Summer 2014 HLC Magazine

-

Upload

fawn-dauer -

Category

Documents

-

view

75 -

download

2

description

Transcript of Summer 2014 HLC Magazine

COMMITTED TO OUR OWNERS’ SUCCESS

HARVEST LAND

Plan Today,Prosper Tomorrow

Summer 2014

Expansion projEcts UndErway in springfiEld

HarvEst Max introdUcEs nEw aErial

iMagEry prodUcts

Comfrey • Morgan • Morton • Springfield • Wabasso

ContentsCheck us out at Harvestland.com

2

Family Corner21

President Obama signed into law the Water Resources Reform and Development

6

The Future of Springfield

New Expansion Underway

8

New Aerial ImageryNew Products

Available

10

12

Dave StukCEO

As I read through the various articles that were submitted for this publication, I can’t help but get excited about what a defining time this is for Harvest Land and the Owners we serve. We have been through a lot these past couple of years and the Harvest Land team has been all about building upon the strong foundation that has existed at Harvest Land for so many years. Please enjoy as your read each article.

The Directors of Harvest Land and AgQuest are a critical part of this amazing company. As such, we are taking the opportunity to highlight one of our directors, John Schwartz. John has been a member of the board since 1997 and is another great example of a loyal and valuable Harvest Land Director. As John mentions in his article, he is part of a large and diverse family operation. Due to this, John brings valuable experience and perspective to the Harvest Land board. He has a way of quickly grasping complex issues, asking the right questions and providing insightful thoughts and ideas. John makes sure that he remains engaged with where Harvest Land is today as well as where we plan to go in the future. As with our other directors, this is not easy as they all lead very busy lives!

We appreciate John’s continued support and involvement as a Director for Harvest Land and AgQuest!

Committed to our Owners’ Success

Board Members

Front Left to Right: Dave Stuk, Roger Kettner, Tim Sullivan, Dave SimonsonBack Left to Right: Cole Trebesch, John Schwartz, Chad Edwards, Terry Flesner, Dan TauerNot Pictured: Bob Liesenfeld.

3

Board Profile

As is so often the case, an invitation from another board mem-ber set John Schwartz on a course of board service that has lasted more than 17 years. “I saw it as a chance to serve and an interesting opportunity to learn more about the cooperative,” John recalls. “It has been a very educational experience.”

John raises crops and, with brothers Joe and Mark, helps manage Schwartz Farms, a family-owned pork production op-eration headquartered in Sleepy Eye. Nephews Tim and Brian are also actively involved.

According to John, board service brings value to both the cooperative and the directors. “As farmers served by the coop-erative, we are able to bring the customer perspective to the decision-making process,” he states. “On the other hand, I’ve learned a number of things through board service that I have taken back to our operation.”

The Value of VisionThe Schwartz family has done business with Harvest Land since 1977, starting with the Morgan Farmers Elevator. John has had a front row seat as the cooperative has evolved.

“We’ve always received excellent service from the cooper-ative,” John emphasizes. “But what I have appreciated most over the years is their forward-thinking approach and ability to see, and take advantage of, opportunities.”

Good management will always be needed, John notes, as the cooperative works to meet the challenges of risk manage-ment and recruiting, training, and retaining good employees. “Those are some of the same challenges we face in our busi-ness, along with market volatility,” John comments.

For his part, John does his best to contribute to the success of the cooperative by working to be a productive board mem-ber. “You have to be open minded and look out for the best interests of all the patrons,” he says. “At the same time, you have to be willing to speak your opinion and not just be a yes man. Ultimately, you have to trust the management you hire.

“I would say that a great management team has been, and still is, Harvest Land’s greatest asset.” John continues.

“Anyone can build brick and mortar, but you need forward-thinking leadership

to achieve long-term success.”

Editor’s note: John and Rosie, his wife of 35 years, have four grown children: Andrew, Daniel, Peter, and Natalie.

John Schwartz

Summer 2014 Harvestland.com

Delivering a Return on Our Relationships

4

Harvestland.com

News from the GM

“Building relationships is about two way communication. The first step is identifying the people,

organizations or groups with whom you should be building those relationships to get the desired return on that relationship”

Despite all the predictions to the con-trary, agriculture remains a relational business. At Harvest Land, we place a high value on relationships—rela-

tionships with our members, first and foremost, but also with our employees, suppliers, strategic partners, and end users. We believe that a good relationship should benefit both parties, generating a positive return on relationship (ROR).

