Yarn Manufacturing

Transcript of Yarn Manufacturing

TEXTILETEXTILEYarn ManufacturingYarn Manufacturing

What is Textile?What is Textile?

Textile refers to any material made of Textile refers to any material made of interlacing fibers; hence textile raw interlacing fibers; hence textile raw materials are those fibers capable of materials are those fibers capable of being converted into yarns and fabrics being converted into yarns and fabrics

FIBER YARN FABRIC

FIBERSFIBERS Cellulosic fiberCellulosic fiber: Cotton, Bast fibers, Leaf : Cotton, Bast fibers, Leaf

fibers, Coir, Kapokfibers, Coir, Kapok Protein fiberProtein fiber: Silk, Wool, Mohair, : Silk, Wool, Mohair,

Cashmere, Camel hairCashmere, Camel hair Synthetic fiberSynthetic fiber: Nylon, Nomex, Kevlar, : Nylon, Nomex, Kevlar,

Polyester, AcrylicPolyester, Acrylic Mineral and Organic fiberMineral and Organic fiber: Glass, Metallic : Glass, Metallic

fiber and Carbon fiberfiber and Carbon fiber

FIBERSFIBERS LengthLength: must be several hundred times the width, to : must be several hundred times the width, to

gives the necessary flexibility which enables them to gives the necessary flexibility which enables them to be spun into yarns.be spun into yarns.

Tenacity or strengthTenacity or strength: to withstand the stresses : to withstand the stresses during spinning and weaving.during spinning and weaving.

ElongationElongation: specified as percentage of starting point : specified as percentage of starting point and it is importance since textile product without and it is importance since textile product without elasticity would hardly be usable.elasticity would hardly be usable.

UniformityUniformity: fibers should have the same length, : fibers should have the same length, width and flexibility to produce even yarns width and flexibility to produce even yarns

YARNYARN Yarn, by Yarn, by ASTM Standard D123, Vol 07.01ASTM Standard D123, Vol 07.01, is a , is a

generic term for a continuous strand of textile generic term for a continuous strand of textile fibers, filaments or material in a form suitable fibers, filaments or material in a form suitable for knitting, weaving or otherwise intertwining to for knitting, weaving or otherwise intertwining to form textile fabric. form textile fabric.

Yarns can be produces in different sizes and Yarns can be produces in different sizes and texture, and also vary in other characteristics. texture, and also vary in other characteristics. Performance and end use of the fabrics are Performance and end use of the fabrics are affected by these yarn characteristics. affected by these yarn characteristics.

TYPES OF YARNTYPES OF YARN

Staple or filamentStaple or filament Single or plied or cordSingle or plied or cord Simple or complexSimple or complex

DIRECTION OF YARNDIRECTION OF YARN Yarns are twisted to hold the fiber Yarns are twisted to hold the fiber

together.together.

S Direction Z Direction

YARN SIZE / NUMBERYARN SIZE / NUMBER

1) Direct System1) Direct SystemWeight in grams of 9000 meters of yarn Denier

Tex

Decitex

Weight in grams of 1000 meters of yarn

Weight in grams of 10000 meters of yarn

2) Indirect System Yarn count (s) Length in hank of 1 pound of yarn (weighs)

1 hank = 840 yards

YARN SIZE / NUMBERYARN SIZE / NUMBER EXAMPLES:EXAMPLES:1.1. 9,000 meters of yarn weighs 40 grams, 9,000 meters of yarn weighs 40 grams,

it is 40 denier yarns. The higher the it is 40 denier yarns. The higher the number of denier, tex or decitex, the number of denier, tex or decitex, the coarser the yarn. coarser the yarn.

2.2. 10 hanks of cotton yarn that weight one 10 hanks of cotton yarn that weight one pound, this is 10s (count) yarn. The pound, this is 10s (count) yarn. The higher the number of yarn count, the higher the number of yarn count, the finer the yarn. finer the yarn.

