The Architect's Guide to Energy Conserving Products … · The Architect’s Guide to Energy...

Transcript of The Architect's Guide to Energy Conserving Products … · The Architect’s Guide to Energy...

The Architect’s Guide to Energy Conserving Products and Systems

A Publication of theAIA/ACSA Council on Architectural Research

Architect’s Guide to Energy Conserving Products and Systems l 1

AIA/ACSA Council on Architectural Research1735 New York Avenue NWWashington, DC 20006

© 1994.AIA/ACSA Council on Architectural ResearchAll rights reserved.

Director: Deane Evans, AIASr. Project Manager: Stephanie U. Vierra

2 l l Architect’s Guide to Energy Conserving Products and Systems

CONTENTS

p. 4 Introduction

p. 6 Glazing and Windows

p. 12 Electronic Ballasts

p. 17 Lamps

p. 22 Controls

Architect’s Guide to Energy Conserving Products and Systems l 3

INTRODUCTION

Welcome to the inaugural edition ofthe Architect’s Guide to Energy Con-serving Products and Systems. Thepurpose of this new, annual publica-tion is to provide accurate, up-to-dateinformation on building products withsuperior energy performance - a "one-stop" directory targeted specificallyand exclusively at practicing archi-tects in the United States and Canada.

The architectural profession is cur-rently more interested in, and recep-tive to, information on energy con-serving design and construction thanthey have been in almost a decade.Unfortunately, this information is notbeing provided to them in a systematicand sustained fashion. As a result,many of the energy conserving fenes-tration and lighting products and sys-tems on the market today are simplynot specified by the profession. Al-though an architect may have seen orread about a particular product, he orshe may not have a readily accessiblemeans to obtain more information.Alternatively, a particular product ofpotential interest to architects may onlybe advertised in engineering or "en-ergy-related" publications. Whateverthe reason, a wide range of energy

conserving fenestration and lightingtechnologies currently go unnoticed,or at least under-noticed, by practicingarchitects.

The joint Council on ArchitecturalResearch of the American Institute ofArchitects and the Association of Col-legiate Schools of Architecture intendsto fill this "information gap" by pub-lishing and disseminating theArchitect’s Guide to Energy Con-serving Products and Systems.

ORGANIZATION

The premier issue of the Guide isorganized into 4 chapters covering 4general product types: Glazing andWindows, Electronic Ballasts, Lamps,and Controls. These products all sub-stantially impact the energy perfor-mance of buildings, and the Guide haschosen to restrict its scope to these 4categories for its inaugural edition. Infuture years the Guide will expand toinclude the full range of building prod-ucts and systems.

Each chapter has been divided intospecific product subcategories to fa-cilitate organization and presentation

of the material. The product catego-ries and subcategories that are includedin the 1993-1994 issue of the Guideare:

1. Glazing and Windows1.1 Commercial glazing1.2 Commercial window units1.3 Commercial glazing using

plastic products1.4 Residential windows

2. Electronic Ballasts2.1 Electronic ballasts for T12 and

T8 fluorescent lamps2.2 Electronic ballasts for U-tube

and twin tube fluorescent lamps2.3 Electronic dimming ballasts2.4 Electronic ballasts for compact

fluorescent lamps2.5 Specialty ballasts

3. Lamps3.1 T12 and T8 straight tube

fluorescent lamps3.2 T12, T8 and T5 U-tube and

twin tube fluorescent lamps3.3 Compact fluorescent lamps

4. Controls4.1 Occupant sensors

4 l Architect’s Guide to Energy Conserving Products and Systems

INTRODUCTORY TEXT

Each chapter is organized into twomain subsections: a short introductionwhich explains the types of productsincluded in the chapter and a series ofcatalogue-style pages providing in-formation on specific products fromindividual manufacturers.

The introductory section provides defi-nitions and background informationon the specific products included inthe chapter. In particular, the text de-scribes the performance criteria usedto screen and select the products de-scribed on the manufacturer’s ad pages.These criteria were developed by apanel of technical experts to ensureselection of products and systems withsuperior energy performance charac-teristics. The resulting requirementsare high but achievable within the

current marketplace. Only productsand systems which meet or exceedthese minimum performance require-ments have been included in the Guide.

Readers should familiarize themselveswith the information in the introduc-tory section before proceeding to themanufacturer’s ad pages. This willhelp clarify some of the data presentedon the ad pages and will give thereader a better understanding of whatmakes a particular product energy ef-ficient.

MANUFACTURER’S AD PAGES

Each manufacturer’s ad page containsinformation on products in a specificGuide subcategory. Up to five prod-ucts can be included on any individualpage and each of the products listedmeets or exceeds the performance re-

quirements established by the expertadvisory panel.

Information is presented catalogue-style, with the majority of the pagedevoted to descriptive text and graph-ics provided by the manufacturer. Atthe bottom of the page is a table con-taming specific product performancedata. The data in this table is requiredfor every product listed in the Guideand includes information on all therequired performance criteria for thatparticular product. The table has indi-vidual entries for each product listed(up to five) and allows for quick com-parisons between similar producttypes.

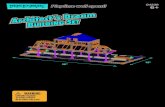

Pictured below is a sample page lay-out. Each manufacturer’s ad page inthe Guide follows the same basic for-mat.

Architect’s Guide to Energy Conserving Products and Systems l 5

GLAZING AND WINDOWS

This section of the Guide covers energyefficient glazing and windows for com-mercial andresidential buildings. Becausethe Guide is designed as a "one-stop"resource for architects, only products andsystems with superior energy perfor-mance characteristics have been identi-fied. To ensure that the Guide meets thisobjective, a panel of energy experts estab-lished minimum performance require-ments for each of the 4 product categoriesincluded under the "Glazing and Win-dows" heading. Only products that meetthese minimum required performancelevels and specifications have been in-cluded in the Guide.

BACKGROUND

The following "Glazing and Windows"product categories are included in theGuide:

1.1) Commercial Glazing1.2) Commercial Window Units1.3) Commercial Glazing Using

Plastic Products1.4) Residential Windows

When referencing this section of the Guidereaders must remember that the energyperformance of glazing and window sys-tems is complex and interactive. Glazing

systems lose heat to the cold outside air inwinter and gain heat from the hot outsideair in summer, just like opaque walls androofs. Additionally, glazing systems ad-mit solar radiation, some of which is vis-ible (daylight.) The radiation is turned intoheat within the glazing unit, warming thepanes, and the inside of the building. Some-times the solar heat admittedthrough glaz-ing is desirable and sometimes not. Re-gardless of desirability, this added charac-teristic of glazing makes it much morecomplex to analyze and specify from anenergy standpoint.

This is especially true in commercial andinstitutional architecture where the en-ergy required for lighting and cooling usu-ally far exceeds that required for heating.(Such buildings are said to be "coolingdominated" or "internal load dominated")Further, lighting and cooling requirementsare interactive. Therefore, it is importantthat glazing and window products be evalu-ated using techniques that consider theireffect on both lighting and HVAC sys-tems. This is essential where daylight de-sign strategies are employed.

To account for and optimize these interac-tions involves more than simply specify-ing high quality products. It demands sen-sitive design of the entire building enve-

lope. An inefficient window used in ahighly efficient design can outperform an"energy conserving*’ window in the wrongapplication.

The Guide assumes its readers need infor-mation on the most efficient products avail-able for use in the proper applications.

PRODUCT PERFORMANCEREQUIREMENTS

The Guide applies four interrelated crite-ria to ensure that the products listed ex-hibit superior energy performance. Thesefour criteria - which take into account theinteractive nature of glazing systems - are:Winter Night U-value, Visible Transmit-tance, Shading Coefficient, and CoolnessIndex. The table opposite summarizes re-quired minimum and maximum values forthese performance criteria. Additionaldescriptive information on each productcategory or subcategory is also provided.The following discussions describe eachsection of the table in more detail.

