Tractor Parts | Heavy Equipment | Jensales - M ......MASSEY FERGUSON SERVICE MANUAL BACKHOE 185,...

Transcript of Tractor Parts | Heavy Equipment | Jensales - M ......MASSEY FERGUSON SERVICE MANUAL BACKHOE 185,...

MH-S-MF185BH+

MMaasssseeyy HHaarr rr iissMMaasssseeyy FFeerrgguussoonn

Service Manual

MF185, MF210, MF212,MF220, MF222, & MF232

THIS IS A MANUAL PRODUCED BY JENSALES INC. WITHOUT THE AUTHORIZATION OF MASSEY HARRIS MASSEY FERGUSON OR IT’S SUCCESSORS. MASSEY HARRIS MASSEY FERGUSON AND IT’S SUCCESSORS

ARE NOT RESPONSIBLE FOR THE QUALITY OR ACCURACY OF THIS MANUAL.

TRADE MARKS AND TRADE NAMES CONTAINED AND USED HEREIN ARE THOSE OF OTHERS, AND ARE USED HERE IN A DESCRIPTIVE SENSE TO REFER TO THE PRODUCTS OF OTHERS.

Serv

ice

Man

ual

MASSEY HARRIS MASSEY FERGUSON

SERVICE MANUAL

BACKHOE 185, 210, 220, 222, 232

MASSEY -FERGUSON

GROUP VIII - SECTION A - PART t

PART l-TESTING AND TROUBLE-SHOOTING BACKHOE HYDRAULIC SYSTEMS

INDEX

Page

TEsn NG PROCEDURES. . . . . . . . . . . . . . . . . . . . . . . 2 Operating Checks. . . . . . . . . . . . . . . . . . . . . . . . .. 2 Additional Checks.. . . . . . . . . . . . . . . . . . . . . . . .. 2

TROUBLE-SHoon NG (Symptoms) . . . . . . . . . . .... 4

An understanding of the particular Backhoe's hydraulic system should be obtained before testing and trouble-shooting is attempted. Refer to the Section that pertains to the Backhoe for specifications and operational description.

The information within this Part applies to the MF Backhoes which are dependant upon the Loader hydraulic system for their oil supply. Some of these Backhoes use the Loader's main relief valve to control the hydraulic pressure within the Backhoe system - others have a separate relief valve for this purpose. The Loader's reservoir filter, hydraulic pump and main relief valve (in most cases) may therefore be considered as a part of the Backhoe's hydraulic system. These components (and their circuits) should be checked to insure they are performing correctly. (Testing and trouble-shooting Loader hydraulics is in Group VII, Section A, Part 1. )

Printed in U.S.A. 1

MASSEY-FERGUSON

GROUP VIII - SECTION A - PART 2

PART 2-VALVES-BACKHOES

INDEX Page

Trouble-Shooting. . . . . . .. . . . ••. ••.. . . . . . . . . . . •. 2 Specifications -MF Part No. 707505 M91 .•• • • •• • . 3

Service Briefs.. • . . . . . • . . . . . . . . • . . • • . . . . . . . .. 3 Servicing Control Valve - MF Part No. 707505M91. 3

Disassembly,................................ 5 Inspection. . . • • •• • •• • . . •. • • . • • • . . . . . • . . • . •• . 7 Reassembl y •. • • . • • • • • • • • • • • • • • • • . • • • • • • • . • . . 7

The instructions for servicing are written while assuming the valve component has been removed from the backhoe.

Good work practices, cleanliness and caution are necessary when working on hydraulic components. These components are precision-made and carelessness in handling or allowing dirt (or other foreign materials) to enter the component can cause extensive damage.

Printed in U.S.A. 1

MASSEY-FERGUSON BACKHOES

To obtain information and SerVlCIng procedures which pertain to the non-adjustable category of circuit relief valves, refer to the heading "Main Relief Valves" within this Part. The information and service procedures for the main relief valves will also apply to this category of circuit reliefs.