To establish those kinds of successful relationships, we must know what our individual customers want. We believe it is important to remember that growers do business with cooperatives who: • Provide win-win solutions• Are progressive, future-focused, and provide benefits to their operation• Ensure that their operation’s “legacy” is realized • Invest in the relationship and deliver their individual desired ROR

Ideally, we need to serve as extensions of our members’ farming operations and help those members be profitable. The recom-mendations, products, and services that we provide must translate into value for our growers who plow them back into their land. That said, we understand that the concept of value is difficult to determine with a broad-based approach. It is not a mathematical formula. Each of our members has a different perception of value and individual needs, and we believe it is our job to invest in the relationship and address those needs.

Change fuels relationshipsThe charts illustrate that farms and cooperatives have a lot in common! There are fewer of us every year, and we face con-tinued increases in the cost of doing business. It doesn’t take a rocket scientist to realize that the landscape is changing rapidly. We have taken commodity prices to break even, or even a loss, on a per acre basis in less than six months.

Because of this we believe our relationship with our members is more important than ever. Like you, Harvest Land Cooperative is in agriculture all day, every day. We understand that the stakes couldn’t be higher. But we also believe that maintaining strong relationships will help us all work together to capture the oppor-tunities.

To that end, you as member owners have built a company that can address many of your needs:•Agronomy inputs •Feed•Harvest Max – Precision Farming •Grain•Ag Financing and Insurance •Energy•Leasing

Ready to build?One of the greatest features of the cooperative business model is the fact that our customer members are also our owners. Harvest Land is committed to investing in one relationship at a time to achieve the best ROR for our members. If you are not a member of Harvest Land, and the kind of relationship we’ve described sounds like something you’ve been looking for, we would love for you to give us a try. If you are a Harvest Land owner, we would appreciate the opportunity to enhance our relationship.

Thank you for your business, and have an enjoyable summer with family and friends.

Delivering a Return on Our Relationships

5

Operating a business in 1980 vs. 2013

DENNIS SCHREIER GENERAL MANAGER

Your Operation Your Growth Your Cooperative

SPCC CHANGE WILL IMPACT FARMERS

On June 16, President Obama signed into law the Water Resources Reform and Development which included SPCC exemption language for farmers. The new language will increase threshold sizes for abo-veground storage tank regulation at the farm level, and allow more farms to self-certify spill plans compared to current EPA SPCC regulations.

Specifically the language will:

•Exempt all farm tanks of 1,000 gallons or less from the SPCC rule, and farms

with an aggregate tank storage capac-ity of 2,500 gallons or less would not have to comply with EPA’s SPCC rule.

• Temporarily increase the farm exemption threshold up to an aggregate of 6,000 gallons of aboveground oil storage pending the completion of a study looking at a permanent exemption for farms with 2,500 to 6,000 gallons.

• Permit farms to self-certify their spill prevention plans if their aggregate aboveground oil storage is between 6,000 and 20,000 gallons with no individual tank greater than 10,000 gallons and no history of oil spills.

• Require a professional engineer to certify the plan if the farm has an individual storage tank greater than 10,000 gallons, an aggregate aboveground oil storage greater than or equal to 20,000 gallons, or a reportable oil discharge.

Biodiesel BoostThe new Minnesota state statute increasing the minimum biodiesel content to 10% went into effect on July 1. The new law mandates that all #2 diesel sold for combustion engines during the months of April-September contain a minimum of 10% bio-diesel by volume.

From October-March, #2 diesel must contain at least 5% biodies-el. The amount of biodiesel required in a blend of #1 and #2 will depend on the blend ratio of the two products.

Down the road, a proposed mandate further increasing the blend from B10 to B20 will become effective May 1, 2018. Finally, #1 diesel fuel is exempt from blending with biodiesel year-round.

How Long?Speaking of storage, how long can you store diesel fuel without encountering performance concerns? As a general rule, diesel fuel should not be stored for longer than six months. If long-term storage is necessary, avoid temperature extremes by storing the fuel in underground or indoor tanks, and use proper ventilation caps. If the fuel is stored for more than one year, it should be tested before use.

Using the highest-quality diesel fuel will also increase storage life. The storage stabilizer additives in Cenex Roadmaster XL® and Ruby Fieldmaster® reduce the formation of gum and varnish and can double the fuel’s storage life. They also contain demulsi-fiers that isolate water by dropping it to the bottom of the tank, making it easy to remove. Pulling the water out helps prevent the formation of algae in the storage tank.

As always, we’re here to answer any performance or storage ques-tions you may have on B10, so feel free to contact us.

PAT MACHT ENERGY DIVISION

MANAGER

ENERGY

Committed to our Owners’ Success 7

Summer 2014 Harvestland.com

We’re done with our spring work, and thanks to your preparation and cooperation, it was very busy but very smooth. Many of you gave us the two-day lead time that was asked for, and it made a big differ-ence.

Now it’s on to our summer projects. The first project will be our seed warehouse expansion, which will double our capacity. Then we’ll start on the new shop and the chemical shed expansion. Both are need-ed, and will improve, our capacity and our efficiency.