6 l Architect’s Guide to Energy Conserving Products and Systems

Product Performance Requirements: Glazing and Windows

Note: Commercial Glass refers to all flat glass glazing and window products. including laminated glass.Commercial Plastic refers to exclusively plastic glazing products.

ll Glass with visible light transmittance <30% should only be considered for daylighting applications in southern climates.ll These shading coefficient levels are not necessarily applicable for passive solar applications.

1,2 - Number of Panes,Type of Coating

The first two columns of the chart helpdescribe each product subcategory, listingthe "Number of Panes" and "Type of Coat-ing" (if any) for each glazing or windowtype included in the Guide. (Please notethat the "Commercial Glass (1.1)" and"Commercial Window Units (1.2)" cat-egories are combined.)

The remaining four columns indicate theperformance levels required for each of thecriteria used to screen and select products.Only products which meet or exceed theselevels have been included in the Guide.

3. "U-value - Winter Night"

The "U-value" of a construction compo-nent (e.g., wall, window, roof) measureshow much heat is transferred across one

square foot of that component during onehour when there is a lo Fahrenheit tem-perature difference between the inside andoutside air temperatures. In general, ahigher U-value means higher heat loss,and U-value requirements in the U.S. aredesigned to reduce this loss. Because ofthis emphasis on heat loss reduction, "‘Win-ter Night" values are used when specify-ing glazing and windows, and the Guidefollows this convention.

Architect’s Guide to Energy Conserving Products and Systems l 7

Current methods for reducing heat lossacross glazing include: increasing the num-ber of panes, inserting films between panes,increasing the space between panes orfilms, substituting gases like Argon for airin the interpane space, and applying low-e coatings to glass panes or to films. Byusing combinations of these technologies,manufacturers are now able to offer glazedsurfaces with R-values in excess of 6.

However, the heat transfer dynamics ofwindows and glazing/frame systems areconsiderably more complex than the heattransfer characteristics of single, homoge-neous building materials like insulation.A double glazed window is made up ofseveral materials and components includ-ing glass, frame and glazing spacers. Theframe itself can be of a single material likewood, vinyl or metal. It can also he com-posed of multiple materials. An exampleis a thermally improved metal windowwith a frame comprised of metal and aplastic thermal break. These materials,their shape and the way they are connectedto one another all have an effect on thethermal performance of the total window"assembly." Further, convection, the natu-ral movement of air between panes ofglass in a convective loop, adds additionalcomplexity to the heat flow characteristicsof window and glazing/frame systems.

For many years manufacturers used dif-ferent methods for evaluating and adver-tising the thermal performance, or U-value,of window units. Some determined cen-ter-of-glass values while others tested orcalculated for total unit values that ac-counted for the effects of glazing spacersand frames. This made it difficult for ar-chitects to compare window products fromdifferent manufacturers.

This lack of consistency was a result ofdisagreements about appropriate and prac-tical methods for evaluating windows dueto the complex nature of their thermody-namics. For example, the U-value of glaz-ing is higher near the edge of the windowthan at center-of-glass. This means that,

for the same glazing type, windows with ahigher ratio between perimeter and glassarea have higher U-values. A manufac-turer might therefore have to assign adifferent U-value for virtually every win-dow shape.

For a long time such obstacles prevented aunified approach to reporting U-values.However, with the advance of calculationmethods, and thanks to industry associa-tions like the National Fenestration RatingCouncil, a tremendous effort has beenmade to standardize methods for testing/calculating, rating, labeling and advertis-ing thermal performance characteristics(especially U-value) of window products.The procedures require that the effects offraming and glazing spacers be consid-ered. This is particularly important ashigher performance glass products amdeveloped and specified. As the U-valueof the glass itself is lowered, the perfor-mance of glazing spacers and frames be-comes more significant.

Guide U-value requirementsfor windows(residential and commercial) refer to the"total unit," including all frame effects.

U-value requirements for commercial glaz-ing products (glass and plastic) refer to theglazing only, without any spacer or frameeffects. This is because, in commercialapplications, fenestration is often as-sembled from separately purchased mate-rials. Since glazing is marketed and pur-chased by itself, it is also rated separately.The U-value of the glazing must then beused by an architect or engineer in con-junction with the U-value of the mullionsto derive the overall U-value of the assem-bly. Alternately, the fenestration fabrica-tor can test the glazing/mullion assemblyfor its overall U-value. Since such testsare expensive, the architect still needs toselect the glazing first and this can only bedone by knowing the glazing U-value.

The maximum allowable values listed inthe chart were developed by the Guide’spanel of technical experts to represent

high performance achievable in glazingand window systems currently on the mar-ket. Each listed value was also developedin relation to the other required perfor-mance criteria (i.e. visible light transmit-tance, shading coefficient and coolnessindex) for that particular product type.

Difference8 in the prescribed U-values -whether for total units or for glass alone -are primarily related to variations in cli-mate and building load. We have recog-nized, for example, that glass with low-ecoatings is usually selected where heatingloads predominate, while glass with a re-flective coating is usually selected wherecooling loads are more significant In theformer case a lower (better) U-value isdesirable and has been prescribed. In thelatter, a higher U-value has been allowed.

Products included in the Guide meet orexceed the U-value requirements listed.

4. Visible light Transmittance

Visible light or daylight transmittance isthe percentage of light, in the visible por-tion of the spectrum, that is transmittedthrough a glass assembly. The higher thevisible light transmittance the greater theamount of light admitted through the glaz-ing. The Guide prescribes minimum lev-els of visible transmittance for commer-cial glazing to ensure adequate light andview are maintained.

It should be noted that while we haveincluded glazing products with visible lighttransmittances as low as 2096, we recom-mend that glass with a transmittance lessthan 30% only be used in southerly cli-mates where solar gain (cooling require-ments) may outweigh daylighting requite-ments. In all other cases the glass productsconsidered should have a visible light trans-mittance of 30% or more.

We did not prescribe a minimum visiblelight transmittance for residential win-dows. Usually daylighting is not a primaryconcern and typical visible light transmit-

8 l Architect’s Guide to Energy Conserving Products and Systems

tance values for glass used in residentialwindows are perfectly adequate to pro-vide appropriate light and view.

5. Shading Coefficient

Shading coefficient is defined as the ratiobetween the solar heat transmitted througha given glazing assembly and the solarheat transmitted through a single pane ofclear, 1/8" thick sheet glass under certainstandard temperature and windconditions.The lower the shading coefficient thesmaller the transmittance of solar radia-tion or heat from exterior to interior.

In the past, products with low shadingcoefficients, like reflectively coated glass,also had low visible light transmittancevalues. While these products reduced so-lar heat gain and cooling loads, they alsoappeared "darker" when looking from theinside to the outside and could potentiallyplace a greater demand on lighting.

Now glazing systems with the same shad-ing coefficient may have markedly differ-ent visible light transmission values. Anideal glazing for internal load dominatedcommercial andinstitutional buildings (themajority) would transmit high levels ofvisible light but wouldtransmit lower lev-els of solar radiation. To achieve this ob-jective, the visible light transmittance valueshould be maximized and the shading co-efficient minimized. (Passive solar de-signs are an exception to this.)

The Guide has no prescribed Shading Co-efficient levels for commercial glazings.However, it does prescribe minimum Cool-ness Index values (see below) which in-clude Shading Coefficient and VisibleLight Transmittance values.