The adjustable category of circuit relief valves may be identified by the design of the cartridge, or by a series of numbers stamped on the head of the valve. Identification of relief valve category by design characteristics may be made by removing the valve from its port and observing the large crossholes through the cartridge (nearest the "cap" end). If a large spring is Visible, the valve may be adjusted. (Information: The "32039" relief valves have a "slotted" cap that screws into the main cartridge. This cap is visible when the valve is installed in its port. Its identifying number should be stamped on one of the "hex flats" on the main cartridge.) If the numbering series stamped on the head of the valve is either "32037", "32039", or "32042" the valve may be identified as adjustable. (Information: Two letters may also appear after the identifying number of the valve. The last letter designates the flow rate capacity of the valve. If the letter "A" is the last suffix letter, the valve has a 3 G PM rating; if the last letter is "B", the valve has a 15 GPM rating, and if the last letter is "C", the valve has a 6 GPM rating. In some cases, a letter then a number will appear after the identifying number of the valve - the last number denotes gpm rating. Stamped under the identifying number of the valve will be its pressure setting.) Use only the recommended relief valve. Check service bulletins and parts books for current application.

Adjustable "Type 32037" Relief Valve

Refer to Fig. 4.

1. Thoroughly clean the relief valve cartridge with a suitable solvent and blow dry with compressed air.

6

2. Disassemble this relief valve as follows:

IMPORTANT: Carefully note the sequence of parts (and their relationship to the "hex" end of the main cartridge) as they are removed from the valve. This will aid in correct reassembly of the valve.

a. Remove snap ring - then remove the

GROUP VIII - SECTION A - PART 2

Fig. 4 - Cutaway Typical of "32037" Relief Valve 1. Cartridge 2. "Ou·Ring 3. Spring 4. Guide

6. IIO'I_Ring 7. Plug Assembly 8. Snap Ring 9. Ball and Retainer Assembly

10. "Ou-Ring 11. Back·Up Washer 12. Shim 13. Shim

5. Seat 14. Shim

ball and retainer assembly from the plug assembly.

b. Unscrew the plug assembly, No.7, from the main cartridge (a small spanner wrench may be used).

CAUTION: Plug assembly is springloaded. Use care when removing.

c. Remove the ball seat, No.5, which may either remain with the cartridge, or the plug assembly.

d. Remove "O"-ring, No. 10, and back-up washer, No. 11, from inner bore of plug assembly.

e. Remove spring, seat guide and shims from cartridge. (Count the number of shims removed, as this same number and thickness should be reinstalled, unless the valve is to be adjusted. This relief valve is adjusted by adding shims to increase pressure setting; or removing shims to decrease pressure setting. Shims are installed between spring and seat guide. )

3. Reassemble the relief valve as follows:

a. Inspect the ball and its seat for evidence of pits or other damage that may prevent it from seating properly. Check that the spring is not broken and that the ball seat will slide over guide. Replace all worn, or damaged, parts and clean all metal parts thoroughly.

MASSEY-FERGUSON

GROUP VIII - SECTION A - PART 3

PART 3-HYDRAULIC CYLINDERS {Backhoes}

INDEX

Page

BASIC SERVICING PROCEDURES............... 2 Disassembly ......••......•....••.......•.. 2 Inspection ..•.••••....•.....•.••..•.....•• 5 Reassembly .•.••••••••••••••••••. . • • . . . . • . • 5

