SWPPP - GCT 4-13-12

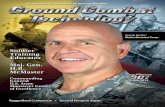

-

Upload

desiree-powers -

Category

Documents

-

view

19 -

download

2

Transcript of SWPPP - GCT 4-13-12

Georgia Ports Authority

Page: 1

Garden City Terminal

1.0 Storm Water Pollution Prevention Team................................................................................3

1.1 Pollution Prevention Team........................................................................................................3

1.2 Employee Training......................................................................................................................6

2.0 Site Description............................................................................................................................6

2.1 Activities at the Facility..............................................................................................................7

a. Container Operations...................................................................................................................7

b. Bulk Operations.............................................................................................................................7

c. Equipment Maintenance..............................................................................................................8

i. Crane Maintenance..................................................................................................................8

ii. Crane & Equipment Fueling Operations................................................................................8

d. Facility Maintenance....................................................................................................................8

i. Vehicle/Equipment Maintenance and Storage......................................................................8

ii. Fueling Operations....................................................................................................................9

iii. Aboveground Liquid Storage Tanks.......................................................................................9

iv. Generators.............................................................................................................................9

e. Tenant: Non-GPA Activities...................................................................................................10

f. New Construction/Facility Rehabilitation..............................................................................10

2.2 General Location Map (General Area and Location)............................................................11

2.3 Site Map (Insert Map)................................................................................................................10

3.0 Summary of Potential Pollutant Sources...............................................................................10

3.1 Activities in the Area.................................................................................................................10

3.2 Pollutants....................................................................................................................................11

a. Container Operations.................................................................................................................11

b. Bulk Operations...........................................................................................................................11

c. Equipment Maintenance...........................................................................................................11

d. Facility Maintenance...................................................................................................................11

e. Tenants: Non-GPA Activities.....................................................................................................12

f. New Construction/Facility Rehabilitation.................................................................................12

3.3 Spills and Leaks..................................................................................................................12

3.4 Non-Storm Water Discharges..........................................................................................12

a. Sanitary Sewer System..............................................................................................................12

b. Vehicle/Equipment Washing......................................................................................................13

Georgia Ports Authority

Page: 2

Garden City Terminal

c. Refrigerated Container Processing..........................................................................................13

3.5 Salt Storage and Pavement Deicing........................................................................................13

4.0 Control Measures.......................................................................................................................13

a. Good Housekeeping...................................................................................................................15

b. Maintenance................................................................................................................................17

i. Holding Tanks..........................................................................................................................18

ii. Maintenance Facility...............................................................................................................18

iii. Catch Basins............................................................................................................................18

c. Spill Prevention and Response Procedures............................................................................18

d. Employee Training......................................................................................................................19

4.1 Monitoring..................................................................................................................................19

4.2 Inspections..................................................................................................................................20

a. Weekly Inspections.....................................................................................................................20

b. Annual Comprehensive Site Inspection...................................................................................20

5.0 Signature Requirements...........................................................................................................23

Georgia Ports Authority

Page: 3

Garden City Terminal

1.0 Storm Water Pollution Prevention Team

1.1 Pollution Prevention Team

Members of the Georgia Ports Authority’s (GPA) Stormwater Pollution Prevention Team for the Garden City Terminal (GCT) are responsible for developing the plan and for assisting the Team Leader in the implementation, maintenance and revision of the plan. A list of Team members are identified in the following member roster and organizational chart:

<SEE POLLUTION PREVENTION TEAM CHART ON THE FOLLOWING PAGE>

Georgia Ports AuthorityGarden City Terminal

GPA - Garden City Terminal

Table 1: Pollution Prevention TeamMember Roster

NAME TITLE PHONE RESPONSIBILITIES

Chris Novack, P.E. Senior Director of Engineering & Maintenance

(912) 964-3914 Signatory Authority

Richard Cox General Manager of Equipment & Facility Engineering

(912) 966-3634 Develop plan elements and stormwater management options regarding equipment operations. Manage preservation of Plan.

Gary Douglas Manager of Contracts and Facilities Maintenance

(912) 964-3810 Coordinate response to spill events. Deploy GPA and response contractor personnel, as required. Ensure plan implementation. Ensure records are made a part of the plan. Assist Team members in developing stormwater management options. TEAM LEADER

Natalie Schanze Environmental Affairs Manager (912) 963-5595 Develop plan elements related to personnel training.

Randy Weitman Manager of Engineering Services (912) 964-3916 Back-up coordination of response to spill events, in absence of Maintenance Supervisor for Support Services.

Moffatt & Nichol Plan Preservation (912) 231-0044 Implement maintenance and revisions to Plan.

SWS Environmental Spill Response Contractor (912) 966-0686 Respond to and control major spill events on the Terminal.

Page 4

Georgia Ports AuthorityGarden City Terminal

GPA - Garden City Terminal

Table 2: Pollution Prevention Team - Organization Chart

Page 5

PLAN DIRECTORH. Wilson Tillotson, P.E.

Senior Director of Engineering & Facilities Maintenance

PLAN COORDINATORRich Cox

G.M. of Equipment & Facility Engineering

SAFETY and SPILL COORDINATORGary Douglas

Manager of Contracts and Facilities Maint.

RESERVE SPILL RESPONSE COORDINATORRandy Weitman

Manager of Engineering Services

SPILL RESPONSE CONTRACTORSWS Environmental

TENNANT COORDINATORRandy Weitman

General Manager of Maintenance

FACILITY COORDINATORRonnie Kessler

Facilities Superintendant

EQUIPMENT COORDINATORDan Rohde

Director of Equipment Maint. & Berth Ops.

