Tech Unit - FH Hydraulic Packer (H78108)

-

Upload

caaguilera -

Category

Documents

-

view

111 -

download

9

description

Transcript of Tech Unit - FH Hydraulic Packer (H78108)

-

PACKER SYSTEMS

Baker Oil Tools

This document is and contains unpublished, copyrighted and confidential information of Baker Hughes, and is revealed for limited purposes only. This documentis the property of Baker Hughes and is to be returned to Baker Hughes on request and may not be reproduced, used or disclosed to persons not having a need toknow consistent with the purpose of the document, without the written consent of Baker Hughes. This document is not rented, loaned or sold, either alone ore inconjunction with equipment or product. 5/10/07 Baker Hughes Incorporated.

TECHNICAL UNITSingle String Retrievable Hydraulic / Hydrostatic Set

IntroductionThe FH Double-Grip Hydrostatic Single

String Packer, Product Family No. H78108, is a re-trievable packer set by either the hydrostatic headof the well, tubing pressure, or both.

Features/Benefits No tubing manipulation required. The setting

mechanism of this packer is released withpump pressure. The packer can be set after thewell is flanged up and the tubing is displaced

Heavy duty operational to hydrostaticpressures of 12,000 to 15,000 psi. (See chartunder the Limitations section of this unit.)

Hydraulic set for low Hydrostatic Head Wells.The FH Hydrostatic Packer can be set by tubingpressure alone at any depth. When thehydrostatic head is less than 1,500 psi,however, the packer must be set hydraulically

Setting mechanism. The design of the settingmechanism ensures sustained pack-off forcethroughout the life of the packer. This tool doesnot depend on trapped hydraulic pressure, butmechanically locks initial setting forces into thePacking Elements. Any additional bottom holepressure or mechanical load due to tubingexpansion is transmitted as additional pack-offforce. Reduction of bottom hole pressure ortubing contraction, however, does not diminishthe initial setting force

Multiple Packing Element System Hydraulic Hold-Down. The Pistons of the

Hydraulic Hold-Down are protected againstdulling while running in the hole by RestrainingPins installed inside the Piston Springs. Afterthe tool is set, the Restraining Pins shear,allowing the Pistons to bite into the casingbefore pressure differential from below issufficient to move the packer

Drawing No. 189-887

Unit No. 8126Rev. B

Date: May 10, 2007Page: 1 of 26

FH Double-Grip Hydrostatic Single-String PackerProduct Family No. H78108

-

Unit No. 8126Rev. B Page 2 of 26

WARNINGUse of Baker equipment contrary to

manufacturers specification may result in property damage, serious injury or fatality.

5-10-07

No Mandrel movement after setting. Alldownward movement of the receptacle withrespect of the tubing, and all upward movementat the tubing with respect to the Receptacle

during setting is trapped in the Body Lock Ring.Once set, the packer will withstand slackoff orupstrain (within the limits of the shear valueselected). All slackoff goes into the packingelements, whereas all upstrain goes throughthe Shear Ring (or Shear Nut) to the Slip Ringand slips to the casing

Optional rotational release. An optional right-hand rotational release with a safety shearvalue of 50,000 lb (40,000 lb on size 43) isavailable on special order

FH Double-Grip Hydrostatic Single-String Packer

Specification GuideCasing Packer Preferred

Range ofCasing IDs

Gage and Guide

Ring OD

PackingElement

OD

PackingElementSpacer

OD

Absolute Limitsof Slip and

Piston Travel

ThreadSpecifications

Box Up andPin Down

OD T and CWt (lb) Size Bore Min Max Min Max4-1/2 9.5-13.5 43A

1.978

3.910 4.090 3.771 3.625 3.771 3.755 4.105

2-3/8 ODEU 8 Rd

5 15-18 43B 4.250 4.408 4.125 3.938 4.125 4.095 4.44311.5-15 43C 4.408 4.560 4.250 4.156 4.250 4.251 4.5915-1/2 26

5-1/220-23 45A2

1.995

4.625 4.778 4.500 4.375 4.500 4.514 4.95015.5-20 45A4 4.778 4.950 4.64113-15.5 45B 4.950 5.190 4.781 4.688 4.781 4.764 5.196

626

20-23 45C 5.191 5.390 5.062 4.938 5.062 5.000 5.63115-18 45D 5.391 5.560 5.156

6-5/8 34 45E2 5.561 5.609 5.406 5.250 5.406 5.122 5.79128-32 45E4 5.610 5.791 5.4846-5/8 24-28 46A4 2.416 5.791 5.921 5.588 5.375 5.475 5.375 5.923 2-7/8 ODEU 8 Rd7 386-5/8 24 47A2

2.000or

2.416

5.830 5.937 5.6565.500 5.656 5.562 6.139

2-3/8 or 2-7/8OD EU 8 Rd

7 386-5/8 17-20 47A4 5.938 6.135 5.812

7

32-3526-29 47B2 6.136 6.276 5.968 5.750 5.968 5.858 6.45620-26 47B4 6.276 6.456 6.07817-20 47C2 6.456 6.578 6.266 6.125 6.266

6.259 7.2607-5/833.7-39 47C4 6.579 6.797 6.45324-29.7 47D2 6.798 7.025 6.672 6.500 6.67220-24 47D4 7.025 7.125 6.812

8-5/844-49 49A2

2.000or

2.500or

3.000

7.511 7.687 7.312 7.000 7.312 7.301 8.2142-3/8,2-7/8,or 3-1/2 OD

EU 8 Rd

32-40 49A4 7.688 7.921 7.53120-28 49B 7.922 8.191 7.781 7.500 7.781

9-5/847-53 51A2 8.343 8.681 8.218 7.938 8.218 8.178* 8.972*40-47 5lA4 8.681 8.835 8.437 8.345** 9.083**29.3-36 51B 8.836 9.063 8.593 8.375 8.593

* Sizes 51A2 or 51A4 when assembled with Piston Material No. H01-86361-00.** Sizes 51A4 or 51B when assembled with Piston Material No. H01-43292-00.

-

Unit No. 8126Rev. B Page 3 of 26

FH Double-Grip Hydrostatic Single-String Packer 5-10-07

Applications1. Run as a single packer.2. Run as a lower packer in multiple packer hook-

ups using dual or triple string packers.3. Run as an upper packer in selective single

string.4. Where displacing and setting is desirable after

the well is flanged up.5. Where well conditions prohibit mechanically set

packers.

Sizes Available2-3/8", 2-7/8" and 3-1/2" Tubing. 4-1/2" through 9-5/8" OD Casing.

LimitationsMaximum Differential Pressure across Seg-ment Retainer Housing (psi):

Maximum Hydrostatic Pressure (psi):

Lock Ring System LimitationAll downward forces from the tubing string are

transmitted through the lock ring system. The load-ing can be a result of, but not limited to, applied setdown weight, thermal expansion, fluid changesand differential pressures. These forces are in ad-dition to tailpipe weight. The Tubemove program

with the appropriate seal bore diameter equivalentwill aid in the quantification of these forces.

Example:Tailpipe Weight (weight of tubing below packer): 5,000#Slackoff Weight (applied after packer is set): 7,000#Thermal Expansion (after packer is set): 4,000#Load on Lock Ring System: 16,000#

Running ToolsNone.

Actuating The PackerThe FH Packer is actuated by pressuring the

tubing to obtain a differential at the packer. To ac-complish this a means for temporarily plugging thetubing below the packer must be provided. For ex-ample, run: 1. A Baker E Hydro-Trip Pressure Sub, Product

Family No. H79928, below the FH Packer. 2. A Baker C Differential Displacing Valve, Prod-

uct Family No. H75912, at some point belowthe FH Packer, provided that operations will notrequire pressuring the tubing internally prior toopening the differential displacing valve, or

3. A Baker Flow Control Seating Nipple at somepoint below the packer. A blanking plug maythen be run and retrieved by standard wirelinetechniques.

If more than one FH Packer is to be run, one ofthe above temporary tubing plugging devicesmust be run below the lowermost packer.When the tubing is pressured in this case, all ofthe Hydrostatic Packers will be set simulta-neously. (If it is desirable to individually set andtest each packer, see Selectively Setting andIndividually Testing Up To Three FH Packerssection.)

