©2015 albert-learning.com Middle East Middle East – Mubarak Verdict.

Timber Design & Technology Middle East - November 2012

-

Upload

andy-macgregor -

Category

Documents

-

view

234 -

download

14

description

Transcript of Timber Design & Technology Middle East - November 2012

1November 2012 | www.timberdesignandtechnology.com

www.timberdesignandtechnology.com

A N A L Y S I S | I N T E R V I E W S | D E S I G N | S U S T A I N A B I L I T Y | T E C H N O L O G Y

Issue 05 | November 2012

DNA testing of wood to help curb illegal logging

World’s tallest timber building ‘tops out’ in Melbourne

‘Out of the Woods - Adventures of 12 Hardwood Chairs’

Illegal logging nets organized crime up to USD 100 billion dollars every year

Miro Forestry aims for leadership within the sustainable plantation forestry industry in West Africa

PLUS Timber industry news, new products, exhibition previews and more

3November 2012 | www.timberdesignandtechnology.com

FROM THE PUBLISHER

Publisher’scomment

Issue 05 | NOVeMBeR 2012

Timber Design & Technology Magazine

PublisherAndy MacGregorpublisher citrusmediagroup.net+971 55 9199 783

Marketing Managereric Hammondmarketing citrusmediagroup.net+971 4 455 8400

editorTony smitheditor timberdesignandtechnology.com

International RepresentativesRabia AlgaAntexpo Org. | Turkey+90 216 541 0390rabia antexpo.net

Timber Design & Technology is published 6 times a year

by Citrus Media Group (powered by WillyMac Associates FZ LLC)Level 14, Boulevard Plaza - Tower One, emaar Boulevard, Downtown Dubai, PO Box 334155, Dubai, uAe

and is printed by Masar Printing Press Great care is taken to ensure the accuracy of the contents of Timber Design & Technology but the publishers accept no responsibility for any errors or omissions. All contents are © 2012 Citrus Media Group and may not be reproduced in any form without prior consent.

Letters and readers’ contributions may be edited at our discretion.

1

November 2012 | www.timberdesignandtechnology.com

www.timberdesignandtechnology.com

A N A L Y S I S | I N T E R V I E W S | D E S I G N | S U S T A I N A B I L I T Y | T E C H N O L O G Y

Issue 05 | November 2012

DNA testing of wood to help curb illegal logging

World’s tallest timber building ‘tops out’ in Melbourne

‘Out of the Woods - Adventures of 12 Hardwood Chairs’

Illegal logging nets organized crime up to USD 100

billion dollars every year

Miro Forestry aims for leadership within the sustainable

plantation forestry industry in West Africa

PLUS Timber industry news, new products,

exhibition previews and more

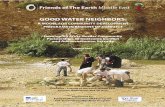

Cover photo:‘Out of the Woods ‘ display

This is the final issue of the magazine for 2012 and the end of our first year of publishing. It

has been quite a steep learning curve for me, but I have met a good number of seasoned wood

industry professionals who have helped me get a grasp of the industry both here in the region

and internationally. Recently I was delighted to be the first representative from the Middle East to

attend the annual meeting of the Woodworking and Furniture Suppliers Magazine Association in

Istanbul. This is a group of 28 publishers from every corner of the globe from Argentina to Taiwan

with a total distribution to over 250,000 industry professionals. We will now have access to the

best possible wood industry news and trends and we plan to share some of this information in our

forthcoming issues.

In this issue, we have covered a range of interesting topics including a feature on how DNA

testing of wood can help combat illegal logging and trade in illegal timber. This has been pioneered

by a company based in Singapore - DoubleHelix - and we were able to track down Jonathan Geach,

Executive Director at the company to learn more about this unique service. Sticking with the same

theme, we have covered a recent report from INTERPOL-UNEP, which estimates the global economic

value of illegal timber trade to be in the region of USD 30 - 100 billion annually. The report focuses

at length on the different methods employed by those involved with illegal logging and outlines key

recommendations to counter this global problem.

As always we invite readers and industry professionals to share their thoughts with us and in

this issue we have featured articles submitted by Dovetail Partners and Broadleaf Consulting. The

former looks at the current state of certification within the timber industry and what next whilst the

latter focuses on the Turkish economy and the market for hardwoods in the country. For those of

you who have been with us from the start, you might remember that in our first issue, we introduced

Cross Laminated Timber and the world’s tallest building - the Stadthaus in London - made from CLT.

Recently, the world’s tallest building made from timber (CLT again) has topped out in Melbourne and

we take a closer look at this structure in this issue.

Looking ahead, we plan to publish five issues of the publication again in 2013 starting in February

and then our Dubai WoodShow special issue in April. We will also be expanding our online activity

with updated news, features, exhibition information and technology developments. Do log on to the

website - www.timberdesignandtechnology.com - for the latest updates and please get in touch if you

have any suggestions for subjects we should consider covering.

Best Wishes,

America’s favourite timber.

For more information on your choice of sustainable AmericanSoftwoods, including certified Southern Yellow Pine, WesternRed Cedar, Douglas Fir, Hemlock and Eastern White Pine, visitwww.americansoftwoods.com

rdar

chite

cts.c

o.uk

www.americansoftwoods.com

16758 SP American softwoods 245(h) x 192(w) Generic Ad .indd 1 09/03/2011 11:16

America’s favourite timber.

For more information on your choice of sustainable AmericanSoftwoods, including certified Southern Yellow Pine, WesternRed Cedar, Douglas Fir, Hemlock and Eastern White Pine, visitwww.americansoftwoods.com

rdar

chite

cts.c

o.uk

www.americansoftwoods.com

16758 SP American softwoods 245(h) x 192(w) Generic Ad .indd 1 09/03/2011 11:16

America’s favourite timber.

For more information on your choice of sustainable AmericanSoftwoods, including certified Southern Yellow Pine, WesternRed Cedar, Douglas Fir, Hemlock and Eastern White Pine, visitwww.americansoftwoods.com

rdar

chite

cts.c

o.uk

www.americansoftwoods.com

16758 SP American softwoods 245(h) x 192(w) Generic Ad .indd 1 09/03/2011 11:16

5November 2012 | www.timberdesignandtechnology.com

IN THIS ISSUE

ContentS

PLUS

p7 Latest news

p46 Showtime

P12

P16

P30

12 SUSTAINABILITYDNA testing of wood to help

curb illegal logging DoubleHelix pioneers testing that

can pinpoint timber species and origin

16 MARKET REPORTIllegal logging nets organized crime up

to USD 100 billion dollars every yearINTeRPOL-uNeP release ‘Green Carbon: Black Trade’

report on illegal timber trade

20 ANALYSISBeyond Certification

Understanding the challenges of certification and identifying opportunities to both improve on existing

programs and develop new approaches

27 ANALYSISTalking Turkey

An assessment of the Turkish market for hardwoods

30 DESIGN & DéCOR‘Out of the Woods - Adventures of 12

Hardwood Chairs’ Ground breaking LCA research helps RCA students

generate full environmental profiles for each of their designs

36 FEATUREWorld’s tallest timber building ‘tops

out’ in MelbourneConstruction innovation heralds new era for

building industry

40 PROFILEMiro Forestry

Company aims for leadership within the sustainable plantation forestry industry in West Africa

43 TECHNOLOGYHOMAG Group hosts the 20th edition of its annual ‘Treff’ expo in SchopflochVisitors experience an unprecedented array of smart

solutions for the production of furniture, windows, floors, staircases and doors at landmark event

46 SHOWTIMEPreview of the upcoming exhibitions

FARLIN GROUP OF COMPANIES ARE VERTICALLY INTEGRATED WITH AN ESTABLISHED PRESENCE WORLDWIDE IN TIMBER LOGS, SAWN TIMBER, PLYWOOD, PANEL PRODUCTS AND COAL FOR ENERGY SECTORS.