PLAN PRESERVATIONMoffatt & Nichol

Program Manager

RUBBER TIRED GANTRY CRANES Shannon McAteer

Manager of RTG Maintenance

SHIP TO SHORE CRANESAdam Deleanides

Manager of STS Crane Maintenance

FLEET MAINTENANCEJerome Aikens

Manager of Fleet Maintenance

TRAINING COORDINATORNatalie Schanze

Environmental Affairs Manager

Georgia Ports Authority

Page: 6

Garden City Terminal

1.2 Employee Training

Frequency and training requirements for all GPA maintenance employees are as follows:

All GPA maintenance employees shall attend a training session on good housekeeping requirements as described below and in Section 4.1.a. This training shall be conducted annually.

A member(s) of the Pollution Prevention Team for the GCT shall be present during the training sessions for good housekeeping.

The purpose of these training sessions is to reinforce both the need to prevent pollution sources from entering the stormwater and the practices required for achieving this. All attendees shall be required to sign an Employee Training Attendance Form (included in Appendix B, Forms) at the conclusion of the training session, certifying their understanding of and their commitment to adhering to GPA-established stormwater management practices.

Newly hired personnel, as part of their initial orientation, shall receive training on this plan.

The training sessions shall cover, at a minimum, the following areas:

Purpose of Stormwater Pollution Prevention Plan (SWP3)

Outdoor storage of materials, surplus parts and equipment, creosote timbers, etc.

Use of tarps and drip pans for the prevention of surface contamination

Spill response and clean-up requirements, as described in the GPA GCT Spill Prevention, Countermeasures, and Control( SPCC) Plan

Legal consequences for failing to comply with SWP3 requirements

2.0 Site Description

The Georgia Ports Authority’s Garden City Terminal is located on the Savannah River near the City of Savannah (see Appendix A, Site Map). Geographic details of the site are presented below:

County: Chatham

City: Garden City

State: Georgia

Lat.: 32º 07’ 23” N

Long.: 81º 08’ 37” W

Receiving Water: Savannah River

Total Acreage on Site: 1,238 acres (approx.)

Georgia Ports Authority

Page: 7

Garden City Terminal

Physical features at the GCT include 10,600 linear feet of wharf, 1,192,166 square feet of covered storage, 485 acres of open storage, and several chemical storage tanks. The major commodities transferred at this Terminal are containerized cargo. Tenants operate many of the activities on the Terminal including a chemical storage facility. The GPA operates several paved container yards, warehouses, various container handling equipment, and a maintenance facility.

2.1 Activities at the Facility

A review of the operational characteristics of the GCT is conducted annually to confirm and review the typical activities described by this plan.

Some materials handled and stored at the GCT are classified as “significant materials” under Title 40 Code of Federal Regulations (CFR) Part 122.26. These include, but are not limited to fuels, metals, and waste products. These materials are described for the GPA operations identified below:

Container Operations

Bulk Operations

Equipment Maintenance: Crane and Fleet

Facility Maintenance

Tenant: Non-GPA Activities

New Construction/Facility Rehabilitation

a. Container Operations

i. The primary function of the GCT is to manage the throughput of import and export containerized cargo through the Port of Savannah. The operations group responsible for movement of this cargo on the terminal (Gate to Yard to Vessel or Vessel to Yard to Gate) operates the equipment used for its transport. There are multiple functional areas on terminal under this classification: Gate Operations, Fleet Operations (Jockey Trucks, Rubber Tired Gantry Cranes (RTG), Top Lifters), Rail Operations (Locomotives & RTG), and Ship Operations (Vessels & Ship to Shore Cranes (STS)). Each group is managed by a Director with designated Managers and Supervisors that coordinate with each other during daily shift operations at the terminal.

b. Bulk Operations

i. There are operations collocated on the GCT that include bundling and stuffing of bulk cargo into containers. This operation occurs in warehouses located within the terminal perimeter, but is the responsibility of the bulk cargo operations team. The operation includes the use of heavy lift machinery such as forklifts and therefore is subject to all the potential pollutants associated.

Georgia Ports Authority

Page: 8

Garden City Terminal

c. Equipment Maintenance

i. Crane Maintenance

Maintenance activities associated with the STSs and RTGs operations such as the transfer of diesel fuel, engine oil, anti-freeze, hydraulic oil, etc. to and from the equipment on location can increase the risk of polluting the surrounding stormwater runoff.

Potential sources of contamination could result from tank rupture during transfer, accidental spills or leaks of material, and from over-topping of drums during collection of used anti-freeze. Should any of these situations occur, the lost material could enter nearby deck drains for discharge to the receiving waters. Minor spills and leaks can leave a residue on the wharf deck, which can then become a source of contamination for stormwater runoff as it passes over those areas.

ii. Crane & Equipment Fueling Operations

Fueling operations of STSs and RTGs are performed by Fleet Operations personnel. The concerns in Section 2.1 Paragraph d.ii apply to this operation.

d. Facility/Maintenance

i. Vehicle/Equipment Maintenance and Storage

The majority of the activities in this area occur north of the GCT Maintenance Facility building. The existing pavement (primarily asphalt) has several large areas affected with grease, oils, or other petroleum products used during vehicle and equipment maintenance. The pavement areas likely affected most are where forklift attachments are stored. Because of pavement grades, a portion of the contaminated runoff flows away from the collection inlet and makes its way around one end of the containment wall to sheetflow across open ground. Other areas are associated with limited maintenance efforts on larger equipment such as Top Lifters and RTG’s. Various lubricants have the potential to leak on the pavement during maintenance, which could then runoff during rainfall into the stormwater collection system.

There are several locations along the north side of the Maintenance Facility where tires have been stored. These tires may contain tar, grease, or other residue that could potentially be a source of pollutants when combined with approaching stormwater runoff.

