TOTAL PRECAST - BPDL inc. Precast A sensible choice for today and tomorrow! With building costs...

-

Upload

phamnguyet -

Category

Documents

-

view

214 -

download

0

Transcript of TOTAL PRECAST - BPDL inc. Precast A sensible choice for today and tomorrow! With building costs...

Since 1976, BPDL has been an industry-leading partner dedicated to ensuring the end-to-end success of large-scale precast concrete-based projects throughout North America. Thanks to the soundness of BPDL’s expertise, architects, contractors and developers know they can rely on tailor-made solutions that fully comply with the most stringent quality standards. Our people go out of their way to help clients benefit from every technical advantage offered by in-plant manufactured precast concrete. Total Precast clearly stands out by far as one of the options with the most advantages.

The name “Total Precast” refersto a construction system approach where architectural & structural precast and prestressed concrete components can be combined to create anentire building.

Rideau Centre Red Garage Ottawa, ON | Architect: IBI Group Architects | Contractor: EllisDon Corporation

Total Precast provides a very unique and versatile approach to building, including precast columns and beams used in conjunction with panelized cladding or load bearing precast walls and double tee or hollow core flooring. At BPDL, it is clear that having easy access to virtually unlimited options helps our experts to fully grasp the individual needs of each client and pinpoint the best solution. The construction project can therefore be achieved in a reasonable, time-saving and cost-effective manner that will benefit every stakeholder involved: developers, architects, engineers and end-users alike.

434 parking spaces162,000 ft2 (can be raised to 235,000 ft2)

33 days for erection33 columns55 horizontal panels36 light walls16 load bearing walls12 beams178 double tee slabs121 architectural walls

Precast’s inherent

fire resistance

eliminates the

time-consuming

fireproofing required

for a steel structure.

Fabrication of

precast elements

during permitting

and/or site

preparation

saves time.

Total Precast is the

high-speed installation

system contractors

seek to erect a building’s

walls, floors and roof in

record time. Hence, the

contractor can enclose

the building quickly,

giving interior trades

faster access.

Precast concrete

components can be

erected during winter,

regardless of the

weather conditions;

sound assets that

help to respect

tight schedules.

A sensible way to build

TOTAL PRECAST

Total Precastcombines quick

building withrigorous control

over time and costs; two solid assetsthat are highly

valued by industryplayers looking

to keep projects on the right track.

Onlyone supply source

for the entire shell = Onlyone contract and BPDL’s Total

Efficiency Promise.

Developers who chose Total Precastsay the system can shed 20% to 50% off

the timetable of a project using steel structures,and provides even greater time savings

when compared to cast-in-placeconcrete construction.

LE S

AIN

T-JU

DE

RES

IDEN

CE

Tota

l Pre

cast

fro

m t

he

gro

un

d u

p!

Alm

a, Q

C C

AN

AD

A |

Arc

hit

ect:

Éri

c Pa

inch

aud

Arc

hit

ecte

| I

Mec

han

ical

/Ele

ctri

cal E

ng

inee

r: G

émel

Exp

erts

-co

nse

ils |

Str

uct

ura

l En

gin

eer:

Sim

on

Lac

roix

The designers chose in-plant

manufactured prestressed

concrete slab floors. This

approach affords numerous

advantages, including: the

design of open-space living

areas, top-of-the-line sound-

proofing between floors and

outstanding fireproofing

performance. With remarkable

precision and lightning-fast

installation, the slabs easily

shape the floors one-by-one.

As soon as the first floors have

been erected, all electrical,

plumbing and HVAC

work may begin.

Precast concrete was also used in

the design of staircases, thus

eliminating the need for on-site

casting. As a result, the site

is always clean and without debris:

two significant advantages

contributing to worker safety

throughout the building process.

All windows and glass plates were fitted

into the components at the plant before

delivery to the site. This way of organizing

construction work relies on a solid

foundation: execution is carried out in a

controlled environment that can in no way

be affected by weather conditions of any

sort, and allows eliminating certain trades

from the construction site.

Certain concrete components that

make up the interior halls were

kept as-cast. Our designers turned

to light sandblasting to create a

unique finish and ensure one-

of-a-kind architectural effects.

This virtually maintenance-free

solution eliminates expensive

finishing costs.

Total Precast is the ideal solution to residential

building projects; hallway load-bearing and

exterior walls support the entire building.

Each panel used to erect the building is designed as

a 12 inches thick concrete sandwich wall.

This construction system

is well-suited for 10- to

12-storey buildings,

depending on building

configuration.

Concrete and ArchitectureThe impressive beauty of Le Saint-Jude’s architecture

lies in the complexity of its curvy lines and wide

variety of finishes. The building’s exterior walls feature

hammered-finish on the balconies, beige sandblasted

concrete walls for the apartments and mosaic work

on the ground floor. The latter was achieved by

integrating small pieces of cast-stone into large

concrete wall sections with false joints. The uniqueness

of the overall appearance of the finish was achieved

using different sandblasting pressures.

The project is a fine example highlighting the unlimited

design possibilities offered by precast concrete.

Regardless of the project, there are no compromises

as regards color, texture, shape and integration

of architectural elements.