Tel: 04 8809 889 | Fax: 04 8809 779 | www.far l indubai.com

farlin_ad_A4.indd 1 25/03/2012 12:01

In OctOber 2012 FarlIn GrOup OFFlOaded One OF the bIGGest ever lOads OF FIlm Faced plywOOd, cOmmercIal plywOOd, mdF and Other panel prOducts at KhalId pOrt In sharjah and dOha pOrt In Qatar. the tOtal sIze OF the carGO was 36,000cbm. mOre vessels lIKe thIs have already been planned tO meet the GrOwInG demand OF Our valuable custOmers FrOm acrOss the Gcc. please cOntact Our sales team tOday FOr ImmedIate servIce.

7November 2012 | www.timberdesignandtechnology.com

NEWS

neWSOne of the few remaining European countries with a significant share of

private forest owners yet without a national forest certification system,

Hungary, has launched the process to develop a PEFC-compliant system.

Representatives from various sectors met for a multi-stakeholder workshop

in Sopron on the Austrian Border at the invitation of the University of West

Hungary, to learn about the benefits of PEFC’s unique bottom-up approach.

PEFC, the Programme for the Endorsement of Forest Certification, requires

countries to develop their own national forest certification standards, in

line with international requirements, and to manage all aspects related to

forest certification independently at national level.

Speakers from PEFC organizations in Austria, Germany, Slovakia

and Slovenia introduced the distinct features of their respective

systems within the context of their specific forest ecosystems, legal

and administrative frameworks, and socio-economic factors. These

experiences provided the backdrop for engaged discussions among

representatives from governments, the forest sector, companies,

research organizations and NGOs concerning how PEFC might work

in practice in Hungary and how the country could benefit from the

lessons learnt in other countries, specifically concerning the needs of

smallholders: at present about 45 percent of the total forest area of

Hungary to Develop National Forest Certification System

Wood must be at the heart of the green economy, say scientists

A green economy must be based on natural, environmentally sound

and sustainable materials and goods. For this, wood is surely the

ideal candidate. It’s a renewable material, and products made from it

store carbon. Through forest products, forests, as well as sequestering

carbon, also play a crucial role in storing carbon and in replacing fossil

fuel, concrete and steel, which have higher carbon emissions and a

significantly larger ecological footprint. At present, the general public,

most policymakers and even the construction industry often see

wood as a ‘traditional’ material, with little or no relevance to modern

technologies and current environmental concerns. However, UNECE

wants to change this perception and has therefore turned to science.

Over 100 experts and scientists gathered in Geneva in October to

discuss Life Cycle Analysis (LCA), and how this methodology can highlight

wood and its qualities as a sustainable material with an increasing

number of innovative uses. LCA can be applied to evaluate the total

environmental impacts of a material or a product throughout its life.

The experts and scientists drew up a set of recommendations for

action by governments, the private sector and UNECE. When discussed

and approved by the UNECE Timber Committee, the recommendations

will help better communicate the benefits of LCA to a larger public so

that consumers can make the right choices when selecting materials

and products.

Paola Deda, Chief of the UNECE/FAO Forestry and Timber Section,

said: “As consumers, we need to be sure we’re not basing our choices

on erroneous beliefs and perceptions. LCA provides us with a scientific

method to assess the ecological footprint of a material or product from

cradle to grave so that we can make informed choices.”

LCA can compare the efficiency and sustainability of wood with that

of other materials for use in different products and purposes. It thus

helps to identify in which instances wood use is the best choice. The

sustainability of using wood for energy, for instance, depends very

much on the life cycle and related impact of the woody material that is

used, as well as on the scale of its use.

The ‘cascaded’ use of wood helps to make the best use of wood and

its ability to store carbon and replace other, less ecologically friendly

materials. In this instance, ‘cascaded’ means where wood is used in

one product and then, at the end of that product’s life recycled into

another. And this process is repeated many times before the ‘final’

wood product is used for energy.

about two million hectares is estimated to be privately owned, with

the vast majority of properties being smaller than one hectare. Only 4

percent of owners have forest properties larger than five hectares.

Participants agreed that there is great potential for advancing

forest certification in Hungary through the development of a national

forest certification system in line with PEFC requirements, which are

specifically designed to cater to the needs of smallholders. Private forest

owners, contractors, and forest professionals have been showing an

increasing interest in PEFC certification in the past few years. A recent

study by the University of Western Hungary concerning the feasibility

of PEFC certification in Hungary has resulted in renewed momentum

with a number of stakeholders showing increasing interest in the

benefits that PEFC can provide.

Building on this momentum, ERFARET, a research and development

organization founded by the University of West Hungary, has started the

process of developing a national forest certification system in line with

PEFC requirements with the support of the 2012 PEFC Collaboration

Fund. This project is also supported by MEGOSZ, the Association of

Hungarian Private Forest Owners, FAGOSZ, the Hungarian Federation of

Forestry and Wood Industries, and PEFC Austria.

8 www.timberdesignandtechnology.com | November 2012

NEWS

Pace presents award-winning Hand

LIGNA and interzum to coordinate their visitor advertising activities

Dubai-based Pace Joinery,

one of the region’s leading

manufacturers of interiors,

furnishings and fittings for

the hotel and hospitality

markets, has appointed Barry

Hand as general manager. The

53 year old South African-

born Hand has over 34 years’

international experience in

construction and interior

fit-out, 15 of those in the

Middle East. He has managed

the fit-out of the Jumeirah

Beach hotel and was part of

the project team at Dubai

International Airport for

over eight years. Hand’s other roles include, founding director of

Plafond interiors and managing director of MEP company Macair.

In addition, regionally and internationally, he has managed

some of the most prestigious interior fit-out projects, two of

which received national industry excellence awards. Hand was

Every two years, wood and furniture specialists from around

the world come to Germany to attend the two most important

trade fairs for their industry: LIGNA in Hannover and interzum

in Cologne. The two fairs are staged in quick succession so that

international visitors can attend both in a single trip. 2013 will be

no different. Together, LIGNA and interzum will once again provide

a comprehensive overview of the materials, design solutions

and technologies currently available for the woodworking, wood

processing and furniture industries. As in the past, the organizers,

Koelnmesse (interzum) and Deutsche Messe AG (LIGNA), are

coordinating their international visitor acquisition and marketing

activities.

In 2013, interzum, the world’s leading trade fair for furniture

making materials and design and interior finishing, will be held

from 13 to 16 May - meaning that it will follow LIGNA rather

than precede it as is normally the case. The reason for the change

relates to the timing of public holidays. LIGNA, the leading

marketplace for the international forestry and wood industries, is

always timed to coincide with Ascension Day. In 2013, however,

Ascension Day falls so early in May that the May Day holiday

would clash with interzum if the latter were to be held before

LIGNA.

