Vacuum Fiber Optic Feedthrough€¦ · Vacuum Fiber Optic Feedthrough Hermetic fiber optic...

Transcript of Vacuum Fiber Optic Feedthrough€¦ · Vacuum Fiber Optic Feedthrough Hermetic fiber optic...

Vacuum Fiber Optic FeedthroughHermetic fiber optic feedthroughs with pigtail interface

SQS has many years of experience in the design and production of optical fiber feedthroughs for vacuum applications. Vacuum fiber feedthroughs are suitable for use in various areas of research and development, and in many industrial applications.

Vacuum fiber feedthroughs are manufactured according to specific customer requirements. We can seal the majority of optical fibers in standard or atypical flanges for various areas of feedthrough applications.

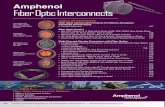

1CH - KF16 - SMA905 - HV 2CH - KF16 - SMA905 - HV - front view 2CH - KF16 - SMA905 - HV - back view

For More Information contact us at +420 493 765 111 or [email protected] Vláknová optika a.s., Komenského 304, 509 01 Nová Paka, Czech Republic www.sqs-fiberoptics.com

Operating temperatures- 40°C / + 85°C (SM and MM version)- 20°C / + 70°C (PM version)- 40°C / + 180°C (SM and MM on request)

Hermeticity-10 -1210 to 10 mbar.l/s

Fiber type PM panda fiber; wavelength range: 400 to 2000nm

SM fiber; wavelength range: 400 to 2000nm

MM fiber; step or graded index

Fiber sleeving Stainless steel flexible tubing (Ø 3mm) or perforated PTFE (Ø 900um)

Flange type CF16 - CF160, KF16 - KF50 or custom made

Flange material Stainless steel (304, 304L and 316L) and others

Connector (stainless steel) FC/PC, FC/APC, SMA 905

Connector (nickle plated brass) FC/PC, FC/APC, ST/PC, SMA 905, PM FC/PC, PM FC/APC

High vacuum feedthrough

KF16 FLANGE MAT. STAINLESS STEEL

TUBING 3 mmMAT. STAINLESS STEEL

O30

CONNECTORSMA 905

L1 = 1900 +500 13 L2 = 1100 +50

0

18

38

18

384

10

O

O17,2

2,5

TUBING 3 mmMAT. STAINLESS STEEL

SMA 905CONNECTOR

3D DRAWING

3D DRAWING

INSPIRED BY CUSTOMERS

18

38

18

38

KF16 FLANGE

CONNECTORS2x SMA 905

TUBING

TUBING

MAT. STAINLESS STEEL

MAT. STAINLESS STEEL

O30

13

4

O13,2

OO

17,2

17,2

2,5

O1

4

L1 = 1500 L2 = 1500

CONNECTORS2x SMA 905

MAT. STAINLESS STEEL

+50+5000

1

2

1 2 2

4CH - KF16 - SMA905 - HV 1CH - CF16 - SMA905 - UHV 4CH - CF16 - SMA905 - UHV

For More Information contact us at +420 493 765 111 or [email protected] Vláknová optika a.s., Komenského 304, 509 01 Nová Paka, Czech Republic www.sqs-fiberoptics.com

3D DRAWING

3D DRAWING

3D DRAWING

Vacuum Fiber Optic FeedthroughHermetic fiber optic feedthroughs with pigtail interface

CONNECTORS4x SMA 905

TUBING 3 mmMAT. STAINLESS STEEL

15,6

O

O

O

13,2

L1 = 1500

O14

L2 = 1500

4x SMA 905CONNECTORS

TUBING 3 mmMAT. STAINLESS STEEL

CF 16 FLANGEMAT. STAINLESS STEEL

7,6

O34

18

38

18

38

TUBING 3 mmMAT. STAINLESS STEEL

CONNECTORSMA 905

L2 = 1100

TUBING 3 mmMAT. STAINLESS STEEL

SMA 905CONNECTOR

15,6L1 = 1900

CF 16 FLANGEMAT. STAINLESS STEEL

7,6

7

34

18

38

18

38

KF16 FLANGEMAT: STAINELES STEEL

CONNECTORS4x SMA 905

TUBING 3 mmMAT. STAINLESS STEEL

O30

13

4

O13,2

O17,2

2,5

O14

L1 = 1500 L2 = 1500

4x SMA 905CONNECTOR

TUBING 3 mmMAT: STAINLES STEEL

18

38

18

38

+50+50

+50 +50

+50 +50

00

0 0

0 0

3

4

5

INSPIRED BY CUSTOMERS

3 4 5

The manufacturing process and materials used allow us to offer vacuum fiber feedthroughs suitable for high and ultra-high vacuum levels. Fiber feedthroughoutputting optical fibers may be mechanically protected by tubing and terminated with various types of optical connectors.

Fiber feedthroughs are designed so that the sealing of optical fibers does not affect transmission parameters of an entire route. The feedthrough construction ensures time stability of transmission parameters in all operating conditions.