The Guggenheim Museum Bilbao, Spain., October 1997 George Zheng Chen 1. School of Chemical and...

-

Upload

maud-benson -

Category

Documents

-

view

221 -

download

0

Transcript of The Guggenheim Museum Bilbao, Spain., October 1997 George Zheng Chen 1. School of Chemical and...

The Guggenheim Museum Bilbao, Spain., October 1997

George Zheng Chen

1. School of Chemical and Environmental EngineeringUniversity of Nottingham

2. College of Chemistry and Molecular SciencesWuhan University

Email: [email protected]

The green metal for the 21st century

Which element is the most abundant/plentiful in the earth’s crust?

Which are the next ten?

Which can be used/considered as engineering materials?

Source: Los Alamos National Laboratory's Chemistry Division, Periodic Table of the Elementsfor School Students. (http://pearl1.lanl.gov/periodic/default.htm)

IVB 22 47.88

Tid 4.54 mp 1670oC

Periodic Table of ElementsPeriodic Table of Elements

11

2233

(O, Si, Al, Fe, Ca, Na, K, Mg, Ti, P, H, C, Mn)

4455

66

77

88

99

1010

1111

1212

1313

Titanium is as strong as steel,but 45% lighter.

Titanium alloys offer much greater corrosion resistance in comparison with stainless steels and other metals for applications such as

Titanium's corrosion resistance, low weight and high strength make it a material ideally suited for long life cycle (LLC) offshore applications.

Pressure vessels/reactor manufactured by Nanjing Baose Titanium Industry Co. Ltd.

chemical reactors, pressure vessels,

gas/liquid transport pipes and off-shore constructions,

and hence long service life.and hence long service life.

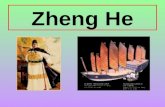

The Guggenheim Museum in Bilbao,

Spain.October 1997

1,300, 000 visitors in the first year.

The exterior of the Museum is clad with thin titanium plates that were supplied by Timet.

Titanium has many aesthetic qualities.

Titanium Q&ATitanium Q&A

Q: Is titanium a good material? A: Yes!As strong as steel but 45% lighter; 60% heavier than aluminium but twice as strong; highly corrosion resistant; physiologically inert; aesthetic qualities; .........

some stainless steels may have both properties but are much heavier.

Q: Is titanium expensive? A: Yes, more expensive than most stainless steel.

Q: Is titanium rare on the earth? A: No!The 9th most abundant element in the earth's crust;The 4th structural metal element,(O, Si, Al, Fe, Ca, Na, K, Mg, Ti, P, H, C, Mn)More abundant than carbon (coal)!

Q: Is it difficult to produce titanium?A: Yes, but shouldn't be.

Ways of Metal ProductionWays of Metal Production

electrochemistry:

Al3+ + 3e Alcathode:

O2- 1/2 O2 + 2e carbon anode:

O2- + C CO + 2e

+1/2 O2 CO2

chemistry:

Fe2O3 + 3/2 C 2 Fe + 3/2 CO2

6e

~ 700 million tonnes / year

~ 45 million tonnes / year

Unsatisfactory process efficiency much higher CO2 emission !!

overall reaction:

Al2O3 +3/2 C 2 Al + 3/2 CO2

6e

Achievements and ChallengesAchievements and Challenges

Comparison of Major Structural Metals

Materials World Production Market Prices

steel ~1,200,000,000 tonnes $100 ~ 150 / tonnestainless steel $1500 ~ 3000 / tonne

aluminium ~35,000,000 tonnes $1500 ~ 2000 / tonnemagnesium ~450,000 tonnes $1300 ~ 1500 / tonne

titanium ~60,000 tonnes $5000 ~ 8000 / tonnetitanium alloys $25,000 ~ 30,000 / tonne

titania (pigment) ~4,200,000 tonnes $1100 ~ 1500 / tonne

TiO2 = Ti + O2 Go (1000K) = 762 kJ / mol O2

2/3 Al2O3 = 4/3 Al + O2 Go (1000K) = 937 kJ / mol O2

2 MgO = 2 Mg + O2 Go (1000K) = 986 kJ / mol O2

Extraction energy increases

Extraction Energetics (Thermodynamics)

Titanium has high affinity with oxygen, not only reacting with oxygen to form oxides, but also absorbing oxygen to form solid solution.