LIGNA and interzum are the world’s foremost trade fairs in their

respective sectors. Together, they cover a very broad spectrum of

exhibition topics, ranging from wood as a renewable material to

woodworking and processing technology to components for the

furniture and interior finishing sectors. For visitors from abroad,

the timing of the two fairs is ideal because it enables them to

take in both events in a single trip – which is eminently feasible,

given that the host cities, Cologne and Hannover, are only 300

kilometers apart by road or two and a half hours by rail.

also involved in projects such as the Queen Alia International

Airport in Jordan and the Military Hospital in Muscat, Oman.

Hand sees his key role with Pace as substantially developing the

company’s manufacturing business to support major international

hotel projects, while at the same time ensuring the bespoke

furniture business maintains its reputation for exceptional quality.

By combining traditional workshops, with state-of-the-art

manufacturing facilities, Pace Joinery has built an enviable

reputation throughout the region for its high-quality, handcrafted,

furniture, which serves its prestigious client-base, as well as

providing interiors, furnishings and fittings for major hotel,

hospitality and retail projects. With an annual turnover in excess

of AED 50 million, Pace has a full-time staff of some 350 skilled

personnel and has manufacturing facilities totaling some 35,000

square feet.

“Pace is renowned, particularly in the hotel, hospitality

and retail sectors, for combining traditional carpentry skills

and craftsmanship with state-of-the-art manufacturing and

fabrication processes. My strategic business plan for this highly

successful regional company is to develop it still further, into an

exceptionally successful organization on an international level,”

said Hand.

Barry Hand, GM, Pace Joinery

9November 2012 | www.timberdesignandtechnology.com

NEWS

Chinese wood imports have fallen dramatically this year

‘Wild West’ timber trade threatens Congo forests

The reduction in construction activities in China during 2012 has

resulted in reduced demand for lumber, and as a consequence imports of

both logs and lumber to China fell substantially in 2012, according to a

report by the Wood Resource Quarterly. Total imports, by value, during

the first eight months was USD 4.3 billion, or 19 percent less than in

2011, with the biggest declines in logs imported from Russia and the

U.S., and in lumber from North America. By volume, log imports were

down 17 percent and lumber imports down 5 percent.

Imports of softwood lumber in August were down for the third

consecutive quarter to 1.1 million cubic meters, which was a decline of

21 percent from May and 23 percent lower than in August 2011. Canada

and Russia are the two dominant suppliers of softwood lumber to China,

together accounting for 84 percent of the total imports, with the U.S.,

Chile and New Zealand making up most of the remaining import volume.

Further, during the first eight months of this year, Russia, Chile and New

Zealand have increased their shipments to China, while volumes from

North America have declined. Exports from the U.S. are down as much

as 41 percent as compared to the same period in 2011.

In August, the average import value for all softwood lumber

imported to China was down nine dollars to USD 203/m3 from a year

ago, according to Customs data. The cost for Russian lumber fell as

much as USD 19/m3, while Canadian average costs were down only

five dollars to USD 200/m3 over the past year. Costs for Canadian

lumber have steadily increased from earlier this year and were at a 12

month-high in August.

Chinese softwood log imports have also fallen dramatically this year.

From January through August, imports from Russia were down 21

percent, and from the U.S., 31 percent as compared to the same period

in 2011. The two other major log-supplying countries, New Zealand

and Canada, have shipped practically the same volume this year as last

year. With the reduced demand for logs by the lumber industry in China,

log prices have fallen through most of 2012. Average import softwood

log values in the third quarter of this year were down 13 percent from

a year ago, and domestic Chinese-fir log prices have fallen about 6

percent in the last year.

Officials in the Democratic Republic of Congo are colluding with foreign

logging firms to support illegal logging, harming local communities and

risking the destruction of the world’s second largest forest, a report

by a campaign group says. Derelict ports in Congo’s riverside capital

Kinshasa are piled high with logs ready to be shipped out to China and

Europe as part of the lucrative timber trade. Much of the timber has

been harvested using permits signed by the ministry of environment in

direct contravention of Congolese law, advocacy group Global Witness

said in the report.

Congo’s forest is part of the Congo Basin that spans six countries in

the central Africa region covering about 500 million hectares, over 130

million of which is in the Congo. It contains thousands of species and a

quarter of the world’s remaining tropical forest.

According to the report, so-called artisanal logging permits - meant

only for small scale tree felling by Congolese nationals - are being

awarded to foreign firms. The companies then use industrial methods

to cut and export large quantities of wood out of the country, while

sidestepping the environmental and social obligations demanded of

industrial logging operations. Attempts to bring order to Congo’s chaotic

forestry sector have seen a ban on all new industrial logging licenses

since 2002, but this has done little to improve the situation according to

Colin Robertson, one of the report’s authors.

“Basically this is a new system to get around the moratorium. Officials

have been giving out artisanal permits to industrial loggers, and it’s

created a completely chaotic situation in the forests,” he told Reuters.

In the heavily forested province of Bandundu at least 146 artisanal

logging permits have been issued in the last 2 years according to the

report, which also shows evidence of some firms having cut far more

than is allowed by artisanal licences. Local chiefs are paid off with

anything from motor bikes or alcohol to allow the trees to be felled,

while rural communities see no benefit at all, the report states.

Congolese conservationists say the situation is as bad if not worse

elsewhere in the country, which is home to 86 million hectares of forest.

However, Victor Vundu, Director of the Ministry of Environment’s legal

team said they were working on clarifying and tightening up legislation

under a new minister.

“It’s not surprising, in a post conflict country where the administration

has been really weakened, that the state should be accused of not

sufficiently controlling the application of the law,” he said.

Industrial logging output from Congo has dropped in recent years

and currently stands at around 350,000 cubic meters per year, as

companies say that without far tighter regulation they cannot compete

with the illegal market.

10 www.timberdesignandtechnology.com | November 2012

NEWS

Emerging African market to drive Danube’s growth

Danube Building Materials has recently extended its presence in

Africa with the opening of its new showrooms in Kenya and Libya.

Conveniently located in the heart of the city, the showroom in Kenya

is situated at Nairobi and spread across 20,000 square feet. Similarly,

the franchise outlet of Danube in Libya is located in Benghazi and is

spread across 35,000 square feet. Both the showrooms showcase an

extensive collection of products including sanitary ware, ceramic tiles,

parquet, flooring, MDF, Chandeliers, Garden Furniture, Timber, Steel,

Hardware etc. Further, the company foresees expansion in other areas

of Africa such as Ethiopia and Tunisia.

“Danube’s commitment to the construction and building materials

market is underlined by our expansion, which is aimed at addressing

the needs of the customers across the region,” said Rizwan Sajan,

Founder & Chairman of Danube Group. “With several construction

projects currently under way and planned projects, there was an

obvious demand for building materials in Africa which has helped us

expand and consolidate our market presence in the region.”

The African market is set for a rebound and the construction

industry is currently gaining momentum across the region with the

demand for building materials giving a much-needed lift to Africa’s

materials manufacturing sector. A new report sponsored by PwC and

carried out by Global Construction Perspectives and Oxford Economics

forecasts that global construction will grow by 67 percent from USD

7.2 trillion to USD 12 trillion annually by 2020. Of this, the Middle

East and African region is expected to outpace the global growth rate.

