VSL News 1991 N°2

Transcript of VSL News 1991 N°2

VSL

2

Editorial

„ he Turning Point" - best-seller of the early 80's - forecasted a new age. The change to a holistic view of the universe, concerned with wholes

rather than with parts, was predicted. “Small is beautiful" and “Quality instead ofQuantity" were also some of the slogans. Many of these thoughts and ideas,based on idealism and utopism, lacked the sense of reality and proportion. Nodoubt, however, they have opened and broadened the mind of individuals andleaders.

What is our answer to the concern of many people who are afraid that the futureevolution of life on earth is seriously endangered and may end in a disaster? Itwould be a cynical answer just-to tell them that they are pessimistic and evenfainthearted. But, we have to tell them that going small is not the solution toovercome the crisis either. How could for instance the necessary quantity ofenergy be found and produced if not by accomplishing projects of a considerablesize?

Nevertheless, there is one subject becoming more and more important in thisconnection. It is The Principle of Quality The VSL Group has always been keenon quality awareness. The ISO Quality Standards, instruments which we haveadopted, establish dear guidelines and direction. Furthermore, Hans Hitz, thenew Quality Assurance Manager at group level, will be guarantor for the rightinterpretation and application. The danger is, however, that in general QA mattersare handled in a too formalistic and bureaucratic way. That will not be the casewithin The VSL Group ! For VSL staff, quality is a matter of company culture andpersonal responsibility in the day to day work of each individual. This new issue ofthe VSL News demonstrates again this highly regarded mission of our group.

Dear reader, do not hesitate to call on us if you need to implement solutions inthe field of specialist engineering construction which combine innovativetechniques with a systems-based approach and a high sense of quality!

The Mission of the Future

Reto JenatschChief Executive Officer

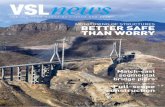

Cover : VSL has a major subcon-tract for the post-tensioning of the6.6 km long STOREBAELT WestBridge in Denmark. The back-ground of the cover photographshows "Svanen" the giant sea-going crane which installs the pre-fabricated bridge caissons, piersand girders, lifting up to 7000 tons.

contents

3Converting Research

Into Reality

4Licensees

6Australia

8USA West

10USA East

12Europe/Middle East

14Far East

T

With the development and intro-duction of PT-PLUS Plastic Duct

for bonded multistrand tendons, VSLhas once again increased its leadershipposition in the post-tensioning industry.The new system furnishes a uniquecombination of advantages unmatchedby any other commercially availableproduct.

The watertight plastic duct greatlyimproves the corrosion protection ofgrouted tendons. This applies espe-cially in configurations designed tocompletely encapsulate the steel.

Corrugated steel ducts can cause fret-ting fatigue due to high contact pres-sures and small relative movementsof the prestressing steel and duct. VSL

PT-PLUS eliminates fretting fatigue,and increases the fatigue strength ofthe tendons.

During tendon stressing, a PT-PLUSduct provides a lower and more reli-able friction coefficient than a steelduct. This results in lower frictionlosses and more effective use of thepost-tensioning steel for in-serviceconditions.

Moreover, testing has confirmed thatPT-PLUS duct can be completely filledwith grout, that bond characteristicsallow full development of the steel'stensile strength, and that, due to theunique shape and wall thickness,wearing through of the duct duringstressing does not occur even at mini-

mum tendon radii typically applied.with steel duct.

The PT-PLUS Plastic Duct System willbe available in four sizes to cover allpractical tendon configurations: threecircular ducts with internal diametersof 59, 76 and 100mm, and a flat ductmeasuring 21 by 72 mm internally. Thesystem also includes special water-tight couplers, grouting connections,vents, drains, anchorage transitions,and cable supports.

Dr Hans Rudolf GanzCTO of The VSL GroupBern, Switzerland

3

VSLConverting Research Into Reality

VSL introduces PT-PLUSTM:An advanced plastic duct system for bondedpost-tensioning tendons

Above: Manufacturing of VSL PT-PLUS Plastic Duct. Right: PT-PLUS Plastic Duct will beinstalled in the TROLL North Sea offshore platform. TROLL is the tallest Condeep platformever built.