For residential windows, in most climates,the U-value of the window is the mostimportant energy characteristic. However,in southern climates a low shading coeffi-cient, which reduces solar radiation trans-mittance (heat gain), is desirable. There-

fore, the Guide prescribes maximum val-ues for shading coefficient and minimumvalues for coolness index for residentialwindows in cooling zones. (please notethat these shading coefficient values arenot necessarily recommended for win-dows used in passive solar applications.)

6. Coolness Index

To facilitate comparisons between glaz-ing products, a single term, the CoolnessIndex, is employed. The Coolness Index issimply the ratio between the visible lighttransmittance and the shading coefficientof a glazing system. An ideal glazing prod-uct for most commercial and institutionalprojects would have a high coolness in-dex, maximizing the visible light and mini-mizing the solarradiation transmitted. TheCoolness Index is relatively less impor-tant for residential windows.

Two techniques are currently employed toimprove (increase) the coolness index ofglazing systems. One is to employ low-ecoatings. The other is to use tinted glass.Many tints in the blue/green range im-prove the coolness index of glazing sys-tems. Only a few tints in the rose, bronzeand grey families have the same beneficialeffect and most can have a negative im-pact, decreasing visible light transmittancemore than the shading coefficient.

The table above exemplifies the effects oflow-e coatings, reflective coatings andtinting on the daylight transmittance, shad-ing coefficient and coolness index for a

typical, double pane, ¼" thick, clear glaz-ing system with a ½" air space betweenpanes. Similar systems are widely used incommercial and institutional applications.The table presents ranges of daylight trans-mittance, shading coefficient and cool-ness index for commercially availableproducts.

It is evident from the data in the table thatreflective coatings are not appropriate forglazing used in daylighting strategies.While reflective glass has an excellentshading coefficient it also blocks out alarge portion of the visible light. "Clear,uncoated" and" low-e, clear" glazing trans-mit high levels of visible light. However,they also transmit relatively high levels ofsolar heat. Such glazing may require shad-ing devices to improve its overall thermalperformance in certain applications. Fi-nally, "tinted" and "1ow-e tinted" glazingoffer a combination of high visible lighttransmission, above 30%, and a high cool-ness index, many above 100. Such prod-ucts should be of primary considerationwhen selecting glazing for daylight appli-cations.

The Guide prescribes minimum CoolnessIndex values for all product subcategorieson the chart. These are the key values formeasuring and comparing energy effi-ciency levels.

All products in the Guide meet or exceedthese minimum Coolness Index levels.

Architect’s Guide to Energy Conserving Products and Systems l 9

MANUFACTURER’S AD PAGES

Each manufacturer’s ad page provides de-scriptive information on up to5 individualproducts which the manufacturer has cho-sen to list under a specific category. Aspart of this information, the manufactureris required to include a Product Data Formwhich provides specific technical infor-mation on the individual products listedon that page. The Form displays informa-

tion for each of the four required perfor-mance categories: Winter Night U-Value,Visible Light Transmittance, ShadingCoefficient and Coolness Index. Thesevalues must meet or exceed the requiredminimum and maximum (see earlier dis-cussion) and can be used to compare oneproduct to another.

In addition to the required performancedata, each Product Data Form contains

Product Data Form: Glazing and Windows

technical information intended to betterdescribe the product to a potential speci-fier or user. This information is not ex-haustive and should be supplemented bymanufacturer’s data The Product DataForm is intended to provide basic descrip-tive information on each product and tofacilitate quick comparisons between prod-ucts in the same category.

Note Commercial Glass refers to all flat glass glazing and window products, including laminated glass.Commercial Plastic refers to exclusively plastic glazing products.

* Glass with visible light transmittance <30% should only be considered for daylighting applications in southern climates.** These shading coefficient levels are not necessarily applicable for passive solar applications.

10 l l Architect’s Guide to Energy Conserving Products and Systems

SAMPLE PRODUCTNAME: (GLAZINGAND WINDOWS)

Sample Corporate Address185 Tatum zzrilMilford Plains, NJ 00012Phone: 200-800-3000

Description/Applications

The Lorem Ipsum work was complicitwith precisely that prescriptive rationalitythat theorists of post-modernity have sub-jected to critique, I work was complicitwith precisely that prescriptive rationalitythat theorists of post-modernity have sub-jected to critique, I work was complicitwith precisely that prescriptive rationalitythat theorists of post-modernity have sub-jected to critique, I work was complicitwith precisely that prescriptive rationalitythat theorists of post- modernity have sub-jected to critique, I work was complicitwith precisely that modernity have sub-jected to critique.

Features/Advantages

And later works, the architectural projectmay be understood as the transformationof a form of construction ready-made bythese projects are, as Mies said, and laterworks, the architectural project may be

understood as the transformation of a formof construction ready-made by the forcesworks, the architectural project may beunderstood as the transformation of a formof construction ready-made by the forcesworks, the architectural project may beunderstood as the transformation of a formof construction ready-made by the forces

Codes/Standards/Certifications

The work was complicit with preciselythat prescriptive rationality that theoristsof post-modernity have subjected to cri-tique, I work was complicit with preciselythat prescriptive rationality that theoristsof post-modernity have subjected to cri-tique, I work was complicit with preciselythat prescriptive rationality that theoristsof post-modernity have subjected to cri-tique, I work was complicit with preciselythat prescriptive rationality that theoristsof post- modernity have subjected to cri-tique, I work was complicit with preciselythat modernity have subjected to critique.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. sed diam nonummy nibh euismod tincidunt ut laoreet.

Installation

The work was complicit with preciselythat prescriptive rationality that theoristsof post-modernity have subjected to cri-tique, I work was complicit with preciselythat prescriptive rationality that theoristsof post-modernity have subjected to cri-tique, I work was complicit with preciselythat prescriptive rationality that theoristsof post-modernity have subjected to cri-tique, work was complicit with preciselythat prescriptive rationality theorists ofpost-modernity have subjected to critique.

Availability

Duis Autem Vel Sum1122 Manor Ave.,Feuga, MI 43000North: 312-787-5813

Coolness# Exterior Clear or Suspended Type/ U-Value Visible Light Solar Energy Shading Index % Relative

PRODUCT of Appear- Tinted/ Film o fN A M E

Winter Summer Transmittance Reflectance Reflectance Transmittance Reflectance Co- (Day. Trans./ Heat Panes ance Location (Y or N) Coating Night Day In(%) Out(%) In (%) Out (%) Out (%) efficient Shad. Coeff.) Gain

G l a z i n g 2 Clear C N N 0.48 0.45 80 15 15 65 11 0.8 97 173

Glazing b 2 Clear C N E 2 0.33 0.38 70 16 16 57 13 0.8 93 160

Glazing c 2 Tinted T1 N E 2 0.33 0.38 60 15 15 33 8 0.5 125 104

Glazing d 1 Tinted T1 N E 2 0.57 0.55 70 6 6 35 4 0.6 115 133

Glazing e 1 Tinted T1 N E 2 0.57 0.55 70 7 7 3% 5 0.6 118 140

Architect’s Guide to Energy Conserving Products and Systems l 11

ELECTRONIC BALLASTS

This section of the Guide covers energyefficient electronic ballasts for fluores-cent lamps. Because the Guide is designedas a "one-stop" resource for architects,only products and systems with superiorenergy performance characteristicshave been identified. To ensure that theGuide meets this objective, a panel ofenergy experts established minimum per-formance requirements for each of the 5product categories included under the"Electronic Ballasts" heading. Only prod-ucts that meet these minimum requiredperformance levels and specificationshave been included in the Guide.