Replacement rails and timber ties are stacked in the loading dock area on the south side of the Maintenance Facility. Various lubricants have the potential to leak during loading and unloading, which could wash off during rain events into the stormwater collection system for immediate discharge into receiving waters.

Several tip carts have been designated throughout the work areas of the facility. These can contain not only miscellaneous metals, but oily parts as well. The tip carts

Georgia Ports Authority

Page: 9

Garden City Terminal

are located in the crane maintenance area, steel fabrication shop and fleet maintenance area. Most of the time these carts are kept underneath covered areas. However it is possible that some runoff could collect potential contaminants from any uncovered carts.

ii. Fueling Operations

A fixed fueling station is located on the west side of the Maintenance Facility. The station dispenses gasoline and diesel fuel from aboveground pumps, which are situated on concrete pavement. The concrete area is surrounded by asphalt pavement, and sheltered by a metal canopy. The station uses automatic shutoff nozzles and complies with current state regulations. Though the station is beneath canopy cover, some quantity of rain water can be expected to blow under the shelter. In order to accommodate this, a trench drain exists between the fuel pumps. Collected stormwater coalesces with deposited fuel and oil from the pump area and discharges directly onto the ground outside the canopy area. In addition, it should be noted that the pavement on which the fueling station lies is high ground relative to adjacent surfaces. As a result, stormwater run-off into the fueling area is limited.

Adjacent to the fueling station are the intake pipes for the underground tanks. Spills that occur during the filling of these tanks have the same ability to enter the stormwater collection system without having entered a separator system. Likewise, fuel residue on the pavement would contaminate the rainfall, entering the collection system without being treated.

RTGs are fueled using the same equipment. However, since the tanks are located near the ground, they are filled directly with the truck hose. A single person is used for the operation. It is possible that stormwater could become contaminated due to accidental spillage and enter the collection system for discharge to the receiving waters.

iii. Aboveground Liquid Storage Tanks

Several above ground liquid storage tanks are located on the north side of the Maintenance Facility. These tanks contain products ranging from mineral spirits to waste oils. Many have a small protective curb in place as a secondary containment to mitigate the effects of a potential tank rupture due to vehicle contact. The storage tanks are provided with covered shelters removing some of the potential contamination of the runoff to either enter the stormwater collection system or possibly overland flow from the pavement to the adjacent ground.

iv. Generators

There are three backup diesel generators at the Terminal. One is located to the east (behind) the Administration Building and the others are near Gate 3 and 4 beside the Container Interchange area, respectively. A single person is used for refueling and each generator is filled directly from the fuel truck hose. It is possible that stormwater

Georgia Ports Authority

Page: 10

Garden City Terminal

could become contaminated due to accidental spillage and subsequently entering the collection system before discharge into the receiving waters.

e. Tenant: Non-GPA Activities

Contract stevedore services, leased agencies and maintenance and repair (M&R) vendors are all considered GPA tenants. They have all been notified by GPA that they are responsible for their own SWP3. However, they are still considered a potential source for stormwater contamination on GPA property. In order to maintain proper adherence to all policy responsibilities, all GCT tenants will present a copy of their respective SWP3 annually to the GPA for addition to the records kept on file by the Team Leader located at the Maintenance Facility.

f. New Construction/Facility Rehabilitation

The GPA is in the process of reorganizing, densifying, and rehabilitating portions of the GCT in order to improve efficiency and container throughput. This includes various capital construction projects and equipment acquisition. The 2022 Master Plan for the terminal provides the road map to reach these goals.

The GPA Engineering Department is responsible for allocating the resources to complete these projects. Through a program management contract to selected engineering firms, the Department mages the design, bid, build process for these projects. Any erosion, sedimentation, and pollution control plans that are needed for these projects are designed by a Level 2 certified Professional Engineer in the State of Georgia and reviewed internally before implementation by a qualified Contractor.

Georgia Ports Authority

Page: 11

Garden City Terminal

2.2General Location Map

Georgia Ports Authority

Page: 12

Garden City Terminal

2.3Site Map

See Appendix A for Site Map details

Georgia Ports Authority

Page: 13

Garden City Terminal

3.0Summary of Potential Pollutant Sources

3.1Activities in the Area

As described in Section 2.1, the following activities occur throughout the GCT:

Container OperationsBulk OperationsEquipment Maintenance: Crane and Fleet Facility MaintenanceTenants: Non-GPA ActivitiesNew Construction/Facility Rehabilitation

3.2Pollutants

a. Container Operations

i. Potential sources of stormwater contamination due to the above activity include pavement areas stained with oils, grease and other mechanical fluids emitted from vehicles and equipment parked outdoors. Pollutant parameters of concern from these sources include oil, grease, total suspended solids (TSS), biochemical oxygen demand (BOD), and chemical oxygen demand (COD).

ii. There are two processing areas used for cleaning out refrigerated container units. One is located in Container Berth Area 1 (CB-1) west of the Vopak tank facility and north of the Chatham Yard Intermodal Container Transfer Facility and the other in CB-8, east of the vegetated wetlands. At both of these locations, water used for cleaning refrigerated containers is supplied by the potable water system. All runoff for the wash areas is captured with a slotted drain system that deposits into an underground wet well which is periodically pumped out. All water captured from both locations is contracted to be removed from the terminal. Pollutants of concern at the refrigerated container wash down areas include pathogens, fecal coliform, BOD, and COD. All of the use washing fluids are captured and removed off terminal.

b. Bulk Operations

i. Same as in Section 3.2 Paragraph a.i.

c. Equipment Maintenance

i. Same as in Section 3.2 Paragraph a.i.

ii. Potential sources of stormwater contamination due to this activity include fuel spills and residue onto paved areas. Pollutant parameters of concern from these sources include total petroleum hydrocarbons (TPH), benzene, toluene, ethyl benzene and xylenes (BTEX), BOD, COD, and TSS.