Libya has a huge potential to become a role model for other Arab

nations considering the steady recovery it is experiencing post the

war. At present, the country is experiencing massive demand across

major sectors of the economy including construction, which bodes

well particularly for foreign companies and investors. Additionally, a

report from Kenya National Bureau of Statistics (KNBS) stated that the

economy of Kenya grew by 4.9 percent in the first quarter of 2011

due to improved productivity in the construction industry.

In addition to its expansion into Africa, Danube has launched

three new showrooms in key locations including Saudi Arabia, Abu

Dhabi, and Al Ain in the first half of this year. To keep pace with the

emerging market trends, Danube has plans to continue opening more

outlets with a view towards creating a stronger market presence

not only in the Middle East but also across the global market. The

company is set to open 20 new showrooms by next year across UAE,

Oman, Qatar, Saudi Arabia and Africa. The increased demand for its

products coupled with its expansion has resulted in the company

growing its workforce since its inception, to 1800 people.

Moreover, the company recently announced a 20 percent growth in

sales for the first two quarters of the fiscal year 2012, with Rizwan

Sajan citing growth and demand for products in the Middle East and

African markets. With its strong cash position, Danube Group is well

poised for a growth of 25 percent over the rest of 2012. Danube’s

growth in sales can be attributed to its provision of world-class

high quality building materials and home interiors combined with

great value and special services. The company’s dedicated focus on

establishing facilities in high potential locations has made it a major

hit with customers.

Farlin Group receives one of the largest single shipments of film-faced and commercial plywood, MDF and panel products for the GCC market

The Farlin Group has recently received one of the biggest

shipments of Film-Faced and Commercial Plywood, MDF

and panel products at Port Khalid, Sharjah. The shipment,

which was estimated at 36,000 cbm, arrived in Sharjah on

a chartered ship - MV Rattana Naree - where approximately

70 percent of the total cargo was offloaded. According to

Abdul Gafar, Business Development Manager at Farlin, the

remainder of the load was directed to Doha Port in Qatar. The

announcement further reaffirms Farlin’s position as a leading

global supplier of timber and timber related products.

The majority of the cargo comprised the group’s own

brand of film faced plywood - Farlinplex - in addition to

commercial plywood, MDF and other panel products. The

materials that were offloaded in Sharjah are primarily for

the UAE market with some of it being routed to Saudi Arabia,

Bahrain and Oman. Meanwhile the shipment to Doha was

earmarked for local consumption in the Qatar and aimed at

local traders in the country who have a strong relationship

with the Farlin Group.

According to Gafar, this shipment represents the ability

of the Farlin Group to continue supplying market demand in

the aftermath of the global economic recession and despite

volatile market conditions. The company is positive of the

growing demand in the region and has expressed a firm

commitment towards ensuring a regular and healthy supply

of products for traders who supply the construction sector in

the UAE and wider GCC.

NEWS

11November 2012 | www.timberdesignandtechnology.com

Image © Farlin Group

Image © Farlin Group

Image © Farlin GroupImage © Farlin Group

www.timberdesignandtechnology.com | November 201212

DnA testing of wood to help curb illegal logging

DoubleHelix pioneers testing that can pinpoint timber species and origin

SUSTAINABILITY

In a recent report (see page 16), Interpol has estimated

that the value of illegal logging is worth more than USD

30 billion a year, while the legitimate annual global trade

is estimated to be worth in the region of USD 115 billion.

Perhaps the biggest shock is a revelation by Interpol that

the trade in illegal logs is worth almost as much as drug

production. One possible solution to this global problem

is through government legislation such as the USA’s Lacey

Act, the European Union Timber Regulation (EUTR), and the

Australian Illegal Logging Prohibition Bill amongst others.

However, the true impact of these measures on illegal logging

is still yet to be fully realized. The answer could perhaps then

lie in the DNA testing pioneered by Double Helix Tracking

Technologies (DoubleHelix). Timber Design & Technology

talks to Jonathan Geach, Executive Director at DoubleHelix to

learn more about DNA testing of wood.

13November 2012 | www.timberdesignandtechnology.com

Established in June 2008, the company today is the leader in applied forest genetics and aims to bridge the gap between cutting edge genetics, forest management and timber supply chain issues

SUSTAINABILITY

such practices. Geach is hopeful that

the progress being made could result

in small-scale laboratories around

the globe carrying out cheap DNA

timber tests for companies, customs

agents and law enforcement agencies

within the next two years.

As the cost of genetics research

continues to fall, novel applications

are becoming viable and affordable

to meet a multitude of challenges

faced by the forestry industry and

beyond. As a result, the range of

services offered by DoubleHelix is

expanding across species and sectors

and includes plantation forestry,

timber certification and genetic

inventory for carbon projects.

Geach goes on to state that the

scope of the company’s services is

spreading significantly across a range

of questions as they aim to find

practical commercial applications at

prices that work for their customers.

This has happened due to a

combination of the breadth of issues

that DNA tests easily resolve and the

company’s ability to introduce more

species and regions into play.

“We are seeing clients in Europe

start to incorporate DNA testing

into supplier contracts to verify

country and species claims. Many

clients are using the EU Timber

Regulation as a spur to examine their

supply chains, often with little real

idea of the existing risk. We bring

together our three strengths - an

understanding of trade, expertise

in legality and cutting edge science.

In this way clients are able to get

ahead of the curve and harness the

EUTR as a marketing opportunity

rather than a new risk in operating

internationally,” says Geach.

The company has also been

According to Geach, DoubleHelix

grew out of a timber product

legality standard in Indonesia called

CertiSource (www.certisource.

co.uk). Established in June 2008,

the company today is the leader in

applied forest genetics and aims to

bridge the gap between cutting edge

genetics, forest management and

timber supply chain issues. As such,

the company is pioneering the use

of applied genetics to verify claims

associated with legality, origin,

sustainability, whilst removing

fraud from within the timber supply

chain and preparing businesses for

legislation in the USA and Europe.

Registered in Singapore, the company

is the first in the world to develop

and commercialize DNA testing

for wood. Geach confidently states

that commercial services have

been purchased by businesses keen

to access markets secure in the

knowledge that they are getting what

they pay for since 2007.

Up until now, the fight against

the trade in illegal timber has been

waged with government regulations

and preventive measures, which

have not met with much success. As a

result, there has been a shift towards

using the criminal justice system and

law enforcement techniques, which

has forced companies around the

world to undertake their own due

diligence or pay the price of neglect.

The DNA testing services offered by

DoubleHelix is helping responsible

companies ensure the legality of the

timber they have procured whilst

also fighting to ensure that common

practices in the timber industry such

as mislabeling, lying about origin or

substituting one type of wood for

another are a thing of the past.

Andrew Lowe, Chief Scientific

Officer at DoubleHelix, is one of

the world’s top plant geneticists

and was responsible for making

the breakthrough in DNA testing

of wood. At his laboratory at the

University of Adelaide in South

Australia, he perfected the method

of extracting DNA taken from a log,

a board, a table or even flooring,

which paved the way for the

commercialized testing of timber.

Today, rapid advances in the field

and plunging costs for DNA testing

of timber now mean that it is

commercially feasible for companies

trying to meet new regulations in

the United States and Europe against

Jonathan Geach, Executive Director, DoubleHelix

Andrew Lowe, Chief Scientific Officer, DoubleHelix

Image © DoubleHelix Image © DoubleHelix

14 www.timberdesignandtechnology.com | November 2012

SUSTAINABILITY

involved in several civil and criminal

actions. Geach recalls the case of a

developer who was concerned that a

decking supplier had provided mixed

species instead of a single species

included in the procurement contract.

