Transmission Line Infrastructure

Transcript of Transmission Line Infrastructure

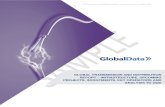

How do the pieces fit together?The conductors are attached to the structures by insulatorsthat prevent contact between the conductor and the structurebecause contact between the two could result in a short circuit,potentially interrupting the power supply. The foundation,structure and insulators must be strong enough to support theweight of the conductor and any wind and ice loads. Shieldwires attached to the top of the structures provide protectionagainst lightning strikes, minimizing the possibility of storm-related outages.

Transmission Line Infrastructure

SHIELD WIRE

INSULATOR

CONDUCTOR

STRUCTURE(weathering steel)

RIGHT-OF-WAY

Terms to knowConductor: A wire made up of multiple aluminum strandsaround a steel core that together carry electricity. A bundledconductor is two or more conductors connected to increasethe capacity of a transmission line.

Circuit: A continuous electrical path along which electricitycan flow from a source, like a power plant, to where it isused, like a home. A transmission circuit consists of threephases with each phase on a separate set of conductors.

Phase: One element of a transmission circuit that has adistinct voltage and current. Each phase has maximum and minimum voltage peaks at different times than the other phases.

Single circuit: A circuit on the same structure with threeconductors.

Shield wire: A wire connected directly to the top of atransmission structure to protect conductors from a directlightning strike, minimizing the possibility of power outages.

Structures: Towers or poles that support transmissionlines.

Insulator: An object made of a material, such as glass,porcelain or composite polymer that is a poor conductor ofelectricity. Insulators are used to attach conductors to thetransmission structure and to prevent a short circuit fromhappening between the conductor and the structure.

Right-of-way: Land area legally acquired for a specificpurpose, such as the placement of transmission facilitiesand for maintenance access.

huntleywilmarth.com

Single pole self-weathering steel

Underground transmission line construction

Transmission line characteristicsThe conductor, structure type, configuration, right-of-wayparameters and other design characteristics of a proposed 345 kilovolt (kV) line will be considered by the MinnesotaPublic Utilities Commission during the Certificate of PublicConvenience and Necessity (CPCN) process.

In addition to line voltage (i.e. 345 kV), typical determiningfactors in deciding the type and configuration of a structure areconductor number and size, wind or ice loads, terrain, structurespacing, right-of-way width and existing buildings adjacent tothe corridor for the proposed lines.

345 kV line characteristicsCONDUCTOR. Each phase would consist of bundledaluminum stranded, steel core conductor sized to carry theappropriate amount of electricity.

STRUCTURES. For 345 kV lines, single steel poles or steelH-frame structures are suitable.

Single pole structures are made of self-weathering steel andplaced on concrete foundations. Single circuit steel poles varyin height from 120 to 150 feet; Double circuit structures varyfrom 90 to 170 feet. Spans (or distance) between structuresrange from 800 to 1,000 feet.

H-frame structures are two steel poles with wood or steelcross bracing and conductor supports. They can be embeddedin the ground without a foundation and vary in height from 100to 150 feet, depending on the span between structures. Thesestructures are suitable only for single circuit configurations.

RIGHT-OF-WAY. A 345 kV line typically requires a 150-footright-of-way. A narrower right-of-way may be acceptablewhere a transmission line is located adjacent to a pre-existingline, road or pipeline corridor.

Underground linesThe proposed Huntley-Wilmarth 345 kV transmission lineproject calls for overhead lines. Underground lines usually areused only in heavily congested urban areas and when there is no viable overhead corridor, such as near an airport. Linesnormally are buried only for short distances.

The biggest difficulties with burying lines are cost and the timerequired to make repairs if there are failures. An equivalentunderground line can cost 10 to 15 times more than the amountof an overhead line, and it creates technical and operationalchallenges. Significantly more time is necessary to locate anddiagnose a problem on an underground line, and repairs candisrupt service for several weeks. Installing underground linesalso can have a considerable environmental impact.

H-frame self-weathering steel

6/22/2017

xcelenergy.com | © 2017 Xcel Energy Inc. | Xcel Energy is a registered trademark of Xcel Energy Inc.