Georgia Ports Authority

Page: 14

Garden City Terminal

d. Facility Maintenance

i. A recycling bin adjacent to the Maintenance Facility building captures grease and other mechanical fluids during vehicle and equipment washing. Overspray from this activity can mix with oil, grease and other pollutants. Pollutant parameters of concern from these sources include oil, grease, total suspended solids (TSS), biochemical oxygen demand (BOD), and chemical oxygen demand (COD).

ii. Same as in Section 3.2 Paragraph c.ii.

iii. Tanks and containers used at this facility store products such as mineral spirits, recycled anti-freeze and used oil. Spills, leaks, drips, and product residue on pavement are potential sources of stormwater contamination. Pollutant parameters of concern from these sources include oil, BOD and COD.

iv. The outside storage of scrap and salvage metal products occurs at numerous locations around this facility. These materials are a potential source of stormwater contamination. Pollutant parameters of concern include TSS and heavy metals.

e. Tenants: Non-GPA Activities

i. Tenants are required to address their own concerns based on their specific industrial activity. The GPA Engineering Department will maintain copies for each of these tenant’s SWP3s. They are required to follow the same rules per the GA EPD for industrial use facilities under a contractual agreement with the GPA. In general pollutants such as those found in Section 3.2 Paragraphs a.i and c.ii apply.

f. New Construction/Facility Rehabilitation

i. Construction activities on the terminal can cause the release of certain pollutants into the existing stormwater management system projects must utilized designed BMPs for mitigation where applicable. Pollutants of concern vary based on the projects location, but in general include fecal coliform, BOD, COD and TSS.

3.3Spills and Leaks

Records of spills or leaks of toxic or hazardous substances at the Terminal are kept on file at the Maintenance Facility. An example of the form used to collect data for such an occurrence is included in Appendix B, Forms.

3.4Non-Storm Water Discharges

During the Annual Comprehensive Site Inspection, each of the stormwater outfalls and BMPs at the Terminal are visually evaluated for the presence of any non-stormwater discharges. The presence of any non-stormwater discharges will be noted in the inspection report and described

Georgia Ports Authority

Page: 15

Garden City Terminal

in the report submitted annually to the GA EPD. To date, a dye test for the facility has not been performed. It will be scheduled within this permit period.

a. Sanitary Sewer System

The Terminal’s sanitary sewer system consists of buried gravity and force main wastewater transmission lines and twelve (12) pump stations. The pump stations collect the wastewater and hydraulically discharge into offsite municipal sewer systems (shown on the Site Map in Appendix A). The offsite receiving municipal systems are owned, operated, and maintained by the City of Port Wentworth Department of Public Works and Garden City Department of Public Works.

Each of the STS cranes have a holding tank for wastewater which feeds to the wharf level. Collected wastewater from each crane station is regularly pumped out and removed from the terminal by disposal contractors.

Two wastewater tile fields are employed for use on the terminal by some of the tenants.

b. Vehicle/Equipment Washing

A wash pad for vehicles and equipment is located along the edge of pavement on the north side of the Maintenance Facility. Used wash water from this operation is collected in a tank and filtered within a Water Filtration System (WFS). After treatment, the wash-down spray is discharged into the sanitary sewer system. The WFS then provides newly recycled water for subsequent washing operations. Due to the presence of the collection tank, no significant quantity of wash water is added to the stormwater system, rendering containment unnecessary.

c. Refrigerated Container Processing

As stated previously in Section 3 paragraph ii, there are two wash-down areas used for cleaning out refrigerated container units. One is located in Container Berth Area 1 (CB-1) west of the Vopak tank facility and north of the Mason rail yard, and the other location is in CB-8 east of the vegetated wetlands. At both of these locations, water used for cleaning refrigerated containers is supplied by the potable water system. All runoff for the wash area at CB-1 is captured with a slotted drain system that deposits into an underground wet well which is periodically pumped out. At the CB-8 locations, all spray from the wash-down area is contained by the construction of curbing which diverts the captured liquids into a holding tank. All water captured from both locations is contracted to be removed from the terminal.

3.5Salt Storage and Pavement Deicing

No salt storage or deicing operations exist on this facility.

4.0Control Measures

Site drainage basins and systems are shown on the Site Map. The portion of the Terminal operated by GPA consists of container yards, warehouses, container handling equipment, and

Georgia Ports Authority

Page: 16

Garden City Terminal

the maintenance facility mentioned above. A majority of the stormwater runoff across paved and unpaved areas throughout the Terminal is collected in a series of grassed swales and drop inlets before discharging into a modified retention area. All stormwater runoff ultimately discharges into the Savannah River, either directly or indirectly through conveyance by Pipemakers Canal. Potential pollutants typical of an industrial facility that may be found in the stormwater runoff include oil, grease, petroleum, hydrocarbons, heavy metals and tire residue. Stormwater from the Terminal and Pipemakers Canal is also subject to the off-terminal affects of upstream and downstream discharges from other sources. A tide gate outfall control structure controls the discharge of Pipemakers Canal into the Savannah River and is maintained by Chatham County.

Land disturbing activities associated with new construction on the Terminal comply with the Georgia Erosion & Sedimentation Act of 1975 (Amended 2004) and the GPA Engineering Procedures Manual. All engineering projects include a phased Erosion, Sedimentation, and Pollution Control Plan that is prepared under the supervision of a Level II Design Professional. The BMPs are inspected regularly after significant storm events and documented according to the specific General Permit applying to that project.