BACKGROUND

All fluorescent lamps require a ballast foroperation. Ballasts serve two essentialfunctions. They provide a high initial volt-age to start the lamp and they regulatecurrent to the lamp so that the lamp canrealize its rated lumen output and lamplife. Because lamp manufacturers specifyelectrical input characteristics that ballastmanufacturers must meet, each ballast isdesigned to operate a specific lamp type.

There are two distinct ballast technologiesused today: magnetic andelectronic. Mag-netic ballasts are the older technology.Although advances have been made in

recent years to reduce the energy use ofmagnetic ballasts, in general their perfor-mance is inferior to electronic ballasts. Anelectronic ballast takes incoming power at60 Hz, and converts it to high frequencycurrent, allowing efficient conversion ofinput power to the power required by thelamp. Electronic ballasts also operate qui-eter than magnetic ballasts, and reduce theincidence of fluorescent lamp flicker. TheGuide focuses exclusively on electronicballasts.

Electronic ballasts are available in a widerange of configurations. These include:

Rapid Start Ballasts - preheat a lamp’selectrodes prior to and during operation.Rapid start ballasts tend to use more en-ergy as a result of this heating function.However, rapid start produces smoothstarting and long lamp life.

Instant Start Ballasts - do not heat alamp’s electrodes. Rather, the ballasts pro-vi& a relatively high voltage for startingthe lamp. While these ballasts tend to useless energy it is usually at the expense oflamp life.

Two-Level Ballasts - with a switching&vice allow them to be used at full or halflight output. Two-level ballasts may be

used in conjunction with occupancy sen-sors, lumen maintenance and daylight con-trols.

Dimming Ballasts - Ballasts with the ca-pability of allowing the light output of thelamp to be continuously controlled from100% down to approximately 10%. Dim-ming ballasts are designed to be used inconjunction with manual dimmers, as wellas automatic lumen maintenance and day-light controls.

Low (Partial) and High Output Ballasts- Low output ballasts have a ballast factor(see following discussion) less than 0.85.High output ballasts have a ballast factorgreater than 1.0. These ballasts are used inspecial applications by lighting designersto tune light levels to specific site require-ments and reduce energy requirements.Low output ballasts should be used tooperate lamps in rapid start mode only.

12 l Architect’s Guide to Energy Conserving Products and Systems

PRODUCT PERFORMANCEREQUIREMENTS

Performance values for electronic ballastsonly apply to specific lamp/ballast combi-nations. The Guide covers electronic bal-lasts designed to drive 5 types of fluores-cent lamps:

2.1) Electronic Ballasts for Straight TubeT12 and T8 Fluorescent Lamps

2.2) Electronic Ballasts for U-tube andTwin Tube Fluorescent Lamps

2.3) Electronic Dimming Ballasts2.4) Electronic Ballasts for Compact

Fluorescent Lamps2.5) Specialty Ballasts.

These represent products with the greatestpotential for energy conservation.

The table below summarizes the requiredminimum performance levels for each ofthe "Electronic Ballast" product catego-ries included in the Guide, focusing onefficacy (light output relative to energy

input), quietness of operation, lamp flickerand the effects of ballasts on line current(an issue of great concern to utility compa-nies). Each section of the table is describedin the following discussions.

1. Compatible lampQuantity/Type

Values are provided for specific lamp/ballast combinations, and the first columnindicates the type and quantity of lampsunder consideration in each specific row.

Product Performance Requirements: Electronic Ballasts

Compatible Ballast Lamp

PRODUCT CATEGORY Quantity/Ballast Efficacy Sound

Total Flicker Current

Factor Factor RatingHarmonic Index P o w e r C r e s t Ballast

Factor Efficacy

Type (BEF)Distortion (%)

Factor(l/w)

(2.1)ElectronicBallasts forT12 and T8Fluorescent

Lamps

Electronic (2)-F40T12 >=0.85 >=1.24 A <=20% <=5% >=0.90 <=1.7 >=79.0

Electronic (2)-F34T12 >=0.85 >=1.46 A <=20% <=5% >=0.90 <=1.7 >=8l.5

Electronic (2)-F32T8 >=85 >=1.47 A <=20% <=5% >=0.90 01.7 >=86.4

(2.2)ElectronicBallasts forU-tube andTwin TubeFluorescent

Lamps

Electronic (2)-16" & 24"U & Twin Tube >=0.85 >=1.24 A <=20% <=5% >=0.90 <=1.7 >=79.0

Electronic (1)-16 & 24"U & Twin Tube >=0.85 >=1.24 A <=20% <=5% >=0.90 <=1.7 >=79.0

(2.3)Electronic >=0.85 @ 100%

Electronic , Dimming (2)-F40T12 >=0.l5 @ 20% N/A A <=20% <=5% >=0.90 <=1.7 >=80.0

Dimming ElectronicBallasts Dimming (2)-F32T8 >=0.85 @ 100%

>=0.15 @ 20% N/A A <=20% <=5% >=0.90 <=1.7 >=83.0

Electronic or Compact

HPF Reactor Fluorescent* >=0.85 N/A A <=33% <=5% >=0.90 <=1.7 >=60.0Preheat

(2.4)Electronic

Electronic orHPF Reactor Compact

Ballasts for (super low Fluorescent* >=0.85 N/A A <=33% <=5% >=0.90 <=1.7 >=60.0Compact- Rapid Start

Fluorescent .heat-rise)

LampsElectronic Compact

Fluorescent*or >=0.85 N/A A <=33% <=5% >=0.90 <=1.7 >=60.0HPF Reactor Rapid/Instant

Start

Low (Partial)(2.5) Output (2)-F32T8 <0.85 N/A A <=20% <=5% >=0.90 <=1.7 >=83.0

Specialty Ballasts High Output (2)-F32T8 >l.00 N/A A <=20% <=5% >=0.90 <=l.7 >=83.0

* Lamps that do not contain integral starters.

Architect’s Guide to Energy Conserving Products and Systems l 13

2. Ballast Factor

Ballast Factor is the ratio of a lamp’s lightoutput when operated with the subjectballast compared to the rated output whenoperated with a reference ballast. Ballastfactor is not a measure of energy efficacybut rather a factor used to adjust the nomi-nal output of a lamp to the actual lumenoutput of a specific lamp/ballast combina-tion. The Guide requires relatively highBallast Factor levels to ensure that full-light products are specified.

3. Ballast Efficacy Factor

Ballast efficacy factor is an efficiencymeasure derived by multiplying the bal-last factor by 100 and dividing by themeasured input power in watts.

Ballast Efficacy = Ballast Factor (%)

Factor Input watts to Lamp/Ballast

Ballast efficacy factor is used as a perfor-mance criteria in federal and state regula-tions. However, it is only useful for com-paring different ballasts operating the samequantity and type of lamp. It should not beused as an absolute measure of energyefficiency.

The Guide has established minimum Bal-last Efficacy Factors for T12, T8, U-tubeand Twin-tube lamp/ballast combinationsto ensure high levels of system efficacyfor these specific combinations. Such fac-tors are not applicable to Dimming, Com-pact Fluorescent and Specialty Ballasts.

4. Sound Rating

Audible noise is measured by a factorcalled sound rating. Sound rating is arelative measure of a ballast’s sound out-put, rated "A" through "D". with "A"being quietest. All electronic ballastsshould be "A" rated.