SPECIFICATIONS AND SERVICE NOTES........ 7 MF Part No. 671 143 M92 ...•..•••..•.•••.. 7 MF Part No. 671 194 M92 .................. 8 MF Part No. 704939 M91 ...•........•..... 9 MF Part No. 705083 M92 .................. 10 MF Part No. 705 801 M91 .................. 11 MF Part No. 706107 M91 .................. 12 MF Part No. 706108 M93 .................. 13 MF Part No. 706 109 M93 .................. 14 MF Part No. 707147 M91 .................. 15 MF Part No. 707412 M91 .................. 16 MF Part No. 707413 M91 .................. 17 MF Part No. 707414 M91 .................. 18 MF Part No. 707415 M91 .................. 19 MF Part No. 707 647 M91 •.......•......... 20 MF Part No. 707949 M91 .................. 21 MF Part No. 708 180 M91 .................. 22 MF Part No. 708 181 M91 .................. 23

The purpose of this Part is to provide instructions for use in repairing the various sizes of cylinders used on MF Backhoes. These instructions are divided into two major phases, as denoted by the following headings:

"Basic Servicing Procedures" - The instructions under this heading are to be used to disassemble, inspect and reassemble the cylinders. These basic procedures may also be used as a guide to perform servicing on a cylinder not listed under· "Specifications and Service Notes".

"Specifications and Service Notes" - This heading provides specifications and data which pertain specifically to a particular cylinder. (The cylinders are listed by their MF Part Number, but may not necessarily be in numerical order.) Tightening torques, positioning of seals (ie: packing) and other pertinent data which may concern the repair of a particular cylinder· may be found under this heading.

Good work practices, cleanliness and caution are necessary when working on hydraulic cylinders. These components are precision-made and carelessness in handling, or allowing dirt to enter the cylinder can cause extensive damage.

Reissue 9/67 1

MASSEY-FERGUSON

GROUP VIII - SECTION A - PART 4

PART 4-SWING ACTUATING CYLINDERS-BACKHOES

INDEX Page

Specifications - MF Part No. 707 324 M91 .............................. 3

Trouble-Shooting Rotary Cylinder -MF Part No. 707 324 M91 ..... . . .. ... .. . . . .. 3

Servicing Rotary Cyl inder -MF Part No. 707324 M91 ................... 5 Disassembly............................... 5 Inspection ................•............... 11 Reassembl y '" . . . . . . . . . . . . • . . . • . . . . . . . . . . .. 12 Operational Check of Dampening

Adjustments ........•.............•...... 13

The instructions for servicing are written while assuming the component has been removed from the Backhoe.

Good work practices, cleanliness and caution are necessary when working on hydraulic components. These components are precision made and carelessness in handling or allowing dirt (or other foreign material) to enter the component can cause extensive damage.

Printed in U.S.A 1

Printed in U.S.A.

MASSEY -FERGUSON

GROUP VII I - SECTION C - PART 1

PART 1-GENERAL INFORMATION, SERVICE SPECIFICATIONS AND ADJUSTMENTS

MF 212 BACKHOE

INDEX

Page

GENERAL INFORMATION .................... 2 Structural Welding Data .................... 2 Hydraulic System Flow. . . .. . . .. . . . . . ... . . . .. 2

System Diagram. . . . . . . . . . . . . . . . . . . . . . . . .. 2 Loader-to-Backhoe Hydraulics........... .. 2 Backhoe Hydraulic Circuit Flow... ......... 2

Control Valve ............................. 4 Anti-Cavitation Return Plate............... 4

Relief Valves..... .... .............. ....... 5 Rotary Cylinder........... ................. 7 Boom, Dipperstick, Bucket and

Stabilizer Cylinders.................. .... 7

SERVICE SPECiFiCATiONS.................... 7 Hydraulic General ......................... 7 Hydraulic Cylinders........................ 7

Rotary Cylinder.......................... 7 Boom Cylinder ................. , . . . . .. . .. 8 Dipperstick Cylinder ..................... 8 Bucket Cyl inder . . . . . . . . . . . . . . . . . . . . . . . . .. 8 Stabilizer Cylinder...... ................. 8

Control Valve ............................. 8

ADJUSTMENTS.............................. 9 "Type 32037" Relief Valves.................. 9 "Type 32042" Relief Valves.................. 9