The developer wanted to use the

company’s services to prove the

mix of species a few years later at

a time when the product was falling

to pieces. Furthermore, governments

and investors interested in forest

carbon schemes such as REDD

are increasingly recognizing the

value of DNA postcodes for trees

to form a security system for their

investment, all of which bodes well

for DoubleHelix.

Aiming to explain the science

behind it all, Geach highlights the

fact that tree’s are individuals and as

such each tree has it’s own unique

DNA. When a tree is cut down and

transformed into a product, its DNA

is still present and can, with skill,

be extracted. The idea is that by

extracting the DNA and conducting

a simple species test, DoubleHelix

will be able to verify the species

of wood and its origin. At present,

this testing is done in only one of

two very specialized laboratories,

but the company is working towards

developing this so that it can be

easily and cheaply handled by

licensed laboratories anywhere in the

world. The aim is to license Lowe’s

DNA extraction technique within

two years to accredited laboratories

globally in a bid to firmly stamp out

the illegal timber trade.

In principle, DNA testing is

extremely accurate due to the unique

DNA signature of each species. One

could then be mistaken for thinking

that the journey for DoubleHelix

has been smooth sailing. The truth

is that when the company launched

in 2008, the concept of DNA testing

was relatively unknown with clients

unable to fully grasp the benefits of

the service. However, with the Lacey

Act in play in the US over the past

few years and the proposed EUTR

set to come into effect in 2013, the

number of clients is growing. Geach

states that the number of clients for

the CertiSource chain-of-custody

and legality verification scheme is

numbered in the hundreds and this

When a tree is cut down and transformed

into a product, its DNA is still present

and can, with skill, be extracted. The idea is that by extracting the DNA and conducting a simple species test,

DoubleHelix will be able to verify the species of

wood and its origin Kevin Hill, Founder of DoubleHelix

Image © DoubleHelix

15November 2012 | www.timberdesignandtechnology.com

SUSTAINABILITY

DNA TesTiNg iN prAcTice: The cAse of The simmoNDs Lumber groupThe Simmonds Lumber Group is one of Australia’s leading wholesale timber importers with an annual turnover of over AUS$ 100 million. The company imports high quality tropical timber flooring, structural components and decking products from a number of countries including the USA, China and Indonesia.

Simmonds sought to safeguard their reputation as a responsible importer of tropical hardwood from Indonesia, a market tainted with high volumes of illegal timber and without adequate solutions at hand to secure their supply chain.

the certisource solution ensured:• Due diligence analysis of Simmonds’ existing supply chain to assess ability of suppliers to meet legality and traceability standards.

• Independent audit of forest sources and sawmill Chain-of-Custody systems against the CertiSource standard for Verified Legal Timber.• Implementation of DNA testing on every batch of timber processed through the audited supply chain from forest to sawmill, providing scientific validation of unbroken Chain-of-Custody.• Simmonds secured supply of CertiSource Verified Legal timber products from Indonesian sawmills. Every product can be traced back to a specific batch of logs from legally harvesting forest concessions.

Simmonds achieved four significant benefits from the solution:• Access to new forest sources they were previously excluded from due to lack of traceability.• Significant risk reduction in their tropical

timber supply chain.• Differentiation of their product offer and brand leadership position in Australia.• Access to new buyers due to assurance of product legality.

These have led to two significant business wins for Simmonds; they have secured a contract to supply Masters Stores (a joint venture between Lowes of the United States and Woolworths of Australia) who are opening 158 outlets across Australia. Simmonds has also successfully penetrated the New Zealand market based on the supply of CertiSource Verified Legal timber.

“From a perspective of legality of our industry at the supply end through to the marketability of products to Australian consumers, this is the way of the future,” said Paul Elsmore, CEO, Simmonds Lumber Australia 2007.

includes both big and small businesses

in Australia, New Zealand and Europe.

Commenting on the company’s

customer base, Geach says: “Clients

for new genetic services tend to

be larger businesses up, mid and

downstream. These lead clients

are enabling us to ensure that the

services we’re developing are what

the market really needs and that

pricing and service structure serves

purpose. This currently numbers less

than 20 but we anticipate a sharp

increase in the next six months,

especially as we hope to see a major

timber audit business and a well

known international certification

brand start piloting our technology.”

The biggest challenge (and a common

misconception as well) to DNA testing

is the fact that clients think a

DNA forest map is required

for comparison purposes.

Constructing such a

map is crucial because

DNA for each species

changes subtly

from one area to

another, acting like a

postcode that can be

used to determine

a sample’s origin.

At the same time,

the process of going

into a forest to take DNA

samples across a species’

entire range is costly and time

consuming. Geach counteracts by

stating that this is only a slight

challenge and it’s more of a

common misconception of the scale of

the issue.

“At present, there are a number

of very useful species identification

services that do not require

background databases. Maps exist

for many species and more are

being made as people increasingly

realize their value. The data is

generally in the public domain and

will be of great use for far more

than legality issues for hundreds of

years to come,” says Geach. “More

recently, the International Timber

Trade Organization has approved

and funded a project that will create

large scale ‘genographic’ maps

of several commonly traded tree

species in seven African countries

and implement DNA based Chain-

of-Custody (CoC) systems in these

countries. This project will

facilitate access to premium

European and United States

markets both of which

have legislation requiring

proof of legality, and

therefore traceability.”

Spurred on by the

early success of the

company, support for

DoubleHelix has come

from both the industry

and from governments.

According to Geach, many

governments have helped not

just with funding but also with

support in championing the idea.

The US, German, Australian, and

Singaporean governments are

a few who have actively supported

the company. From an industry

perspective, Geach believes that

once a person grasps the simplicity

of genetic solutions to timber supply

chain issues, and the longer term

view of global forestry, they quickly

recognize it’s inevitability. In the

Middle East, Kevin Hill, the founder

of DoubleHelix, is confident that

DNA CoC will play an important

part in reducing cost and providing

more security when incorporating

compliant timber products into LEED

and other Green Building standard

projects given the widespread

prevalence of ‘green building

standards’ in the construction sector.

“Our business is going through

several cycles. We have gone

through the proof of concept phase

where we have shown that these

services work, are affordable and

people like them. We are now going

through a wider commercialization

phase and will finally get to a point

where we own and license IP. This

will allow third-party businesses

to offer the technology solution

whether they are a timber supply

chain auditor, lab services company

or otherwise involved in compliance

issues, investment or forestry.

In short, people who adopt our

technology now are benefiting by

winning new business, accessing

markets they’re previously excluded

from as well as reduce risk and

cost of risk management/security,”

concludes Geach.

16 www.timberdesignandtechnology.com | November 2012

MARKET REPORT

In a new report released by

INTERPOL and the United Nations

Environment Programme (UNEP), the

economic value of the illegal timber

trade by organized crime groups is

estimated to be worth between USD

30 and 100 billion annually, which

represents around 10 - 30 percent

of the global wood trade. The Rapid

Response Report, entitled ‘Green

Carbon: Black Trade’, states that illegal

logging now accounts for between

15 - 30 percent of the global legal

trade and significantly hampers the

Reducing Emissions from Deforestation

and Forest Degradation (REDD)

initiative - one of the principal tools

for stimulating environmental change,

sustainable development, job creation

and reducing emissions.