Le Saint-Jude

95 d

ays

of

inst

alla

tio

n

1,77

0 p

anel

s

695

slab

s

115,

173

ft2

of

flo

or

spac

e

220

exte

rio

r w

alls

224

bal

con

ies

25 b

eam

s

6 fl

oo

rs

126

un

its

236

colu

mn

s

12 s

tair

case

s

16,9

75 lb

s =

ave

rag

e p

anel

wei

gh

t

180,

563

ft3

of

pre

cast

co

ncr

ete

IN FIGURES

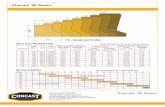

ANCHOR SYSTEMSAnchoring system design is adapted to each project

“Relying on Total Precast concrete components for this project gave our team the freedom to integrate complex architectural precast concrete elements that we had never experimented with before. We took great pleasure in developing the plans with the manufacturer. This way, we made sure the final result would meet our expecta-tions in terms of quality and functionality. Total Precast provides unheard of precision, efficiency and is perfectly in line with worldwide green building principles.” - Eric Painchaud, EPA Architect

“Each precast concrete wall makes up a seismic force and wind absorbance system. Distributing the forc-es over numerous components allows using a lim-ited number of connections between panels, thus permitting industry-leading installation speeds.”

- Simon Lacroix, Eng. M.Sc.A.

Eliminates thermal bridges

Hot-dipped galvanizing done byBPDL toensurequality andrespectschedules

Slab

– S

lab

Co

nn

ecti

on

Slab

– E

xter

ior

Wal

l Co

nn

ecti

on

Insi

de

Wal

l – In

sid

e W

all C

on

nec

tio

n

CROSS-SECTION

CROSS-SECTION

CROSS-SECTION

PLAN VIEW

A-A CROSS-SECTION

INSIDE WALL

INSIDE WALL

INTERIOREXTERIOR

20M CONTINUOUS

PL2 1/2”X4”X5/8”

20M x 68”LG20M x 68”LG

20M x 8”LG

135°

TYP.

45°

HSS8”X8”X5/8”X5 1/2”LG

PL2 1/2”X4”X5/8”+1–HOLE 1”ø

DYWIDAG THREADED ROD7/8”ø (#6)

25M CONTINUOUS SEE PAGE B-701

NON-SHRINK GROUT f’c=35MPa min.

HEXAGONAL NUT(#6)

HEXAGONAL NUTHALLWAY SIDE APARTMENT SIDE

DYWIDAG THREADED ROD

A

A

SLAB

A

A

SLAB

SLABBALCONY

STEELSPACER6” X 4”

21/2”

11/2”

21/2”

7”

2”

3”

6”3”

8”

6”

6”

8”

1”

4”

1’ –

0”

2”

28”

28”

12”

8”

9/16”

5/8”

1/2”

3/4”

3/4”

1/4”

Designedby ourtechnicalteam

It is only fair to state that precast concrete plays a first-rate role in sustainable development, since it significantly contributes toward gaining the points required to achieve LEED(*) certification.

Great thermal mass, recyclability, reusability, and minimal waste generation during the prefabrication process and installation on construction sites; these are but a few of the qualities architects and developers are looking for when selecting a construction system.

Choosing to integrate Total Precast into a project, right from the early design stages, is among the wisest decisions design experts can make. Doing so enables to take full advantage of the innovative character of precast concrete.

In short, when compared to other building systems, precast concrete is the high-quality, long-lasting solution needed to achieve the optimal service life of any building.

(*)

Pote

nti

al c

on

trib

uti

on

of

33 p

oin

ts t

ow

ard

LEE

D C

erti

fica

tio

n®

Can

ada

NC

TOTALLY

GREEN

Le Préfabriqué Intégral présente

de considérables avantages tels la

résistance aux séismes et

aux grands vents, l’insonorisation,

la durabilité

et l’entretien réduit.

Due to its density, concrete has the capacity to absorb and store large amounts of heat. This thermal mass enables concrete to react very slowly to outside temperature variations. This characteristic reduces peak heating & cooling loads and even delays them for several hours.

SHELLPERFORMANCE

The thermal performance of precast concreteinsulated walls is among the industry’s best.

Excellentfireproofing

performance

Reductionof HVAC

equipmentsize

Optimizationof energy

performance (LEED)

Heating & cooling load comparisons

Time (hours)

Ther

mal

load

BTU

/ho

ur

ft2

FireproofInsulated concrete sandwich walls can hold

back fire for up to 4 hours.

Comfort and safetyTotal Precast offers unrivalled advantages, such as: resistance

to seismic disturbances and strong winds, soundproofing,

durability and minimum maintenance.

6” concrete sandwich wall

Metal frame wall

Woodframe wall

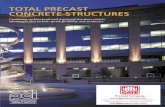

Total PrecastA sensible choice

for today andtomorrow!

With building costs continuouslyon the rise, contractors

and designers must workhand-in-hand to find

cost-effective solutions that enable them to attain set objectives,

despite ever-decreasing delivery schedules.

Equally important, sustainabledevelopment must be the focalpoint of their thinking process.

To this end, Total Precast fullymeets these requirements.

Observable results can be seenas soon as the construction

of a building begins and throughout its

service life.

GOOD, BETTER…AND THE BEST!

RETHINKING CONSTRUCTION