1

MASSEY -FERGUSON

GROUP VIII - SECTION C - PART 2

PART 2-HYDRAULIC SYSTEM-MF 212 BACKHOE

INDEX

Page Page

FILLI NG THE HYDRAULIC SYSTEM ........... 2 Initial Filling.............................. 2 Normal Refilling. .. ........ ........ ........ 3

CONTROL VALVE........................... 3 Specifications ............................. 4 Removing the Control Valve. . . ...... ..... ... 4 Servicing the Control Valve ................. 5 Installing the Control Valve................. 5

ROTARY (SWI NG) CYLINDER ................ 6 Specifications ............................. 7 Removing the Rotary Cyl inder . . . . . . . . . . . . . . .. 7 Servicing the Rotary Cylinder...... .. ..... ... 8 Install ing the Rotary Cyl inder . . . . . . . . • . . . . . .. 8

STABILIZER CyLINDERS...................... 8 Specifications ............................. 9 Removing Stabilizer Cylinder. ..... . .. ........ 9 Servicing Stabilizer Cylinder. .. . .... . .. ..•... 9 Installing Stabilizer Cylinder................. 9

BOOM CyLINDER........................... 9 Specifications ............................. 10 Removing Boom Cylinder ..................... 10 Servicing Boom Cylinder ..................... 10 Installing Boom Cylinder ..................... 10

DIPPERSTICK CyLINDER ...................... 12

Specifications ............................. 12 Removing Dipperstick Cylinder ............... 12 Servicing Dipperstick Cylinder ............... 12 Installing Dipperstick Cylinder ............... 12

BUCKET CYLI NDER .......................... 13 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . .. 13 Removing Bucket Cylinder ..... '" ........... 13 Servicing Bucket Cylinder .........•......... 13 Installing Bucket Cylinder ................... 15

HOSES AND TUBES ......................... 15 Hydraulic System Diagram ................... 15 Main Pressure and Return Connections. . . . . . . .. 15 Control Val ve Connections ................. 15 Rotary and Stabilizer Cylinder Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 15 Boom, Dipperstick and Bucket Cyl inder Connections ...................... 15

OIL COOLER KITS .......................... 15 TROUBLE-SHOOTING AND TESTING ......... 18

Operational Check of Backhoe. . . . . . . . . . . . . .. 18 Operational Check of Swing. . . . . . . . . . . . . . . .. 18 Trouble Symptoms. . . . . . . . . . . . . . . . . . . . . . . . .. 19 Adjustments .............................. .

SPECIAL TOOLS ............................ 23

This Part contains instructions for removing and installing the hydraulic components of the MF 212 Backhoe. Hose and tube routing, trouble-shooting of the Backhoe and specifications related to the hydraulic components are also included within this Part.

Hydraulic system flow is described in Part 1 - "General Information, Service Spec-ifications and Adjustments" within this Section .

• CAUTION: Good work practices, cleanliness and caution when \iII working on, or around, hydraulically actuated equipment are necessary. Hydraulic components are precision-made and dirt, dust (or other foreign materials) entering the system can cause damage. Serious injury to personnel can be the result of allowing anyone who is not familiar with the system and its controls to operate the controls during the servicing procedures. Safety precautions, along with good "common horse sense", should always be observed.

Directions given within this Part are as they would appear to the operator while seated at the Backhoe controls, unless otherwise specified.

P~;n+<>,.1 in I! C fl 1

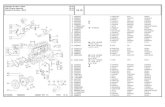

MASSEY -FERGUSON MF 212 BACKHOE

BUCKET

DIPPERSTICK CYLINDER

STABILIZER

BOOM CYLINDER

GROUP VIII - SECTION C - PART 2

CYLINDER

LEFT STABILIZER

Fig. 1 - Identification of MF 212 Backhoe Hydraulic Components

FILLING THE HYDRAULIC SYSTEM

The MF 212 Backhoe uses oil supplied by the Loader reservoir. The type of oil recommended is type "A" automatic transmission fluid conforming to MF Specification No. M-1110. (The MF Spec. No. is on the container. )

NOTE: Use only the recomnlended type of oil in the system.