The first of which will eventually be four new 500,000-gallon liquid fertilizer tanks for UAN and starter fertilizer will be built this summer. We plan to automate the new tank for 24-hour loading when the installation is complete.

Finally, we’ll be combining two ground piles into one much larger pile, which will be filled with a large external conveyor. You can see where all the improvements will be located in the aerial shot on page 9.

Of course, we want to get things done as quickly as possible, but the ultimate goal is to have all the new capacities functional in time for the 2015 season.

SCOTT ARNSDORF AGRONOMY OPERATIONS

WORK UNDERWAYin Springfield

tHE fUtUrE of springfiEld• New Chemical Warehouse• New Grain Ground Pile• New Shop Building• Seed Warehouse Expansion• New 500,000 Gallon Liquid Fertilizer

Storage Tank

AGRONOMY

8

Harvestland.com

Springfield Expansion

PLANNING TODAYYields Productivity Tomorrow

Success does not occur without planning. That’s the reason we have invested many hours as a team planning for the current and future needs of your cooperative. One very visible outcome of the planning process is the expansion currently underway at our Springfield terminal, which Scott discusses in his arti-cle. This will help us deliver on our promise to bring your operation value for years to come.

As a team, we also discuss ways in which we can help bring your operation value in the near term. Mid summer may not be the time of year you traditionally think about purchasing crop inputs, but we are. For the past several years, we have tracked the cost of crop nutrients at various points in time, then compared them to the following year’s new crop price to determine if there is a fair value to offer our growers. As a result, we have put together a fall crop nutrient offering which you and your account manager can dis-cuss. This offering gives you the ability to lock in crop nutrient prices and offset this expense with a new crop grain contract.

Broad Spectrum of ServiceWe also invest time considering the best way to bring all of the diverse offerings your cooperative has to bear on your operation, and to deliver value in terms of agricultural inputs,services, and risk management.

The higher commodity prices we have experienced the past few years gave many of you the opportunity to update your equipment and facilities, as well as expand your use of technology. We offer Harvest Max, our technology division, which was created with one purpose: To harness technology in order to maximize yield on every acre in your operation.

Harvest Land agronomists are also licensed crop insurance agents. Because they are closely involved in your operation and understand what it takes to produce a crop from start to finish, they will get you the right coverage.

Your cooperative also offers financing through AgQuest, whose primary objective is to offer you, our owners, agricultural financing. Harvest Land is truly a one-stop shop with a focus solely on agriculture. The profits we produce are returned to you as dividends and invested to help ensure you can remain the best producers in a global market for generations to come.

The depth of Harvest Land’s commitment to the success of your operation is apparent in our diverse offerings. Utilizing these additional offerings and taking advantage of our experienced personnel, who understand the whole of agricultural production, not just a piece, will assist you in making better decisions to improve your operation.

Summer 2014 Harvestland.com10

AGRONOMY

JIM BOYLE CROP NUTRIENT

MANAGER

Harvestland.com

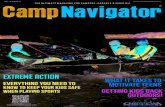

HARVEST MAX INTRODUCESNEW AERIAL IMAGERY PRODUCTS

MATT PIETIG HARVEST MAX

MANAGER

New for the 2014 growing season are a variety of products featuring high-resolution aerial im-agery. These products are available to Harvest Max members, Harvest Land customers, and other interested area growers.

Harvest Max Aerial will feature three different imagery types; red blue green (RBG) images, near infrared (NIR), and a normalized differ-ence vegetation index (NDVI). Multi-spectral imagery can be a great aid in assessing crop damage, including wind and hail damage, fer-tilizer application, and compaction issues, such as weeds and plugged irrigation nozzles.

RBG images are similar to what you’ll see on Google Earth. While RBG light wavelengths are absorbed into the plant and converted to food, NIR wavelengths, which are invisible to the human eye, are reflected by plants. NIR is one of the main image types used to determine crop health.

The NDVI images provide quantitative informa-tion on the health of the crop in the field, and create what is often referred to as an “in-sea-son” yield map. The green colored zones have the most robust growth and volume of vegeta-tion, while the yellow and red sections indicate less vegetative growth. This information can be used to make management decisions on the application of inputs like fertilizer and fungi-cides.

Aerial photos can be taken at any time throughout the growing season, though I recommend flying when corn is around 4-feet tall. By that stage there is enough vegetation to obtain quality images, and applications can still be made to the crop based on what our images show.

For pricing and other information, please con-tact me at 507-430-2127.

Committed to our Owners’ Success 11

AGRONOMY

RBG

NIR

NDVI

SUCCESS STARTS WITH THE SEED

With the challenging 2014 plant-ing season completed, along with our first pass of spraying, it’s time to talk about some new products for 2015. We are excited about the additions to our 2015 lineup that filled a couple of holes we had this past year.