Production (extraction & refining) Fabrication (alloying & fabrication)

Why Is Titanium Expensive?Why Is Titanium Expensive?

Operation Details CostRutile (96% TiO2) or concentratedTiO2 from Ilmenite (FeTiO3)

4%(£1,200 / tonne)

Chlorination to TiCl4 9%

Production(The Kroll Process,invented in 1940)

Magnesium reduction 25%Preliminary arc melting withmaster alloy addition

12%(£15,000 / tonne)

Second melting 3%

Fabrication

Fabrication to end products(e.g. 2.5 cm thick plate)

47%(£30,000 / tonne)

($

($

($

The Kroll Process (1)The Kroll Process (1)

Carbo-chlorination (~900oC) Magnesium reduction (~900oC, some heat from reaction, slow)

source: D. McQuillan and M. K. McQuillan, Titanium, Butterworths Scientific Publications, London (1961).

Vacuum distillation (>1000oC, slow)

Distribution of Ti metal after magnesium reduction (cross section view).

The Kroll Process (2)The Kroll Process (2)

10 m

Ti sponge

source: D. McQuillan and M. K. McQuillan, Titanium, Butterworths Scientific Publications, London (1961). + GZ Chen

The Kroll Process (Summary)The Kroll Process (Summary)

The Kroll Process is a multi-step and batch type pyrometallurgical process and runs for a couple of weeks to produce a few tonnes of titanium sponge, even when using a modern reactor (d. & h: ~1.5 & ~8 m).

1. Carbo-chlorination (~900oC)TiO2 (rutile) + 1.5 C + 2Cl2 (g)

= TiCl4 (g) + 0.5 CO2 (g) + CO (g)

2. Magnesium reduction (Metallothermic reduction)(~900oC, some heat from reaction, slow)

TiCl4 (g) + 2 Mg = Ti (sponge) + 2 MgCl2

3. Vacuum distillation (>1000oC, slow)

4. Pneumatic collection

5. Electrolytic recycling of by product (~500oC, molten salt, continuous)

MgCl2 = Mg + Cl2 (g)

TiO2 (金红石)

TiCl4

(Ti + MgCl2)

Ti MgCl2

Cl2

Mg

C

vacuum distillation

mol

ten

salt

elec

trol

ysis

TiO2 (金红石)

TiCl4

(Ti + MgCl2)

Ti MgCl2

Cl2

Mg

C

vacuum distillation

mol

ten

salt

elec

trol

ysis

(rutile)

During his visit in Japan in 1953, Dr. William J Kroll predicted the replacement of his invention, the Kroll Process, by an electrochemical method in the next 15 years! (The photo shows Kroll at a vacuum-type high-frequency melting furnace during testing in a laboratory of KOBE Titanium.) Source: http://www.kobelco.co.jp/titan/e/history.htm

In later years, Dr. Kroll was quoted many times by saying,

“It might, however, be fair to say, that titanium will be made competitively by fusion electrolysis within the next 5 to 10 years.” (1959, Extractive Metallurgy Division Lecture, American Institute of Mining, Metallurgy, and Petroleum Engineers)

Electrolytic ExtractionElectrolytic Extraction

Conventional concept of electrolysis

energy = nFEW / mM = 6718 kWh/tonne

n: number of electrons transferred (4)F: Faraday constant (96500 C/mol)E: voltage of electrolysis (3.0 V)W: mass of titanium produced (1 t = 106 g)m: number of joules per kWh (3.6x106 J)M: molar mass of titanium (47.88 g)