VSL

4

Licensees

Civielco B-V, the VSL licensee inHolland, has been commissioned

to carry out renovations to the Ijssel-brug bridge. Built in 1970 by the freecantilever method the two double boxgirders with a main span of 150 m arethe first and largest bridges in theNetherlands where large-scale pre-stress renovation is being applied.

The accumulative effects of shrinkage,creep and relaxation have led toexcessive sagging of the bridge whichhas resulted in the nickname, the"dented bridge". Further, multilayerprestressing bar congestion and tightlyfitting ducts made grouting difficult.

Based on examinations, approximately40% of the bars were not adequatelygrouted raising concerns about corro-sion of the prestressing bars.

Repairs involve correction of sagging,and drilling into the duct at regularintervals with the use of endoscopes togauge the quality and completeness ofgrouting. High-viscosity synthetic resinand vacuum grouting methods, whereappropriate, are being used to com-plete duct grouting.

Jacco Riem Civielco B.V At Leiden, Holland

This cable-stayed bridge namedafter one of Sapporo's sister cities,

Munich in Germany, will be completedin October 1991, after a constructionperiod of three years.

The project employed a variety of newengineering and construction tech-niques including inverted T-type spread

foundations using pneumatic caissons,prestressed concrete main girderserected by the free cantilever method,and concrete pylons constructed with ajumping stage.

The VSL stay cables contained up toeighty 0.6" strands, in polyethylenepipes with cement grout for corrosion

protection. Anchorage devices as wellas 1500-ton jacks were tailored by VSLto cope with the magnitude of theforces and particular conditions of thisproject.

In order to minimize the cable eccen-tricities and temporary stresses in thepylon during construction, to avoidcable vibration due to wind, and toprovide an aesthetically pleasing layoutof cables, cables of one side of thepylons were bifurcated (split in half)with a Y-shaped anchorage. Develop-ment of the anchorage included staticand fatigue tests.

This project is the first major applica-tion of bifurcated stay cables any-where in the world.

Shusuke Sakata VSL Japan Corporation Tokyo, Japan

The „dented bridge“ receives help

Excessive sagging of main span will becorrected by large-scale repair scheme.

VSL Stay Cables for Sapporo Munich Bridge

Corrosion-protected VSL Stay Cable System provides reliable performance, long servicelife and low maintenance.

The Malibamatso River Bridgespans the Pelaneng Valley, and

crosses the Malibamatso River. A damwill cause the valley to be flooded to adepth of 80 m at the bridge site. Steepcliffs, tall piers, winter temperatures of-15° C and concrete aggregates withpoor creep and shrinkage propertiesadded to the challenge of this project.

To overcome the large creep andshrinkage properties of even the bestavailable aggregates, 1200 t permanenthydraulic jacks were installed under

most of the bridge bearings. The jacksallow for adjustments of up to 100 mmto compensate for differential shorten-ing of the piers over the design life ofthe bridge.

The superstructure, which consisted ofa 465 m box girder 10.9 m wide and3.45 m deep, was incrementallylaunched to overcome problems withconstruction access. Casting the entiresuperstructure at one location in a 24.5m long casting area improved workingconditions, made cold weather concre-

ting procedures easier and enhancedoverall quality of the finished structure.The post-tension tendon layout wasrationalized to suit the method ofconstruction. The tallest piers weretemporarily braced by lateral andlongitudinal VSL stays during thelaunching of the superstructure.

Brian Cox Steeledale Systems (Pty.) Ltd.Johannesburg, South Africa

5

VSL

The combination of pier slipforming andincremental launching of the dech provedthe most effective construction method

VSL Incremental Launching and Post-Tensioning speed construction ofSouth African bridge

VSL

6

VSL Australia

Two new cable stayed bridgesrecently completed in Sydney both

used VSL Stressbars to form the cablestay supports. The use of VSL Stress-bars for lightly loaded suspensionstructures such as these is bath eco-nomical and practical from the cons-truction point of view.

