SUMA Rührtechnik GmbH Martinszeller Str. 21 … · 1 2 0 1 1 SUMA Rührtechnik GmbH Martinszeller...

-

Upload

vuongkhanh -

Category

Documents

-

view

254 -

download

1

Transcript of SUMA Rührtechnik GmbH Martinszeller Str. 21 … · 1 2 0 1 1 SUMA Rührtechnik GmbH Martinszeller...

1

2

0

1

1

SUMA Rührtechnik GmbHMartinszeller Str. 21DE-87477 Sulzberg

Telephone +49 83 76 / 92 131-0Fax +49 83 76 / 92 131-19

E-mail: [email protected]

PRICE LIST

Agitators for Liquid Manure & Biogas

valid from April 1, 2011to December 31, 2011

Our delivery, payment and

warranty terms apply for sales.

Subject to design changes.

This price list supersedes

all previous ones.

All prices are without statutory VAT.

AG

RA

R

2

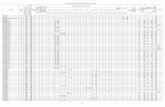

Price for GIANTMIX Z3 with UNIVERSAL HITCH FRAME, support, Wedi standard seal and propeller

Price inEUR

PIPE LENGTH

3.50 m 4.00 m 4.50 m 5.00 m 5.50 m

Z3 HYU 2,512.00 2,603.00 2,638.00 2,673.00 2,769.00

Z3 WEU 3,058.00 3,149.00 3,184.00 3,219.00 3,315.00

Price for TROLLEY / Giantmix Z3

Type Price in EUR

Trolley Z3 189.00

Giantmix Z3 HYUThe Giantmix Z3 HY with universal hitch frame U is a tractor driven agitator that is known for by its ease of handling, smooth running components and high efficiency. The bearing technology (taper roller bearing) allows the transfer of the thrust forces to the propeller shaft (galvanized, Ø100 x 3.0 mm) or frame. This allows our mixer to operate at 1000 rpm. Additionally our design is modular which makes it is easy to access all internal com-ponents for parts replacement.

The connection to the tractor is made via a hitch and lower link.

Giantmix Z3 WEUThis model is same as the Giantmix Z3 HYU and has a reversing gear unit (WE) for two rotational direc-tions. This is particularly advan-tageous in the case of difficult applications and square contain-ers. The rotation direction can be changed by reversing the universal drive shaft connections.

Trolley for the Giantmix Z3 The Giantmix Z3 with universal hitch frame can be easily pushed by hand with the aid of the trol-ley. Particularly advantageous, if for example the Giantmix is to be stored in an equipment shed.

PropellerA selection of galvanized push and pull propellers in various sizes (see page 7) are available.

Power requirement at 1000 rpm.:Ø 480 mm (approx. 60 HP / 44 kW)Ø 520 mm (approx. 82 HP / 60 kW)Ø 560 mm (approx. 98 HP / 72 kW)Ø 580 mm (approx. 120 HP / 88 kW)

GIANTMIX Z3 HYU / Z3 WEU for open and closed containers

Z3 HYU in an open pit Z3 HYU in a covered pit

Giantmix Z3 HYU with trolley

Giantmix Z3 WEU

AG

RA

R

3

Price for Giantmix Z3 HY/ FR for stationary installation:

Type Price in EUR

Giantmix Z3 HY with 2.0 m pipe (Wedi) and propeller D560 galvanized

1,541.00

Giantmix Z3 HY with 2.0 m pipe (GLRD) and propeller D560 in V2A

2,669.00

Giantmix Z3 HY with 2.0 m pipe (Wedi) and propeller D560 in V2A

2,200.00

Giantmix FR 3 stationary 11 kW with 2.5 m pipe (GLRD) and propeller H580 in V2A

6,756.00

Giantmix FR 4 stationary 15 kW with 2.5 m pipe (GLRD) and propeller H620 in V2A

6,918.00

Rubber /compression seal Ø 200 with galvanized compression plates 298.00

Installation support with clamps, galvanized 440.00

Console for installation with clamps, galvanized (see illustration) 407.00

Oil / surge tank for checking the sealing 141.00

Stationary InstallationThe stationary installation of the Giantmix Z3 HY through the con-tainer wall is an economical alterna-tive for agitating in elevated liquid manure tanks. A tapping drill hole with Ø of 200 mm is required for installation with concrete contain-ers. This tap drill hole should be on the same level as the power take-off on the tractor and be offset sideways by 10° - 25° away from the center depending on the container size.