We will be utilizing various plots in our area to examine the per-formance of the key hybrids detailed to the right. This will give

us a better idea of exactly where they fit best on your farm. One of these plots is our Harvest Max plot located near Gilfillan, where we

are conducting studies on hybrid yield by population and hybrid response to soil type. Our interns and account managers take some time each week to evaluate how these hybrids are responding to different yield environments.

For more information on this plot and what’s coming for 2015, contact your account manager and plan on joining us for Plot Day on August 21. Watch for details.

Top HybridsDKC 45-65: •Better emergence than 46-20, medium populations/good ear flex •Shorter plant with good Goss’s Wilt tolerance •Consistent yields across all soils with good standabilityDKC 46-36: •High yielding/“home farm” hybrid •Very good roots and stalks/ shorter plant stature •Fixed ear type/push populations for best performanceDKC 49-72: •Best roots in the lineup/medium populations with good ear flex. •Drier that 48-12 and 49-29 •Excels in your most productive soilsDKC 50-63: •Great for corn on corn/defensive corn •Great Goss’s Wilt score •Fixed ear plant/push populations for best yield performanceDKC 52-84: •Drier and better yielding than other 103 day hybrids •Average drought score/average test weight •Race horse type of corn with average Goss’s Wilt score Croplan 4099: •Top end yield/ Home Farm type of corn •Great Goss Wilt score/good for corn on corn •Push populations for best performanceCroplan 4199: •Handles variable soils very well/better stalks than 4099 •Excellent disease package with good early season vigor •Very good roots with an average Goss’s Wilt scoreCroplan 5146: •Great roots and stalks with good drydown •Average Goss’s Wilt score and stress tolerance •Fixed ear type/ Push populations for best performanceCroplan 5369: •Good yields across all environments •Flowers very early/ handles heat very well •Very good roots and late season drydown NK 42Z: Artesian •Top end yield performance •Very short plant with great drydown •Semi-flex ear to suit most soil types

BRETT BRAULICK SEED DIVISION

MANAGER

Summer 2014 Harvestland.com12

AGRONOMY

Committed to our Owners’ Success 13

AGRONOMYGRAIN

Could this be the best crop ever? That has been the question traders have been throw-ing around all summer, with increasing opti-mism as the growing season has progressed without any major threats. While the USDA pegged the national average corn yield at a projected 165.3 bushels per acre for this year, the consensus has been that this market is trading at 170 bushels or even more. There-fore, the biggest question we’ve been hearing

as of late is when will we hit a bottom?

As you all very well know, the old saying is that rain makes grain. Much of South-central Minnesota saw too

much rain the last couple of months. However, as our crop continues to turn around it is becoming more of a possibility that the rest of the nation’s record yields may outweigh our drowned-out areas, and then some. Many large areas in big corn producing states, including the “I states” of Iowa, Indiana, and Illinois, haven’t seen a bad day since the seed has been in the ground, and long-term forecasts continue to look non-threatening.

As far as conditions are concerned, the good/excellent ratings on corn have been coming back every week around that 75% number, and have even bounced up to a 76% recently. Keep in mind this is a time of year where conditions usually start to decline, and they have yet to do so. Soybeans have followed the same trend, checking in around 73%, and improving along the way. To put that into perspective, the national corn crop looks to be the best since 2004, and the beans the since 1994.

With that being said, it will be interesting to see where technical trading comes into play going forward. As of July 23, corn had a Relative Strength Index (RSI) of 22, and beans scored a 26. Anything under 30 is considered to be an oversold market. However, both crops seem to be breaking through technical barriers daily, and implementing new contract lows. In addition, the funds are sitting long and may need to sell off to a meaningfully short position if record crop is recognized. If the August 12 WASDE & Crop Progress reports come out bearish, a new price environment could very well be realized, deeming the cur-rent technical supports worthless.

As you are probably wondering while reading this, is there any bullish news? Barring an early frost or major weather concern very soon, it isn’t looking good for upcoming prices. At some point, we will hit a level that is positive for demand, but at this point it is hard to tell when that will be. Some analyst are stating that the lows will not be in until after harvest. With that in mind, it is never a bad idea to look ahead to the next growing season and to implement some risk management strategies. Another big crop in 2015 on top of large stocks could slam the door on deferred months’ prices.

Grain Intern Returns There’s a familiar face shadowing Kurt this summer. Grain merchandis-ing intern Jalen Pietig is back for his second year at Harvest Land. The Agricultural Economics major is in the accelerated master’s program at South Dakota State, and felt the experience he gained last summer and winter break was more than enough to bring him back.