The VSL Stressbars are preassembledon the deck prior to installation. Longstays are coupled on site for ease oftransport and handling. The stays are

coated with a white epoxy paint forboth corrosion protection and aesthe-tics.

One bridge provides access to the newUniversity of Western Sydney over thebusy Great Western Highway at Wer-rington, while the other bridge providesa pedestrian access way linking thePower House Museum in Sydney, to anadjoining carpark and mono-rail stationwithin the Darling Harbourredevelopment complex.

Mark Sinclair VSL Prestressing (Aust.) Pty Thornleigh, Australia

VSL Australia introduced theRetained Earth Wall System to

the Australian construction market in mid1990. Since then, three major retainingwall projects have been awarded toVSL with a total surface area in excessof 7000 m .

The project shown here is the CityWest Link Road at Lilyfield, an innersuburb of Sydney. The project consistsof a ramp structure which providesaccess for the City West Link Road tocross a busy rail yard via a prestressedconcrete bridge.

The ramp structure has two adjacentVSL Retained Earth Walls over its fulllength of 195 m. The walls rise to aheight of 7.5 meters where they cometogether to form an abutment for therail overbridge.

For aesthetic reasons, a ribbed surfacefinish was chosen by the client, theRoads & Traffic Authority of New SouthWales.

Neil Audsley VSL Prestressing (Aust.) Pty Ltd.Thornleigh, Australia

VSL Stressbars support two new Sydney bridges

VSL Stressbar-stayed bridges are now inservice at University of Western Sydneyand the Darling Harbour complex.

VSL Retained Earth tm System gaining ground in Australia

Precast facing panels are available in avariety of panel shapes, sizes and finishes.

The redevelopment of the formerT & G Building in Melbourne's

famous Collins Street involves thepreservation of a historic city streetscape - and creation of a "new" buil-ding complex. The original internalstructure was completely guttedleaving behind the fine ,,Art Deco"facade measuring over 150 meters inlength on 3 sides and rising up to 45meters above street level. The facadewas temporarily supported by a steelbracing structure conceived anddesigned by the structural engineers,from The Meinhardt Group.

A new prestressed concrete structurewas built behind the old facade. Post-tensioned flat slabs with drop panelswas the chosen floor system on an8.1 m x 8.1 m grid. The VSL basedsystem was utilized as the permanentsupport for the facade when thetemporary bracing was removed. Atotal area of approximately 44,000 m2

of post-tensioned flooring was cons-tructed in a little over ten weeks.

One of Australia's largest buildingcompanies, Grocon Pty. Ltd., whocarried out this project, are justly proudof the speed of construction and theeconomic result for such a largecomplex project.

Reter Rlley VSL Prestressing (Aust.) Pty Ltd.Melbourne, Australia

7

VSL

New building form Old

New post-tensioned floor structure providespermanent support for old facade.

VSL

8

USA West

The State of Washington's KingCounty Aquatics Facility ranks third

in size in the nation for a structure ofthis type according to the designers,TRA Architects/Engineers (Seattle).

Early in the planning stage, VSL wasasked to take part in the feasibilitystudy to determine the most economicsolution for construction of the compe-tition and diving tanks, the featuredattractions of the facility.

Concerns regarding stress reversal (fulltank/empty tank/buoyancy) and crackcontrol were alleviated with the use ofa post-tensioned concrete option. Inaddition, with post-tensioned concrete,reinforcing steel congestion wasdramatically reduced and a saving inconcrete of approximately 25 % wasrealized. Buoyancy during an emptytank condition was counteracted withauger cast friction piles anchored tothe tank bases.

Walls and bases of both tanks werepost-tensioned using the fully encap-sulated VSL CP+ unbonded mono-strand system.

Within one month of being awardedthe post-tensioning subcontract, VSLproduced placing drawings, fabricatedtendons and delivered all material forthe project !

Fred Robinson VSL Corporation Lynnwood, Washington

The VSL solution for aquatic tanks

VSL CP + Post-Tensioning provided effectivecrack control, eliminated rebar congestion,and reduced concrete quantity by 25 %.