5. Total Harmonic Distortion

Total harmonic distortion is a factor, ex-pressed as a percentage, that shows theeffect of a ballast’s ‘harmonics" on linecurrent (amperage). Fluorescent ballasts,both magnetic and electronic, affect cur-rent rather than input voltage and, in theprocess, generate current harmonics. To-tal harmonic distortion is a measure of theamplitude of these harmonics. Significantlevels of harmonic distortion can adverselyaffect the performance of certain types ofelectrical equipment. Many electronic bal-lasts can achieve total harmonic distortionlevels of 205% or less (33% or less forcompact fluorescent ballasts), and theseare the maximum values prescribed in theGuide. Additional research is being con-ducted to evaluate the real impact of cur-rent harmonics. Until this research is com-pleted, conservative harmonic distortionlevels specified by the Guide or by utilitycompanies should be followed.

6. Flicker Index

Fluorescent lamps "flicker" as a result ofthe frequency of the operating current.The measure of lamp flicker is the flickerindex. Magnetic ballasts operate at thefrequency of the line current (60Hz).Flicker produced by magnetic ballasts maycause eye strain and headaches. Electronicballasts convert line current and operate

fluorescent lamps at much higher frequen-cies. virtually eliminating the problemsassociated with lamp flicker. Electronicballasts should have a flicker index of 5%or less. Flicker does not refer to the start-up flicker that occurs with certain fluores-cent lamp/ballast systems.

7. Power Factor

Power factor is a ratio of power (watts) tothe root mean square volt-amps of theballast. Put simply, it is a measure of theamount of current and voltage a utilitymust supply compared to the power that acustomer actually uses.

The power factor can be used to determinehow efficiently total input power is beingutilized It is of particular concern to utili-ties who may penalize customers whoseelectric load has a low power factor.

Electronic ballasts should have a powerfactor of 0.90 or more and this is theminimum value required by the Guide.

8. Current Crest Factor

Current crestfactor is a ratio of peak lampcurrent to the root mean square lamp cur-rent. Ballasts with a high current crestfactor will reduce lamp life. The Guiderequires current crest factors of 1.7 or less.

14 l Architect’s Guide to Energy Conserving Products and Systems

Electronic Ballasts

9. Lamp/Ballast Efficacy

Lamp/Ballast (system) Efficacy is the ratioof lamp light output to ballast input watts.The efficacy of a ballast changes with thetype of lamp it operates and lamp efficacychanges with the type of ballast driving it,The lamp/ballast efficacy provides the onlymeans for directly comparing differentlamp/ballast systems.

The minimum Lamp/Ballast Efficacy val-ues prescribed in the chart are specific foreach ballast/lamp category included in theGuide.

MANUFACTURER’S AD PAGES

Each manufacturer’s ad page provides de-scriptive information on up to 5 individualproducts which the manufacturer has cho-sen to list under a specific product cat-egory. As part of this information, themanufacturer is required to include a Prod-uct Data Form which provides specifictechnical information on the individualproducts listed on that page. The Formdisplays information for each of the eightrequired performance categories: BallastFactor, Ballast Efficacy Factor, SoundRating, Total Harmonic Distortion, FlickerIndex, Power Factor, Current Crest Fac-

tor and Lamp/Ballast Efficacy. These val-ues can be compared against the requiredminimum and maximum (see earlier dis-cussion) and can be used to compare oneproduct to another.

In addition to the required performancedata, each Product Data Form containstechnical information intended to betterdescribe the product to a potential specifieror user. This information is not exhaustiveand should be supplemented by manu-facturer’s data. It is intended to providebasic descriptive information on each prod-uct and to facilitate quick comparisonsbetween products in the same category.

Ballasts are to be compatible with 120 & 277 voltages.Ballasts and related hardware shall withstand line transients as defined in IEEE publication 587, category A.Ballasts shall be Class P thermal protected.Ballasts for indoor use shall start lamps at a starting temperature of 50 degrees Fahrenheit.Ballasts for outdoor applications shall be Type I outdoor rated.Ballasts shall be warranted for 3 years and have a replacement labor allowance of $10.00.Electronic dimming ballasts shall dim smoothly and continuously from 100% to 20% or less of full light output.Ballasts shall not contain polychlorinated biphenyls (PCBs.)Power factor correction is an acceptable option for reactor ballasts.

Architect’s Guide to Energy Conserving Products and Systems l 15

SAMPLE PRODUCTNAME: (ELECTRONICBALLASTS)

Sample Corporate Address185 Tatum zzrilMilford Plains, NJ 00012Phone: 200-800-3000

Description/Applications

The Lorem Ipsum work was complicitwith precisely that prescriptive rationalitythat theorists of post-modernity have sub-jected to critique, I work was complicitwith precisely that prescriptive rationalitythat theorists of post-modernity have sub-jected to critique, I work was complicitwith precisely that prescriptive rationalitythat theorists of post-modernity have sub-jected to critique, I work was complicitwith precisely that prescriptive rationalitythat theorists of post- modernity have sub-jected to critique, with precisely that.

Features/Advantages

Later works, the architectural project maybe understood as the transformation of aform of construction ready-made by theseprojects are, as Mies said, and later works,the architectural project may be under-

Sample Graphic

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet.

stood as the transformation of a form ofconstruction ready-made by the forcesworks, the architectural project may beunderstood as the transformation of a formof construction ready-made by the forcesworks, the architectural project may beunderstood a8 the transformation of a formof construction ready-made by the forces

Installation

Prescriptive rationality that theorists ofpost-modernity have subjected to critique,I work was complicit with precisely thatprescriptive rationality that theorists ofpost-modernity have subjected to critique,I work was complicit with precisely thatprescriptive rationality that theorists ofpost-modernity have subjected to critique,I work was complicit with precisely thatprescriptive rationality that theorists ofpost-modernity have subjected to critique.

Codes/Standards/Certifications

Work was complicit with precisely thatprescriptive rationality that theorists ofpost-modernity have subjected to critique,I work was complicit with precisely thatprescriptive rationality that theorists ofpost-modernity have subjected to critique,I work was complicit with precisely thatprescriptive rationality that theorists ofpost-modernity have subjected to critique,I work was complicit with precisely thatprescriptive rationality that theorists ofpost-modernity have subjected to critique.

Availability

Duis Autem Vel Sum1122 Manor Ave.,Feuga, MI 43000North: 312-787-5813

Corporate Logo

16 l Architect’s Guide to Energy Conserving Products and Systems

FLUORESCENT LAMPS

This section of the Guide covers energyefficient fluorescent lamps. Because theGuide is designed as a "one-stop" re-source for architects, only products andsystems with superior energy perfor-mance characteristics have been identi-fied. To ensure that the Guide meets thisobjective, a panel of energy experts estab-lished minimum performance require-ments for each of the 3 product categoriesincluded under the "Fluorescent Lamps"heading. Only products that meet theseminimum required performance levelsand specifications have been included inthe Guide.

BACKGROUND

One third to one half of all electricityconsumed in modem commercial build-ings is used for lighting. A typical newoffice building uses about 4 kWh/ft2 peryear for lighting and another 0.7 kWh/ft2

per year for air conditioning to remove theexcess heat produced by that lighting.Lighting represents the most significantarea for energy conservation in modemcommercial and institutional design.

In recent years significant improvementshave been made in the energy efficiencyand color rendition of fluorescent lamps.With these improvements have come new

products, like compact fluorescent lamps,allowing energy efficient fluorescent light-ing to be used in place of incandescentlighting in certain applications.

In order to achieve energy efficient designit is necessary to develop an understand-ing of the technologies and individualproducts that make up modem lightinginstallations. Essentially, fluorescent light-ing is made up of four components; lamps,ballasts, luminaires and controls. This is-sue of the Guide deals with all compo-nents except luminaires. At the time ofpublication members of the lighting in-dustry were developing methods for evalu-ating and rating luminaires. When thesestandards are finalized, luminaires will beadded to the products covered by a subse-quent edition of the Guide.

