Volvo Penta Center - Installation Procedure: EVC-D D9/D11/D13...

Transcript of Volvo Penta Center - Installation Procedure: EVC-D D9/D11/D13...

D11 D13

DIAGNOSIS

DATALINK

SENDERS

DIAGNOSIS

DATALINK

SENDERS

Installation Procedure: EVC-D D9/D11/D13 InboardInstallation Procedure: EVC-D D9/D11/D13 Inboard

Document number: 47700918

Release date: 05-2010

NMEA interface

InstrumentsADU

Multilink hub

Multilink hub

Multilink hub

Buzzer

Generic Button Panel(Start/Stop panel)Information displays

Information display

Levers

Levers

Lever connections

Lever connections

Lever

Lever connections

Buzzer

Connection for safety lanyard Connection for safety lanyard

Key switch

Analog key interface

Analog key interface

Key switch

Buzzer

PCU

Diagnose con-nection (VODIA)

Connection for safety lanyard

Rudder angle sender

Rudder angle sender

Fresh water and fuel level senders

Fresh water and fuel level senders

Engine Engine

Engine

FlybridgeD9/D11/D13, twin engine installation

Typical installation / Main stationD11/D13, twin engine installation

Controls Key switch

Multilink features

D9: Mount PCU

Typical installationD9, single engine installation

IMPORTANT! Never cut or modify the Volvo Penta EVC harnesses. For extra power supply, use the Volvo Penta relay for external accessoaries.

7” displayInformation displays & Generic Button Panel

Stand-alone HCU

Multisensor Instruments

Use template when making holes in dash-board

Use cable ties to fix cables

Use cable ties to fix cables

Dash board hole diameter: 32 mm (1.26”)

Dash board hole diameter: 52 mm (2.05”)

Dash board hole diametersInstruments: 110 mm (4.33”) 85 mm (3.35”) 52 mm (2.05”) Instruments, flush mounted: 105 mm (4.13”) 83 mm (3.27”) 49 mm (1.93”)

2.5–12 mm (0.1–0.5”)

Max. 2.5 mm (0.1”)

12–25 mm (0.5–1.0”)

4 mm (0.16”)

Flush mount

Hull

Tightening torque: 5 Nm (3.7 lbf.ft)

Safety wire

Marine sealant

EVC system tachometer

Flush mount

Use template when making hole in dash-board

Flush mount: Use template when making hole in dashboard

Multilink minimum requirements:NOTE! Either 7” display or Information displays.

Additional multilink features:

Max. 10 mm (0.24”) dashboard thickness

Decal

Reverse gear connections

Engine connections

Standard–right hand rotation: Connector PRIMARY to solenoid P Connector SECONDARY to solenoid S

Trolling

Trolling

Rev. pick-up

Rev. pick-up

Secondary (S)

Secondary (S)

Primary (P)

Primary (P)

Oil temp./pres-sure

Oil temp./pres-sure

Helm station

Helm station

Engine Engine IMPORTANT! This end of

Y-connector must be con-nected directly, without exten-sion, to levers.

Y-connector

Multiple helm stationsZF280/ZF286/ZF305/ZF311/ZF325

MG5065/MG5075/MG5114

Transmission cable connector

Connecting the multisensor to the HCU

Multilink hub

HCU

Multisensor

Multilink breakout

Connecting multiple Multilink hubsOK! For information on cable lengths etc.

please refer to Installation manual.

NOT OK!

7

7

1b 1b

3 3

4 4

4

4

4

4

5

5

5

5

9 9

7

7

12

7

11 11

7 7 7

7

99

10

7 7

76

44

1a

2

47

70

09

18 0

5-2

010

Components and Cables

Controls

Components

Instruments**) Only in combination with EVC system tachometer

Cables

Sender

Fuel level sender 3–180 ohm

Fuel level sender 240–30 ohm

Sender

Water level sender 3–180 ohm

Stand-alone HCU

Twin engine levers

Built-in HCUs

Single engine lever

Built-in HCU

Key switch, main station

Kit, One/two key switches

AKI

Analog key interface

Multilink hub

6 cable sockets

Fresh water level **

Diameter 52 mm (2.05”)

EVC system tachometer

Diameter 85 mm (3.35”) 110 mm (4.33”) 0–4000 rpm

Coolant temp **

Diameter 52 mm (2.05”) C°, F°

Speedometer Unitless **

Diameter 85 mm (3.35”) 110 mm (4.33”)

