TNB - UG Cable System Design Manual (GI Crossing)

description

Transcript of TNB - UG Cable System Design Manual (GI Crossing)

-

Page | i

June 2012 Asset Management Department, TNB Distribution Division

Underground Cable System Design Manual

-

CHAPTER 3 CABLE LAYING SPECIFICATIONS Underground Cable System Design Manual Distribution Division

Page | 75

3.2 Laying Cables in Pipes / Ducts Although direct buried method is preferred by TNB but sometimes cable needs to be laid in pipes or ducts especially in situation where direct buried method is not suitable.

Situations where pipes/ducts are required: a) Road crossing b) Highway crossing c) Railways crossing d) Monsoon drain crossing e) Culvert crossing f) River crossing

The common methods used by TNB for crossings are: a) Pipes or ducts installation via open cut b) Horizontal Directional Drilling (HDD) / trenchless c) Laid in G.I. pipe above ground d) Cable bridge

When parallel circuits are to be installed in the same trench, a minimum distance of at least two (2) cable diameters should be maintained.

Whenever pipe/ducts are installed at road crossings for cable laying, additional pipes/ducts may be laid for future use. Where more than one length of pipe is used, suitable pipe joints/adapters shall be used around each joint.

The three types of pipes used by TNB are: a) High Density Polyethylene (HDPE)

o Corrugated single wall and double wall o Grade PN10

b) PVC Class B with SIRIM approved label c) Galvanised Iron (G.I.) Pipes

-

CHAPTER 3 CABLE LAYING SPECIFICATIONS Distribution Division Underground Cable System Design Manual

Page | 76

A summary of specific applications for different pipes is shown in Table 3-2.

3.2.1 Types of Pipes

3.2.1.1 High Density Polyethylene (HDPE)

Double Wall Corrugated HDPE

Where pipes/ducts are required for road crossing, Double Wall Corrugated HDPE pipes may be used if encased in concrete.

Figure 3-7: Double Wall HDPE Corrugated Pipe

When cables are to be laid in HDPE pipes, one 150 mm diameter HDPE Pipe/duct is required for each single core, three core and four core XLPE cable and one 100 mm diameter HDPE pipe/duct for each pilot cable or fibre optic cable.

The HDPE pipes shall be able to be connected by pipe connection means of double connection sleeves or equivalent connection accessories manufactured with the same material and shall be of sand proof or water proof (special case). The HDPE pipe shall comply to TNB technical specification for HDPE pipes8.

8 Technical Specifications, Single & Double Wall High Density Polyethylene (HDPE) Corrugated Pipe, 7 April 2000.

-

CHAPTER 3 CABLE LAYING SPECIFICATIONS Underground Cable System Design Manual Distribution Division

Page | 77

HDPE Grade PN10 HDPE pipe of grade PN10 is used as duct sleeve in HDD installations.

Figure 3-8: HDPE grade PN10

3.2.1.2 PVC Pipe Class B PVC pipe Class B is used as protective sleeve for road crossings with concrete encasement. It is also used as a protective sleeve for cables installed on cable bridges. The Class B PVC pipe should have the SIRIM approved label.

Figure 3-9: Class B PVC ducts

-

CHAPTER 3 CABLE LAYING SPECIFICATIONS Distribution Division Underground Cable System Design Manual

Page | 78

3.2.1.3 Galvanised Iron (G.I.) Pipes G.I. pipes are used as a protective sleeve for all crossings.

x Only used for 3 core and 4 core cables, and single core cables laid in trefoil.

x Cannot be used for single core cables laid singularly (alone) due to induced and circulating eddy currents in the G.I. pipes9.

x Sizes: o 150 mm diameter for power cables o 100 mm diameter for communication cables

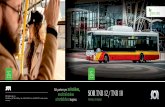

Figure 3-10: Underground electrical ducts crossing a roadside drain

9 Pekeliling Pengurus Besar Kanan (Kejuruteraan) Bil. A17/2008- Larangan Merentang Kabel 1 Teras dalam Paip Besi GI

Roadside drain

G.I. pipes

HDPE pipes

-

CHAPTER 3 CABLE LAYING SPECIFICATIONS Underground Cable System Design Manual Distribution Division

Page | 79

3.2.2 Sizes and Usage of Pipe/Ducts TNB uses various types of pipes/ducts for cable laying and crossing. The standard size for pipes/ducts approved for each usage is as show in Table 3-2.

Table 3-2: Summary of pipes/ducts usage and sizes Type of Pipe/Ducts Diameter (mm) Usage

HDPE double wall corrugated

100, 150 Paved and unpaved roads not to be used for bridge crossing

HDPE double wall corrugated

50 Communication cable ducting

HDPE PN10 100, 150 HDD for crossings G.I. pipes 100, 150 All crossings

450 Crossings culverts for one circuit 1C cable in HDPE pipes

914 Crossings culverts for two circuits 1C cable in HDPE pipes

PVC Class B 100, 150 Bridge Crossing Paved and unpaved roads

Monsoon Drain & Culvert Crossings

For single core XLPE cable crossing on top of monsoon drain and culvert, G.I. pipes of 450 mm/914 mm diameter shall be used for each circuit, enclosing three 150mm diameter Double Wall HDPE Corrugated Pipe duct for every three single core XLPE cables and one 100 mm diameter Single or Double Wall HDPE Corrugated Pipe duct for pilot cable or fibre optic cable. Similarly for two circuits and above, two and more 450 mm diameter G.I. pipes shall be used10.

10 P&PA Specifications