Size 43 Sizes 45, 46, and 47 Sizes 49 and 51 6,000 7,500 10,000

Size 43 Sizes 45, 46, and 47 Sizes 49 and 51 12,000 15,000 12,500

Hydrostatic Pressure LimitationsFor NACE Mandrel

Flow Wetted *Brass Screws Annealed Screws

Packer Size

No. of Actuation

Shear Screws

75,000 psi Min Yield Strength22Rc Max

110,000 psi Min Yield Strength

CRA

75,000 psi Min Yield Strength22Rc Max

110,000 psi Min Yield Strength

CRA

432 5,200 8,100 5,000 7,9006 4,000 6,800 3,300 6,200

452 7,200 11,000 6,800 10,6004 6,100 9,900 5,300 9,100

46/472 9,100 13,200 8,800 13,0008 6,900 11,000 5,800 10,000

49/512 10,600 11,300 10,300 11,0008 7,900 8,500 6,600 7,300

* Refer to Field Bulletin ENG-007-89 for definitions of Flow Wetted, Internally Wetted, and Exposed.

Size Load Limit (lb)43 50,0004546 70,0004749 50,00051

NOTE: Earlier versions of the size 47 contained a system limited to 40,000#.

-

FH Double-Grip Hydrostatic Single-String PackerUnit No. 8126 Rev. B Page 4 of 26

5-10-07

OperationNOTE: Using a Baker E Hydro-Trip Pressure Sub.1. For applications where the hydrostatic pressure

is 1,500 psi or above:Run packer to setting depth, flange up the welland displace tubing. Place a ball in the tubingstring and pump down to seat in the E Hydro-Trip Pressure Sub below the FH Packer. In-crease the tubing pressure to approximately1,000 psi over the annulus pressure at thepacker. (At hydrostatic pressure over 7,500 psi,the actuating pressure will increase with in-creasing hydrostatic pressure due to load onsegment retainer.) This shears the shearscrews in the segment retainer, allowing it tomove up, releasing the ring segments, and un-locking the connector mandrel from the man-drel. The hydrostatic pressure of the well fluidthen forces the connector mandrel down intothe atmospheric chamber. This action movesthe receptacle down toward the slip ring, settingthe slips and packing off the tool. The down-ward movement of the receptacle, packing ele-ment mandrel and connector mandrel, etc., isheld by the body lock ring engaging the man-drel. If, after the packer is set, the tubing con-tracts, the mandrel can move up until the shearring retainer contacts the shock absorber at thebottom of the setting sleeve. This movementwill be retained in the body lock ring. If the tub-ing elongates, the downward force of the man-drel is transmitted through the body lock ring,packing element mandrel, receptacle, packingelements and cone, adding to the setting force.

After the packing elements are sealed off, anydifferential pressure from below the tool will ac-tuate the hydraulic hold-down pistons and en-gage them in the casing. The tubing pressuredifferential is then increased across the hydro-trip pressure sub ball seat to pump the ballthrough the finger-type ball seat and allow it togravitate to bottom. The ball seat fingers will ex-pand into the recess provided and leave thetubing full opening. (See Tech Unit 8083, E Hy-dro-Trip Pressure Sub, Production Packer.)

2. For applications where the hydrostatic pressureis less than 1,500 psi:The FH Hydrostatic Packer is designed to allowthe packer to be set hydraulically at shallow

depths where the hydrostatic pressure is notsufficient to effectively set the packer. NOTE: In near zero hydrostatic applications the FHPacker has little internal friction to resist tubingrotation. Left-hand torque applied to the FH Mandrelin the set position can thread the body lock ringdown onto the upward looking face of the connectorsleeve. Continued rotation can unthread the left-hand connection between the connector sleeve andthe element mandrel thus releasing the pack-off. Iftubing rotation is anticipated on a future shallows setjob, the connection between the connector mandreland the element mandrel should be locked togetherwith an appropriate thread locking compound withthe consideration that there should be a method ofbreaking the connection. The connection should notbe set screwed together, as the thin cross sectionswould not effectively accept a set screw.

For this application, the packer is dressed withan additional number of shear screws to in-crease the actuating pressure to 2,000 psi. (Re-fer to chart shown in this unit for the requirednumber of shear screws for each size packer.)The actuating pressure is increased from 1,000psi to 2,000 psi under this condition in order toprovide additional stretch in the tubing at thetime the packer is set so that there is a greaterlikelihood that the rebound will shoulder themandrel against the shear ring when the hydro-trip pressure sub is sheared out. In order to al-low adequate safety factor, the hydro-trip pres-sure sub must be dressed to require 3,500 psidifferential to blow the ball through the sub. NOTE: In order for the packer to be set, the hydro-trip pressure sub must allow the tubing pressure tobe increased over the annulus pressure to a levelsufficient to release the ring segments. It isimportant to NOTE that in wells that take fluid underhydrostatic pressure alone, it is possible to obtain adifferential across the ball without pressuring thetubing. If the tubing below the ball is isolated fromthe annulus (as with a permanent packer below thehydrostatic packer), the ball could shear the hydro-trip pressure sub, without setting the packer. Underthese conditions, provisions should be made forrunning a seating nipple and landing a plug onwireline.

-

Unit No. 8126Rev. B Page 5 of 26

FH Double-Grip Hydrostatic Single-String Packer 5-10-07

Using a Baker C Differential Displacing Valve

If operations do not call for pressuring the tub-ing internally, a Baker C Differential DisplacingValve (see Tech Unit 3214, Production Packers)may be used instead of the hydro-trip pressuresub. The differential displacing valve offers distinctadvantages in cases where it is advantageous todisplace the tubing after the well is flanged up andthe tubing sealed off in a packer below the Hydro-static Packer. The differential displacing valve isopened by pressuring the tubing (not sufficiently toset the Hydrostatic Packer). The tubing may thenbe displaced. Drop a ball to set the HydrostaticPacker and close the differential displacing valve.

Using a Blanking Plug If a seating nipple or Baker L Sliding Sleeve,

Product Family No. H81004, is run below the Hy-drostatic Packer, the packer may be set by landinga plug in the sleeve or nipple. (In most cases, theplug can be run, the packer set, and the plug re-trieved in one trip in the well.)NOTE: Remember that the segment retainer of the FHPacker is actuated by tubing pressure. This prohibitspressure testing with a tubing tester through the packer.However, the packer can be dressed with sufficientshear strength to allow limited testing of lower packers,etc.

The ball seats in the E Hydro-Trip Pressure Suband the C Differential Displacing Valve have a re-stricted ID until the packer is set and the ball seatsheared. Remember this if either collar locators orthru-tubing perforating guns are used. The mini-mum ID of the ball seat is listed in the respectiveunit covering each tool.

For Selectively Setting and Individually Testing up to Three FH Packers

The FH Packer is adaptable to individual set-ting and testing by a simple adjustment of shearscrews in the segment retainer housing. Dress thelowermost packer with two brass shear screws.(When dressing packers for this type hookup, allpackers going on one string should be dressedwith shear screws from one box to ensure similarityof shear values.) Dress the second (middle packerin three packer hookups or upper in two packerhookups) with five brass shear screws, and a third(upper) packer with eight brass shear screws. Thisallows the packers to be set individually. The first

will set with approximately 1,000, the second 2,000and the third 3,000 psi differential at the packer. Inorder to test the packers individually, a means oftemporary communication between the tubing andthe casing (e.g., a L Sliding Sleeve below eachpacker) will be necessary. The lower packer canbe set and tested down the casing. The secondpacker can then be set, the sleeve below itopened, and the second packer tested down thecasing. The third packer is set and tested the sameway. It is recommended that a blanking plug beused to temporarily plug the tubing for setting thepackers due to the higher pressures involved.

Releasing ProcedureThe standard FH Packer is equipped with a

30,000 lb Shear Ring for a straight upstrain re-lease. Other values of shear rings available areshown in the table below.

An alternate rotational release is available onspecial order, which permits the packer to be re-leased by taking an upstrain and rotating to theright. The rotational release has a 50,000 lb(40,000 lb on size 43) straight upstrain shear outsafety release.