VSL has recently completed workon the Astronaut's Memorial at the

Kennedy Space Center in Florida.

VSL designed the structural, mechani-cal, optical and control systems andacted as General Contractor for theconstruction of this unique project,which is now listed as a NationalMonument.

The Memorial includes a tilting steelframe mounted on a turntable. Theframe supports a plane of black granitepanels. Six panels had the names ofthe astronauts cut out by water jet.

The tilting mechanism combined withthe rotating mechanism allows theMemorial to track the sun, while thegranite panels face away from the sun

and reflect the clouds and the sky.Mirrors on the back of the frame directthe sunlight through the names andthus create the impression of thenames glowing in the sky.

Guida Schwager VSL Western Campbell, California

9

VSL

The Astronaut’s Memorial: A challenge fulfilled

Now complete and recognized as a U.S. National Monument, the Astronaut’s Memorialstands at the entrance to Spaceport USA, Kennedy Space Center, Florida.

Mirrors attached to steel trusses at the rearof the rotating wall track the sun and reflectits light through the cut out names in thewall’s granite.

VSL

10

USA East

VSL Springfield recently completeda 3 tank complex with a total vol-

ume of 10.7 million gallons for PerdueFarms in Accomac, Virginia.

The project consisted of two similar 4.0million gallon waste water treatmenttanks and a 2.7 million gallon clarifier.

The VSL post-tensioned solution waschosen in a competition with a conven-tionally reinforced scheme for reasonsof speed and economy. VSL perfor-med as both the post-tensioningmaterial supplier and the engineer ofrecord. D.W. Burt Concrete Construc-tion provided the balance of the con-crete package to complete the tanks inplace. The tanks were designed with 5in. slab-on-grade with thickened edgesutilizing the VSL CP+ mono-strandtendon. The larger tanks had a heightof 30 ft., a 150 ft. diameter, and a wall

thickness of 12 in. These tanks weredesigned with bonded horizontaltendons and unbonded CP+ verticaltendons. The clarifier had a heightof 18 ft., a diameter of 160 ft. and awall thickness of 10 in. The wall of thistank was designed with unbondedCP+ tendons both horizontally and

vertically. All concrete construction wascompleted in a 6 month time frame.

Henry Cronin VSL Eastern Springfield Virginia

VSL frame design beats precast concrete by $450,000

Medical building frame is designed to accommodate two additional floors.

VSL serves as Engineer of Record for large tank complex

Clarifier tank was designed with corrosion protected CP + monostrand tendons in vertical and horizontaldirections.

When Iowa Methodist MedicalCenter decided to build a new

medical office building on their campusin downtown Des Moines, Iowa, pre-cast concrete was the intended framingsystem. VSL worked with the ownerand general contracter to provide analternative post-tensioned concreteframe design which met their needsand provided considerable savings.

The six storey structure contains over85,000 sq.ft. of elevated slab with liveloads of up to 375 psf. The roof isdesigned to support the construction oftwo future floors without shoring andwithout encroaching on occupiedtenant space.

VSL acted as Engineer-of-Record forthe structural frame which consisted ofpost-tensioned beams and slabs. TheVSL solution eliminated the need forshear walls and provided increasedceiling space and greater flexibility formechanical and electrical services.

Keith JacobsonVSL Eastern Minneanolis Minnesota

Construction is currently underwayon The National Concrete Masonry

Association's INCMAI "Lifestyle 2000Home". This project is located in theNational Association of Home Builders'National Research Park in Bowie,Maryland. The NCMA along with VSLand others is sponsoring the construc-tion of this very advanced 2300 squarefoot structure which features uniqueconcrete masonry products includingthe VSL post-tensioned masonry sys-tem which is used to vertically pre-stress special masonry blocks in afoundation wall.