SealingBearing housing seal either WeDi (shaft seal rings) or GLRD (mechanical seal SiC-SiC).

The pipe sealing ring is made of a special rubber compound (EPDM 70 shore) with compression plates. The agitator is stabilized with a sup-port structure, which is fixed out-side the elevated tank by means of a foundation.

For seal monitoring the use of an oil surge tank is recommended.

Max installation depth for the agita-tor and compression seal is 6.0 m.

Rubber compression ring seal Ø 200

GIANTMIX Z3 / FR installed stationary for elevated tanks

Giantmix FR with installation console and rubber compression seal

Unilateral wide-angle drive shaft

Price for “Walterscheid” drive shaft for Z3 and Z4

Type Price in EUR

Unilateral wide-angle drive shaft WWE 2480 (L=860) 96 kW (130 HP) at 1000 rpm

792.00

Normal drive shaft W 2400 (L=860)96 kW (130 HP) at 1000 rpm

399.00

Normal drive shaft W 2500 (L=1010)162 kW (220 HP) at 1000 rpm

691.00

Giantmix Z3 HY with installation console and rubber compression seal

AG

RA

R

4

Guide RailThe guide rail with wall cage can be permanently installed in a slalom system.

The wall cage is attached to the channel wall aperture (75 x 75 cm). The Giantmix with the 70 cm wall frame can be slid into the guide rails. The pipe is secured by a gripper clamp and the wall frame is secured to the wall cage.

Versions available:•GIANTMIX Z3 HY for one rota-

tional direction, mobile or sta-tionary installation. Available with push or pull propellers Ø 520 or Ø 560 mm.

•GIANTMIX Z3 WE with reversinggear unit for optional bidirectional rotation.

•GIANTMIX MZR with a drivemotor, PTO stub and H580 propel-lers (MZR3) or H580ES (MZR4) for optional electric or tractor-hitched operations. Optionally available are automatic or manual con-trol system (page 12). Includes the connecting cable 7x4+2x1 mm².

Additional FeaturesFor the stationary use of the Giant-mix Z3 HY or Z3 WE the gripper clamp should be used for fastening. Suspension grommets/eyes are pro-vided for easy transport e.g. with front loader (see page 7). The Giant-mix MZR also contains one clamp-ing and suspension grommet for fastening.

For the mobile use of the Giantmix Z3 HY or Z3 WE, an optional uni-versal hitch frame is available for attaching to the tractor (see page 6).

Giantmix MZR

Support yoke Guide rail Wall cage

Gripper clamp Suspension grommets / eyes Large agitator support

Wall frame

GIANTMIX Z3 / MZR WITH GUIDE RAIL for ring and slalom channels

GIANTMIX (with Wedi standard seal, enforced support, wall frame, propeller), MZR design has a 7 m connecting cable, however no switch.

Price inEUR

PIPE LENGTH

4.00 m 4.50 m 5.00 m 5.50 m

Z3 HY 2,114.00 2,130.00 2,166.00 2,262.00

Z3 WE 2,660.00 2,676.00 2,712.00 2,808.00

MZR 3 (11 kW) 6,066.00 6,106.00 6,137.00 6,235.00

MZR 4 (15 kW) 6,227.00 6,267.00 6,298.00 6,396.00

Guide rail, cpl (galvanized)

732.00 758.00 785.00 812.00

AccessoriesforGIANTMIX EUR

Manual reversing star-delta switch (for MZR) 549.00

Soft start controller with timer up to 15 kW (for MZR) 2,055.00

Oil / surge tank for checking the sealing 141.00

Surcharge for sealing with mechanical seal SiC/SiC 572.00

Surcharge for model of agitator pipe, propeller, wall frame with stainless steel support (1.4301 / V2A)

1,703.00

Surcharge for model of guide rail with stainless steel wall cage (1.4301 / V2A)

1,032.00

AG

RA

R

5

Function of Ring and Slalom Systems

Outside wall

Stable floor

Cellar depth

60 80300

20 40 60 80400

Example for 5.0 m agitator length

Lintl

Shaft length

40

20

40

60

80

-100

-200

20

40

60

30

0

Depression

0

Recommended installation dimensions for guide rail with wall cageShaft height Shaft length Agitator pipe length

1.80 m 3.55 m 4.00 m2.00 m 4.00 m 4.50 m2.20 m 4.45 m 5.00 m2.40 m 4.90 m 5.50 m

ApplicationA closed flow channel system for liquid manure ment to flow through the agitator in the enclosed system.