Determination Of Shear Release ValuesRefer to Mandrel and Tubing Area Table.

As the shear ring limits the upward travel of themandrel when the packer is set, thereby prevent-ing the packer from unsetting, it is imperative thatdue consideration be given to the selection of ashear-out value. Four general sets of conditionsare described below. (Remember that the follow-ing calculations include only piston effect due topressure. Other factors, specifically ballooning andtemperature effects, can contribute significantly tothe force on the shear ring. If the packer(s) is to beused for treating or stimulation, these factors mustbe considered, and a Baker Engineer consulted.)

Shear Ring Availability Chart

Size Shear Ring (lb) 20,000 30,000 40,000 50,000 43 x x x 45 x x x x 46 x x x x 47 x x x x 49 x x x x 51 x x x x

-

FH Double-Grip Hydrostatic Single-String PackerUnit No. 8126 Rev. B Page 6 of 26

5-10-07

Am = Area of Mandrel OD Ai = Area of Tubing ID Ao = Area of Tubing OD Pt = Change in Tubing Pressure (psi) Pa = Change in Casing Pressure (psi)

1. Lower Packer, Annulus Pressure Constant pressure increase in the tubing re-sults in a force up on the shear ring equal to thepressure change multiplied by the cross-sec-tional area (Am - Ai). A decrease in tubing pres-sure results in a force down on the tubing equalto the change in pressure multiplied by thecross-sectional area (Am - Ai).

2. Lower Packer, Tubing Pressure Constant A pressure increase in the annulus results in aforce down on the receptacle equal to the pres-sure change multiplied by the cross-sectionalarea (Am - Ao). A pressure decrease in the an-nulus results in a force up on the tubing equalto the pressure change multiplied by the cross-sectional area (Am - Ao). If there is a change in both the annulus and thetubing pressure, the net resultant force may becalculated by subtraction of forces as calculat-ed in step 2 from forces as calculated in step 1.Net Resultant = Pt (At - Ai) - Pa (Am - Ao). A positive result to the above equation indi-cates a net resultant force up on the shear ring,and a negative result indicates a net resultantforce down on the receptacle.NOTE: Values of AP should be substituted in theequations with proper signs (+ for increase, - fordecrease).

3. Single Packer Installation - Tubing Plugged With the tubing plugged, and assuming con-stant annulus pressure above the packer, apressure differential across the plug in favor oftubing will act down with a force equal to thepressure differential multiplied by the area ofthe tubing ID. A pressure differential in favor ofthe annulus below the packer and plug will actup with a force equal to the differential pressuremultiplied by the area of the packer mandrelOD. Pressure changes in the annulus above thepacker will result in a force acting down equal tothe pressure change multiplied by the area ofthe mandrel OD minus the area of the tubingOD. P (Ao - Am) A negative result from this equation indicates a

force down. A positive result indicates a forceup.

4. Two or More Packer Installation - TubingPlugged Two or more packer installation, packers andtubing same size, production, or injection be-tween packers:If the tubing is plugged between packers withthe tubing and annulus equalized between thepackers, a pressure differential across the plugin favor of the tubing above the plug results in aforce down equal to the differential pressuremultiplied by the area of the tubing ID. A pres-sure differential in favor of the annulus belowthe plug results in a force up equal to the differ-ential pressure multiplied by the area of thepacker mandrel OD.Since it would be almost impossible to foreseeand calculate all of these factors, a 30,000 lbshear value will usually suffice unless it isknown in advance that any of the above forceswill be unusually large. For instance, if the in-stallation is such that the zone above the lowerpacker in a selective completion can be drawndown considerably, the upward force describedin step 4 should be calculated to verify that the30,000 lb shear force is sufficient.Likewise, if the well is to be treated from thesurface at high rates, thereby cooling the tubingconsiderably, temperature effects could be-come significant and should be calculated orestimated.Tubing shrinkage acts with a force up on thepacker loading the shear ring. Tubingelongation places weight on the packer.

Mandrel and Tubing AreasToolSize

TubingSize (Am - Ai) (Am - Ao) Am

432-3/8"

1.15 0.2* 4.245 1.8 0.5 4.9

46 and 47

4.0 2.7 7.12-7/8" 2.4 0.6

49 and 51

2-3/8" 2.8 1.5 5.92-7/8" 3.6 1.8 8.33-1/2" 3.4 1.0 10.5

* On this size packer the annulus hydrostatic exerts aforce up on the mandrel equal to 0.2 square in, result-ing in a load placed on the shear ring. This effect is small, but should be taken into accountwhen selecting a shear ring for the packer.

-

Unit No. 8126Rev. B Page 7 of 26

FH Double-Grip Hydrostatic Single-String Packer 5-10-07

DisplacingWhen displacing the tubing string, displacing

volumes must not be in excess of 3 bbl/min in orderto prevent swabbing off the Packing Element Sys-tem.

Conversion of RangeAny range of the FH Packer may be field con-

verted to any other range in the following manner:

To change receptacle, gage ring, guide ring,packing elements and spacers:1. Remove Top Sub.2. Back Receptacle off from Packing Element

Mandrel and remove Gage Ring from Recepta-cle.

3. Remove Packing Elements and Spacers.4. Back Gage Ring off of Cone.5. Replace with proper size Gage Ring.6. Place proper Packing Elements and Spacers

on Packing Element Mandrel.7. Place proper Gage Ring on Receptacle and

Receptacle on Packing Element Mandrel. Tochange Slips, refer to steps 3, 12, 13, 14, 15and 16 of Assembly Instructions.

Lubricating InstructionsWhen assembling tool, apply: 1. Baker Downhole Grease, Product Family No.

H49921, to: a. All straight threads, O-rings, screws, pistons

and sealing surfaces. b. Slip ring slots, cone slots and slip areas that

contact these two parts. c. Pack the space between the slip ring and

segment retainer (see drawings). This willhelp prevent buildup of well fluids in this crit-ical area.

2. Bakerseal, Product Family No. H89920, to alltapered threads.

Assembly InstructionsRefer to Drawing Nos. 188-396 sizes 46 and 47,180-916 size 49, and 189-887 size 51.

Sizes 46, 47, 49 and 511. Install all O-rings.2. Assemble the Pistons (11), Piston Springs (10),

Restraining Pins (9) and Piston Retainers (12)in the Receptacle (6).

3. Assemble the Slips (27) in the Cone (20) andSlip Ring (29).

4. Install the Segment Retainer (30) into the Seg-ment Retainer Housing (38) and install theproper number of Shear Screws (31).

5. Install the Pickup Ring (36) in the Segment Re-tainer Housing (38).

6. Place the Segment Retaining Ring (50) on theConnector Mandrel (28) and install the Connec-tor Mandrel in the Segment Retainer (30).

7. Place the Mandrel (2) in the vise and clamp justabove the wicker threads.

8. Move the Connector Mandrel Assembly upfrom the bottom of the Mandrel (2).

CAUTION0-ring friction requires the use of somedriving force. Take care not to damage theseal diameter of the Mandrel (2). A woodenblock placed against the piston end of theConnector Mandrel (28) and struck with arubber mallet will drive the assembly ontothe Mandrel.

9. Align the segment slots with the groove on theMandrel (2).

10.Place the Segment Retainer Housing (38) inthe vise.

11.Install the Ring Carrier (25) and Lock Ring (24)onto the Mandrel (2).

12.Make up the Slip Rings (29), Slips (27), andCone Assembly onto the Segment RetainerHousing (38). NOTE: LEFT-HAND thread.

13.Sizes 49 and 51 only: Install the Lock Ring Re-tainer (23) in the Packing Element Mandrel(19).

14.Slide the Packing Element Mandrel (19) onfrom the top end and stab through the Cone(20). Thread onto the Connector Mandrel (28)LEFT-HAND thread and make up hand-tight.

Packing Element Systems AvailableTemperatureRange (oF)

PackingElement System

70 - 275 90-70-9070 - 200 80-60-80Y250 - 350 95-80-95Y

Y Special Order Only.