Advantage: cost = £0.03 (UK) x 6718 = £202 / tonne Ti

Dissolving titanium compounds (e.g. TiCl4 and TiO) in molten salts

TiCl4 = Ti4+ + 4Cl- orTiO = Ti2+ + O2-

Electrowinning titanium from the molten salt solution(electro-deposition)

Ti4+ + 4e = Ti or Ti2+ + 2e = Ti (cathode)

Cl2depositedTi

Electrolyte +Ti compound

TiCl4 gas

0.73 SrCl2 + 0.27 LiCl (m.p. 565oC)(Sr2+ helps formation of larger crystals)

Electrolytic cell for titanium deposition from a solution of TiCl2/TiCl3 (0.1~1M) in 0.73 SrCl2 + 0.27 NaCl (m.p. 565oC, Sr2+ helps formation of larger crystals). [M.B. Alpert, F.J. Schultz and W.F. Sullivan, J. Electrochem. Soc., 104(1957)555]

ProblemsRedox cycling of the multi- valent titanium ions

cathode: Ti4+ + e = Ti3+;Ti3+ + e = Ti2+

anode: Ti2+ = Ti3+ + e; Ti3+ = Ti4+

Failure of diaphragm Dendritic deposition

Titanium dendrite deposited from a solution of K2TiF6 in 850-950oC molten NaCl [M. A. Steinberg, M. E. Sibert, J. Electrochem. Soc., 102 (1955) 641.]

Titanium dendrite deposited from a solution of TiO in 850-900oC molten CaCl2 [M. E. Sibert, Q. H. McKenna, M. A. Steinberg, & E. Wainer, J. Electrochem. Soc., 102 (1955) 252.]

Cathode: TiO2 + 4e = Ti + 2O2-

Anode (inert):2O2- = O2(gas) + 4eCarbon anode:3O2- + 2C = CO + CO2 + 6e

before

Electrolysis of Solid TiOElectrolysis of Solid TiO22

3.0 V, 950oC, molten CaCl2

O2-

after10 m

Experimentally confirmed in Cambridge

electrolyte

oxide

metal

Electron transfer occurs at the metal | oxide interface of the 3PI

Oxygen transfer occurs at the oxide electrolyte interface of the 3PI

Electrolysis of an Insulator Oxide: Electrolysis of an Insulator Oxide:

Separated Electron and Oxygen Transfer at 3PISeparated Electron and Oxygen Transfer at 3PI

3PI: electrolyte-oxide-metal three phase interline (boundary), e.g. (CaCl2 | TiO2 | Ti)

electron conductor(Mo wire)

electrolyte(molten CaCl2)

3PI

metal oxideparticle

(e.g. TiO2)

e

O2- to anode

Consequence: (1) continuous formation of new 3PI (propagation of 3PI).(2) electrolytic conversion of insulator oxide to metal.

eO2-

3PI3PI

eO2-

3PI

eO2-

3PI

eO2-

3PI

eO2-

3PI

Dr Chen and the philosopher's stoneSep 21st 2000 From The Economist print edition

TITANIUM ought to be a gift to engineers. It is light, strong and heat resistant. But gifts are supposed to be free, and titanium is expensive. That is not because it is particularly rare (titanium dioxide is the basis of white paint) but because it is hard to extract as a pure metal. If George Chen of Cambridge University and his colleagues are correct, however, that extraction could soon become a lot easier and cheaper.

There are two ways to get metal out of an oxide ore. One is to react the ore with a substance that has a greater affinity for oxygen than the metal in question, a process known as chemical reduction. The other is to break it up with electricity, a process known as electrolysis. Iron is made industrially by the first process. Aluminium is made by the second. At the moment, titanium is made by the first, but unlike purifying iron, from which the oxygen is removed cheaply by reaction with carbon in the form of coke, purifying titanium is a two-stage operation. First, the ore is heated with carbon and chlorine to produce titanium tetrachloride. Second, the titanium tetrachloride is reduced with either sodium or magnesium.