“I look forward to building relationships with Harvest Land grain customers moving forward as well as further develop-ing my grain marketing skills,” Jalen says.

KURT SOUPIR GRAIN DIVISION

HEADING INTO A LOWER PRICE ENVIRONMENT

14

•Diversify

•Grow

No doubt farming is cyclical. It wasn’t too long ago the grain markets saw all-time highs only to drop again a few years later to what we have today. Diversifying proved to be a common denominator for everyone.

Let’s face it - Livestock is here to stay. Our infrastructure, labor, processing plants, water and farmland prove the Midwest is great place to be for raising livestock and will be here well into the future. So, would a swine facility fit your future needs?• A child entering the operation• Need to diversify• Current buildings need replacing• Improve efficiencies• Build Equity• Capture available nutrients

15

TURN LOW QUALITY INTO HIGH OUTPUT

If you’re a beef producer interested in making better use of your feed-stuffs, improving feed efficiency, and boosting average daily gain (ADG), then we have just the prod-uct for you. Energy Balancers from QLF® are complete mineral products designed to reduce corn and or oth-er by-products in the ration. When feeding an Energy Balancer product at a 3-pound feeding rate you can replace approximately 1.9 pounds of dry corn or 2.1 pounds of HMC in the ration.

Energy Balancers positively impact the intake and utilization of higher roughage, dry, and starter/grower diets. They are a great tool to use if you have limited corn supplies, are feeding low-quality forages, or in finishing diets.

Consistent Intake Getting your cattle to maintain consistent feed intake on a daily basis is one key to maximizing gain. Energy Balancers promote consistent intake in three ways: 1. Improved Palatability – This is particularly important with low quality forages. Energy Balancers improve the acceptability and intake of these ingredients, improving rumen function. 2. Improve Ration Integrity – Energy Balancers reduce physical separation of the ration, prevent sorting, and encourage uniform intake of all ration components, including additives. 3. Improved Rumen and Animal Efficiency – Energy Balancers provide readily fermentable carbohydrates along with NPN to boost rumen microbial production and efficiency, leading to im-proved animal performance.

If Energy Balancers sound like a good fit for your feeding program, or you want to know more, contact me.

What We OfferFeed isn’t all we do at Harvest Land. No matter what segment of the livestock business you’re in, we offer a variety of services. Swine producers, for instance, can take advantage of these resources:

• Pig Sourcing–If in need of a flow, short or long-term, we have a number of sources we can access for you. While pig supplies are tight at the moment, they may open up as we roll into fall.

• Investor Groups–Some have expressed interest in partnered ownership of farrowing facilities. We have a wide range of connections with like-minded producers.

• Available Finishing Barns – the status of barns is extremely fluid. If you are in need of pig space, let us know.

• New Construction – Looking to replace or expand? Maybe you want a way to bring the next generation into your operation. Whether you want to contract feed or be independent, we can help finance your building through AgQuest and provide the nutritional support.

Fall Harvest PlansWith plenty of moisture, corn is growing rapidly, and soon we will be taking corn silage or high moisture grain. Remember, the cor-rect moisture level is critical, so let me help zero in on the optimum moisture level for each crop. I can chop representative samples to check moisture and map out when to harvest. One gauge for timing of harvest is roughly 45 days after tasseling.

Finally, as commodity prices and feed quality change, let me update your beef cow rations to meet daily nutritional needs and achieve the proper condition score. Our program is simple and effective— let us prove it.

Finally, we have a new and improved grain bank program. Contact me at 507-276-7281 if you are interested in learning more.

JEFF BERDAN ANIMAL NUTRITION

MANAGER

Summer 2014 Harvestland.com

FEED

16

The final school bells have rung, and now it’s time for your children to start enjoying the long sum-mer days that they have waited for so patiently. Children love the hot summer months because it provides them with the perfect opportunity to spend time in the outdoors doing many of theactivities that they love. Whether

swimming, biking, camping, fishing or playing sports, there is some-thing for everyone. It’s important to remember, however, that certain hazards can come along with the

fun. Here are a few of the many important summer safety tips that could help you and your family have a fun and safe summer.

Tick BitesTicks are responsible for a variety of illnesses including Lyme dis-ease and Rocky Mountain Spotted Fever. Here are some ways to protect you and your family:• Wear protective clothing – long sleeves, long pants, tucking pants into socks, especially when, spending large amounts of time in grassy or wooded areas. • Use tick/bug repellent. • Use insect repellent for pets. • Stay in the center of paths, keeping away from overgrown areas, and not sitting directly on the ground.• Perform tick checks on all family members every day. • Be aware of signs and symptoms of tick-related illnesses. • Call a doctor with any concern and questions.