All construction activity on the GCT is also subject to the NPDES General Permit. GPA is designated the “Operator” of the Garden City Terminal known as the “Common Development” which falls under GAR 100003. As required under this permit, an Erosion, Sedimentation, and Pollution Control Plan (ES&PC) must be developed, implemented, and maintained for all construction sites. This plan must include the BMPs established in the Manual for Erosion & Sedimentation Control in Georgia, identify all potential pollution sources from a construction site, and recommend the appropriate BMPs to manage them.

For the existing facility, vegetative BMPs are the primary method used in treating the runoff. Structural BMPs are also used, but typically just for retrofitting the existing system. These BMPs are consistent with the Manual for Erosion & Sedimentation Control in Georgia, mitigate the release of sedimentation from terminal activities, and control erosion caused excess velocities by stormwater runoff.

As a Municipal Separate Storm Sewer System (MS4) operator, the GPA has developed a Stormwater Management Plan (SWMP) which addresses the potential pollutants on the Terminal and the appropriate BMPs to manage them. In general, the runoff from the Terminal is collected in a series of catch basins and conveyed via underground drainage pipes to a wetland, pond, or grassed swale. The detention and retention aspects of the SWMP provide an appropriate BMP for treating and managing the runoff from most of the Terminal. Where it is not feasible to incorporate vegetative BMPs, the GPA judiciously employs other structural BMPs to mitigate the discharge of polluted runoff into the receiving waters of the Terminal.

The co-mingling of hazardous substances or oil into the stormwater discharge(s) from the GCT is prevented or minimized, in accordance with the SWP3. Industrial General Permit No. GAR 050000 does not relieve GPA of the reporting requirements of Georgia’s Oil or Hazardous Material Spills or Releases Act, 40 CFR part 177 and 40 CFR part 302. This permit does not authorize the discharge of hazardous substances or oil resulting from an on-site spill.

Georgia Ports Authority

Page: 17

Garden City Terminal

The 2006 EPD NPDES Permit #GAR 050000, Part IV.D.8 states “Facilities with potential pollutant sources that are subject to the reporting requirements under the Emergency Planning and Community Right to Know Act (EPCRA) Section 313 (SARA Title III) must identify any substances for which releases are required to be reported may be exposed to precipitation in the SWP3. The SWP3 must include a narrative description of best management practices used to minimize contact of such substances with stormwater runoff.”

BMPs are measures used to prevent or mitigate pollution from any type of activity. BMPs are a very broad class of measures and may include processes, procedures, schedules of activities, prohibitions on practices, and other management practices to prevent or reduce water pollution. Baseline BMPs are practices that are inexpensive, relatively simple, and applicable to a wide variety of industries and activities. The purpose of baseline BMPs is to highlight how these common practices can be improved and tailored to prevent stormwater pollution.

Baseline BMPs shall address, at a minimum, the following components:

Good Housekeeping Maintenance Spill Prevention and Response Procedures Employee Training

The Baseline BMPs and the corresponding responsible member of the Pollution Prevention Team (see Paragraph 2.2, “Organizational Chart”) are described as follows:

a. Good Housekeeping

The appropriate personnel shall be responsible for ensuring the implementation of the following policies and/or procedures. The Inspection Checklists for each functional area are included in Appendix B, Forms. All Personnel shall be responsible for maintaining a clean and orderly work environment. In order to accomplish this, the following tasks shall be performed:

i. The Pollution Prevention Team Leader shall mark on the site plan the location for storage of various materials. The site plan shall be kept in a central location and updated, as different materials are stored on-site.

ii. The Team Leader shall periodically identify all chemicals used on the site to determine if they are included on approved GPA chemical list.

iii. All containers shall be clearly labeled as to contents, along with any special handling, storage, or disposal requirements.

iv. All drums and containers of petroleum or chemicals used at the terminal shall be stored in the storeroom or in a covered area outdoors in accordance with all applicable safety regulations. All containers shall be stored so that they are not in contact with the ground surface. Secondary containment systems shall be inspected weekly and any free product immediately removed and properly disposed of. Clean stormwater shall be discharged through a drain line in the containment wall. The Team Leader, or his designee, shall be assigned the

Georgia Ports Authority

Page: 18

Garden City Terminal

responsibility for inspection and drainage of the containment area, and the normal maintenance of the drain valve in a locked position. Drums and other accumulated waste residue shall be removed as needed from the storage areas.

v. Waste containers of sufficient capacity shall be provided and labeled as to what refuse should be placed in each container. If a private company provides waste disposal services, a copy of the types of waste they shall accept and their disposal schedule shall be posted. Containers for waste oil or parts contaminated with oil shall be provided within a contained area.

vi. Employees shall be required to pick up trash or waste at the end of each day.

vii. Existing or occurring leaks or spills of petroleum products shall be quickly cleaned up.

viii. All materials that are stored outside shall be stored in a high area that is not subject to stormwater flow. Material shall be stored in neat piles on pallets or blocking away from the ground surface, and shall be covered with waterproof tarps whenever possible.

ix. Any work which may involve the release of petroleum products or chemicals shall be performed within the maintenance area. If this is not possible, then the work shall be performed in an area subject to minimal stormwater flow and as far from the storm inlets as possible. Personnel shall place drip pans or tarps beneath the work area to catch any leaks or spills, when feasible. Prior to and after container crane maintenance, the pier deck shall be inspected and any spills onto the pavement shall be cleaned up immediately. To the greatest extent possible, no work that might result in spills shall be performed in open areas while it is raining or when rain is threatening.

x. Fuel tanks shall not be filled to their maximum capacity. Signs reminding employees of this shall be placed on the fuel pump and all storage tanks.