There are two different procedures to be used when filling the hydraulic system. The reason is to prevent overfilling of the reservoir (avoiding unnecessary loss of fluid) or damage to the pump (due to the lack of an adequate supply of oil).

NOTE: If the hydraulic pump is operated without an adequate supply of oil, the pump nwy be damaged in a very short time.

Refer to the subheading "Initial Filling of the System", if the system is being filled for the first time or if the system is being filled after extensive overhaul of the hydraulic cylinders.

Refer to the subheading "Normal Filling of the System" whenever the system has beenpro-

2

perly filled before and is only being checked for proper oil level, or whenever servicing of the Backhoe has resulted in a minor loss of fluid from the system.

INITIAL FILLING

The procedures under this subheading are recommended whenever the Backhoe hydraulic system is being filled for the first time, or whenever the system is being refilled after extensive overhauling of the hydraulic cylinders.

The instructions are given while assuming that the Backhoe boom, dipperstick and bucket system are on the ground, and that the Loader hydraulic system has been previously filled. (To obtain instructions on filling the Loader system, refer to the appropriate section in Group VII that pertains to the Loader model being used. )

1. Check that all hoses are properly connected.

2. Check the reservoir fluid level as indicated by the dipstick. Fill, as necessary, using the recommended type oil.

MASSEY -FERGUSON

GROUP VIII - SECTION D - PART t

PART 1 -GENERAL SPECIFICATIONS, DESCRIPTION

AND LUBRICATION-MF 220 BACKHOE

Specifications .. Description Lubrication ...

INDEX Page

2 4

10

The MF 220 Backhoe is a tractor mounted backhoe used with either the MF 5 Dozer or the MF 100, MF 101, MF 102, MF 200 or MF 300 Loaders.

Additional specifications and description may be obtained by referring to specific parts within this section of the manual that pertain to the particular component or assembly in question.

Left and right- hand directions given within this part are as they would appear to the operator seated at the backhoe control levers, unless otherwise specified.

Fig. 1 - MF 220 Backhoe

1

MA~~t Y -t-tKuU~UN

GROUP VIII - SECTION D - PART 3

PART 3-HYDRAULIC SYSTEM-MF 220 BACKHOE

INDEX Page

Specifications. ......•.•....... ...•.......•••. 2 System Operation and Description............... 8 Filling the Hydraulic System with Fluid ....•..... 19 Control Valve. . . . . . . • . . . • • . . • . . . . • . • • . • • • . • .• 21 Rotary Cylinder and Line Filter •.•.•..•••••..... 23 Stabilizer Cylinders ..•..•.•••.•.•.••....•.•••. 27 Boom Cylinder ............................... 28 Crowd Cylinder .............................. 31 Bucket Cylinder •.•.••.•......••••..••••••••.. 31 Boom Lock Valve· • . . • • • . . . . • . . • • . • . . . • • • • . . .. 33 Crowd Lock Valve. . . . . • . • . . . . . • • • . • . . . . . . . . •. 36 Selector Valve •..••.....•••.•.•.•..••••.•...• 38 Hoses and Tubes ..•••••.......•••.••••••.•.... 39 Special Tools ....•.•..•.••...•.•..••..•...... 44

This part provides specifications and data pertaining to the MF 220 Backhoe hydraulic system and its components.