Helmet Safety• An appropriate helmet must be worn whenever a child is “on wheels”. This means bicycles, scooters, skates, rollerblades and skateboards. It’s also a good idea to wear wrist guards when roller blading and skateboarding.• To work correctly, the helmet must fit properly. • Remember, helmets can be life saving and can protect a child from serious injury.

Pedestrian Safety• Teach children to walk, not run, across the street. • Younger children should cross only with an adult or and older, responsible child.• Whenever crossing the street, try to make eye contact with any drivers nearby to be sure they see you.• Teach your children to avoid running out from between parked cars or other obstructions that may limit drivers view. • Use sidewalks whenever possible. • Always hold your child’s hand near any moving or parked car.

Water Safety• Adult supervision is extremely important. Parents need to focus on their children 100% of the time. No distractions! • Practice “touch supervision.” This means, at all times, the super vising adult is within an arm’s length of the child being watched when near or in the water.• Remember, children can drown in many different types of water sources, including bathtubs, toilets, buckets, baby pools, backyard swimming pools, community pools, streams, and creeks.

Sun Protection• Try to avoid sun exposure during peak sun hours (10 a.m. to 6 p.m.)• Sunscreen is a must on both sunny and cloudy days! Look for products with UVA and UVB protection and an SPF of at least 15. • Sunscreen should be applied liberally 30 minutes before going out in the sun, and reapplied every two hours or sooner if swimming, sweating, or toweling off.• Look for and use shade whenever possible.

Dehydration and Heat Related Illnesses• Keeping your child well hydrated is very important,• Do not wait until a child says he/she is thirsty before offering fluids. At this point, he is already dehydrated, so be sure to provide plenty of fluids before going outside, while out in the heat and afterwards, Playing in the hot summer sun means lots of fluid losses, so avoid strenuous activities during peak sun hours. Look for shade and take lots of breaks.• Seek medical attention immediately for any signs of heat related illness.

Remember to keep these tips in mind while you are outside enjoying all that summer has to offer and you are sure to have a fun and safe summer.

SAFETY

Committed to our Owners’ Success 17

AARON GUGGISBERG

SAFETY DIRECTOR

KEEP KIDS SAFE THIS SUMMER

Community

Emergency Safety Day

We would like to thank the parents and their children, volunteers, Morgan Fire and Police Department, Ambulance Crew, K-9 Unit, and local businesses for making this event a great success. We had about 60 children in attendance and they had they opportunity to meet

emergency response volunteers from Morgan. The children also learned about wellness and the importance of eating healthy.

Community FocusSafety is everyone’s business, particularly in a smaller community. Members of our volunteer fire departments go above and beyond to protect area residents, and Harvest Land is proud to support their efforts.

Recent donations to the Morgan and Morton fire departments will help provide firefighters with the tools they need to do their jobs. The Morgan Fire Department received a donation of $35,000 to support the department’s purchase of an updated first responder pumper truck. The new truck arrived June 4 and replaces the old city pumper.

“With limited funds, we depend on donations from local compa-nies and individuals to help with our purchases,” Jason Kevelin, treasurer of the Morgan Fire Department explains. “Without the support of the community and businesses, it would be a struggle to provide quality rescue services to our area.”

Lifesaving equipmentHarvest Land Cooperative also donated a grain engulfment rescue tube to the Morton Fire Department. Every year, rural areas continue to see grain accidents involving injuries and fa-talities. This donation will ensure the proper equipment is in place to increase the chance of survival in the event of an accident.

This grain engulfment rescue tube will help assist first responders in preventing fatalities that result from victims being trapped in grain bins. The tube consists of four interlocking units that form a cylinder, which can be driven into the grain surrounding the trapped individual. When the unit surrounds the victim, it will stop the flow and pressure of the grain. Rescue workers can then remove the grain that surrounds the victim and slowly extract him. Fire department members have received proper training in the use of the rescue tube.

“At Harvest Land Cooperative, we are always thinking safety for not only our employees, but also our area farmers,’ says Harvest Land safety director Aaron Guggisberg. “We want to help the local fire department, as well as agriculture employees, receive the proper equipment and training to deal with unanticipated situa-tions that may occur. This grain engulfment rescue tube is one of many ways we try and help keep everyone safe in the area communi-ties.”

Fire department members Dillon Kuehn & Tony Mages are pic-tured with Harvest Land employees Matt Mude & Aaron Guggis-berg.

Left to Right:Bob Fischer, Curt Meyers, Tony WIldt, Mark Dauer, Duane Jemmings, Scott Welter, Keith Hinrichs, Barb Fischer(City Council Member), HLC Board of Directors: Dave Simonsen, Dan Tauer, Harvest Land Safety Director-Aaron Guggisberg, Harvest Land CEO-Dave Stuk, Lowell Blick (Rural Association Member), Jason Kevelin, Denny Wildt, Mark Jacobs, & Keith Christensen.