xi. Employees shall inspect areas after performing any activity involving oil, chemical or other related products. Any spills shall be cleaned up immediately, using absorbent products. Used absorbents shall be disposed of properly.

xii. Liquids used in cleaning shall be minimized as much as possible and all work shall be performed over a drip pan or other appropriate container. Liquid cleaners shall be reused as much as possible and disposed of properly. Special care shall be taken to avoid mixing certain cleaners with petroleum products to avoid creating noxious chemical reactions or explosions.

xiii. Batteries shall be stored under cover. Before storage, all batteries shall be checked for cracks. Damaged and old batteries shall be properly disposed of at

Georgia Ports Authority

Page: 19

Garden City Terminal

an approved disposal area.

xiv. Containers, drums and bags shall be stacked according to the manufacturer’s instructions. This helps to avoid damaging the containers, etc. from improper weight distribution and possibly causing a spillage or leakage of product.

xv. Containers drums and bags shall be stored away from direct traffic routes to prevent accidental ruptures from contact with vehicles or equipment.

xvi. Aboveground and underground oil and fuel storage tanks shall not be left unattended during filling operations.

xvii. Surfaces in fueling and work areas shall not be intentionally hosed down. Spill pads or other spill mitigation devices shall be used during fueling activities. Signs shall be posted at fueling area and throughout the facilities addressing this practice.

xviii. Vehicle or equipment washing shall only occur at the wash pad adjacent to the Maintenance Facility or at the CB-1 reefer trailer wash facility. All other outdoor vehicle or equipment washing which allows wash water to run directly into a storm drain shall not be permitted without an individual NPDES industrial wastewater permit.

xix. Non-operational vehicles or equipment stored for salvage shall be immediately drained of all fluids (Maintenance Facility).

xx. Oil filters shall be completely drained in a designated tank or prior to disposal.

xxi. Used florescent lights shall be gathered and stored at an approved location before disposal. Broken bulbs shall be bagged according to the manufacturer’s recommendations before disposal.

xxii. Individually packaged oils, lubricants and other flammable liquids shall be stored in an NFPA approved, vented, flame retardant storage cabinet to mitigate release into the storm system.

xxiii. Where practicable, the following products shall be recycled:

Degreasers Used oils and filters Anti-freeze Cleaning solutions Vehicle batteries Hydraulic fluid

If products cannot be recycled, properly labeled containers for disposal shall be

Georgia Ports Authority

Page: 20

Garden City Terminal

provided.

b. Maintenance

The Pollution Preventive Plan Team Leader shall itemize all mechanical equipment used by GPA at the GCT. Equipment shall include any stationary or mobile equipment that has the potential to leak petroleum products. Each piece of equipment shall be numbered, and a schedule for inspections and routine maintenance shall be numbered, and a schedule for inspections and routine maintenance shall be developed for each piece of equipment. A list of equipment maintained on-site and inspection schedules are included in the Maintenance Division Policy and Procedures Manual and are incorporated into this plan by reference. In addition, the items listed below shall be included in the aforementioned manual. Changes or revisions to the Maintenance Division Policy and Procedures Manual shall be evaluated for potential impacts to this SWP3.

i. Holding Tanks

These tanks shall be stick dipped daily and the reading recorded in a logbook. When the tank is at 85% of capacity, arrangements shall be made for immediate pump out and proper disposal of the contents. The inspector shall compare daily readings for signs of product loss through tank walls.

ii. Maintenance Facility

The WRS (wash water filtering equipment) shall receive preventive maintenance according to the manufacturer’s requirements for efficient operation. All mechanical components shall be checked for wear and replaced as warranted.

iii. Catch Basins

All stormwater catch basins shall be inspected periodically and cleaned as needed to maintain flow.

c. Spill Prevention and Response Procedures

Spill prevention and response activities shall be conducted in accordance with the GPA GCT SPCC Plan.

In addition, preventive measures shall include the use of automatic shut-off devices on all fuel dispensing nozzles.

The Manager of each functional area above shall assign an individual to be responsible for coordinating and implementing the spill response procedures.

These procedures shall include:

Identification of product spilled

Georgia Ports Authority

Page: 21

Garden City Terminal

Notification of appropriate municipal authorities (police, fire, hospital, treatment plants, etc., if required)

Liquid spills shall be contained with absorbents

Dry product spills shall be controlled by sweeping, shoveling or excavation

Absorbent materials are available in maintenance vehicles and necessary equipment for proper clean-up of spills is on terminal. GPA has contracted with an independent environmental company (Spill Response Contractor) to manage any spill that may occur on terminal.

A spill and leak report form included in Appendix B, Forms shall be completed for each spill and shall indicate the following:

Location of spill

Time, date of spill

Description of spilled product

Cause of spill and estimated quantity

Procedures used to contain and recover spilled product

Method of disposal of recovered product

Suggestions to prevent recurrence

Suggested modification to the spill response plan (if necessary)

After completion, forward the report of the spill to the Team Leader to be added to the file on record at the Maintenance Facility. Reports shall be forwarded within 5 days of event. The Team Leader shall ensure the significant spills are plotted on the Terminal Site Map.

d. Employee Training

Employee Training that is relevant and effective is critical to executing this SWP3. The required training is conducted on the SWP3 annually during January and as per Section 1.2.

4.1Monitoring

GPA has conducted a comprehensive and voluntary stormwater sampling program over the past two years at the GCT. This information is included in Appendix C Sampling Data.