0–40 1/Hour 0–60 1/Hour

Alarm instrument **

Diameter 52 mm (2.05”)

Voltmeter **

Diameter 52 mm (2.05”) 12 V, 24 V

Rudder indicator **

Diameter 52 mm (2.05”)

Front ring kit (nut)

Diameter 52 mm (2.05”) Black/Chrome

Diameter 85 mm (3.25”) Black/Chrome

Diameter 110 mm (4.33”) Black/Chrome

Front ring kit (clamp)

Diameter 52 mm (2.05”) Black/Chrome

Diameter 85 mm (3.25”) Black/Chrome

Information display

One per driveline and helm station. Not in combination with 7” display.

Generic Button Panel

Function configured at startup

Fuel level **

Diameter 52 mm (2.05”)

Engine oil pressure **

Diameter 52 mm (2.05”) bar, psi

Turbo pressure **

Diameter 52 mm (2.05”) bar, psi

7” display

Not in combination with Information display.

4-in-1 Gauge **

Diameter 110 mm (4.33”)

Coolant temp Voltage Oil pressure Fuel level

NMEA 0183 interface NMEA 2000 interface

Incl. cables 0.5 m (1.4 ft.)

Aux. Dimmer Unit (ADU) **

Incl. cables 0.5 m (1.4 ft.)

7” display power supply for 12 V systems

Incl. cables 0.5 m (1.4 ft.)

Multisensor

Transom mounted

A-CAN

Analog lever interface

Relay for external ac-cessories

12 V, 24 V

Buzzer Multisensor

Hull mounted

4. Standard EVC bus cable, 6-pin*

Feet Meter Part no.

16 5.0 874789 23 7.0 889550 30 9.0 889551 36 11.0 889552 42 13.0 888013

*) One cable per engine has to be ordered.

5. Y-connector, 6-pin

Feet Meter Part no.

1.6 0.5 3588972

7. Multilink/tachometer/syn-chronization cable, 6-pin

Feet Meter Part no.

5 1.5 3886666

9. Extension cable, 6-pin

Feet Meter Part no.

5 1.5 3889410 10 3.0 3842733 16 5.0 3842734 23 7.0 3842735 30 9.0 3842736 36 11.0 3842737 66 20.0 21172469 131 40.0 21172470

11. Extension cable, 3-pin

Instruments

Feet Meter Part no.

3 1.0 874759 10 3.0 3807043

3. Sender cable, 6-pin

Feet Meter Part no.

16 5.3 3807229

6. Stbd. AKI adapter, 4/8-pin

Feet Meter Part no.

0.6 0.2 21421946

8. Aux. relay cable, 6-pin

Feet Meter Part no.

3.3 1 21427463

10. 7” display cable, 6-pin

Feet Meter Part no.

5.5 1.7 21514712*

*) Incl. in display kit

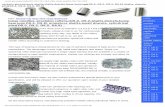

Connector dimensions

3-pin

H = 18 mm (0.71”) W = 26 mm (1.02”) D = 26 mm (1.02”)

6-pin

H = 21 mm (0.82”) W = 23 mm (0.88”) D = 32 mm (1.26”)

4-pin

H = 25 mm (0.97”) W = 18.5 mm (0.73”) D = 25.5 mm (1.00”)

6-pin

H = 25 mm (0.97”) W = 22 mm (0.87”) D = 26.5 mm (1.03”)

8-pin

H = 25 mm (0.97”) W = 29.5 mm (1.15”) D = 25.5 mm (1.0”)

12-pin

H = 23 mm (0.88”) W = 41 mm (1.62”) D = 48 mm (1.90”)

Rudder angle sensor

3–180 ohm

2. Engine–PCU cable D9

Feet Meter Part no.

10 3.0 21122603 16 5.0 21122605

1a Transmission cable harnesses D9

ZF Feet Meter Part no.

10 3.0 3594238

MG 10 3.0 3594240

1b Transmission cable harnesses D11/D13

ZF Feet Meter Part no.

6 1.8 40005751

MG 6 1.8 40005752

MGX 4 1.2 21159075

4” display

Display incl. cable 1.5 m (5 ft.)

In combination with Information display

12. Y-split multilink, 6-pin

Feet Meter Part no.

1.6 0.5 3588206

13. Display cable, 6/12-pin

Feet Meter Part no.

5 1.5 3588207*

*) Incl. in display kit

W

D

H

W

D

H HH HH

W W WW

D

D DD