“We want to help the local fire department, as well as agriculture employees, receive the proper equipment and training to deal

with unanticipated situations that may occur.”

Community

19

With the complexities involved in modern agricultural produc-tion, farmers need to understand every aspect of their opera-tion to make informed decisions. So do those they work with.

That’s why it makes so much sense to work with a collection of ex-perts who understand

every part of your farming enterprise and work together as a team, rather than with individuals who only see a small part of the big picture. Bringing the team approach to our customers is what Harvest Land is all about.

Under One RoofAs a business relationship manager, I’m a point person who can put a customer in contact with any other member of the Harvest Land and AgQuest team. Whether they are looking for information or assistance with financing, agronomic inputs and services, feed, insurance, energy, or any other aspect of agricul-tural production and risk management, we have the expert.

By doing business with us, you place a team of advisors at your disposal. All of us are interested in establishing long-term relationships and really getting to know the people and the operations we work with. That makes the job easier for every-one, and yields better results for our customers and for us.

In addition to our expertise, there is also the advantage of convenience. It’s pretty nice to line up your inputs in one office, then walk across the hall and finance those inputs. That also makes the process of loan processing and approval much more efficient.

The AgQuest team at Harvest Land consists of Melissa Robert-son and I, who keeps track of us, serves as a constant point of contact, and is laser focused on customer service.

Don’t go at it alone. If you’d like to put a team of experts to work for you, talk to Melissa, any Harvest Land account manag-er, or myself.

For further information or questions please contact Kari Scholtz @ 507-430-9094; [email protected] or Melissa Rob-ertson @ 507-723-7378; [email protected]

AgQuest

IT TAKES A TEAM.. AND WE’VE GOT ONE

Our Newest Business Relationship Manager

Though she’s new to the position, Kari Scholtz is an old hand when it comes to AgQuest and Harvest Land. She’s worked with us for five years, joining the team after working for 15 years in a local community bank. Kari also understands the farmer’s point of view, as she and her husband raise corn, beans, and canning crops and Angus Cow/Calf Operation near Comfrey Minnesota.

“I’m excited about my new position and the chance to get out and work one-on-one with producers,” Kari states. “I know it takes time to build a relationship and reach the point where I’m up to speed on their operation and they are comfortable with me. But I’m ready and willing to roll up my sleeves and get busy.”

KARI SCHOLTZAGQUEST BUSINESS

RELATIONSHIP MANAGER

20

ACREAGE REPORTING DEADLINE NEARS

While the growing season is well underway for most farmers, there are an unfor-tunate few who still haven’t turned a wheel. That’s why we have prevented plant-ing coverage, as a part of your crop insurance policy, because we just don’t know what Mother Nature has in store for us from year to year. That’s also the reason crop insurance is one of the best risk management tools available.

We are under the same rules and regulations as we have been the last couple of years. If we have a prevent plant indemnity over $200,000 the insurance company will need to complete a 3 year production review. The review will provide hard records to show final bushel records for the last 3 years. This will need to be completed by the insurance company and finalized prior to receiving any prevent plant indemnities. If this pertains to you, please give us a call and we can show you the detail of what needs to be done and we can set up your policy to start the process.

If you have had prevented planting claims in the past, you may want to consider the prevented planting buy-up option for the 2015 crop year. This allows you to buy, for a small charge, 5%-10% more coverage in addition to the 60% coverage already on your policy.

Make the CallIn the event you have hail or winds that affect your crops, call and let your agent know so a notice of probable loss can turned in. Remember, too, that stand-alone hail applications can still be written at any time prior to damage to the crop until approximately August 1.

AgQuest had received a fair amount of phone calls regarding replanting. If you had a replant claim, the most important thing to do was to call. A claim was to be turned in and the adjuster to release those acres prior to replanting. To qualify for a replant claim, you would need to replant at least 20 acres or 20% of a unit back to the same crop. Replant claims will not be paid out until the acreage report has been completed. The acreage reporting date was July 15, so once your acreage report has been processed you will be receiving your qualified replant payments.

The corn replant payment calculation is 8 bushels x $4.62 x share, soybeans are 3 bushels x $11.36 x share, and sugar beets are $80.00/acre.

Your crop insurance policies will be billed on August 15. To avoid additional interest on your policies payments should be postmarked on or before September 30. Make sure that your postmark date is legible and timely to avoid additional interest. If your payment is not postmarked on or before the last day, 1.25% interest will attach each month the payment is not received.

SilageIf you will be chopping for silage, please contact your AgQuest Agent prior to your start date, so we can take the proper steps according to your policy to get a claim turned in and have an adjuster contact you.

For more information contact your local agent @ 866-259-3666.