Forests worldwide bind CO2 and

store it - so called Green Carbon - and

help mitigate climate change. However,

deforestation accounts for an estimated

17 percent of global carbon emissions,

which is about 1.5 times greater than

emissions from the entire world’s

air, road, rail and shipping traffic

combined. According to the report,

the vast majority of deforestation

and illegal logging takes place in the

tropical forests of the Amazon basin,

Central Africa and Southeast Asia, with

recent studies projecting that illegal

logging accounts for 50 - 90 percent

of the volume of all forestry in key

producer tropical countries and 15 - 30

percent globally.

“Funding to better manage forests

represents an enormous opportunity to

not only address climate change but to

reduce rates of deforestation, improve

water supplies, cut soil erosion and

generate decent green jobs in natural

resource management,” said Achim

Steiner, UN Under-Secretary General

and UNEP Executive Director. “Illegal

logging can, however, undermine

this effort, robbing countries and

communities of a sustainable future,

if the unlawful activities are more

profitable than the lawful ones under

REDD+.”

A number of certification schemes

and programmes have evolved as

a means to reduce illegal logging.

These schemes, such as voluntary

trade agreements including the EU

Forest Law Enforcement, Governance

and Trade (FLEGT) Voluntary

Partnership Agreements (VPAs), or

Forest Stewardship Council (FSC)

certification, have been relatively

successful in bringing stakeholders

Illegal logging nets organized crime up to USD 100 billion dollars every year

‘Green Carbon: Black Trade’ outlines the severity of the

illegal timber trade and makes recommendations to combat this global problem

17November 2012 | www.timberdesignandtechnology.com

MARKET REPORT

together and generating incentives for

legal exports and more sustainable

forestry. Additionally, the Convention

on International Trade in Endangered

Species of Wild Fauna and Flora

(CITES) is increasingly being used by

states to ensure that trade in listed

timber species is legal, sustainable and

traceable.

The report points out that the

main aims of the aforementioned

programmes are to promote

sustainable trade. With the exception of

CITES, they are not designed to combat

organized crime and are not effective

in combating illegal logging, corruption

and laundering of illegal timber in

tropical regions. Other incentives and

subsidies to offer alternative incomes

are also unlikely to be effective when

illegal logging and laundering offer

much higher profits and very low risk.

Furthermore, widespread collusive

corruption from local officials to the

judiciary, combined with decentralized

government structures in many tropical

countries, provide little or no economic

incentive for illegal loggers and corrupt

officials to change their practices.

The report goes on to state that

to become effective, voluntary

trade programmes and the effective

implementation of CITES, must be

combined with an international

law enforcement investigative and

operational effort in collaboration with

domestic police and investigative task

forces in each country. This is to ensure

that a local decline in illegal logging

is not offset by increases elsewhere,

as international cartels move to new

sources of illegal timber.

“The threat posed to the

environment by transnational

organized crime requires a strong,

effective and innovative international

law enforcement response to protect

these natural resources and combat

the corruption and violence tied to this

type of crime, which can also affect a

country’s stability and security,” said

Ronald K. Noble, Secretary General of

INTERPOL.

In the last five years, illegal

logging has moved from direct illegal

logging to more advanced methods of

concealment and timber laundering.

The report outlines more than 30

ways of conducting illegal logging,

laundering, selling and trading in

illegal logs. Primary methods include

falsification of logging permits, bribes

to obtain logging permits (in some

instances noted as USD 20 - 50,000 per

permit), logging beyond concessions,

hacking government websites to obtain

transport permits for higher volumes

or transport, laundering illegal timber

by establishing roads, ranches, palm

oil or forest plantations and mixing

with legal timber during transport or

in mills.

According to the report, the much

heralded decline of illegal logging

in the mid- 2000s in some tropical

regions was widely attributed to a

short-term law enforcement effort.

However, long-term trends in illegal

logging and trade have shown that this

was only temporary, and illegal logging

continues unabated today. More

importantly, the apparent decline in

illegal logging is due to more advanced

laundering operations masking criminal

activities, and not necessarily due to

an actual decline in illegal logging. In

many cases a tripling in the volumes

of timber ‘originating’ from plantations

in the five years following the law

enforcement crackdown on illegal

logging has come partly from cover

operations by criminals to legalize and

launder illegal logging operations.

The report also cites other cases of

increased illegal logging that involve

road construction and the cutting of

wide corridors, which facilitates land

clearing by impoverished settlers, who

are later driven away by ranchers and

soy producers, such as has occurred

in the Amazon. Companies make

money from clearing the initial forest,

have impoverished farmers convert

forestland to farmland, and then

push these farmers off to establish

In the last five years, illegal logging has moved from direct illegal logging to more advanced methods of concealment and timber laundering

The heALTh of our foresTs

net loss of forest

current forest cover

net gain of forest

dryland degradation

Source: Adapted from a map by Philippe Rekacewicz originally published in UNEP-FAO Vital Forest Graphics , 2009; data source from MA 2005.

18 www.timberdesignandtechnology.com | November 2012

MARKET REPORT

rangeland for cattle.

Funneling large volumes of illegal

timber through legal plantations, across

borders or through mills, is another

effective way to launder logs. In some

instances, illegal loggers mix illicit

timber with 3 - 30 times the amount of

officially processed timber, which also

constitutes tax fraud. Many of these

illegal operations involve bribes to

forest officials, police and military, and

even royalties to local village heads.

In addition, other scams include the

falsification of eco-certification.

Experts concur that much of the

laundering of illegal timber is only

possible due to large flows of funding

from investors based in Asia, the EU

and the US, including investments

through pension funds. As funds are

made available to establish plantations

operations to launder illegal timber and

obtain permits illegally or pass bribes,

investments, collusive corruption and

tax fraud combined with low risk

and high demand, make it a highly

profitable illegal business, with

revenues up to 5 - 10 fold higher than

legal practices for all parties involved.

This also undermines subsidized

alternative livelihood incentives

available in several countries. In

addition to increased organized crime

involvement, the report also highlights

a rise in other crime types linked

to illegal logging, including murder,

violence, threats, corruption, fraud and

theft, with indigenous forest dwellers

particularly affected. The challenges

already facing indigenous peoples are

further compounded as companies now

launder illegally felled timber under

fraudulent permits for ranches or

plantation establishment schemes.

According to the report, efforts to

stop this black trade must concentrate

on increasing the probability of

apprehending illegal logging syndicates

and their networks, reducing the flow of

timber from regions with high degree of

illegality by adapting a multi-disciplinary

law enforcement approach, developing

economic incentives by discouraging the

use of timber from these regions and

introducing a rating of companies based

on the likelihood of their involvement in

illegal practices to discourage investors

and stock markets from funding

them. When combined with economic

incentives, through REDD+ and trade

opportunities through CITES and FLEGT,

these actions may become successful in

reducing deforestation, and ultimately,

carbon emissions.

INTERPOL and UNEP, through the

UN agency’s GRID Arendal centre in

Norway, have also established a pilot-

project called LEAF (Law Enforcement

Assistance to Forests) funded by

the Norwegian Government agency

NORAD to develop an international

system to combat organized crime in

close collaboration with key partners.