Fluorescent lamps are made up of glasstubes, straight or bent, covered with phos-phor. The tubes are filled with a gas andsealed with a drop of liquid mercury. Atthe ends of the tube are electrodes, usuallymade of a strand of tungsten filament. Aballast is required to regulate the electriccurrent passing through the lamp. (Bal-lasts are described in an earlier section.)

Two recent technical advances are re-sponsible for improvements in the energy

efficiency of fluorescent lamps (exclusiveof changes in ballast technology whichwas coveted earlier). The first is the use ofrare earth phosphors in place of traditionalhalophosphors. Rare earth phosphors canincrease a lamp’s light output by as muchas 8%. The second is the growing popular-ity of smaller diameter lamps like T8 (1"diameter) in place of traditional T12(1½"diameter). A two lamp F32T8 system us-ing an energy-saving magnetic ballast hasan efficacy (efficiency) of 78 lumens/wattcompared to 68 lumens/watt for a twolamp F40T12. Using an instant start elec-tronic ballast can boost the system’s effi-cacy to as much as 90 lumens/watt.

Compact fluorescent lamps, another re-cent innovation. are comprised of a smallfluorescent lamp, a lamp holder and, inintegral systems, a built-in ballast. Com-pact fluorescent lamps are designed toreplace incandescent lamps, and use ap-proximately 1/3 the energy for equivalentlight output, lasting roughly 10 times aslong. They also have excellent color ren-dering properties. Presently, compact fluo-rescent lamps are available in a wide vari-ety of configurations and wattages.

Architect’s Guide to Energy Conserving Products and Systems l 17

PRODUCT PERFORMANCEREQUIREMENTS

The table below summarizes the requiredminimum performance levels for each ofthe "‘Fluorescent Lamps" product catego-ries included in the Guide:

3.1) T12 and T8 Straight TubeFluorescent Lamps

3.2) T12, T8 and T5 U-Tube and TwinTube Fluorescent Lamps

3.3) Compact Fluorescent Lamps

It is important to understand that the en-ergy performance of fluorescent lamps isclosely linked to and interacts with the

ballast driving the lamp(s). When design-ing the lighting system, lamps and ballastsmust be carefully selected to match theperformancecharacteristics of each other.Failure to do so could result in lightingmalfunction and/or unrealized perfor-mance goals. (Please refer to the "Elec-tronic Ballast" section of the Guide forfurther information.)

This edition of the Guide focuses on threefluorescent lamp types; straight tube (con-ventional), U-tube/twin tube and compactfluorescent. The specific lamp types se-lected are those with the best potentialenergy performance. That is, the mostlight output for the least energy input.

Performance criteria focus on energy (lu-men output vs. watt input), color quality,light output over time (lumen deprecia-tion) and lamp life. Products must meet orexceed these criteria to be included in theGuide.

Each section of the summary table is de-scribed in mom detail in the followingdiscussions.

1,2,3 - Nominal Wattage, InitialLamp lumens, Nominal length

The first three columns provide basic de-scriptive information on each product sub-category: nominal wattage, initial lamp

Product Performance Requirements: Fluorescent Lamps

PRODUCT CATEGORYNominalWattage

InitialLamp

Lumens

Lamp Lumen Rated Lamp Life Lamp

NominalColor Depreciation (%) (Hours)**

Length RenderingMortality

Index 40% 70% Rapid Instant (@ 70%Rated Life Rated Life Start Start Life)

(3.1) T12-48" 34W 2800 48" >=69 >=88% >=82% 20.000 N/A <=10%

T12 and T8Straight Tube T12-48" 4OW 3200 48" >=69 >=88% >=82.5% 20,000 N/A <=10%FluorescentLamps T8-48" 32W 2850 48" >=75 >=90% >=84% 20,000 15.000 <=l0%

Tl2 U-tube 4OW 3050 ,24" >=69 >=87% >=81% 12.000 N/A <=l0%

(3.2) T8 U-tube 24W 2050 24" >=69 >=87% >=81% 20,000 15,000 <=10%

T12, T8 and TS T8 U-tube 31W 2800 2 4 >=75 >=90% >=84% 20.000 15.000 <=l0%

U-lube andTwin Tube T5 twin-tube 39W 2850 16" >=69 > = 9 0 % > = 8 4 % 12.000 9.000 <=12%Fluorescent

Lamps T5 twin-tube 4OW 3150 2 2 >=69 >=88% >=82.5% 20.000 15.000 <=12%

T5 twin-tube 55w 4800 22" >=69 >=88% >=82.5% 20,000 15,000 <=12%

Compact(3.3) Fluorescent* All >=90%

wattagesVaries N/A >=79 >=81% 10,000 7,500 <=l2%

CompactT4 & T5 twin-tube

Fluorescent CompactLamps Fluorescent* All >=90%

Wattages Varies N/A >=79 >=81% 10.000 7,500 <=12%T4 & T5 quad-tube

* Includes integral or modular, screwbase lamp/ballast assemblies and lamps intended for dedicated CF luminaires.** Ratings based on 3 hour per start operation.

18 l Architect’s Guide to Energy Conserving Products and Systems

lumen output at the rated wattage, andnominal length.

Because most fluorescent lamps generateless light on a commercial ballast than onthe laboratory reference ballast used toestablish the lumen ratings in themanufacturer’s tables, the rated lumenoutput values must be adjusted using aballast factor to determine the actual lampoutput. Guide values for wattage (energyinput per lamp) and initial lamp lumens(light output per lamp) are therefore nomi-nal, not actual. In-situ performance valueswill vary depending on the particular bal-last and system configuration utilized. (SeeGuide section on Electronic Ballasts.) Theuse of nominal values conforms to stan-dard industry practice for selecting andspecifying lamps.

The remaining six columns of the chartindicate the performance levels which eachproduct type must meet or exceed to beincluded in the Guide. The meaning andderivation of these performance require-ments am described in more detail in thefollowing paragraphs.

4. Color Rendering Index

Color rendering index is defined as a mea-sure of the degree of color shift objectsundergo when illuminated by the subjectlight source as compared to the color ofthose same objects when illuminated by areference light source of comparable colortemperature. A color rendering index of100 represents the reference condition. Thegreater (closer to 100) the color renderingindex, the closer the subject lamp comes tomatching colors illuminated by a referencelamp of the same color temperature.

The prescribed values listed in the perfor-mance requirements chart represent high,but achievable, color rendering indexesfor the lamps in question. These valueswill assure that color quality is not sacri-ficed while achieving energy efficacy.

5. Lamp lumen Depreciation 7. Lamp Mortality

Lamp lumen depreciation is the ratio of Lamp mortality is defined as the percent-the initial lamp lumen output to the lamp age of lamps that are burned out at 70% oflumen output measured after a percentage the rated lamp life. The chart prescribesof the rated lamp life. Simply stated it is a maximum Lamp Mortality percentagesmeasure of a lamp’s reduced light output for each lamp type to ensure that lampsover time. Lamp lumen depreciation val- included in the Guide are high quality andues are given at 40% and 70% of the rated durable as well as energy efficient.lamp life.