Initially, after switching on the agi-tator, the level drops at the lead-ing edge of the propeller and rises somewhat on the other side, creating a level difference up to 40 cm ide-ally. Due to the flow and the gradient the floating and sinking layers of the manure make their way to the agita-tor for churning.

Thick liquid manure does not flow very well and has a higher flow resistance, that’s why a gradient is needed. On the contrary, thin liquid manure makes it harder to create and maintain a gradient. When con-structing a flow channel, please note that narrow long channels are more beneficial than wide and short ones.

However depending on the consis-tency of the liquid manure (high water content, a lot of litter / fodder residues), it may not be possi-ble to maintain a gradient at large depths due to the consitency of the manureö. Often the flow will occur at the center, thus floating layers are inadequately churned. This can be avoided by stirring the manure on a regular basis.

For a chanel depth of approx. 2.10 m a depression of about 30 cm is rec-ommended, in order for mixing to occur when levels are low.

Channel arrangement

Giantmix MZR Giantmix Z3 HY

AG

RA

R

6

Universal hitch frame for Giantmix Z3

Type Price in EUR

Universal hitch frame (LG=100) for pipe length of 3.50 m 755.00

Universal hitch frame (LG=125) for pipe length of 4.00 m 772.00

Universal hitch frame (LG=150) for pipe length of 4.50 to 5.50 m 790.00

GIANTMIX Z3 Standard Version and Universal Hitch Frame

Giantmix Z3 HY basic version

Universal hitch frame for Giantmix Z3

Giantmix Z3 HY / Z3 WEGalvanized agitator pipe (Ø 100 mm), with multiple-bearing drive shaft, coupled on both ends. The propeller thrusting force is absorbed by two taper roller bearings. The bearing housing is flanged to the drive shaft as a complete unit. The intermediate bearings in the pipe are made of sin-tered metal. The drive head (power take-off connection) is also flanged to the shaft and contains double bearings.

Standard sealing with high qual-ity shaft seals (Wedi) that rotate on a hardened bushing prevents shaft wear. Galvanized power take-off guard and agitator are supported with fixing clamps.

The propeller is screwed onto the hub to ease replacement. The Giant-mix Z3 HY is designed to rotate one direction. The Giantmix Z3 WE has a reversing gear unit (WE) for optional pull and push agitation. The rotation direction can be changed by reversing the universal drive shaft connections.

An optional mechanical seal (GLRD) is available for the Z3 with high grade SiC/SiC ceramic rings. Pricing upon request.

Universal hitch frameThis frame is for universal use of your Giantmix Z3 pipe. The base frame is made of galvanized rectangu-lar tubing 80/40/4, with an eccen-tric bolt (with safety chain) and arrester cable. The cross shaft con-nection is screwed to the base frame and adjustable for different lower link lengths. The supporting yoke can be adjusted to the different tractor sizes (hitch - lower link) and secured on the base frame with socket pins.

Giantmix Z3 WE basic version

Standard / Basic Pricing of GIANTMIX Z3 (without frame, support and without propellers):

Price inEUR

PIPE LENGTH (galvanized)

3.50 m 4.00 m 4.50 m 5.00 m 5.50 m

Z3 HY (Wedi) 1,351.00 1,426.00 1,443.00 1,478.00 1,574.00

Z3 WE (Wedi) 1,897.00 1,972.00 1,989.00 2,024.00 2,120.00

Surcharge EUR

Mechanical seal SiC-SiC instead of standard seal 572.00

AG

RA

R

7

Pull propeller S Push propeller D High-performance propeller HD

Propeller for Giantmix

Price for type Galvanized steelHardened or stain-

less steel (V2A)Power require-

ment at 1000 rpm.

D/S 480 285.00 637.00 44 kW (60 PS)

D/S 520 285.00 637.00 60 kW (82 PS)

D/S 560 285.00 637.00 72 kW (98 PS)

HD 580 299.00 651.00 88 kW (120 PS)

HD 620 310.00 662.00 100 kW (136 PS)

HD 660 325.00 677.00 130 kW (177 PS)

HD 700 363.00 715.00 160 kW (218 PS)