System description is included within this part, along with removal and reinstallation procedures for the hydraulic components. Actual servicing (disassembly,

Fig. 1 - MF 220 Backhoe

MASSEY-FERGUSON

GROUP VIII - SECTION F - PART 1

PART 1 - GENERAL SPECIFICATIONS, DESCRIPTION AND LUBRICATION - MF 222 AND MF 232 BACKHOES

INDEX Page

SPECiFiCATIONS ............................. 2 Operating Dimensions ....................... 2 Backhoe - General . . . . . . . . . . . . . . . . . . . . . . . .. 2 Hydraul ic - General ....................... 2

DESCRIPTION. . . . . .. .. . . . . . . . . . . . . .. . . .. . . . .. 5 The Main Frame ............................ 7 Stabi I izers ................................. 7 Swing Post and Mast Assembly ................ 7 Boom, Dipperstick and Buckets ............... 8 Hydraul ics ................................ 8

LUBRiCATION ................................ 8

The MF 222 and 232 Backhoes are tractor mounted and used with either the MF 100, MF 200 or MF 300 Loaders.

Additional specifications and description may be obtained by referring to specific Parts within this Section of the Manual that pertain to the particular component or assembly in question.

Left and right-hand directions given within this Part are as they would appear to the operator, seated at the Backhoe control levers, unless otherwise specified.

Fig. 1 - MF 222 Backhoe Fig. 2 - MF 232 Backhoe

Printed in U.S.A 1

MASSEY-FERGUSON

GROUP VIII - SECTION F - PART 2

PART 2 - REMOVING AND ATTACHING THE BACKHOE MF 222 AND MF 232 BACKHOES

INDEX Page

Safety Precautions .........•...•..•..•....... 1 Removing Backhoe from Tractor. . . . . . . . . . . . . . . . . 1 Attaching Backhoe to Tractor .................. 5 Adj ustments ................................. 6

Adjusting Swing Cushioning ... ,... .. ... . . .... 6

The purpose of this Part is to provide instructions for the removal and attaching of the MF 222 and MF 232 Backhoes.

The adjustment for swing cushioning is included within this Part to enable it to be made when the Backhoe is mounted to the tractor.

The directions given within this Part are as they would appear to the operator seated at the Backhoe controls (unless otherwise specified).

SAFETY PRECAUTIONS REMOVING BACKHOE FROM TRACTOR The following safety precautions should be

observed when working on, or around, hydraulically actuated equipment: Select a level area to satisfactorily store the

Backhoe while it is detached from the tractor. 1. Do not attempt to tighten a hydraulic

connection while pressure is on the system.

2. N ever loosen or attempt repair of a connection while the hydraulic pump is operating (i. e., when engine is running).

3. Do not allow anyone to stand in front of a disconnected hose assembly.

4. Do not allow anyone to stand under (or near) a raised boom, dipperstick or bucket.

5. Do not operate the control valve levers unless you are sitting in the proper operating position and do not allow anyone unfamiliar with the control lever functions to operate the levers during servicing procedures.

Pri:,tcd i:- U.5."\.

1. Use hydrauliC system pressure to place the boom, dippers tick and bucket in a "tripod" position with the stabilizers on the ground. The boom should be angled upward, the dipperstick angled downward, the bucket should be resting on the ground and the stabilizers should be lowered until they are just beginning to relieve the weight of the Backhoe from the tractor. (See Fig. 1.)

NOTE: Do not actuate the control levers when the hydraulic pump is not circulating the oil. (If the fluid is displaced from one side of the cylinder piston due to the weight of the implement, and the pump is not delivering the oil to the opposite side of the cylinder, the reservoir may overfill and oil will leak out the breather.)