The prestressing system which wasdesigned, furnished and installed byVSL features individual 1/2 in. diam-eter 270 K strands which weregreased and coated with extrudedpolyethylene for maximum corrosionprotection. The tendons are spaced 32in. apart and are eccentrically locatedwithin the block cavities for maximumeffectiveness in resisting lateral earthpressure. Special concrete blockswhich were designed and fabricated byVSL contain the anchorages and burs-ting reinforcement. The lower blockfeatures a special self-activating

monostrand anchorage while the upperblock has a conventional CP+ mono-strand anchorage. The self-activatinglower anchorage allows for tendoninstallation after the wall masonry workis completed.The completed house will serve as apreview of how masonry could beused in homes which will be built inthe next century.

John Crigler VSL Eastern Springfield Virginia

11

VSL

Home of the future built with post-tensioned masonry

Vertical post-tensioning strengthens masonry walls and furnishes resistance to imposed deformations from lateral earth pressure.

VSL

12

Europe / Middle East

Located on the Geneva - St. Julienroad, the East Bridge crosses the

Plan des Ouates section of the Genevaring road.

This bridge consists of a skew con-crete prestressed slab. The two spansare supported by abutments at eachend and by nine reinforced concretecolumns of 1 m diameter in themiddle. In plan, the bridge deck formsa parallelogram, approximately 85 mlong, 25.1 m wide and varying in thick-ness from 1.1 to 2.1 m.

This project is of particular interestbecause of the unusual geometry, thedimensions and the large quantity ofconcrete (2600 m3) placed during onecontinuous shift of 24 hours with 180men. 60 trucks supplied the concretefrom 2 batching plants.

The 92 VSL tendons of type EC 5-31were pushed in prier to concreting,had a total length of 4364 m and werestressed in 3 stages. Due to reducedblock-out dimensions, special stressingchairs were required.

The consulting engineers were AndréSumi and Georges Babel with theparticipation of Prof. R. Walther, EPFL;the contractors were a joint venture ofZschokke-Bariatti-Spinedi.

Pierre Alain Aigroz VSL International Ltd.Crissier, Switzerland

The telecommunication tower onMount Collserola, a Norman Foster

design, is without any doubt one of

Barcelona's new landmarks. A steelaerial of 83m towers above a 205mhigh concrete shaft. The 68 m high ser-vice building is suspended 84m abovefoundation level. The whole structureis stabilized by a system of steel strandstays, ground anchors and Kevlarcables.

In the construction procedure, maincontractor Cubiertas y MZOV fromBarcelona made extensive use of therationalization and simplification heavylifting technique can provide. In an earlyconstruction stage, the two sections ofthe steel aerial were placed by craneinside the shaft. The structural steelframing and the floor slabs of the 12storey service building were erectedstanding on ground level. The 100tons aerial and 2600 tons servicebuilding were brought to their final levelby means of VSL Heavy Lifting. Inaddition, VSL Heavy Lifting was usedfor the telescopic pull out of the aerialto bring it to its final height.

Erich Môschler VSL International Ltd.Lyssach, Switzerland

Swiss bridges are builtto last !

92 VSL E 5-31 tendons provide exceptionaldurability and structural integrity.

12 storey service building assembled on ground,shown being lifted 85 meters to its final position.

VSL heavy Lifting simplifies construction ofBarcelona tower

21T91

The Sefid Rud Dam, completed in1962, has a maximum height of

106 meters above foundation level anda total length of 417 meters at crestlevel. This concrete dam consists of 24buttresses, 14 meters wide, a rightbank abutment and a gravity structureon the left bank housing an intermedi-ate level spillway.

During June 1990 an earthquake ofmagnitude 7.3 struck the region of theSefid Rud Dam (approximately 200kmnorth-west of Teheran).

The dam suffered extensive cracking atseveral locations, with most horizontalcracks in a region 18 meters below thecrest.

Rehabilitation works included ancho-ring the upper part of the dam to theconcrete body below the cracks byapplying prestress of approximately100 MN to each buttress. To produce atotal equivalent dead weight forcewould have required some 100,000cubic meters of concrete!

234 VSL permanent rock anchors with54 0.6 inch strands each, were installedwithin the dam buttresses at an incli-nation varying from 2° to 22°, using aspecially designed VSL homing device.The average anchor length was 40meters.

Strengthening the dam before thearrival of the seasonal floods gave theproject an extreme sense of urgency.VSL installed the first anchor on March3, 1991, with stressing of the lastanchor on July 4, 1991!