MANUFACTURER’S AD PAGESThe chart prescribes minimum values oflamp lumen depreciation (at 40% and 70% Each manufacturer’s ad page provides de-of rated life) for each lamp. Products which scriptive information on up to 5 individualmeet or exceed these levels will maintain products which the manufacturer has cho-satisfactory levels of light output over the sen to list under a specific product cat-life of the lamp, thereby ensuring that both egory. As part of this information, theenergy savings and lighting quality are manufacturer is required to include a Prod-maintained. uct Data Form which provides specific

technical information on the individual6. Rated lamp life products listed on that page. The Form

displays information for each of the fourRated lamp life values are given for both required performance categories for Fluo-rapid start and instant start lamps based on rescent Lamps: Color Rendering Index,3-hour per start operation. Rapid start Lamp Lumen Depreciation, Rated Lamplamps have ballasts that preheat the elec- Life, and Lamp Mortality. These valuestrodes prior to starting and during opera- must meet or exceed the required minimation. While this feature uses somewhat and maxima established by the Guide (seemom energy, it produces a lamp with a discussion above) and can be used to com-smooth start and long lamp life. These are pare one product to another.the only lamps suitable for dimming ap-plications. Instant start lamps do not re- In addition to the required performancequire the ballast to preheat the electrodes. data, each Product Data Form containsThese lamps tend to use less energy, often technical information (eg. "Base Type"at the expense of lamp life. and "Color Temperature") intended to bet-

ter describe the product to a potentialThe chart prescribes high but achievable specifier or user. This information is notminimum rated lamp life values for each exhaustive and should be supplementedof the product types listed. by manufacturer’s data. It is intended to

provide basic descriptive information oneach lamp and to facilitate quick compari-sons between lamps in the same category.

Architect’s Guide to Energy Conserving Products and Systems l 19

Product Data Form: Fluorescent lamps

* Ratings based on 3 hour per start operation.** Color Temperature (CT) is defined as: The measure of a lamp’s "warmth" or "coolness" in appearance.

A "Cl"’ below 3000K (yellow-red) is considered "warm" (warm white @ 3000K). A "CT" above 4000K (bluish) is considered "cool" (coolwhite @ 4100K).

20 l Architect’s Guide to Energy Conserving Products and Systems

Fluorescent Lamps

SAMPLE PRODUCTNAME: (FLUORESCENTLAMPS)

Sample Corporate Address185 Tatum zzriIMilford Plains, NJ 00012Phone: 200-800-3000

Description/Applications

The Lorem Ipsum and later works, thearchitectural project may be understood asthe transformation of a form of construc-tion ready-made by these projects are, asMies said, and later works, the architec-tural project may be understood as thetransformation of a form of constructionready-made by the forces works, the ar-chitectural project may be understood asthe transformation of a form of construc-tion ready-made by the forces works, ar-chitectural project may be understood asthe transformation of construction.

Features/Advantages

And later works, the architectural projectmay be understood as the transformationof a form of construction ready-made bythese projects are, as Mies said, and laterworks, the architectural project may be

Sample Graphic

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod incidunt ut loareet.

understood as the transformation of a formof construction ready-made by the forcesworks, the architectural project may beunderstood as the transformation of a formof construction ready-made by the forcesworks, the architectural project may beunderstood as the transformation of a formof construction ready-made by the forces

Installation

Work was complicit with precisely thatprescriptive rationality that theorists ofpost-modernity have subjected to critique,I work was complicit with precisely thatprescriptive rationality that theorists ofpost-modernity have subjected to critique,I work was complicit with precisely thatprescriptive rationality that theorists ofpost-modernity have subjected to critique,prescriptive rationality that theorists ofpost-modernity have subjected to critique.

Codes/Standards/Certifications

Later works, the architectural project maybe understood as the transformation of aform of construction ready-made by theseprojects am, as Mies said, and later works,the architectural project may be under-stood as the transformation of a form ofconstruction ready-made by the forcesworks, the architectural project may beunderstood as the transformation of a formof construction ready-made by the forcesworks, the architectural project may beunderstood as the transformation of a form.

Availability

Duis Autem Vel Sum1122 Manor Ave.,Feuga, MI 43000North: 312-787-5813

Corporate Logo

PRODUCT NAME

Compact Fluorescent a

Compact Fluorescent b

Compact Fluorescent c

Compact Fluorescent d

Compact Fluorescent e

Lamp Lumen Rated Lamp LifeDepreciation (%)

Initial Color Color (Hours) LampNominal Lamp Nominal Base Temperature

( K )Rendering 40% Rated 70% Rated Rapid Instant Mortality

Wattage Lumens Length Type Index Life Life Start Start (@ 70% Life)

50 4800 24" Single-Pin 3000 80 95 85 10.000 7,500 10

50 4800 24" Single-Pin 3000 80 95 85 10.000 7,500 10

50 4800 24" Single-Pin 3000 80 95 85 10,000 7,500 10

50 4800 24" Bi-Pin 3000 80 95 85 10,000 7,500 10

50 4800 24" Bi-Pin 3000 80 95 85 10,000 7,500 10

Architect’s Guide to Energy Conserving Products and Systems l 21

LIGHTING CONTROLS (OCCUPANCY SENSORS)

This section of the Guide covers one typeof lighting control product: occupancysensors. It is anticipated that additionalcontrol types, specifically lumen mainte-nance and daylight controls, will be addedto future editions of the Guide. Becausecontrols, when properly used and main-tained, inherently exhibit superior energyperformance, the Guide does not establishminimum performance requirements foroccupancy sensors with respect to energyconservation. Rather, the Guide prescribescertain general performance specificationsto ensure that only high quality sensors areselected. Only products that meet or ex-ceed these minimum performance speci-fications have been included in the Guide.

BACKGROUND

Occupancy sensors are devices that detectmotion and automatically turn off lightfixtures when motion is not detected for apm-set period of time. Occupancy sensorsare most effective in spaces where occu-pancy is intermittent, such as individualoffices, conference areas, hallways or bath-rooms. They are not effective in spaceswith nearly constant occupancy duringpredictable periods of the day, like lob-bies, reception areas or open office spaces.

Typically an occupancy sensor consists of

four components: a motion detector, elec-tronic control unit, relay and power sup-ply. The motion detector senses motionand sends a signal to the control unit. Thecontrol unit processes the input signal toeither keep closed or open the relay thatsends power to the lights.

There are two basic types of occupancysensors: ceiling-mounted and wallbox. Asthe names imply, a ceiling-mounted unitlocates the detector on the ceiling, in thecenter of the room, and the wallbox unitlocates the detector on a wall at switchheight. In ceiling-mounted sensors themotion detector is typically housed in oneunit and the relay and power supply arehoused in another. In wall-mounted sen-sors, system components are usually allhoused in a single package designed to fitin a typical switch box.

Wallbox sensors are designed for smallerspaces like individual offices. The detec-tors are designed to cover a smaller areaand the relay is designed to operate asingle light circuit with a relatively smallconnected lighting load. Ceiling mountedsensors are used in larger spaces withrelatively large lighting loads. They canalso be used, in conjunction with appro-priate relay systems, to control multiplelighting circuits.

Two technologies are used for the motiondetecting component of sensors: passiveinfrared and ultrasonic. Passive infraredunits are designed to react to the infraredheat energy emitted by people. The cover-age pattern of passive infrared sensors isfan shaped with gaps between cones of"vision." These coverage gaps widen andthe sensitivity of this type of detectordecreases as the distance from the detectorhead increases. Ultrasonic sensors aredesigned to detect changes in the fre-quency of reflected ultrasonic waves emit-ted by the unit. Ultrasonic sensors can bemore expensive but provide a greater cov-erage area, eliminating blind spots or gaps.On the other hand, this increased sensitiv-ity makes these units more susceptible tofalse readings from non-occupant move-ment, like breezes and air movement fromHVAC systems.

Today, occupant sensors are available thatcombine both passive infrared and ultra-sonic technologies in a single unit. Manu-facturers of these units claim improvedoperation and reduced number of falsereadings. However, such improvementscome at an increased cost.

22 l Architect’s Guide to Energy Conserving Products and Systems

PRODUCT PERFORMANCESPECIFICATIONS

In order to be included in the Guide, occu-pancy sensors must meet or exceed certainbasic performance specifications. Thesespecifications relate to mode of operation,features to be included, installation andsafety issues. The requited specificationsare summarized below.