However, the cost of implementing an

effective international law enforcement

scheme and training capacity to

substantially reduce the emissions

from illegal logging is estimated to be

approximately USD 20 - 30 million

dollars annually. While INTERPOL is

currently leading the police related law

enforcement response through Project

LEAF, its success requires strong,

constant, and sustainable commitment

from governments, civil society, and

the private sector.

The newly established International

Consortium on Combating Wildlife

Crime (ICCWC), chaired by the CITES

Secretariat and comprised of INTERPOL,

the United Nations Office on Drugs

and Crime (UNODC), the World Bank

and the World Customs Organization

(WCO), also provides a substantial

new commitment to the sharing and

coordination of a comprehensive

international effort to help combat

wildlife crime, including illegal logging.

In fact, the ICCWC represents the

entire enforcement chain - customs,

Key recommeNDATioNs of The iNTerpoL-uNep reporT• Strengthen and consider funding opportunities for the development of a full-fledged Law Enforcement Assistance to Forests (LEAF) programme under INTERPOL and UNEP in close collaboration with all ICCWC partners, REDD+, FLEGT and other relevant programmes and agencies. The objective of the programme is to implement coordinated international and improved national law enforcement and investigative efforts to reduce illegal logging, the international trade in illegally felled timber and forest-related corruption including tax fraud and laundering.

• Increase national investigative and operational national capacities through an INTERPOL based training scheme to strengthen and build national task forces on combating illegal logging and laundering. This includes strengthening national law enforcement agency cooperation and co-ordination through

supporting the formation of national taskforces to ensure enforcement of laws and regulations related to forests.

• Centralize nationally the issuing of permits for land clearance whether for logging, plantations or ranching and permits for road transport of timber with strong anti-counterfeit measures.

• Develop an INTERPOL classification system of geographic regions within countries according to the suspected degree of illegality in collaboration with National Central Bureaus (NCBs) and other relevant stakeholders. This includes defining upper limits of volumes of logs to be transported, restricting transport funnels of all timber from such illegal logging regions and monitoring forest change on a regional basis.

• Encourage national tax fraud investigations with a particular focus on

plantations and mills laundering, under- or over-reporting of volumes and over- or under-invoicing, tax fraud and misuse of government subsidies.

• Reduce investment attractiveness in forest enterprises active in regions identified as areas of illegal logging by implementing an international INTERPOL-based rating system of companies extracting, operating in or buying from regions with a high degree of illegal activity. This includes investigating possible complicity of investors in funding illegal activities related to logging, transporting, laundering or purchasing illegally logged timber.

• Strengthen the resources available to ICCWC to have a dedicated role, unit(s) and responsibility at global and regional levels, as appropriate, specifically tasked to combat illegal logging and international trade in illegally logged or procured timber and wood products.

police and justice. It also addresses

anti-money laundering and serves as

a model at the international level for

the sort of cooperation that is required

amongst enforcement agencies at

the national level to more effectively

combat illegal international trade in

timber products.

MARKET REPORT

Lastly, priority attention must be

given to investigation of tax fraud,

corruption and anti-laundering,

including substantially increasing the

investigative and operational capacity

of national task forces working with

INTERPOL, against logging companies,

plantations and mills.

This feature contains

information and text

from the Summary of the

INTERPOL-UNEP Report.

The report - Green Carbon:

Black Trade - is available for

download on the INTERPOL

and UNEP websites.

CAD+T Middle East JLT, PO Box 262353, Indigo Icon, Offi ce 507, Jumeirah Lake Towers, Dubai, UAE, Mobil.: +971(0) 50-2738319, Tel.: +971(0) 4-4477880, Email: offi [email protected]

20 www.timberdesignandtechnology.com | November 2012

ANALYSIS

Dr. Jeffrey Howe and Kathryn Fernholz of Dovetail

Partners share their views on the certification of forests

In 2013, the world will mark the 20-

year anniversary of third-party forest

certification. After 20 years of effort,

approximately 10 percent of the world’s

forests have been certified through various

programs. During this time, many changes

have occurred in the forest sector and in the

practice of forest management. Yet, in spite

of many successes, major hurdles remain.

Although it could clearly be argued that

global forestry has been affected positively,

not only are 90 percent of the world’s

forests uncertified but also the certified

10 percent was already the best-managed

forestland in existence. So the key question

now is what will the next 20 years of forest

improvement look like? Will we continue on

the certification path we are on, or will we

thoughtfully assess and apply the lessons

learned in order to chart an improved

course? Based upon the knowledge

gained over the past two decades and the

experiences of other eco-labeling systems, it

is clear that a better method is needed, and

is possible. It is time to move beyond the

forest certification of the past generation

and entertain a broader, more inclusive, and

more cost effective approach.

The existing approach to forest

certification is extremely complex and is

inflicting significant cost on the forest sector.

It is complex in that current systems have

become moving targets with ever changing

standards and inconsistent interpretations

that undermine the credibility of the

entire effort. The current approaches to

forest certification have created confusion,

hypocrisies in the way standards are being

applied, and they have failed to adequately

address emerging issues such as illegal

logging and bio-energy production. Forest

certification is also costly. To date, it is

Beyond Certification Understanding the challenges of certification and identifying opportunities to both improve on existing programs and develop new approaches

Although it could clearly be argued that global forestry has been affected positively, not only are 90 percent of the world’s forests uncertified but also the certified 10 percent was already the best-managed forestland in existence. So the key question now is what will the next 20 years of forest improvement look like?

ANALYSIS

21November 2012 | www.timberdesignandtechnology.com

likely that hundreds of millions of dollars

have been spent in order to recognize the

existing best-managed forestlands in the

world. One shudders to think of the costs

and the complexities of addressing the

remaining forest segment under the current

approach. There are many diverse benefits

being realized from forest certification, but

the focus needs to be on the forest, rather

than the process, and the approach needs to

be easily applicable to more diverse forest

management situations.

In marketing terms, forest certification

is a well-defined attribute, but an unclear

benefit. When organic certification was

evolving, a similar situation occurred.

Organic certification was initiated by non-

governmental organizations and evolved

into competing systems that established

diverse standards and attempted to raise

the bar on each other to gain recognition

as the ‘gold standard’. Over the course

of nearly 20 years (1972-1990), as the

market potential for organic increased, the

competing standards and their changing

requirements became a barrier to growth

and a bottleneck to supply. In addition, the

perceived benefit from ‘organic’ became

muddied by the growing and diverse

claims of various producers scattered over

wide geographic areas. In response, the

U.S. and other nations chose to establish

government-based programs for managing

organic standards. These programs resulted

in many significant changes. Key among

these was a clarification of the legal

definition of ‘certified organic’, which

demystified the benefit to the marketplace.

These changes were followed by dramatic

growth in the organic market. The U.S. sales

of organic products have grown from USD

1 billion in 1990 (when the Organic Food

Production Act was passed) to an estimated

There are many diverse benefits being realized from forest certification, but the focus needs to be on the forest, rather than the process, and the approach needs to be easily applicable to more diverse forest management situations

Dr. Jeffrey Howe, Dovetail Partners

Image © Dovetail Partners

22 www.timberdesignandtechnology.com | November 2012

ANALYSIS

USD 20 billion in 2007; and grew an average

of 18 percent each year between 2007-

2010. The USDA Organic Program also drove

the creation of a new space for the direct

marketing of local products as a ‘deeper

shade of green’.