2. Sufficiently loosen (or remove) the lock-

1

MASSEY-FERGUSON

GROUP VIII - SECTION F - PART 3

PART 3-HYDRAULIC SYSTEM-MF 222 AND MF 232 BACKHOES

INDEX Page Page

SYSTEM OPERATION AND DESCRiPTION............................... 2

Backhoe -to-Loader Hydrau Ii cs ••••••••••••••• 2 Oil Cooler Kit... •••••••••••••••••••••••• 3

Backhoe Hydraulic Circuits.................. 3 Boom Lockout Valve. • • • • • • • • • . • • • • • • • • • • • 5 Control Valve •......•••..•••.•.••.•• It • • • 6 ReliefValves ..••..••..••.••••.•..•.••••• 7

FILLING THE HYDRAULIC SYSTEM WITH FLUiD...................................... 8

Initial Filling of the System.................. 8 Normal Fill ing of the System................. 9

CONTROL VALVE •••••••••••••••••••••••••••• 10 Specifications .•.••.••••••••••••••.•.•.•••• 11 Removing the Control Valve ••••••••••••••••• 12 Servicing the Control Valve ••••••••••••••••• 13 Reinstalling the Control Valve ............... 13

ROTARY CyLINDER •••••••••••••••••••••••••• 14 Specifications .............•.........••..•. 17 Removing the Rotary Cyl inder ...... .. .. • .. ... 18 Servic ing the Rotary Cyl inder • • • • • • • • • • • • • • •• 19 Reinstalling the Rotary Cylinder ............. 19 Adjusting Swing Cushioning •••••••••••••••••• 21

STABILIZER CYLINDERS ...................... 22 Specifications (Used W/MF 222 Backhoe) •••••• 23 Removing Stabil izer Cyl inders -

MF 222 Backhoe ••••••••••••••••••••••••• 24 Servicing Stabilizer Cylinders -

MF 222 Backhoe .•••..••••••••••••••••••• 24 Reinstalling Stabilizer Cylinders -

MF 222 Backhoe ••••••••••••••••••••••••• 24 Specifications (Used W/MF 232

Backhoe) • • • • • . . . • . . . . • • . • . . • • . . • . • • . • • •• 25 Removing Stabilizer Cylinders -

MF 232 Backhoe • • • • • • • . • • • • • • • • • • • • • • •• 26 Servicing Stabilizer Cylinders -

MF 232 Backhoe ••••••••••.•••••••••••••• 27 Reinstalling Stabilizer Cylinders -

MF 232 Backhoe ••••••••••••••••••••••••• 27

BOOM CyLINDER •••.•••.•••..••••••.••.•••• 27 Specifications (Used W/Standard Boom) ••••••• 28 Specifications (Used W/Long Boom) ••••••••••• 29 Removing Boom Cyl inder ••••.••••••••••••••• 30 Servicing Boom Cylinder •••••••••••••••••.•• 30 Reinstalling Boom Cylinder •••••••••••••••••• 30

CROWD (DIPPERSTlCK) CYLINDER ............. 30 Specifications (Used W/Standard Boom) •••••••• 31 Specifications (Used W/Long Boom) •••• • • • • • •• 32 Removing Crowd Cyl inder ••••••••••••••••••• 32 Servicing Crowd Cylinder ................... 33 Reinstall ing Crowd Cyl inder ••••••••••••••••• 33

BUCKET CYLINDER .......................... 33 Specifications ............................. 34 Removing Bucket Cylinder ••••••••••••••••••• 35 Servicing Bucket Cylinder ................... 36 Reinstall ing Bucket Cyl inder ••••••••••••••••• 36

BOOM LOCK VALVE ......................... 36 Specifications .......•..•..•..•............ 36 Removing Boom Lock Valve. • • • • • • • • • • • • • • • •• 37 Servicing Boom Lock Valve •••••••••••••••••• 38 Installing Boom Lock Valve .................. 38

OIL COOLER KITS ••••••••••••••••••••••••••• 38 Oil Cooler Installation - MF 3165

Tractor •••••••••.•••••••••••••••••••.••• 41 Oil Cooler Installation - MF 302/304

Tractors ••••••..•••••.•••.•.••••.••••.•• 41 HOSES AND TUBES ••••.••••••••••••••••••••• 41

Main Line Pressure and Return Connections •••••••••••••••••••..•••.•••• 44

Control Valve Connection.. • • • • • • • • • • • • • • • •• 44 Stabilizer Hydraulic Connections ••••••••••••• 44 Hose Routing Through Swing Post •••••••••••.• 44 Boom Crowd and Bucket Cylinder

