T Split-range control - JUMO · In split-range operation the output is split over multiple...

Transcript of T Split-range control - JUMO · In split-range operation the output is split over multiple...

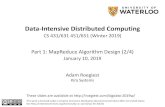

Normally the output level of a controller (0 to 100 %) is generated by a single act-uator (0 to maximum output). In split-range operation the output is split over multiple actuators. For example, if two equally dimensioned actuators are used, for an output level of 0 to 50 %, the out-put is increased by the first actuator. For output levels of 50 to 100 %, the output will then be increased by a second act-uator as well.

Split-range operation with refrigerationThe controller used for the supply tem-perature continuously calculates an out- put level between 0 % and 100 % corre-sponding to a value between "no cooling capacity“ and "maximum cooling capac-ity“. With an output level of up to 50 % the feed pump increases the flow rate quan-tity of the cooling medium. If an output level of 50 % is not sufficient, a refrigerat-ing machine provides additional cooling of the cooling medium. In this way small amounts of heat are dissipated through the cooling tower. The cost-intensive

refrigerating machine is not used until maximum cooling capacity is reached.

Split-range operation: configurationWhen actuators with continuous control are used, for example a converter each for the feed pump and refrigerating machine, a continuous controller with two analog outputs is used. The configuration is ex-tremely simple for JUMO controllers such as the JUMO IMAGO 500 type: first the analog input of the controller is adapted to the sensor that is used. Generally RTD temperature probes are used in this case, occasionally thermo-couples as well. Then the controller type is defined, "continuous controller". The controller output level is assigned to the analog outputs as a function. Scaling for the example described here is arranged so that an output level of 0 to 50 % con-trols one analog output from 4 to 20 mA and an output level of 50 to 100 % controls another analog output from 4 to 20 mA in addition (see diagram). If necessary the refrigerating machine (output level > 50 %)

can also be suppressed for a defined period of time. Split-range operation is also possible for two-state and three-state controllers with cycling binary out-puts. The JUMO IMAGO 500 is used for this application as are the controller series JUMO dTRON 300 and JUMO DICON.

Summary and outlookThere are many reasons for split-range operation. In the example shown here it is used to assign precedence to diverting heat energy via a cooling tower instead of with a refrigerating machine, thereby sustainably reducing energy use and saving money. The function can also be implemented without a control unit. In this case a single inexpensive JUMO controller then controls the supply tem-perature. It is responsible for controlling both actuators.

Waste heat is produced in many industrial processes. Ideally this heat is fed into district heating networks, used to preheat raw materials or otherwise used efficiently. If there is no way to make use of the heat energy, it must be given off into the environ-ment. Cooling towers can be used in this process to lower costs and save resources. If ambient temperatures are elevated or if the process requires especially low temperatures, refrigerating machines are used in addition. These hybrid plants consisting of a cooling tower and refrigerating machine are especially energy efficient when controlled in split-range operation.

Split-range controlEnergy efficiency with multi-stage cooling

Additional information+49 661 [email protected]

The diagram shows a possible application for a JUMO IMAGO 500 controller, ensuring energy-efficient split-range operation of a cooling plant with two analog outputs.

Setpoint valueActual value

Feed pump with converter

From cooling tower

Refrigerating machine with heat exchanger

To process (supply)

FrequencyOutput level0 to 50 %4 to 20 mA

50 to 100 %4 to 20 mA

JUMO IMAGO 500 Multichannel process and program controllerType 703590

T

Cooling medium

Worth Knowing