables

*J. William Gibbs (1928)

-

8/12/2019 6 Phase Diagram

6/22

Phase Diagram BKTK-2011

Water - Sugar

-

8/12/2019 6 Phase Diagram

7/22Phase Diagram BKTK-2011

Nickel - Copper

Melting point

of Cu

Melting point

of Ni

-

8/12/2019 6 Phase Diagram

8/22Phase Diagram BKTK-2011

The phase composition

T

emperature,

C

Composition, wt%

L (liquid)

A

B

C

L +

TA

TB

TC

CoCL C

Tie line / Isotherm

-

8/12/2019 6 Phase Diagram

9/22Phase Diagram BKTK-2011

The phase amount

T

emperature,

C

Composition, wt%

L

A

B

C

L +

TA

TB

TC

CoCL C

R S

Lever rule

L mass fraction :

WL= (C-Co)/(C-CL)

mass fraction :W

= (Co-CL)/(C-CL)

CL

WL+C

W

= Co

-

8/12/2019 6 Phase Diagram

10/22Phase Diagram BKTK-2011

Development of microstructure

equilibrium process

-

8/12/2019 6 Phase Diagram

11/22Phase Diagram BKTK-2011

Development of microstructure

nonequilibrium process

-

8/12/2019 6 Phase Diagram

12/22Phase Diagram BKTK-2011

Eutectic system

L (liquid)

+ L + L

+

A

B

C

F

G

H

E

(X) (Y)

liquidus

solidus

solvus

Composition (wt%)

Temperature(C)

TE

CECE CE

( ) ( ) ( )cooling

E E Eheating

L C C C

-

8/12/2019 6 Phase Diagram

13/22Phase Diagram BKTK-2011

Microstructure of the eutectic system

L (liquid)

+ L + L

+

(X) (Y)Composition (wt%)

Temperatu

re(C)

A B C

-

8/12/2019 6 Phase Diagram

14/22Phase Diagram BKTK-2011

Microstructure of the eutectic system (2)

(A) (B) (C)

primary

eutecticprimary

eutectic

Eutectic structure

-

8/12/2019 6 Phase Diagram

15/22Phase Diagram BKTK-2011

Eutectoid system

+ +

+

E

(X) (Y)

solvus

Composition (wt%)

Temperatu

re(C)

( ) ( ) ( )cooling

E E Eheating

C C C

-

8/12/2019 6 Phase Diagram

16/22

Phase Diagram BKTK-2011

Peritectic system

L

+ L

+ L +

P

(X) (Y)Composition (wt%)

Temperatu

re(C)

cooling

heatingL

-

8/12/2019 6 Phase Diagram

17/22

Phase Diagram BKTK-2011

Systems with intermediate phases

-

8/12/2019 6 Phase Diagram

18/22

Phase Diagram BKTK-2011

Iron-Carbon System

FCC

BCC

BCC

Iron carbide

-

8/12/2019 6 Phase Diagram

19/22

Phase Diagram BKTK-2011

Iron-Carbon System (2)

Eutectic reaction at 1147C:

3(4.3 % ) (2.14 % ) (6.7 % )cooling

heatingL wt C wt C Fe C wt C

Eutectoid reaction at 727C:

3(0.76 % ) (0.022 % ) (6.7 % )cooling

heatingwt C wt C Fe C wt C

-

8/12/2019 6 Phase Diagram

20/22

Phase Diagram BKTK-2011

Iron-Carbon System (3)

The most commond Fe-C alloys:

Pure iron (< 0.008 wt%C)

Steel (0.008 wt%C 2.14 wt%C)

Cast iron (2.14 wt%C

6.70 wt%C)

The microstructure of the alloys is strongly dependent on

both the C content and temperature treatment during

fabrication.

-

8/12/2019 6 Phase Diagram

21/22

-

8/12/2019 6 Phase Diagram

22/22

Phase Diagram BKTK 2011

Heating or cooling through

hypoeutectoid