Connections. . • . • • • • • • . • • • • • . • . . . • • • • • • •• 44 TROUBLE-SHOOTING ....................... 49

Operational Check of Swing Adjustment. • • • • •• 49 Trouble Symptoms ••••••••••••••••••••••••.• 49

SPECIAL TOOLS. ••••••••••••••••••••••••••••• 54

This Part provides specifications and data pertaining to the MF 222 and MF 232 Backhoe hydraulic systems and their components.

System description is included within this Part, along with removal and reinstallation procedures for the hydraulic components. Actual servicing (disassembly, etc. )

Printed in U.S.A. 1

MASSEY-FERGUSON

GROUP VIII - SECTION F - PART 4

PART 4-MAJOR STRUCTURE ASSEMBLIES,

MOUNTING KITS AND ACCESSORY ITEMS

INDEX Page

Safety Precautions •••••••••••••••••••••••••• 1 Welding Structure Assembl ies ••••••••••••••••• 2 Main Frame Assembly...... ••••••• ••••••••••• 4

MF 222 Main Frame ••••••••••••••••••••••• 4 MF 232 Main Frame ••••••••••••••••••••••• 4

Boom Assemb I y • • • • • • • • • • • • • • • • • • • • • • • • . • • • • • 4 Standard Boom Assembly. • • • •• • • •• • • • •• • • • • • 4 Long Boom Assembly.. ••• • • • • • • • • • • • • • • • •• • 4

Dipperstick Assembly •••••••••••••••••••••••• 4 Standard Dipperstick Assembly •••••••••••••• 13 Long Dipperstick Assembly.................. 13

Buckets ••••••••••••••••••••••••••••••• • • • • • 13 Mounting Kits........................... .•. 17

Mounting Kit (Used w/MF 100 and 200 Loaders) ••••••••••••••••••••••••••••••• 17

Mounting K it (Used w!MF 300 Loader) •••••••••••• 0 • • • • • • • • • • • • • • • • • • • 17

Accessory Items ••••••••••• • • • • • • • • • • • • • • • . • • 17 Spike Kit •••••••••••••••••••••••••••••••• 17 Street Pad Kit •••••••••••••••••••••••••••• 20 Boom Lock Valve ••••••••••••••••••••••••• 20 Spec iel Tools ••• • • • • • • • • • • • • • • • • • • • • • • • • • • 20

The instructions within this Part pertain to the main structural assemblies of the Backhoes, which include the main frame, the boom, the dipperstick, the bucket and four-bar linkage. Information pertaining to the mounting kits and accessory items is included, as well as general information pertaining to welding of the structure assemblies.

Directions given within this Part are as they would appear to the operator seated at the controls, unless otherwise specified.

SAFETY PRECAUTIONS

The following safety precautions should be observed when working on, or around, hydraulically actuated equipment.

1. Do not allow anyone to stand under a raised boom, dipperstick or bucket; or in front of a disconnected hose assembly.

2. Do not operate the control levers un-

less you are sitting in the proper operating position.

3. Do not allow anyone who is not familiar with the Backhoe controls to actuate the controls during servicing.

4. Never loosen or attempt repair of a connection while the hydraulic pump is operating.

INDEX

CYLINDERS

Boom and Crowd -185 - 210

Bucket - 185 - 210

Stabilizer -185 - 210. . .

Swing-185 ..... .

Swing - Rotary Vane - 210

FILTER

Page

1

3

5

7

9

Line - Rotary Vane Cylinder - 210 . . 14

VALVES

Cushion Valve - Swing - 185 15

Relief Valve - Rotary Cylinder - 210 . 16

Six Spool- Hydreco - 185 - 210 17

Stack Type - Cessna - 210 21

Selector Valve -185 - 210 . . . 24