13

VSL

Rehabilitation Works of the Sefid Rud Dam

A total of 234 permanent rock anchors tie thecracked upper sectin fo the dam to thestable lower concrete

Isam S. Sahawneh VSL International Ltd.Lyssach, Switzerland

VSL

14

Far East

The North-South Link is economi-cally a vital road addition for

Jakarta. Some 12 of the 16 kilometerlength are elevated. This US$ 120million project was opened for trafficin January 1991.

The elevated structure consisted of4100 post-tensioned I-beams spanning35m, supported on 318 piers. The

post-tensioned pierheads whichweighed 400 tons were rotated inplace by 90 degrees to minimize dis-ruption to traffic during construction.

PT VSL Indonesia was awarded thecontract for post-tensioning and erec-tion of these I-beams. Using a laun-ching gantry, an average of 200 beamsper month were erected!

The construction of the project wasundertaken by a consortium consistingof PT Hutama Karya, PT Yala PerkasaInternational and PT Jaya Konstruksi,all of Indonesia.

Johannes Himawan PT VSL Indonesia Jakarta, Indonesia

New North-South road link for Jakarta

VSL raises the roof if Indonesia Garuda Indonesia, the country'snational airline, has had its third

hangar roof lifted by VSL in February1991. The completed steel roof struc-ture along with its mechanical andelectrical fixings weigh nearly 3,000tons and cover an area of 25,725m2

1210 x 122.5ml. VSL jacks were usedin conjunction with an automatedelectronic sensing device to monitorand control the lifting with an accuracyof 2 mm. The hangar has six concretepiers, which were temporarily bracedduring lifting.

Johannes Himawan PT VSL IndonesiaJakarta, Indonesia

The 3,000 tonnes roof structure was lifted into position with a levelling accuracy during liftingof 2 mm.

VSL Launching Gantry placed a total of 4,100 I-beams, averaging 200 beams per month.

27T91

The Kwung Tong Bypass links theEastern Harbour Crossing with the

new Tates Cairn Tunnel. The Bypassconsists of 3.7 kilometers of twinsingle cell boxes with spans rangingfrom 35 m to 48 m. Erection of thesuperstructure started in December1989 and was completed in March1991, one month ahead of schedule.

This was the first time the precastsegmental free cantilever method hasbeen adopted in a Hong Kong project.It has proven to be a major success! The segments were produced by thematch casting method on a short linesystem and transported along the pre-viously erected bridge deck to thelaunching gantry. The elimination of

falsework and scaffolding are signifi-cant advantages of this method in adensely populated urban environment.

VSL Engineers (HK) Ltd. supplied andinstalled all the post-tensioning cables.In total 2,100 tons of strand wasinstalled with 11,500 anchoragesranging in size from EC 5-12 to EC 5-31. The erection work was carried outon a continuous twenty four hour basiswith two shifts per day. Progress wasrapid with the completion of one spanof twin box girders every three days.

Mobashir A. Zia VSL Engineers (HK) Ltd.Hong Kong

15

VSL

On the fast track with Hong Kong's first precast segmental project

Post-tensioned free cantilever segments provide rapid construction progress.

28T91

VSL

VSL

VSL NEWSI S S U E T W O 1 9 9 1

Published byVSL International Ltd.

Editor: Therese WengerP.O. Box 7124, 3001 Berne/Switzerland, Tel 41-31-66 42 22, Fax 41-31-66 42 50, TIx 911755 vsl ch

Layout by comDesign Berne/Switzerland. Produced/Printed in Singapore by Panache Design, MCI (P) 164/1/90

Australia –New ZealandAustraliaVSL Prestressing (Aust.)Pty. Ltd.P.O. Box 102Pennant Hills, NSW 21206 Pioneer AvenueThornleigh, NSW 2120Tel 61-2-484-5944Tlx AA 25891Fax 61-2-875-3894

VSL Prestressing (Aust.)Pty. Ltd.P.O. Box 171Albion, QLD. 4010Tel 61-7-265-6400Tlx AA 44703Fax 61-7-265-7534