Finally, do you have a binder with details on your property and casualty policy, but aren’t completely certain what all that documentation means?

Don’t worry...our AgQuest P & C agents are available to help answer your questions or ask for a quote. Contact Tim @ 612-756-2903 or Amber @ 320-894-0663.

AgQuest Insurance Agency is an equal opportunity provider.

KATHY MAINERAGQUEST INSURANCE

OFFICE MANAGER

Comitted to our Owners’ Success 21

AgQuest

WHAT’S COOKING?We found this delicious recipe online. But we know that our readers can really cook and are just as creative as anyone on the Web, so we want to hear from you. If you have a do-it-yourself project or

favorite recipe you’d like to share, send it to [email protected]. We’re looking for the best from the country to share in our next issue of Harvest Land magazine.

Upcoming Area Events:Buttercorn Days.....August 15-16Renville County Fair.....August 15-17Harvest Land Plot Day.... August 21

Summer 2014 Harvestland.com22

Family

Harvestland.com

Quick Icebox Sandwiches Recipe

Mix pudding and milk according to package directions; refrigerate until set. Fold in whipped topping and chocolate chips. Place 24 graham crackers on a baking sheet; top each with about 3 tablespoons filling. Place another graham cracker on top. Wrap individually in plastic wrap; freeze for 1 hour or until firm. Serve sandwiches frozen. Yield: 2 dozen.

23Committed to our Owners’ Success

•1 package (3.4 ounces) instant vanilla pudding mix

•2 cups cold milk

•2 cups whipped topping

•1 cup (6 ounces) miniature semisweet chocolate chips

•24 whole graham crackers, halved

ww

Meet the Interns

In Order: Parker Kretsch, Andrea Muller, Jalen Pietig, Emma Christensen, Ryan Beyer, Whitney Wills, Jonathon Tauer, Kolton DeBerg, Kyle Veenstra

•“The employees at Harvest Land are a joy to work with and I love the environment of working here.” Whitney Wills

•“I look forward to continue to meet new customers and take in as much information as possible before I head back to school this fall.” Jalen Pietig

•“Getting to know the growers that I have worked with throughout my internship has been a wonderful experience as well.” Emma Christensen

•“The way everyone works together makes the process of each department flow smoothly and get work done together.” Ryan Beyer

•“I've enjoyed learning more about the different chemicals and applying what I've learned at school to this internship.” Andrea Muller

Summer 2014 Reflections

24

•“Interacting with coworkers, growers, and general operations at Harvest Land has been enhanced this summer as we are all in our second year as interns.” Parker Kretsch

•“Working in the Marketing and Media Department has been a fun experience and I can’t wait to take the knowledge I’ve learned to school this fall.” Kolton DeBerg

“Tell me and I’ll forget; show me and I may remember; involve me and I’ll understand.”

Although we have had to fight the weather to get in the fields thus far, the interns in the Harvest Max program have had a busy summer. Interacting with coworkers, growers, and general operations at Harvest Land has been enhanced this summer as we are all in our second year as interns. We have been busy doing anything from delivering products to figuring out what diseases we are seeing in the soy-beans. Through results at the plant diagnostic lab at South Dakota State University, we found that most of the dead spots in the beans are a disease called rhizoctonia, caused by warm and moist soils. We’ve looked at bean treatment check strips and the stand is almost always noticeably better. On rainy days we have time to work on our individual projects such as fertility management or weed control and chemis-try. When scouting for weeds we found that the pre emerge herbicides worked well this year.

Several other trials we have tended to over the summer are showing positive results. We have taken many side by side pictures of trials such as Ascend applied versus no Ascend, starter, N-serve, and other forms of fertilizer trials and applications. The visual is definitely present; it will be interesting to see what happens in the fall. Even with the huge drowned out pothole at our Harvest Max Plot at the corner of highway 67 and county road 13, we have been able to get quality pictures of the different varieties and populations. Towards the end of our summer internship we will be busy getting field signs up, cal-culating fertilizer recommendations, soil sampling, scouting for aphids and corn rootworm, and various other things. The interns appreciate the opportunity to have this experience at Harvest Land Coop. We hope our hard work turns into valuable information for our growers in the future.

-Matt Pietig- Harvest Max Manager

Intern-a student or trainee who works, sometimes without pay, at a trade or occupation in order to gain work experience.

25

•Improve

•Expand

At Harvest Land and AgQuest we are here to help.

Our program options reach different levels of production•Independent Operators – Pig sourcing and networking •Contract Growers – Lower risk with other viable swine producers!

Not only swine buildings but cattle too! We’re not limited to hogs. Our support can help you with other plans in livestock production.

Contact: Jeff Berdan @ 507-276-7281 or Kari Scholtz @ 507-430-9094