Agitator Blades and Accessories for Giantmix Z3

Individual positions for Z3 accessories

Type Price in EUR

Agitator support Z3 (galvanized) 133.00

Agitator support Z3, reinforced for wall frame (galvanized) 186.00

Wall frame Z3 70 x 70 cm suitable for support Z3, large (galvanized) 230.00

Protective ring Z3 Ø72/Ø62 cm (galvanized) 281.00

Gripper clamp Z3 (galvanized) 88.00

Suspension grommet Z3 (galvanized) 41.00

Protective ring Gripper clamp Wall frame 70x70 cm - Ø 60 cm

Support Suspension grommets / eyes Z3 support reinforced for the wall frame

PropellersWe have different propeller sizes for the Giantmix Z3, intended for dif-ferent applications. Each propeller is designed for pull (S) or push (D) agi-tation. When considering a type S or D propeller remember that maxi-mum mixing is only achieved in the intended direction. Pull propellers are only available up to 560 mm dia. In addition, we have a high perfor-mance propeller (H), that can only be used for push agitation due to its shape. For upgrading D-propellers to H-propellers an extended support may be necessary.

For abrasive applications, the propel-lers can also be provided in hardened design, with an up to 3 times great-erdurability in comparison to the gal-vanized design.

The listed performance data in the table are approximate values for thin liquid manures. This can be up to 25 % less for thick liquid manures.

SupportsDepending on the application the Giantmix Z3 can be fitted with the following accessories:

•simplesupport-forregularuse

•reinforcedsupport- forslalomorregular use

•wallframe-forslalomapplications

•gripperclamp-forfixingGiantmixto support bracket at guide rail

• suspension grommets - help withtransport

• protective ring - all around pro-tection for propeller and for use in concrete cones

AG

RA

R

8

GIANTMIX Z4 HY complete assembly including propeller, universal hitch frame, support and 2 hydraulic cylinders, without drive shaft:

Type Price in EUR

Z4 HYU 5.0 m (Wedi) 4,264.00

Z4 HYU 6.0 m (Wedi) 4,358.00

Z4 HYU 7.0 m (Wedi) 4,757.00

Surcharge for mechanical seal SiC-SiC instead of standard seal 572.00

Accessories

Hydraulic pivoting cylinder 782.00

Surcharge for reverse gear unit (see notice) 571.00

Protective ring Z4 Ø92/Ø80 cm complete for 120 pipe (galvanized) 439.00

Wall frame Z4 80x80 cm complete for 120 pipe (galvanized) 702.00

Wall frame Z4 70x70 cm complete for 120 pipe (galvanized) 599.00

Agitator support Z4 normal (contained in the series, omitted in case protective ring or wall frame is used.)

193.00

Giantmix Z4 HYU with universal hitch frame

Giantmix Z4 HYU with three point frame for open and closed pits

Giantmix Z4 HYU with universal hitch frameThe Giantmix Z4 HYU is a robust tractor driven agitator (piping Ø 120 mm) that is designed for use in open and closed pits. The matching design of the universal hitch frame provides absolute ease of operation. The advantages of the universal hitch frame lie in the combination of the 3-point hitch, the robust and proven design form and two parallel hydrau-lic cylinders for reach.

The Giantmix Z4 is available with two different sealing systems. The model with the shaft sealing rings (Wedi) is recommended for occasional use. For longer operating times the mechani-cal seal (GLRD) with SiC/SiC ceramic rings is recommended.

For closed pits we have an optional pivoting cylinder and latch.

Minimum opening on closed pits is 80x120 cm for 6.0 m pipe length or 80x150 cm for 7.0 m.

As a further option there is a revers-ing gear unit for changing the rota-tional direction for push and pull agitation.

PropellerA selection of galvanized propellers in different sizes are available.

Power consumption at 1000 rpm.:

Ø 560 mm (approx. 98 HP / 72 kW)

Ø 580 mm (approx. 120 HP / 88 kW)

Ø 620 mm (approx. 136 HP / 100 kW)

Ø 660 mm (approx. 177 HP / 130 kW)

Giantmix Z4 at an open pit Giantmix Z4 at a closed pit with pivoting cylinder

AG

RA

R

9

Giantmix Z6 HYU The Giantmix Z6 has been built for high power tractors that agitate open pits and sludge lagoons with harsh operating conditions. The Giantmix Z6 was developed for tractors range with 240 HP and above, for performance, durability and a longer life.

Agitator pipe Agitator pipe (Ø 193.7 x 6.3 mm) galvanized, with multiple-bearing drive shaft Ø70 mm, coupled at both sides. The propeller thrusting force is absorbed in the bearing housing (propeller side) by two 60/130 mm taper roller bearings. The drive shaft is sealed using a mechanical seal with SiC/SiC ceramic rings. The bear-ing housing is flanged to the drive shaft as a complete unit. The drive head with power take-off connec-tion 1-3/4” (6-splines) is flanged to the shaft and has two 60/130 mm grooved ball bearings. The Giantmix Z6 HY is designed to rotate in one direction.