Prior to this permit period, the GPA has been acting in an exempt status and therefore conducted no required sampling. Subject to this new permit and period, the GPA will conduct the following monitoring and sampling program stipulated in the IGP related to the SIC Codes 4491 and 6512 as described in Section 2.1:

a. Annual benchmark monitoring will be conducted for three (3) outfalls where:

i. Locations are shown on the Site Map for the terminal,ii. Industrial activities are similar in nature for each outfall, iii. Discharges are comingles and substantially identical, and

Georgia Ports Authority

Page: 22

Garden City Terminal

iv. Run-off coefficients, pollutant sources, and control measures are similar.

b. Annual benchmark monitoring will be performed for the following constituents:

i. Oil & Grease 15 mg/Lii. Total Suspended Solids 100 mg/Liii. Dissolved Lead Hardness Dependent (Appendix E of IGP)iv. Dissolved Zinc Hardness Dependent (Appendix E of IGP)

c. Annual benchmark monitoring is performed:

i. Once in the first quarter of the calendar year after the permit coverage is granted, and

ii. According to the procedures established in Section 6 of the IGP.

d. Impaired Stream Segment Monitoring is performed for the Savannah River as follows:

i. Monitoring shall conform with the requirements established in Paragraph C.2.2 “Dissolved Oxygen” of Appendix C of the IGP,

ii. Annual benchmark monitoring will be conducted for:

a. Five Day Carbonaceous Biochemical Oxygen Demand (CBOD5)b. Ammonium Nitrogen (NH3-N)

iii. Ultimate Oxygen Demand (UOD) will be calculated using the following:

a. UOD=[(CBOD5 x 1.5) + (NH3-N x 4.570)] andb. Applicable benchmark value for UOD not to exceed 125 mg/L

4.2Inspections

a. Weekly Inspections

Equipment and functional areas shall be inspected and inspection reports prepared in conjunction with Policy No. 400.7 of the Maintenance Division Policy and Procedures Manual. Any pollutant sources discovered should be listed on the Weekly Inspection Report Form (included in Appendix B, Forms), as well as the name of the person responsible for remedial action and a brief description of what action shall be taken. The person taking corrective action shall sign the form stating when the action was completed.

In addition to areas specified in the Maintenance Division Policy and Procedures Manual, the weekly inspection shall include the following:

Catch basins shall be observed for debris build-up, Leaks and drips from parked vehicles and equipments (This includes discharges

from the WRS) Product on pavement

Georgia Ports Authority

Page: 23

Garden City Terminal

Stains on pavement Improper storage of materials Leakage or oil sheen at fuel containment areas

Forward the report of the inspection to the Team Leader for inclusion in the file at the Maintenance Facility. Completed reports shall be forwarded within 5 days of event.

b. Annual Comprehensive Site Inspection

The Annual Comprehensive Site Inspection is a requirement for permitees to comply with the IGP. It is required to be conducted by personnel who possess the knowledge and skill to assess conditions and activities that could impact stormwater quality at the permittee’s facility, and who can also evaluate the effectiveness of the control measures in place. The GPA Engineering Department has assigned this task to their Program Manager, which is essentially an extension of their staff. The inspection is performed under the direct supervision of a licensed Professional Engineer in the State of Georgia and is consistent with O.C.G.A 43-15.

i. The inspection periods for the IGP are as follows:

a. Permit Effective Date – December 31, 2012b. January 1, 2013 – December 31, 2013c. January 1, 2014 – December 31, 2014d. January 1, 2015 – December 31, 2015e. January 1, 2016 – December 31, 2016

ii. This inspection shall be conducted annually in the month of January and must cover all areas of the facility affected by the requirements in the IGP, including the areas identified in this SWP3 as potential pollutant sources where:

a. Industrial materials or activities are exposed to stormwater,b. Any areas where control measures are used to comply with the effluent limits,

andc. Areas where spills and leaks have occurred in the past 3 years.

iii. The inspection must also include a review of monitoring data collected. Inspectors must consider the results of the past year’s visual and analytical monitoring when planning and conducting inspections. Inspectors must examine the following:

a. Industrial materials, residue, or trash that may have or could come into contact with storm water;

b. Leaks or spills from industrial equipment, drums, tanks, and other containers; c. Offsite tracking of industrial or waste materials or sediment where vehicles enter

or exit the site;d. Tracking or blowing of raw, final, or waste materials from exposed areas to

areas of no exposure; e. Control measures needing replacement, maintenance, or repair;

Georgia Ports Authority

Page: 24

Garden City Terminal

f. Equipment needed to implement the SWP3, such as spill response equipment; and

g. EPD’s most current 305(b)/303(d) impaired stream segment list and list of approved TMDLs (found at http://www.gaepd.org/Documents/IndustrialStormwater.html) must be reviewed during each annual comprehensive site compliance evaluation and related to water-quality-based monitoring as required in Appendix C of the IGP and any potential corrective actions. Documentation of the inspector’s findings must be kept with the SWP3 records and signed in accordance with B.7 on the annual report.

iv. Stormwater control measures required by the IGP must be observed to ensure that they are functioning correctly. In addition, if outfalls are inaccessible, nearby downstream locations must be observed.

v. Certification that all discharge points have been visually tested or evaluated at least once each year for the presence of non-storm water discharges other than the allowable non-storm water discharges currently identified under Part 1.1.3 of the IGP. The certification shall include the identification of potential significant sources of non-storm water at the site, the date of any visual testing and/or evaluation, and the on-site drainage points that were directly observed during the visual test.

vi. The corresponding Annual Report shall be submitted no later than January 31st to the GA EPD.

Georgia Ports AuthorityGarden City Terminal

5.0Signature Requirements

“I certify under penalty of law that this document and all attachments were prepared under my direction or supervision in accordance with a system designed to assure that qualified personnel properly gathered and evaluated the information submitted. Based on my inquiry of the person or persons who manage the system, or those persons directly responsible for gathering the information, the information submitted is, to the best of my knowledge and belief, true, accurate, and complete. I am aware that there are significant penalties for submitting false information, including the possibility of fine and imprisonment for knowing violations.”