-

FH Double-Grip Hydrostatic Single-String PackerUnit No. 8126 Rev. B Page 8 of 26

5-10-07

15.Align the slots in the Packing Element Mandrel(19) with the holes in the Cone (20) and insertthe Torque Pins (22).

16.Using a wrench on the undercut diameter locat-ed just above the piston end of the ConnectorMandrel (28), make up the Packing ElementMandrel (19) to the Connector Mandrel andtighten.

17.Install the Ring Segments (35) and SegmentRetaining Ring (50).

18.Push the Piston end of the Connector Mandrel(28) into the Segment Retainer Housing (38).For size 47: The end of the Piston should comeapproximately flush with the end of the Seg-ment Retainer Housing. On sizes 49 and 51: Itwill protrude approximately 1/2". If the RingSegments (35) are in the proper place, theMandrel (2) can be struck from the bottom endwith movement not to exceed 1/4".

19.Install the Snap Ring (42) on the Mandrel (2).20.Make up the Setting Sleeve (41) onto the Seg-

ment Retainer Housing (38).NOTE: LEFT-HAND thread.

21.Install the Lower Seal Ring (43).22.Install the Lower Seal Ring Retainer (44).23.Install the Shock Absorber (45).24.Install the Shear Ring Retainer (46).25.Install the Shear Ring (48) and move the Shear

Ring Retainer (46) back over the Shear Ring.26.Install the Cap Screws (47).27.Install the Bottom Sub (49).28.Install the Gage Ring (15) (or the Guide Ring for

size 49) and the Packing Element System(16,17,18).

29.Install the Gage Ring (15) on the Receptacle (6)and thread the Receptacle on the Packing Ele-ment Mandrel (19).

30.Sizes 49 and 51 only: Install Upper Seal Ring(7).

31.Make up the Top Sub (1).

Size 43 OnlyRefer to Drawing No. 188-572.1. Install all O-rings.2. Assemble the Pistons (11), Piston Springs (10),

Restraining Pins (9) and Piston Retainers (12)in the Receptacle (6).

3. Assemble the Slips (27) in the Cone (20) andSlip Ring (29).

4. Install the Segment Retainer (30) into the Seg-ment Retainer Housing (38) and install theproper number of Shear Screws (31).

5. Install the Packing Element Mandrel (19) intothe Segment Retainer Assembly. The lowerend of the Packing Element Mandrel should beinserted into the upper end of the Segment Re-tainer Assembly and pushed through until thering segment slots are exposed at the lowerend of the Segment Retainer Housing (38).

6. Place the Mandrel (2) in the vise and clamp justabove the tubing thread at the lower end.

7. Install the Seal (32) onto the Mandrel (2). NOTE: The Seal (32) should be turned inside outprior to assembly so that when it is installed, the flatside is down into Mandrel (2) groove and the OD ofthe Seal is rounded as shown in Drawing No. 333-962.

Drawing No. 333-962

8. Install the Packing Element Mandrel (19) andthe Segment Retainer Assembly onto the upperend of the Mandrel (2).

CAUTION O-ring friction requires the use of somedriving force. Take care not to damage theseal diameter of the Mandrel (2). A woodenblock placed against the piston end of theConnector Mandrel (28) and struck with arubber mallet will drive the assembly ontothe Mandrel.

9. The Ring Segment (35) slots on the Packing El-ement Mandrel (19) must be aligned with thegroove on the Mandrel (2).

10.Make up the Top Sub (1) onto the Mandrel (2)hand tight and place the Top Sub in the vise.

11.Insert the Segment Retaining Ring (50) overthe lower end of the Packing Element Mandrel(19).

12.Install the Ring Piston (53) over the lower endof the Mandrel (2) and make up onto the Pack-ing Element Mandrel (19). Wrench space is lo-cated on the Ring Piston and a back-up wrench

-

Unit No. 8126Rev. B Page 9 of 26

FH Double-Grip Hydrostatic Single-String Packer 5-10-07

should be placed on the Packing Element Man-drel within the limits of the two torque pin slots.

CAUTION Do not place a back-up wrench on the sealdiameters of the Packing Element Mandrel(19).

13.Align the Ring Segment (35) slots with thegroove on the Mandrel (2) and install the RingSegments.

14.Install the Segment Retaining Ring (50) into thegroove of each Ring Segment (35).

15.Slide the Segment Retainer Housing Assemblyback over the Packing Element Mandrel (19)and Ring Segments (35) until it shouldersagainst the Ring Piston (53). The lower end ofthe Segment Retainer Housing (38) should bealmost flush with the lower end of the Ring Pis-ton when the parts are shouldered.

16.Place the packer in the vise with the vise tight-ened on the Segment Retainer Housing (38). (Ifthe Ring Segments (35) are properly contained,the Mandrel (2) can be struck from the lowerend with no more than 1/4" movement of theMandrel.)

17.Install the Snap Ring (42) on the Mandrel (2). 18.Bring the Setting Sleeve (41) on from the bot-

tom end and make up onto the Segment Re-tainer Housing (38). NOTE: LEFT-HAND thread.

19.Install the Lower Seal Ring (43). 20.Install the Lower Seal Ring Retainer (44). At

this point, the setting mechanism of the packercan be checked by striking the Mandrel (2) fromboth ends alternately. Repeat twice. If the RingSegments (35) are in the proper place, totalmovement should not exceed 1/4" to 3/8". If theMandrel moves more than this amount, theRing Segments are out of position, and the toolmust be reassembled.

21.Install the Shock Absorber (45). 22.Install the Shear Ring Retainer (46). 23.Install the Shear Ring (48) and move the Shear

Ring Retainer (46) back over the Shear Ring. 24.Install the Cap Screws (47) into the Shear Ring

Retainer (46).25.Install the Bottom Sub (49). 26.Install the Slip Ring (29), Slips (27), Cone (20)

and Torque Pins (22).

27.Install the Upper Gage Ring (15) and the Pack-ing Element System (16, 17, 18).

28.Install Lower Gage Ring (15) on the Receptacle(6) and install the Receptacle in the followingmanner: a. Install the Makeup Ring (52) onto the Pack-

ing Element Mandrel (19). b. Slide the O-ring (14) over the upper end of

the Mandrel (2) and onto the end of the Pack-ing Element Mandrel (19).

c. Install the Lock Ring (24) and Ring Carrier(25) onto the upper end of the Mandrel (2)within approximately 1-3/4" of the end of thePacking Element Mandrel (19).

d. Place the Receptacle Assembly onto the up-per end of the Mandrel (2) and slide down un-til the Lock Ring (24) and Ring Carrier (25)are positioned back against the shoulder inthe Receptacle (6). This leaves the O-ringgroove in the Receptacle clear to install theO-ring (14).

e. Make up the Receptacle (6) onto the PackingElement Mandrel (19) and shoulder on theMakeup Ring (52).

Size 45 OnlyRefer to Drawing No. 188-566. 1. Install all O-rings.2. Assembly the Pistons (11), Piston Springs (10),

Restraining Pins (9) and Piston Retainers (12)in the Receptacle (6).

3. Assemble the Slips (27) in the Cone (20) andSlip Ring (29).

4. Install the Segment Retainer (30) into the Seg-ment Retainer Housing (38) and install theproper number of Shear Screws (31).

5. Install the Pickup Ring (36) in the Segment Re-tainer Housing (38).

6. Place the Segment Retaining Ring (50) on theConnector Mandrel (28) and install the Connec-tor Mandrel in the Segment Retainer (30).

7. Place the Mandrel (2) in the vise and clamp justabove the wicker threads.

8. Move the Connector Mandrel Assembly upfrom the bottom of the Mandrel (2).

CautionO-ring friction requires the use of somedriving force. Take care not to damage the

-

FH Double-Grip Hydrostatic Single-String PackerUnit No. 8126 Rev. B Page 10 of 26

5-10-07

seal diameter of the Mandrel (2). A woodenblock placed against the piston end of theConnector Mandrel (28) and struck with arubber mallet will drive the assembly ontothe Mandrel.

9. Align the segment slots with the groove on theMandrel (2).

10.Place the Segment Retainer Housing (38) inthe vise.

11.Install the Ring Segments (35) and SegmentRetaining Ring (50).