Universal hitch frameBase and hitch frames made from 120/60/6 galvanized rectangular tubing with two 90/40 hydraulic cyl-inders with a decline up to 45°.

PropellerThere is a choice of Ø 700MS and Ø 850MS, high performance push propellers, with average pitch.

Power requirement at 1000 rpm.:

Ø 700 mm (approx. 218 HP / 160 kW)

Ø 850 mm (approx. 272 HP / 200 kW)

GIANTMIX Z6 HYU complete assembly including propeller H700, three point frame, hydraulic cylinder, support, without drive shaft:

Type Price in EUR

Z6 HYU 7.5 m 10,232.00

Z6 HYU 9.0 m 11,926.00

Accessories Price in EUR

Normal universal drive shaft W 2600 (L=1210) 1-3/4 6-key

193 kW / 260 HP at 1000 rpm2,003.00

Protective ring Ø120/90 cm 1,189.00

Propeller, H850MS, galvanized 462.00

Giantmix Z6 HYU with universal hitch frame for open pits and containers

Giantmix Z6 for manure management open pit

Giantmix Z4 with universal hitch frame and protective ring

AG

RA

R

10

Standard models of OPTIMIX with propellers, motor bracket for 80-/100 mm square pipe, 10 m connection cable, without switch.

Type Power rpm Propeller Price in EUR

U 75-1450 7.5 kW 1 450 Ø 300 mm 3,820.00

UG 75-435 7.5 kW 435 Ø 480 mm 4,958.00

UG 75-380 7.5 kW 380 Ø 520 mm 5,340.00

UG 110-380 11 kW 380 Ø 580 mm 5,941.00

UG 150-380 15 kW 380 Ø 620 mm 6,050.00

Optimix ECO in the agricultural use version:

ECO 75-380 7.5 kW 380 Ø 520 mm 4,195.00

ECO 110-380 11 kW 380 Ø 580 mm 4,958.00

ECO 150-380 15 kW 380 Ø 620 mm 5,177.00

Accessories EUR

Manual star-delta switch for 7.5 / 11 / 15 kW 549.00

Start-up control with timer up to 7.5 kW 1,763.00

Start-up control with timer up to 15 kW 2,055.00

V2A cable clip for cable guide on hauling cable, price per piece 19.00

Connecting cable 7x4 +2x1 mm² per additional meter 19.00

Price for propeller in stainless steel or hardened, refer to page 7

Standard versionSubmersible motor-driven agita-tor (IP68 -10 m) with temperature sensors in the windings and sep-arate oil baths for motor, gear unit and drive end. The winding and rotor are optimally cooled by the oil bath inside the motor; which conducts the heat evenly throughout the hous-ing. Each compartment is seperated by built in safety seals to prevent contamination.

Running smoothness and agita-tion performance are optimized by the bearing design. The axial force placed on the propeller are managed by 2 taper roller bearings, leading them thru the agitator housing.

The standard model is designed for a 400 V and 50 Hz mains supply. Special models are available upon request.

Motor bracket with 4-roller guide system suitable for an 80 or 100 mm square tube, 10 m connecting cable (7x4+2x1 mm²). A switch is not included.

AccessoriesSoft start controller with timer auto-mates the agitation intervals. Manual switch box also available for manual star-delta operation.

OptimixTypeUG(ATEXZone2)with motor support V2A (housing GGG40)

Submersible motor-driven agitator Optimix Type UG and Type ECO (agricultural model)

Optimix Type ECO with 4 roller guidesonly for agricultural use (steel housing

Soft start controller with timer

AG

RA

R

11

Guide Mast EV 1The V2A guide mast 80/80/4 is clamped to the top and screwed to the bottom of the concrete tank with a (galvanized) bracket. The guide mast is permanently attached and the submersible mixer is pivot-able up to 60°. The removable gibbet with cable winch is installed above on the guide mast. This means that the weight of the motor load is on the pit floor and not on the container wall. The submersible motor is low-ered on the guide mast using V2A Ø 6 mm cable.

Guide Mast EV3Same as EV 1, however it is is in stainless steel, intended for a dowel fixing on concrete tank wall.

Guide Mast EV4Same as EV3, except with roof sup-port for fixing on concrete roofs.