These reducing agents are more expensive than coke. They require batch processes rather than continuous ones. And titanium tetrachloride is a volatile, corrosive liquid that is difficult to handle. Metallurgists have thus been searching for years for a way to coax titanium out of its ore by electrolysis. Dr Chen, who has published his results in this week’s Nature, believes he has found one.

In standard electrolysis, the compound to be broken up is dissolved in a fluid called an electrolyte. Remember those chemistry lessons spent sticking electrodes into copper sulphate solution? In that case, the electrolyte was water. For the electrolysis of titanium dioxide, the preferred electrolyte is molten calcium chloride. Past attempts, however, have relied on dissolving the tetrachloride (or sometimes the dioxide) into the molten calcium chloride. These have failed because of the way that titanium atoms behave when they are in such a solution.

Dr Chen’s calculations showed, however, that it should be possible to reduce titanium dioxide electrically without having to dissolve it. Instead, one of the electrodes dipped into the calcium chloride is made of solid titanium dioxide. Other chemists have avoided doing this because they reckoned that solid dioxide is an insulator and therefore could not be electrolysed. But Dr Chen’s observation suggested this electrolysis could happen because the dioxide becomes a conductor once a tiny amount of oxygen is removed from it.

The result was that the electrode turned from oxide to metal in a way that would have pleased a medieval alchemist. And if the process can be scaled up, the sort of riches that alchemists dreamed of might be available. For not only titanium could be produced this way. Other expensive metals, such as vanadium and chromium, could also become cheaper. And by compounding the electrodes out of mixed oxides it may be possible to create useful alloys in one go, rather than purifying their ingredients separately.

The result was that the electrode turned from oxide to metal in a way that would have pleased a medieval alchemist. And if the process can be scaled up, the sort of riches that alchemists dreamed of might be available.

crushing/millingwashing in water

metal powder

powdermetallurgy

FFC Cambridge Process FFC Cambridge Process

metallised pellets

conventional metallurgy

molten salt electrolysis

molten CaCl2

pellets of metal oxide

60 240180120 300 360 420

0.5

1.0

1.5

2.0

Typical current-time relations oxygen insoluble in

metal, e.g. Cr

oxygen soluble in metal, e.g. Zr

oxide of multivalent metal, e.g. Ti, Nb

curr

ent

/ A

time / min

porous cathode preforms (pellets)

metal oxide powder(single or mixed)

This past March the U.S. Defense Advanced Research Projects Agency (DARPA) tapped three materials research groups to address this persistent problem. Agency managers awarded separate contracts totaling $5 million to Titanium Metals Corporation (TIMET) and two others to fund parallel efforts to develop potentially low-cost production routes for titanium and its alloys.

The Volkswagen Lupo FSI is being marketed as the lowest fuel consumption gasoline car in the world, achieving 94 miles per gallon.

The Volkswagen Lupo springs, produced from TIMET’s patented TIMETAL LCB alloy, contributed to the 180 lb. overall weight reduction achieved by the FSI model versus the standard model Lupo.

Similar in strength to steel at half the weight, titanium is also about twice as flexible as steel--resulting in spring designs that are 60 to 70 percent lighter and offer up to a 40 percent height reduction compared to corresponding steel springs, according to the company.

Source: http://aftermarket.theautochannel.com/articles/2001/01/11/012676.html

60 million units per year150 kg titanium per unit9 million tonne titanium per year$4000 per tonne titaniumMarket: $36 billion per year

Energy saving

Less emission Uncompromised safety

Titanium & CarsTitanium & Cars

Encourage the use of hydrogen storage and fuel cell systems.

Car weight reduction

Vehicle weight / lb

Mile

s p

er g

allo

n