12.Install the Segment Retainer Housing (38) overthe Ring Segments (35). The Pickup Ring (36)will be shouldered against the piston end of theConnector Mandrel (28).

13.Install the Snap Ring (42). 14.Install the Setting Sleeve (41).

NOTE: LEFT-HAND thread.15.Install the Lower Seal Ring (43). 16.Install the Lower Seal Ring Retainer (44). 17.Install the Shock Absorber (45). 18.Install the Shear Ring Retainer (46). 19.Install Shear Ring (48) and move Shear Ring

Retainer (46) back over Shear Ring. 20.Install Cap Screws (47). 21.Install Bottom Sub (49). 22.Install Connector Mandrel Ring (26). 23.Install Ring Carrier (25) and Lock Ring (24). 24.Install Lock Ring Retainer (23) into Packing El-

ement Mandrel (19).25.Make up Packing Element Mandrel (19) onto

Connector Mandrel (28).NOTE: LEFT-HAND thread.

26.Make up Slip (27), Slip Ring (29) and Cone As-sembly onto Segment Retainer Housing (38).NOTE: LEFT-HAND thread.

27.Install Torque Pins (22) to Cone (20). 28.Install lower Gage Rings (15) and Packing Ele-

ment System (16,17,18). 29.Install upper Gage Ring (15) on Receptacle (6)

and install Receptacle on Packing ElementMandrel (19).

30.Make up Top Sub (1).

Checking Correct Assembly Of Packers - All Sizes

It is important that the Ring Segments of the FHPackers be positioned and retained correctly.Therefore, each packer must be checked at as-sembly in the following manner: 1. Strike lower end of Mandrel (2) with a rubber

mallet. 2. Repeat on upper end. 3. Repeat above steps, checking Mandrel (2)

movement each time. Packer is assembled cor-rectly if Mandrel does not move more than 3/8"in either direction.

For Optional Rotational ReleaseRemove Lower Seal Ring Retainer (44), Shock

Absorber (45), Shear Ring (48) and Shear RingRetainer (46). Replace with the alternate LowerSeal Ring Retainer (61), Shear Nut Retainer (62)and Shear Nut (64). NOTE: The Shear Nut (64), on the size 43 FH Packer,is designed to shear at approximately 40,000 lb. Allother sizes will shear at approximately 50,000 lb.

-

Unit No. 8126Rev. B Page 11 of 26

FH Double-Grip Hydrostatic Single-String Packer 5-10-07

Areas, Pressures and Shear Screws

PackerSize

SettingArea (in.2)

Min TubingPressure**

To Set Packer and Pack-Off

with ZeroHydrostatic

Area (in.2)Available

For ShearingShear

Screws

Shear Screws TubingPressure (psi)Required ToShear EachShear Screw Size

Number InStd Assy

Number ToActuate Packer

At 2,000 psi*

Hydrostatic Hydraulic Brass Annealed Steel BrassAnnealed

Steel43 3.2 1.8 4,050 psi 3.0 10-32

2 Brass

6 5 300 410 45 4.5 2.7 2,750 psi 4.3

5/16-184 3 550 750

466.2 3.8 2,560 psi 6.6 6 4 360 490 47

498.6 4.1 4,000 psi 7.9 3/8-16 5 3 450 610 51

*When hydrostatic pressure is less than 1,500 psi.**Minimum tubing pressure for setting can be reduced if some but not sufficient hydrostatic pressure isavailable. Example: The minimum force required for setting size 45 packer is:

F = (2,750 psi) x (2.7 in.2) = 7,425 lb With a Hydrostatic Head of 600 psi F = force available from Hydrostatic = (600 psi) x (4.5) = 2,700 lb therefore force required from Hydraulic setting is F" = F - F = 7,425 - 2,700 = 4,725 lb Then minimum tubing pressure required for setting when Hydrostatic Head is 600 psi is

F" P = 4,725 lb

2.7 sq in. Hydraulic Setting Area 1,750 psi = =

Pressure may also be applied to the annulus in low hydrostatic applications to reduce the minimum tubingpressure required for proper pack-off.

-

Unit No. 8126Rev. B Page 12 of 26

FH Double-Grip Hydrostatic Single-String Packer5-10-07

Optional Rotational ReleaseDrawing No. 333-961

Dimensional DataRefer to Drawing Nos. 188-572 size 43, 188-566 size 45,

188-396 sizes 46 and 47, 180-916 size 49 and 189-887 size 51.

DimSize

43 45 46 47 49 51 2-3/8" OD 2-7/8" OD 2-3/8" OD 2-7/8" OD 3-1/2" OD 2-3/8" OD 2-7/8" OD 3-1/2" ODA 3.062

2-3/8 ODEU 8 Rd

3.500 3.062 3.500 3.062 3.688 4.500 3.062 3.688 4.500

B 2-7/8 ODEU 8 Rd2-3/8 ODEU 8 Rd

2-7/8 ODEU 8 Rd

2-3/8 ODEU 8 Rd

2-7/8 ODEU 8 Rd

3-1/2 ODEU 8 Rd

2-3/8 ODEU 8 Rd

2-7/8 ODEU 8 Rd

3-1/2 ODEU 8 Rd

C 2.277 2.391 2.891 2.609 2.891 2.609 3.109 3.500 2.375 2.875 3.500D 3.750 4.500 5.500 7.250 8.125E 2.307 2.500 3.000 2.750 3.250 3.656 2.750 3.250 3.656F See Specification Guide G 3.750 4.500 5.500 5.500 7.250 8.125H 1.978 1.995 2.416 2.000 2.416 2.000 2.500 3.000 2.000 2.500 3.000

J43A: 3.750

43BC: 4.094

45AB: 4.500

45CDE: 5.031

5.500 47AB: 5.50047CD: 6.250 7.250

K 1.984 2.000 2.406 1.984 2.406 1.984 2.406 2.969 1.984 2.406 2.969M 5.750 4.880 8.000 4.880 8.000 4.880 5.250 8.000 4.880 5.250 8.000N 7.750 7.500 10.810 7.680 10.810 14.380 14.750 17.500 9.250 9.620 12.370P 17.130 16.630 21.690 18.560 21.690 30.500 30.690 33.250 28.750 29.130 31.880Q 32.380 39.940 40.000 42.250 45.380 57.880 58.060 60.630 57.500 57.880 60.630R 49.250 58.190 65.500 62.560 65.690 78.310 78.380 80.310 77.250 77.630 80.380S 59.750 69.190 76.440 73.380 76.440 88.690 88.880 91.440 88.000 88.380 91.130T 65.810 75.250 82-310 79.440 82.310 94.690 94.690 97.060 94.69 97.060

U - 5.500 47AB: 5.50047CD: 6.188 -

-

FH D

ouble-Grip H

ydrostatic Single-String PackerU

nit No. 8126

Rev. B

Page 13 of 26

5-10-07

FH Double-Grip Hydrostatic Single String PackerAssembly and Dimensional Data Drawing No. 188-572, Size 43

-

FH D

ouble-Grip H

ydrostatic Single-String PackerU

nit No. 8126

Rev. B

Page 14 of 26

5-10-07FH Double-Grip Hydrostatic Single String Packer

Assembly and Dimensional Data Drawing No. 188-566, Size 45

-

Unit No. 8126Rev. B Page 15 of 26

FH Double-Grip Hydrostatic Single-String Packer 5-10-07

FH Double-Grip Hydrostatic Single String PackerParts List, Sizes 43 and 45

Refer to Drawing Nos. 188-572 size 43 and 188-566 size 45.