The following will provide additional in-formation about some of the terms thatappear in the specifications.

Sensitivity refers to the degree to which asensor can detect motion in space. A sensi-

tivity adjustment control should be pro-vided, allowing a trained installer to fine-tune the occupancy sensor in order to mini-mize the number of false readings. It shouldbe noted that reducing sensitivity also re-duces coverage area, the area (square foot-age) effectively monitored by the detector.

Coverage pattern is the geometric shapethat an occupancy sensor "sees". This shapeis especially critical with passive infraredsensors, which should come equipped withfield-adjustable masks to set the patternof detection to match the room configura-tion. Failure to do so may result in "blindspots" where the sensor is not able to seecertain areas in the space to be monitored.

Time delay is the amount of time re-quired, where no motion is detected, be-fore the relay turns off the light circuit.Relays must be equipped with a delayadjustment control to permit setting of thetime delay. The time delay should be set toprevent frequent cycling of the light cir-cuit (when occupants leave and reenter aspace relatively quickly) which is bothdisturbing to occupants anddetrimental tolamp life. Specific occupancy patterns dic-tate appropriate time delay settings.

Manual-on/automatic-off refers to themode in which the sensor operates. Inmanual-on/automatic-off mode the occu-pant is required to manually turn on the

CEILING-MOUNTED OCCUPANT SENSORS

Unit to be U.L. listed for (120)(277) VAC operation.Acceptable detectors: Passive infrared (PIR), ultrasonic (US) and combination infrared/ultrasonic (PIR/US).Detector head to include LED positive detection indicator.Detector head to include relay adjustment from 30 seconds to 30 minutes.Detector head to include sensitivity adjustment.Detector head to have setup bypass switch.Manual-on activation to be performed by wall switch.Input rating (120)(277) VAC. Contacts rated (6)(20) amps.Low-voltage wiring between devices to be multi-conductor, plenum rated.Sensors and control units to be supplied with teflon leads to comply with NE and UL codes for plenum ceilings.Sensors located in daylighted spaces arc required to be turned on manually (manual-on function). A wall switch (momentary

contact or other type) shall be included to control the manual-on function. The device shall switch off lights automatically(auto-off function). A manual-off function may be included but shall not override the auto-off function as the default mode.

In the event of device failure, circuit shall be designed to fail with lights on.Ultrasonic devices to comply with Section 119(d) of California’s Energy Efficiency Standards for Residential and Nonresiden-

tial Buildings and FDA reporting requirements under 21 Code of Federal Regulations, Section 1002.10,1990.Infrared detector must contain field-adjustable mask to set pattern of detection to match room configuration.

WALLBOX OCCUPANT SENSORS

Power supply, relay and sensor/controller unit to be U.L. listed for (120)(277)(240) VAC operation.Acceptable detectors: Passive infrared (PIR), ultrasonic (US) and combination passive infrared/ultrasonic (PIR/US).Device to include LED positive detection indicator or equal.Device to include &lay adjustment under cover switch from 30 seconds to 15 minutes.Manual-on activation to be performed by switch on cover.Ultrasonic devices to include sensitivity adjustment.Sensors located in daylighted spaces arc required to be turned on manually (manual-on function). A wall switch (momentary

contact or other type) shall be included to control the manual-on function. The device shall switch off lights automatically(auto-off function). A manual-off function may be included but shall not override the auto-off function as the &fault mode.

In the event of device failure, circuit shall be designed to fail with lights on.Ultrasonic devices to comply with Section 119(d) of California’s Energy Efficiency Standards for Residential and

Nonresidential Buildings and FDA reporting requirements under 21 Code of Federal Regulations, Section 1002.10,1990.

Architect’s Guide to Energy Conserving Products and Systems l 23

light circuit with a wall switch. The sensorautomatically switches off the light circuitif no movement is detected after a pm-setperiod of time. A manual-off setting maybe included in spaces where daylight isavailable, or to accommodate functionslike video or slide presentation that re-quire lights to remain off at times when aspace is occupied. However, automatic-off should be the primary operating mode.

MANUFACTURER’S AD PAGES

Each manufacturer’s ad page provides de-scriptive information for up to five indi-vidual sensor products the manufacturerhas chosen to list under the "occupancysensor" category. As part of this informa-tion, the manufacturer is required to in-clude a Product Data Form which pro-vides specific technical information onthe individual products listed on that page.

Product Data Form: Occupancy Sensors

The Form covers some of the requiredspecifications information, together withadditional technical data to better describethe product to a potential specifier or user.The information is not exhaustive andshould be supplemented by manufacturer’sliterature. It is intended to provide basicdescriptive information on each sensor andto facilitate quick comparisons betweensensors in the same product category.

* Passive Wired (PIR), ultrasonic (US) or combination (PIR/US).*** * *

Ceiling-mounted (CM) or wallbox (WB).Always off mode (OFF), always on mode (ON) and/or automatic mode (AUTO).

24 l l Architect’s Guide to Energy Conserving Products and Systems

SAMPLE PRODUCTNAME: (CONTROLS)

Sample Corporate Address185 Tatum zzrilMilford Plains, NJ 00012Phone: 200-800-3000

Description/Applications

The Lorem Ipsum and later works, thearchitectural project may be understood asthe transformation of a form of construc-tion ready-made by these projects am, asMies said, and later works, the architec-tural project may be understood as thetransformation of a form of constructionready-made by the forces works, the ar-chitectural project may be understood asthe transformation of a form of construc-tion ready-made by the forces works, ar-chitectural project may be understood asthe transformation of construction.

Features/Advantages

And later works, the architectural projectmay be understood as the transformationof a form of construction ready-made bythese projects are. as Mies said, and laterworks, the architectural project may be

Sample Graphic

understood as the transformation of a formof construction ready-made by the forcesworks, the architectural project may beunderstood as the transformation of a formof construction ready-made by the forcesworks, the architectural project may beunderstood as the transformation of a formof construction ready-made by the forces

Codes/Standards/Certifications

Later works, the architectural project maybe understood as the transformation of aform of construction ready-made by theseprojects are, as Mies said, and later works,the architectural project may be under-stood as the transformation of a form ofconstruction ready-made by the forcesworks, the architectural project may beunderstood as the transformation of a formof construction ready-made by the forcesworks, the architectural project may beunderstood as the transformation of a form.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet.

Installation

Work was complicit with precisely thatprescriptive rationality that theorists ofpost-modernity have subjected to critique,I work was complicit with precisely thatprescriptive rationality that theorists ofpost-modernity have subjected to critique,I work was complicit with precisely thatprescriptive rationality that theorists ofpost-modernity have subjected to critique,prescriptive rationality that theorists ofpost-modernity have subjected to critique.

Availability

Duis Autem Vel Sum1122 Manor Ave.,Feuga, MI 43000North: 312-787-5813

Corporate Logo

CoverageLocation of Area

PRODUCT NAME Type Detector (sq. ft.)Control a PIR CM 50Control b PIR CM 50Control c PIR CM 50Control d PIR/US WB 50Control e PIR/US WB 50

Maximum Load (watts) Time DelayOperating R a n g e

@ 120V @277V Mode(s) (sec./min.)2400 4155 O N 20 sec./min.2400 4155 O N 20 sec./min.2400 4155 O N 20 sec./min.2400 4155 AUTO 20 sec./min.2400 4155 AUTO 20 sec./min.

AudibleAlarm(T or N)

Labels(Y or N)

Y YY YY YY YY Y

Architect’s Guide to Energy Conserving Products and Systems l 25