So, what would a better forest certification

system look like? How can the benefits of

certification be clarified in the marketplace?

There are many possible answers. One

approach would be to have forest certification

simply take greater advantage of existing

forest management infrastructure and

expertise, recognize the benefits of existing,

effective regulatory systems (e.g., U.S.

laws), and utilize terminology that has

greater acceptance in, and attraction to, the

marketplace. Marketplace acceptance could

be tested for attributes like GMO-free wood,

wood grown without the use of pesticides

or herbicides, or wood from forests that are

regenerated with native species. Another

approach would be to develop a comparative

index that ranks forest practices based upon

a small number, but clearly identifiable and

understandable forestry considerations. Using

this type of approach, product market claims

could be based on regional or global rankings

(e.g., wood comes from forests among the top

10 percent in the world or attains four out of

five stars). In addition to these possibilities,

further approaches and/or improvements

in forest certification could be defined by

interviewing both current and potential users

(especially in tropical areas) to identify those

methodologies that they would see as having

significant potential to increase the practice of

responsible forestry.

Pursuing additional options and

enhancements might allow the forest sector

to rapidly move beyond the current limits

of forest certification. The original goal

hasn’t changed. We still need to dramatically

decrease deforestation in tropical areas.

According to the UNECE, in the twenty years

since certification was formed we have

certified only 2 percent (200 million acres) of

tropical forest while over 700 million acres of

tropical forest has been deforested. We also

need to be able to identify wood from well-

managed forests across the globe. In addition,

U.S. markets need to be assured that the wood

products they purchase meet the requirements

of the Lacey Act.

The first question that matters for the forest

sector at this point is: Do we want the next 20

years of forest certification to look like that last

20? If the answer is No, which it must be for

anyone who cares about forests and the forest

sector, then the next question is: How can we

most effectively move beyond current forest

certification methodologies to dramatically

benefit forests? And the answer to that

question is to pursue a system that leads us to

the core principles of what wood means as a

renewable, infinite, sustainable, responsible and

natural product. Good examples and abundant

experience now exist to allow us to modify,

change, and adapt to a better future.

When you make maple syrup there is a

time after all the preparation and collection

of material (sap and firewood usually) from

the forest that you simply have to turn up the

heat, stir it up a bit, and tend to it carefully

to make it come out well. Certification may

be at the same point. The original goal of

forest certification was to create a label that

would enable the market to identify and

select wood from well-managed forests and

thus allow demand from the marketplace

to provide economic benefit that would

translate into increased funding for better

forest management practices. In short, the

goal was to link clear market choices with

sustainable forestry.

In order to understand the current

challenges of certification and to identify

opportunities to both improve on existing

programs and develop new approaches, we

need to take a look at forest certification from

two opposite ends of the spectrum, that of the

forest and that of the marketplace to see if it is

successfully addressing that original goal and

to recommend a possible next step.

The Forest PerspectiveTwenty years ago there was no common

agreement on the definition of ‘sustainable

forestry’. Today, with great regard to forest

certification, there appears to be a general

consensus on what good forestry entails.

However, this consensus has not been boiled

down to a finite number of characteristics

to which individual landowners are held

accountable. Instead, current sustainable

forestry is a complex series of interwoven

ecological relationships on which no two

landowners may find uniformity. In an attempt

to consider every possible negative outcome,

certification has become similarly complex.

This complexity provides incredible

strength when it results in comprehensive

auditing that leaves no stone unturned,

reviews all aspects of forest management,

and helps identify a full spectrum of

opportunities for improvement. For land

managers that want to make changes (or

need to), the current certification process

can be very constructive in identifying key

gaps and setting priorities for strategic

improvements. However, for land managers

that are already doing a very good job and

are in regions with significant regulatory and

management structure already in place (i.e.,

many of the current certificate holders), this

According to the UNECE, in the twenty years since certification was formed we have certified only 2 percent (200 million acres) of tropical forest while over 700 million acres of tropical forest has been deforested

Kathryn Fernholz, Dovetail Partners

Image © Dovetail Partners

Image © AHEC

24 www.timberdesignandtechnology.com | November 2012

ANALYSIS

emphasis on the details can be extremely

frustrating and costly. As one manager put

it in a private conversation, “it’s frustrating

spending time and money trying to be ‘more

perfect’ when there are a world of issues to

be addressed on other lands.”

The broad-brush approach inherent in

some certification systems appears to lead

to cost inefficiencies as well. For example,

the lack of trust in existing infrastructure

(e.g., government, management planning,

and legal systems) leads to unnecessary

administrative costs to landowners in

regions like North America. Also, in some

instances, the attempt to address globally

issues that are dominantly of regional

concern leads to efforts that appear

unnecessary. The net result is high forest

management costs related to certification

(or penalties) on well-managed sites and

few lands that are certified in regions (e.g.,

tropics) where sustainable forestry is in

greatest need of attention.

The Market PerspectiveThe key to success of a certification system

is its effectiveness in the marketplace. This

effectiveness is primarily based on trust

in the certified brand. It has been said that

we trust those that we believe have the

ability and the commitment to do what

they say. Thus, certification is as effective

as the extent to which the certified label is

recognized and trusted.

To date certification is relatively

unrecognized in the marketplace in North

America, at least by the average consumer,

and the concept of certification is both

poorly understood and poorly differentiated

from other ‘green’ marketing activities. For

example, is forest certification of the wood

in a product equal to, more, or less important

than attributes such as VOC-free?

Certification is also relatively

unrecognized and poorly differentiated in

the market channels that transfer wood

products. In the U.S. approximately 4,000

of the estimated 200,000 wood products

companies are chain-of-custody certified

today, and research suggests that even

key individuals from companies that are

certified are poorly informed as to what

that certification actually means. It is also

common for individuals and organizations

to ask the difference between certification

programs when in fact they really don’t

know anything about either, and are simply

trying to define them by their variances

rather than their attributes. Thus actual

benefits to the customer remain undefined

and no value can be placed.

To a certain extent some of this lack

of understanding of certification by the

marketplace can be explained by the

complexity of the systems they represent, but

it is also true that there are no simple claims

that can be made about today’s certified

wood products because there are almost no

universal truths. For example, the simplest

claim of all, the source of the wood, cannot

be universally guaranteed. That is, a seller

couldn’t necessarily claim that the wood in a

labeled certified product actually comes from

certified forests. It is hard to convince buyers

that a product has extra value when there are

no definable benefits to that claim.

Result of two perspectives - is it working?So is the marketplace providing funding

for the benefit of forest management?

It is hard to see that this is true at this

point. Anecdotally it would appear that the

opposite is true, meaning that costs have

increased while selling prices have remained

stagnant. Certainly, it is true that some new

buyer-seller relationships have been created

and there are benefits to aligning like-

minded organizations. But there is little to

no evidence that a clear premium exists for

certified products, in general.

So, how do we solve this? How do we

clearly answer the question of what it

means to support sustainable forestry

with the purchase of sustainable forest

products? First, we recognize the value

of the current programs. The current

certification programs and systems offer a

robust structure and model for developing

exemplary forest management systems

where they are lacking. The level of detail

and breadth of issues that are covered

help develop professional levels of forest

stewardship. But the gap of providing a

straightforward and guaranteed benefit for

the market can’t be filled by these systems

as they currently operate.