ItemNo. Description

No.Reqd

Size and Material No.43 45

1 Top Sub*

2-3/8 OD Tubing

1

H01-88313-00 2.277 OD 2" Stub Acme Box

x Box As Ordered

Product Family No. H457602-3/8 NU Box x Box As Ordered2-7/8 OD

Tubing3-1/2 OD Tubing -

2 Mandrel 1 H01-88308-00 H01-80991-004 O-ring 1 -5 O-ring 1 HWW-B229-H40 HWW-B333-H40

6 Receptacle 1 H02-06422-00 45A, 45B: H01-85631-0045C, 45D, 45E: H01-85630-007 Upper Seal Ring 1 -

8 Flat Head Socket Cap Screw ** HWW-GD0B-0D1(10-32 x 3/8 lg) [12]HWW-G11B-0H4

(5/l6-18 x 1/2 lg) [9]

9 Restraining Pin ** H01-58260-00 [16] 45A, 45B: H01-56420-00 [12]45C, 45D, 45E: H01-56619-00 [12]

10 Piston Spring ** H01-52251-00 [16] 45A, 45B: H01-53924-00 [12]45C, 45D, 45E: H01-55266-00 [12]

11 Piston **43A: H01-52309-00 [8]43B: H01-52310-00[8]43C: H01-52311-00 [8]

45A: H01-53966-00 [6]45B: H01-53967-00 [6]

45C: 45D: H01-53968-00 [6]45E: H01-53969-00 [6]

12 Piston Retainer ** H01-88311-00 [4] H01-88023-00 [3]13 O-ring ** HWW-B125-H40 [8] HWW-B224-H40 [6]14 O-ring 1 HWW-B146-H40 HWW-B234-H40

15 Gage Ring 243A: H01-60479-0043B: H01-60482-0043C: H01-60483-00

45A2: H01-60484-0045A4: H01-60485-0045B: H01-60486-0045C: H01-60487-0045D: H01-60468-0045E2: H01-60490-0045E4: H01-60491-00

16 Long Packing Element 243A: H01-58895-0043B: H01-58896-0043C: H01-58897-00

45A: H01-58898-0045B: H01-58899-00

45C, 45D: H01-58901-0045E: H01-58902-00

17 Packing Element Spacer **43A: H01-69488-00 [2]43B: H01-69489-00 [2]43C: H01-69490-00 [2]

45A: H01-69482-00 [2]45B: H01-69491-00 [2]

45C, 45D: H01-69492-00 [2]45E: H01-69493-00 [2]

18 Short Packing Element43A: H01-58876-0043B: H01-58877-0043C: H01-58878-00

45A: H01-58881-0045B: H01-58880-00

45C, 45D: H01-58884-0045E: H01-58886-00

19 Packing Element Mandrel 1 H01-88309-00 H01-80976-00

-

Unit No. 8126Rev. B Page 16 of 26

FH Double-Grip Hydrostatic Single-String Packer5-10-07

20 Cone 1 H01-86491-00 H01-86490-0022 Torque Pin 2 H01-98284-00 H01-98286-0023 Lock Ring Retainer 1 - H01-90853-0024 Lock Ring 1 H02-06404-00 H01-90854-0025 Ring Carrier 1 H01-90967-00 H02-06385-0026 Connector Mandrel Ring 1 - H01-80981-00

27 Slip 4 43A: H01-70023-0443B, 43C: H01-70248-0345A, 45B: H01-70676-03

45C, 45D, 45E: H01-70249-0028 Connector Mandrel 1 - H01-86465-0029 Slip Ring 1 H01-88315-00 H01-80975-00

29A Slip Stop Ring 1 -30 Segment Retainer 1 H01-86473-00 H01-86466-00

31 Headless Brass Screw 2 HWW-GF0B-0BB(10-32 x 5/16 lg)HWW-GE1B-0DB(5/16-l8 x 3/8 lg)

32 Seal (size 43 Only) or O-ring 1 H01-62191-00 HWW-B228-H4033 O-ring 1 HWW-B232-H40 HWW-B234-H4034 O-ring HWW-B235-H40 HWW-B238-H4035 Ring Segment 3 H01-88302-00 H01-88474-0036 Pickup Ring 1 - H01-86468-0037 O-ring 3 HWW-B233-H40 HWW-B236-H4038 Segment Retainer Housing 1 H01-86472-00 H01-86467-0039 O-ring 1 HWW-B153-H40 HWW-B241-H4040 O-ring 4 HWW-B229-H40 HWW-B231-H4041 Setting Sleeve 1 H01-88303-00 H01-80986-0042 Snap Ring 1 H01-88305-00 H01-80987-0043 Lower Seal Ring 1 H01-88304-00 H01-80988-00

44 Lower Seal Ring Retainer 1 43A: H01-88298-0043B: 43C: H01-88992-0045A, 45B: H01-80989-00

45C, 45D, 45E: H01-88990-0045 Shock Absorber 1 H01-88295-00 H01-80990-0046 Shear Ring Retainer 1 H02-11145-00 H02-11146-00

47 Button Head Cap Screw or Socket Head Cap Screw 3HWW-G10B-0D2

(10-24 NC x 3/8 lg)HWW-G118-0H0

(1/4-20 NC x 1/2 lg)48 Shear Ring (30,000 lb) 1 H01-90927-00 H01-90930-00

49Bottom Sub*(Box x Pin)

2-3/8 OD Tubing

1

Product Family No. H457302-3/8 NU Box x Pin As Ordered

2-7/8 OD Tubing

-3-1/2 OD Tubing

50 Segment Retaining Ring 1 H01-88688-00 H01-88335-0051 O-ring 1 HWW-B228-H40

-52 Makeup Ring 1 H01-88316-0053 Ring Piston 1 H01-88297-0054 O-ring 1

-55 Guide Ring 1*For other available threads, specify first seven or five digits of number shown and specify threads desired. **Number required shown in brackets [ ].^See Drawing No. 207-446, Packing Element Assembly Procedures, for number of Spacers required. ^^Use these two parts, H01-86436-00 and H01-86437-00, as a set. Do not mix with other older parts.

FH Double-Grip Hydrostatic Single String PackerParts List, Sizes 43 and 45 (Continued)

Refer to Drawing Nos. 188-572 size 43 and 188-566 size 45.

ItemNo. Description

No.Reqd

Size and Material No.43 45

-

Unit No. 8126Rev. B Page 17 of 26

FH Double-Grip Hydrostatic Single-String Packer 5-10-07

FH Double-Grip Hydrostatic Single String PackerAlternate Parts, Sizes 43 and 45

Refer to Drawing Nos. 188-572 size 43 and 188-566 size 45.

ItemNo. Description

No.Reqd

Size and Material No.43 45

16 Long Packing Element

80 Hard

2

43A: H01-58895-0143B: H01-58896-0143C: H01-63996-00

45A: H01-58898-0245B: H01-58899-01

45C, 45D: H01-64002-0045E: H01-64003-00

95 Hard43A: H01-58895-0243B: H01-58896-0243C: H01-63999-00

45A: H01-58898-0345B: H01-58899-03

45C, 45D: H01-64007-0045E: H01-64008-00

18 Short PackingElement

60 Hard

1

43A: H01-58876-0143B: H01-58877-0143C: H01-65317-00

45A: H01-58881-0245B: H01-58880-02

45C, 45D: H01-65323-0045E: H01-65325-00

80 Hard43A: H01-58876-0243B: H01-58877-0243C: H01-65318-00

45A: H01-58881-0245B: H01-58880-01

45C, 45D: H01-65324-0045E: H01-65326-00

48 Shear Pin20,000 lb

1H01-90926-00H01-90928-00

-

H01-90929-00H01-90931-00H01-90932-00

40,000 lb50,000 lb

61 Lower Seal Ring Retainer 1 43A: H01-88314-0043B, 43C: H01-88944-0045A, 45B: H01-88075-00

45C, 45D, 45E: H01-88945-0062 Shear Nut Retainer* 1 H01-88689-00 -

63 Headless Brass Screw* 2 HWW-GE18-0HB(1/4-20 x 1/2 lg)HWW-GE18-0DB (1/4-20 x 3/8 lg)

64 Shear Nut* 1 H01-88692-0040,000 lbH01-88056-00

50,000 lb64A Non Shear Rot. Release Nut* 1 - H01-86964-00

-

FH D

ouble-Grip H

ydrostatic Single-String PackerU

nit No. 8126

Rev. B

Page 18 of 26

5-10-07FH Double-Grip Hydrostatic Single String Packer

Assembly and Dimensional Data Drawing No. 188-396, Sizes 46 and 47

-

Unit No. 8126Rev. B Page 19 of 26

FH Double-Grip Hydrostatic Single-String Packer 5-10-07

FH Double-Grip Hydrostatic Single String PackerParts List, Sizes 46 and 47

Refer to Drawing No. 188-396.