YARN MANUFACTURING YARN MANUFACTURING PROCESSPROCESSBLOWROOM

CARDING

DRAWING

ROVING

RING FRAME

COMBING

BLOWROOMBLOWROOM first step of cotton yarn first step of cotton yarn

production production for opening, cleaning and for opening, cleaning and

dust removal, blending, dust removal, blending, and prepared for carding and prepared for carding process.process.

CARDING

DRAWING

ROVING

RING FRAME

COMBING

BLOWROOM

CARDINGCARDINGFUNCTIONS:FUNCTIONS: Opening to the individual fibers.Opening to the individual fibers. Elimination of impuritiesElimination of impurities Elimination of duskElimination of dusk Disentangling of nepsDisentangling of neps Elimination of short fibersElimination of short fibers Fiber blendingFiber blending Fiber orientationFiber orientation Sliver formationSliver formation

CARDING

DRAWING

ROVING

RING FRAME

COMBING

BLOWROOM

Main Parts:Main Parts:1.1. Taker inTaker in - - to open flocks out to open flocks out

of the feed batt, to lead them of the feed batt, to lead them to the dirt-eliminating parts to the dirt-eliminating parts under the roller and to deliver under the roller and to deliver them to the main cylinder them to the main cylinder

2.2. Main cylinderMain cylinder - - separate the separate the fibers, pull them into fibers, pull them into somewhat parallel form.somewhat parallel form.

3.3. DofferDoffer - - to take the individual to take the individual fibers from the main cylinder fibers from the main cylinder and condense them to web and condense them to web form form

CARDINGCARDINGCARDING

DRAWING

ROVING

RING FRAME

COMBING

BLOWROOM

DRAWINGDRAWINGFunctions:Functions:

To improve evenness of the sliverTo improve evenness of the sliver To arrange fiber in parallelTo arrange fiber in parallel BlendingBlending Dust removalDust removal

Drawframe has a series of rollers (drafting arrangement) rotating at Drawframe has a series of rollers (drafting arrangement) rotating at different rates of speed.different rates of speed.

CARDING

DRAWING

ROVING

RING FRAME

COMBING

BLOWROOM

COMBINGCOMBING to upgrade the raw material to upgrade the raw material

by removing the short fibers. by removing the short fibers. Combed yarn is stronger, Combed yarn is stronger, more uniform, has greater more uniform, has greater shine, smoother and purer shine, smoother and purer

Functions:Functions: Eliminate short fibersEliminate short fibers Eliminate remaining impuritiesEliminate remaining impurities Eliminate nepsEliminate neps

CARDING

DRAWING

ROVING

RING FRAME

COMBING

BLOWROOM

ROVINGROVINGFunctions:Functions: The attenuation of the sliver.The attenuation of the sliver. Impart protective twist in order to Impart protective twist in order to

increase the strength of slivers.increase the strength of slivers. Winding of the roving into a Winding of the roving into a

package that can be transported, package that can be transported, stored and used on the ring stored and used on the ring spinning.spinning.

CARDING

DRAWING

ROVING

RING FRAME

COMBING

BLOWROOM

SPINNINGSPINNING final step on producing yarn final step on producing yarn Functions:Functions:

Attenuate the roving until required Attenuate the roving until required fineness is achievedfineness is achieved

To impact strength to the fiber strand To impact strength to the fiber strand by twisting itby twisting it

To wind up the resulting yarn in a To wind up the resulting yarn in a suitable for storage, transportation suitable for storage, transportation and further processingand further processing

CARDING

DRAWING

ROVING

RING FRAME

COMBING

BLOWROOM

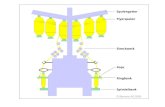

SPINNINGSPINNING

Front zone draft

Middle zone draft

Back zone draft

![MANUFACTURING STUDIES FOR 3D HYBRID YARN BASED …...The hybrid yarn textiles are heated to process temperature with infrared radiation (compare next chapter and [10]). Subsequently,](https://static.fdocuments.net/doc/165x107/5f52e6ccce7bae302f56f613/manufacturing-studies-for-3d-hybrid-yarn-based-the-hybrid-yarn-textiles-are.jpg)