VSL Prestressing (Aust.)Pty. Ltd.P.O. Box 3981 Summit RoadNoble Park, VIC. 3174Tel 61-3-795-0366Fax 61-3-795-0547

New ZealandPrecision Precasting(Wgtn.) Ltd.Main Road SouthPrivate Bag, OtakiTel 64-694-8126Tlx aalensn nz 32069Fax 64-694-8344

USA West–CanadaUSAVSL Corporation1671 Dell AvenueCampbell, CA 95008Tel 1-408-866-6777Tlx 821 059Fax 1-408-374-4113

VSL Western1077 Dell AvenueCampbell, CA 95008Tel 1-408-866-5000Fax 1-408-379-6205

VSL Corporation10810 TalbertFountain Valley,CA 92708Tel 1-714-964-6330Fax 1-714-965-3265

VSL Corporation91-313 Kauhi StreetEwa Beach, HI 96707Tel 1-808-682-2811VSL Corporation4208 198th Street, S.W.Lynnwood, WA 98036Tel 1-206-771-3088Fax 1-206-672-3020CanadaCanadian BBR (1980) Inc.P.O. Box 37Agincourt, OntarioM1S 3B4Tel 1-416-291-1618Tlx 065-25190 bbr cdaFax 1-416-291-9960

USA EastUSAVSL EasternP.O. Box 8668006 Haute CourtSpringfield VA 22150-0886Tel 1-703-451-4300Fax 1-703-451-0862

VSL Corporation5555 Oakbrook ParkwaySuite 530Norcross, GA 30093Tel 1-404-446-3000Fax 1-404-242-7493

VSL Corporation7223 N.W. 46th StreetMiami, FL 33166-6490Tel 1-305-592-575Fax 1-305-592-5629

VSL Corporation11925 12th Avenue SouthP.O. Box 1228Burnsville,MN 55337-0228Tel 1-612-894-6350Fax 1-612-894-5708

VSL Corporation1414 Post and PaddockGrand Prairie, TX 75050Tel 1-214-647-0200Fax 1-214-641-1192

VSL Corporation608 Garrison StreetUnit V, Lakewood, CO 80215Tel 1-303-239-6655Fax 1-303-239-6623

VSL Corporation370 Middletown Blvd.,500

Langhorne, PA 19047Tel 1-215-750-6609Fax 1-215-757-0381

Far EastSingaporeVSL Singapore Pte. Ltd.151 Chin Swee Road11-01/10

Manhattan HouseSingapore 0316Tel 65-235-7077/99Fax 65-733-8642

BruneiVSL Systems (B) Sdn. Bhd.P.O. Box 33Bandar Seri Begawan 2600Tel 673-2-229153/221827Fax 673-2-221954

Hong KongVSL Engineers (HK) Ltd.20/F., East Town Bldg.41 Lockhart RoadP.O. Box 20056Wanchai/Hong KongTel 852-5-201-600Tlx 83031 vslhk hxFax 852-865-6290

SwitzerlandVSL International AGKönizstrasse 74Postfach 71243001 BernTel 41-31-66 42 22Tlx 911 755 vsl chFax 41-31-66 42 50

VSL International AGBernstrasse 93421 LyssachTel 41-34-47 99 11Tlx 914 131 vsl chFax 41-34-45 43 22

AustriaSonderbau GesmbHSechshauser Strasse 831150 WienTel 43-222-812-0280Tlx 134 027 sobau aFax 43-222-812-0280 33

BrazilRudloff-VSLIndustrial Ltda.Rua Dr. E. Th. Santana, 158Barra FundaSao Paulo / CEP 01140Tel 55-11-826 0455Tlx 113 1121 rudf brFax 55-11-826 62 66

ChileSistemas Especiales deConstruccion SAJosue Smith Solar 434Santiago 9Tel 56-2-233-1057/1081Fax 56-2-231-1205

FranceVSL France s. à r.l.154, rue du Vieux-Pont-du-Sèvres92100 Boulogne-BillancourtTel 33-1-4621-4942Tlx 200 687 vslpari fFax 33-1-4761-0558