Chris Novack, P. E. DateDirector of Engineering and Facilities MaintenanceGeorgia Ports Authority

Georgia Ports AuthorityGarden City Terminal

Appendix A

Site Map

Georgia Ports AuthorityGarden City Terminal

Appendix B

Forms:

Spill and Leak Report Form

Weekly Inspection Report Form Facility Maintenance

Weekly Inspection Report Form Equipment Maintenance

Weekly Inspection Report Form Container Operations

Weekly Inspection Report Form Bulk Operations

Georgia Ports AuthorityGarden City Terminal

Spill and Leak Report Form

Location of spill:

________________________________________________________________________________________________________________________________________________________

Date and time of spill:

____________________________________________________________________________

Description of product spilled:

________________________________________________________________________________________________________________________________________________________

Estimated volume of spill:

____________________________________________________________________________

Cause of spill:

________________________________________________________________________________________________________________________________________________________

Procedures used to contain and recover spill:

________________________________________________________________________________________________________________________________________________________

Method of disposal of recovered product:

____________________________________________________________________________

Suggestions to prevent recurrence of spill:

________________________________________________________________________________________________________________________________________________________

Spill and leak report completed by:

____________________________________________________________________________

Date:

____________________________________________________________________________

Georgia Ports AuthorityGarden City Terminal

Weekly Inspection Report Form Facility Maintenance

The Team Leader, or his designee, shall inspect their functional area once a week and shall indicate below any pollutant sources identified, actions to be taken and by whom, and when clean-up tasks should be completed.

Inspection By:_________________________________________________________________

Date:________________________________________________________________________

Areas to be identified during Inspection are:

Storage Areas:________________________________________________________________

Work Areas:__________________________________________________________________

Parking Areas:________________________________________________________________

Disposal Areas:_______________________________________________________________

Other Areas noted or of Concern:_________________________________________________

Pollutant Source(s) Identified (Type):_______________________________________________

Action Required:_______________________________________________________________

Action Should Be Complete by date:_______________________________________________

Action To Be Taken By (Date and Individual):________________________________________

The above actions were performed by me or under my supervision.

Signature:__________________________________________________Date:______________

Georgia Ports AuthorityGarden City Terminal

Weekly Inspection Report Form Equipment Maintenance

The Team Leader, or his designee, shall inspect their functional area once a week and shall indicate below any pollutant sources identified, actions to be taken and by whom, and when clean-up tasks should be completed.

Inspection By:_________________________________________________________________

Date:________________________________________________________________________

Areas to be identified during Inspection are:

Storage Areas:________________________________________________________________

Work Areas:__________________________________________________________________

Parking Areas:________________________________________________________________

Disposal Areas:_______________________________________________________________

Oil Tanks:____________________________________________________________________

Other Areas noted or of Concern:_________________________________________________

Pollutant Source(s) Identified (Type):_______________________________________________

Action Required:_______________________________________________________________

Action Should Be Complete by date:_______________________________________________

Action To Be Taken By (Date and Individual):________________________________________

The above actions were performed by me or under my supervision.

Signature:__________________________________________________Date:______________

Georgia Ports AuthorityGarden City Terminal

Weekly Inspection Report Form Container Operations

The Team Leader, or his designee, shall inspect their functional area once a week and shall indicate below any pollutant sources identified, actions to be taken and by whom, and when clean-up tasks should be completed.

Inspection By:_________________________________________________________________

Date:________________________________________________________________________

Areas to be identified during Inspection are:

Storage Areas:________________________________________________________________

Work Areas:__________________________________________________________________

Parking Areas:________________________________________________________________

Disposal Areas:_______________________________________________________________

Fuel Points:__________________________________________________________________

Fuel and Oil Tanks:____________________________________________________________

Other Areas noted or of Concern:_________________________________________________

Pollutant Source(s) Identified (Type):_______________________________________________

Action Required:_______________________________________________________________

Action Should Be Complete by date:_______________________________________________

Action To Be Taken By (Date and Individual):________________________________________

The above actions were performed by me or under my supervision.

Signature:__________________________________________________Date:______________

Georgia Ports AuthorityGarden City Terminal

Weekly Inspection Report Form Bulk Operations

The Team Leader, or his designee, shall inspect their functional area once a week and shall indicate below any pollutant sources identified, actions to be taken and by whom, and when clean-up tasks should be completed.

Inspection By:_________________________________________________________________

Date:________________________________________________________________________

Areas to be identified during Inspection are:

Storage Areas:________________________________________________________________

Work Areas:__________________________________________________________________

Parking Areas:________________________________________________________________

Disposal Areas:_______________________________________________________________

Fuel Points:__________________________________________________________________

Fuel and Oil Tanks:____________________________________________________________

Other Areas noted or of Concern:_________________________________________________

Pollutant Source(s) Identified (Type):_______________________________________________

Action Required:_______________________________________________________________

Action Should Be Complete by date:_______________________________________________

Action To Be Taken By (Date and Individual):________________________________________

The above actions were performed by me or under my supervision.

Signature:__________________________________________________Date:______________

Georgia Ports AuthorityGarden City Terminal

Employee Training Attendance Form

The undersigned have attended a Stormwater Pollution Prevention Training Session held on:

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

Georgia Ports AuthorityGarden City Terminal

Appendix C

Sampling Data

Georgia Ports AuthorityGarden City Terminal

Appendix D

Annual Comprehensive Site Inspection

Georgia Ports AuthorityGarden City Terminal

Appendix E

Notice of Intent

Georgia Ports AuthorityGarden City Terminal

Appendix F

Permit