ItemNo. Description

No.Reqd

Size and Material No.46 47

1 Top Sub*

2-3/8 ODTubing

1

- Product Family No. H457602-3/8 EU Box x Box As Ordered2-7/8 OD Tubing

Product Family No. H469102-7/8 NU Box x Box As

Product Family No. H457602-7/8 NU Box x Box As Ordered

3-1/2 OD Tubing -

2 Mandrel 1 H01-80594-00 H01-80595-50 -2-3/8H01-80594-50 -2-7/84 O-ring 1 -5 O-ring 1 HWW-B337-H40

6 Receptacle 1 H01-85629-00 47A2, A4, B2, B4: H01-85629-0047C2 C4, D2, D4: H01-85628-007 Upper Seal Ring 1 -

8 Flat Head Machine Screw 9 HWW-G11B-0M1(5/16-18 x 5/8 lg)

9 Restraining Pin 12 H01-58258-00 47A2 A4, B2, B4: H01-58258-0047C2 C4, D2, D4: H01-56419-00

10 Piston Spring 12 H07-57597-00 47A2, A4, B2 B4: H07-57597-0047C2, C4, D2, D4: H01-39542-00

11 Piston 6 H01-43915-0047A2, A4: H01-43915-0047B2, B4: H01-43916-00

47C2, C4, D2, D4: H01-43917-0012 Piston Retainer 3 H01-80658-0013 O-ring 6 HWW-B230-H4014 O-ring 1 HWW-B242-H40

15 Gage Ring 2 H01-65097-00

47A2: H01-60492-0047A4: H01-60493-0047B2: H01-60494-0047B4: H01-63797-0047C2: H01-60495-0047C4: H01-60496-0047D2: H01-60497-0047D4: H01-60498-00

16 Long Packing Element 2 H01-58904-00

47A2, A4: H01-58904-0047B2, B4: H01-58905-0047C2, C4: H01-58907-0047D2, D4: H01-58909-00

17 Packing Element Spacer 2 H01-98416-00 [2]

47A2, A4: H01-69497-0047B2, B4: H01-69483-00 47C2, C4: H01-69498-0047D2, D4: H01-69499-00

18 Short Packing Element H01-58888-00

47A2, A4: H01-58888-0047B2, B4: H01-58890-0047C2, C4: H01-58892-0047D2, D4: H01-58893-00

-

Unit No. 8126Rev. B Page 20 of 26

FH Double-Grip Hydrostatic Single-String Packer5-10-07

19 Packing Element Mandrel 1 H01-80597-0020 Cone 1 H02-07233-0022 Torque Pin 2 H01-98288-0023 Lock Ring Retainer 1 -24 Lock Ring 1 H01-90087-0025 Ring Carrier 1 H02-06399-0026 Connector Mandrel Ring 1 -

27 Slip 4 H02-65656-06 47A2, A4, B2, B4: H02-65656-0647C2, C4, D2, D4: H02-65657-0028 Connector Mandrel 1 H01-86435-0029 Slip Ring 1 H01-80601-00

29A Slip Stop Ring 1 -30 Segment Retainer 1 H01-86436-00^^

31 Headless Brass Screw 2 HWW-GE1B-0DB (5/16-18 x 3/8 lg)32 Seal (size 43 Only) or O-ring 1 HWW-B336-H4033 O-ring 1 HWW-B343-H4034 O-ring HWW-B347-H4035 Ring Segment 3 H01-80605-0036 Pickup Ring 1 H01-80606-0037 O-ring 3 HWW-B344-H4038 Segment Retainer Housing 1 H01-86437-00^^39 O-ring 1 HWW-B248-H4040 O-ring 4 HWW-B339-H4041 Setting Sleeve 1 H01-80607-0042 Snap Ring 1 H01-80608-0043 Lower Seal Ring 1 H01-80611-00

44 Lower Seal Ring Retainer 1 H01-80609-00 47A2, A4, B2, B4: H01-80609-0047C2, C4, D2, D4: H01-88993-0045 Shock Absorber H01-80610-0046 Shear Ring Retainer 1 H02-11148-00

47 Button Head Cap Screw or Socket Head Cap Screw 1HWW-G118-0M2

(1/4-20 NC x 5/8 lg)48 Shear Ring (30,000 lb) 1 H02-40248-00

49Bottom Sub*(Box x Pin)

2-3/8 OD Tubing

1

- Product Family No. H457302-3/8 NU x Pin as Ordered2-7/8 OD Tubing

Product Family No. H457302-7/8 Box x Pin As Ordered

3-1/2 OD Tubing -

50 Segment Retaining Ring 1 H01-88827-0051 O-ring 1

-52 Makeup Ring 153 Ring Piston 154 O-ring 155 Guide Ring 1

*For other available threads, specify first seven or five digits of number shown and specify threads desired. **Number required shown in brackets [ ].^^Use these two parts, H01-86436-00 and H01-86437-00, as a set. Do not mix with other older parts.

FH Double-Grip Hydrostatic Single String PackerParts List, Sizes 46 and 47 (Continued)

Refer to Drawing No. 188-396.

ItemNo. Description

No.Reqd

Size and Material No.46 47

-

Unit No. 8126Rev. B Page 21 of 26

FH Double-Grip Hydrostatic Single-String Packer 5-10-07

FH Double-Grip Hydrostatic Single String PackerAlternate Parts, Sizes 46 and 47

Refer to Drawing No. 188-396.

ItemNo. Description

No.Reqd

Size and Material No.46 47

16 Long Packing Element

80 Hard

2

H01-58904-01

47A: H01-58904-0147B: H01-58905-0047C: H01-64012-0047D: H01-54013-00

95 Hard H01-58904-02

47A: H01-58904-0247B: H01-58905-0347C: H01-64016-0047D: H01-64017-00

18 Short Packing Element

60 Hard

1

H01-58888-01

47A: H01-58888-0147B: H01-58890-0247C: H01-65331-0047D: H01-65333-00

80 Hard H01-58888-02

47A: H01-58888-0247B: H01-58890-0147C: H01-65332-0047D: H01-65334-00

48 Shear Pin20,000 lb

1H02-40247-00H02-40249-00H02-07343-00

40,000 lb50,000 lb

61 Lower Seal Ring Retainer 1 H01-80653-00 47A2, A4, B2. B4: H01-80653-0047C2, C4, D2, D4: H01-88946-0062 Shear Nut Retainer* 1 -

63 Headless Brass Screw* 2 HWW-GE1B-0SB (5/l6-18 x 3/4 lg)

64 Shear Nut* 1 H01-80652-0050,000 lb64A: Non Shear Rot Release Nut* 1 H01-86950-00

* For use on tools with rotational release. Replaces items 44 through 48.

-

FH D

ouble-Grip H

ydrostatic Single-String PackerU

nit No. 8126

Rev. B

Page 22 of 26

5-10-07FH Double-Grip Hydrostatic Single String Packer

Assembly and Dimensional Data Drawing No. 180-916, Size 49

-

FH D

ouble-Grip H

ydrostatic Single-String PackerU

nit No. 8126

Rev. B

Page 23 of 26

5-10-07

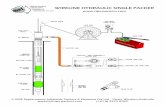

FH Double-Grip Hydrostatic Single String PackerAssembly and Dimensional Data Drawing No. 189-887, Size 51

-

Unit No. 8126Rev. B Page 24 of 26

FH Double-Grip Hydrostatic Single-String Packer5-10-07

FH Double-Grip Hydrostatic Single String PackerParts List, Sizes 49 and 51

Refer to Drawing Nos. 180-916 size 49 and 189-887 size 51.