GermanySUSPA Spannbeton GmbHMax-Planck-Ring 1P.O. Box 30334018 Langenfeld-RhldTel 49-2173-79020Tlx 172173412 suspalfFax 49-2173-790-220

IndonesiaPT VSL IndonesiaJalan Bendungan Hilir RayaKav. 36A Blok B No. 3Jakarta 10210Tel 62-21-586 190fax 62-21-581-217

JapanVSL Japan CorporationTachibana Shinjuku Bldg. 4F2-26, 3-chome, Nishi-Shinjuku, Shinjuku-kuTokyo 160Tel 81-33-346-8913Fax 81-33-345-9153

GreeceVSL Systems S.A.18, Valaoritou, Str.Athens 106 71Tel 30-1-36 38 453Fax 30-1-36 09 543

IndiaKillick Prestressing Ltd.Killick House/Killick EstateBaji Pasalkar Marg,ChandivliBombay – 400 072Tel 91-22-57 84 481Fax 91-22-57 85 076Tlx 11-72 394

ItalyPRECO S.r.l.Via Olona 12Tel 39-2-4818 031Tlx 335-392 prebet iFax 39-2-284 4173

NetherlandsCivielco B.V., P.O. Box 751Rhijnhofweg 92300 AT LeidenTel 31-71-768-900Fax 31-71-720-886

NorwayVSL Norge A/SP.O. Box 1734001 StavangerTel 47-4-563-701Tlx 33054fax 47-4-562-721

PeruPretensado VSL del PeruSAAvenida Principal 190Santa Catalina, Lima 13Tel 51-14-718-347Fax 51-14-729-492

PortugalVSL Prequipe SAEquipamento eMontagens, SAAv. da Republica, 47-2 Esq.1000 LisboaTel 351-1-793-12-19Tlx 404-64852 prequi pFax 351-1-793 0901

KoreaVSL Korea CO., Ltd.5/F, Yang Jae Building261 Yangjae-DongSeocho-Gu, SeoulTel 82-2-574-8200Tlx vslkor k 28786Fax 82-2-577-0098

MalaysiaVSL Engineers (M) Sdn.Bhd., 39 B Jalan Alor50200 Kuala LumpurTel 60-3-242-4711Fax 60-3-242-9397

Saudi ArabiaAzzam Trading &Contracting Est.P.O. Box 4280Jeddah 21491Tel. 966-2-694 0930Fax 966-2-694 0019Tlx 605576 sa

South AfricaSteeledale Systems(Pty.) Ltd.P.O. Box 1210Johannesburg 2000Tel 27-11-613-7741/9Tlx 426 847 saFax 27-11-613-7404

SpainVSL Iberica S.A.Nunez de Balboa 4828001 MadridTel 34-1-578 11 59Fax 34-1-577 89 54Tlx 52-47 462

SwedenInternordiskSpännarmering ABVendevägen 8918225 DanderydTel 46-8-753 02 50Tlx 11524 skanska sFax 46-8-753 4937

TurkeyYapi Sistemleri Insaat veSanayii A.S.Balmumcu, Arzu SokakNo. 5 Daire 380700 Besiktas – IstanbulTel 90-1-174-09 54Tlx 39552 ypss trFax 90-1-174-23 08

United KingdomBalvac Whitley Moran Ltd.P.O. Box 4,Ashcroft Road, KirkbyLiverpool L33 7ZSTel 44-51-549 2121Fax 44-51-549 1436

TaiwanVSL Systems (Taiwan) Ltd.1 Fl, No. 20-1, Lane 107Hoping East Road, Sec. 2Taipei, R.O.C.Tel 886-2-707-7253Fax 886-2-704-0463

ThailandVSL (Thailand) Co., Ltd.7th Fl, Sarasin Bldg.14 Surasak RoadSilom, BangrakBangkok 10500Tel 66-2-237-3288/89/90Fax 66-2-238-2448

VSL OPERATING UNITS, SUBSIDIARIES AND LICENSEESEurope – Middle East – Africa – South America