ItemNo. Description

No.Reqd

Size and Material No. 49 51

1 Top Sub*

2-3/8 OD Tubing

1

Product Family No. H45760 2-3/8 EU Box x Box As Ordered

2-7/8 OD Tubing

Product Family No. H45760 2-7/8 EU Box x Box As Ordered

3-1/2 OD Tubing

Product Family No. H46910 3-1/2 NU Box x Box As Ordered

2 Mandrel 1H01-88025-00 - 2-3/8H01-88026-00 - 2-7/8H01-88027-00 - 3-1/2

4 O-ring 1 HWW-B350-H40 HWW-B352-H40

5 O-ring 1HWW-B358-H40 - 2-3/8HWW-B339-H40 - 2-7/8 HWW-B342-H40 - 3-1/2

6 Receptacle 1 H01-85627-00 H01-86360-00

7 Upper Seal Ring 1H01-85625-00 - 2-3/8H01-85624-00 - 2-7/8H01-85623-00 - 3-1/2

H01-86089-00 - 2-3/8H01-86090-00 - 2-7/8 H01-86091-00 - 3-1/2

8 Flat Head Socket Cap Screw ** HWW-G11B-0M1(5/16-18 x 5/8 lg) [9]HWW-G11B-0M1

(5/16-18 x 5/8 lg) [12] 9 Restraining Pin ** H01-56421-00 [12] H01-56421-00 [24] 10 Piston Spring ** H01-39542-00 [12] H01-53925-00 [24]

11 Piston ** H01-52115-00 [6] 51A2: H01-86361-00 [8] 51A4, 51B: H01-43292-00 [8] 12 Piston Retainer ** H01-88044-00 [3] H01-58275-00 [4] 13 O-ring ** HWW-B236-H40 [6] HWW-B238-H40 [8] 14 O-ring 1 HWW-B250-H40 HWW-B436-H40

15 Gage Ring **49A2: H01-61886-00 [1]49A4: H01-61887-00 [1]49B: H01-61888-00 [1]

51A2: H01-86117-00 [2] 51A4: H01-86118-00 [2] 51B: H01-86119-00 [2]

16 Long Packing Element 2 49A2, 49A4: H01-61877-0049B: H01-61878-0051A2, 51A4: H01-61413-00

51B: H01-61414-00

17 Packing Element Spacer 2 49A2, 49A4: H01-69500-00 [2]49B: H01-69501-00 [2]51A2, A4: H01-69502-00

51B: H01-69503-00

18 Short Packing Element - 49A2, 49A4: H01-61875-0049B: H01-61876-0051A2, 51A4: H01-61415-00

51B: H01-61416-00 19 Packing Element Mandrel 1 H01-88104-00 H01-89105-00 20 Cone 1 H01-98289-00 H02-74779-00 22 Torque Pin 2 H01-98290-00 23 Lock Ring Retainer 1 H01-80274-00 24 Lock Ring 1 H01-90518-00 25 Ring Carrier 1 H02-06400-00 26 Connector Mandrel Ring 1 -27 Slip 4 H02-65658-00 28 Connector Mandrel 1 H01-86475-0029 Slip Ring 1 H01-80277-00 H02-74778-00

29A Slip Support Sleeve 1 - H02-74774-0029B Piston Stop Ring 1 - H02-77371-0030 Segment Retainer 1 H01-86477-00

31 Headless Brass Screw 2 HWW-GE1D-0SB (3/8-16 x 3/4 lg)32 Seal (size 43 Only) or O-ring 1 HWW-B340-H40

-

Unit No. 8126Rev. B Page 25 of 26

FH Double-Grip Hydrostatic Single-String Packer 5-10-07

33 O-ring 1 HWW-B349-H40 34 O-ring HWW-B429-H40 35 Ring Segment 3 H01-88819-00 36 Pickup Ring 1 H01-86478-00 37 O-ring 3 HWW-B425-H40 38 Segment Retainer Housing 1 H01-86476-00 39 O-ring 1 HWW-B256-H40 40 O-ring 4 HWW-B343-H40 41 Setting Sleeve 1 H01-80283-00 42 Snap Ring 1 H01-80284-00 43 Lower Seal Ring 1 H01-80285-00 44 Lower Seal Ring Retainer 1 H01-80286-00 45 Shock Absorber H01-80287-00 46 Shear Ring Retainer 1 H02-11149-00

47 Button Head Cap Screw or Socket Head Cap Screw 1HWW-G51D-0M2(3/16 NC x 5/8 lg)

48 Shear Ring (30,000 lb) 1 H02-40261-00

49Bottom Sub*(Box x Pin)

2-3/8 OD Tubing

1

H457-30-75503-1/2 NU x 2-3/8 EU

2-7/8 OD Tubing

H457-30-75663-1/2 NU x 2-7/8 EU

3-1/2 OD Tubing

H457-30-75553-1/2 NU x 3-1/2 EU

50 Segment Retaining Ring 1 H01-88800-00 51 O-ring 1

-52 Makeup Ring 153 Ring Piston 154 O-ring 1 - HWW-B439-H40

55 Guide Ring 149A2: H02-40160-0049A4: H02-40163-0049B: H02-40164-00

-

*For other available threads, specify first seven or five digits of number shown and specify threads desired. **Number required shown in brackets [ ].^^Use these two parts, H01-86436-00 and H01-86437-00, as a set. Do not mix with other older parts.Piston H01-86361-00 may be used on 51A4 size when H01-43292-00 is not available.

FH Double-Grip Hydrostatic Single String PackerParts List, Sizes 49 and 51 (Continued)

Refer to Drawing Nos. 180-916 size 49 and 189-887 size 51.

ItemNo. Description

No.Reqd

Size and Material No. 49 51

-

Unit No. 8126Rev. B Page 26 of 26

FH Double-Grip Hydrostatic Single-String Packer5-10-07

FH Double-Grip Hydrostatic Single String PackerAlternate Parts, Sizes 49 and 51

Refer to Drawing No. 189-887.

ItemNo. Description

No.Reqd

Size and Material No.49 51

16 Long Packing Element

80 Hard2

49A: H01-64018-0049B: H01-64019-00

51A: H01-64022-00 51B: H01-61414-01

95 Hard 49A: H01-64020-00498: H01-64021-0051 A: H01-64024-00 518: H01-61414-02

18 Short Packing Element

60 Hard1

49A: H01-65335-0049B: H01-65337-00

51 A: H01-65339-00 51B: H01-61416-01

80 Hard 49A: H01-65336-0049B: H01-65338-0051A: H01-65340-00 51B: H01-61416-02

48 Shear Pin20,000 lb

1H02-40260-00 H02-40262-00 H02-40263-00

40,000 lb50,000 lb

61 Lower Seal Ring Retainer 1 H01-80295-0062 Shear Nut Retainer* 1 -

63 Headless Brass Screw* 2 HWW-GE1B-0SB(5/l6-18 x 3/4 lg)

64 Shear Nut* 1 H01-80296-0050,000 lb64A: Non Shear Rot Release Nut* 1 -

* For use on tools with rotational release. Replaces items 44 through 48.

Unit No. 8126IntroductionFeatures/BenefitsSpecification GuideApplicationsSizes AvailableLimitationsHydrostatic Pressure Limitations For NACE Mandrel

Lock Ring System LimitationRunning ToolsActuating The Packer

OperationUsing a Baker C Differential Displacing ValveUsing a Blanking PlugFor Selectively Setting and Individually Testing up to Three FH Packers

Releasing ProcedureShear Ring Availability ChartDetermination Of Shear Release ValuesMandrel and Tubing AreasPacking Element Systems AvailableDisplacingConversion of RangeLubricating Instructions

Assembly InstructionsSizes 46, 47, 49 and 51Size 43 OnlyDrawing No. 333-962

Size 45 OnlyChecking Correct Assembly Of Packers - All SizesFor Optional Rotational ReleaseAreas, Pressures and Shear Screws

Optional Rotational ReleaseDrawing No. 333-961Dimensional Data

FH Double-Grip Hydrostatic Single String PackerAssembly and Dimensional Data Drawing No. 188-572, Size 43Assembly and Dimensional Data Drawing No. 188-566, Size 45Parts List, Sizes 43 and 45Alternate Parts, Sizes 43 and 45Assembly and Dimensional Data Drawing No. 188-396, Sizes 46 and 47Parts List, Sizes 46 and 47Alternate Parts, Sizes 46 and 47Assembly and Dimensional Data Drawing No. 180-916, Size 49Assembly and Dimensional Data Drawing No. 189-887, Size 51Parts List, Sizes 49 and 51Alternate Parts, Sizes 49 and 51