Guide Mast EV5Floor support in which the V2A guide mast 100/100/4 is inserted and guided by a V2A wall bracket at the top. The lifting boom is mounted to the outside of the container wall so it can be rotated. This version can also be used on containers with foil covers. Side swivel range of the sub-mersible motor is approx. 60°. Stan-dard model for up to 6.0 m container depths. Cable routing is placed on rear side of guide mast.

AccessoriesWork platform 80 x 120 cm suitable for open and foil covered concrete containers.

Working platform to dowel fix to the concrete container

Optimix with EV5, cable routing on the square piping and working platform with soft start controller

Optimix with EV5 and cable routing

Guide Mast EV for Optimix UG, ECO and 2A

Optimix with EV3 dowel fixing

Optimix with EV4

Suspension mounting frame “EV” for SUMA submersible motor-driven agitators

Type Guide mast Price in EUR

EV1 (for clamping) for 4.0 m container depth 80x80x4 2,573.00

EV3 (for dowel fixing) for 4.0 m container depth 80x80x4 2,300.00

EV4 (ceiling bracket) for 4.0 m container depth 80x80x4 3,129.00

EV5 (for dowel fixing) for 6.0 m container depth 100x100x4 3,696.00

Type EUR

Surcharge per 0.5 m for guide mast 80x80x4 to 6.0 m 72.00

Surcharge per 0.5 m for guide mast 100x100x4 to 8.0 m 97.00

Galvanized work platform for concrete container 1,238.00

AG

RA

R

12

Optimix ECO with PVC frame for stationary use in the slalom system

OPTIMIX ECO with galvanized propellers, 10 m cable, complete with PVC seal plate (98 cm x 2.0 m) - without controller

TYPE Price in EUR

ECO 75-380 / stationary (7.5 kW) 5,665.00

ECO 110-380 / stationary (11.0 kW) 6,426.00

ECO 150-380 / stationary (15.0 kW) 6,647.00

Z rails V2A (set with VA-dowel) 367.00

Manual star-delta switch for 7.5 / 11 / 15 kW 549.00

Start-up control with timer up to 7.5 kWto 15 kW

1,763.002,055.00

Optimix stationaryThe Optimix ECO with attached PVC plate is designed for stationary oper-ation in ring and slalom channels.

Installation can either be made

together with Z rails on a wall aperture or

into a wall slot with guide groove provided by the customer.

For the standard model the PVC plate is 98 cm wide x 200 cm high and 30 mm thick. The flow ring and frame for the motor mount are made from coated galvanized steel. As a stan-dard, 10 m of connecting cable is enclosed.

Optimix Type ECO with PVC seal plate for stationary use in the slalom system

60100

3070...180

70...90

120...140

Recommended size in cm

100...120

AG

RA

R

13

Optimix mobile for closed containers

OPTIMIX - mobileThe mobile submersible motor-driven agitator, with or without gear unit, is particularly suitable for operation with different liquid manure contain-ers. The easy to move agitator is trol-lied to the pit opening, and lowered, using the cable winch. The maximum depth is 3.5 m. Stability is ensured by a cross-bar clamped onto the pit roof. The agitator is a unit completely ready for use. The side pivoting range is approx. 110° in each direction.

The trolley on the standard model is 97 cm wide; the U75 has an alterna-tive smaller model with a width of 57 cm.

Pit openingFor the Optimix U75-1450 a minimum

opening of 32 x 62 cm is required, for

the Optimix UG75-435 with opening

of 48 x 90 cm.

Overall heightSufficient ammount of space must be

provided to set up the OPTIMIX. The

space required to set up the device

height is calculated from the lowering

depth, measured from the upper edge

of the pit plus 1.1 m.

H = T + 1.1 m

Optional telescopic guideIn case of limited roof height an optional telescopic guide pipe model can be supplied. The usable lowering depth (from the pit top edge) calcu-lated roughly by:

T = 2 · (H - 1.0)

H: maximum device height in meters

T: lowering depth in meters

Optimix U with narrow trolley and a telescopic design

OPTIMIX - mobile model, completely ready-to-use, (motor, galvanized propeller, manual switch box, bracket, trolley)

for pits up to 3.5 m deep

Type Propeller Price in EUR

U75-1450 narrow* (7.5 kW - 1,450 rpm) Ø300 5,499.00

U75-1450 standard* (7.5 kW - 1,450 rpm) Ø300 6,434.00

UG75-435 standard* (7.5 kW - 435 rpm) Ø480 7,573.00

UG110 standard* (11.0 kW - 380 rpm) Ø560 8,788.00

Surcharge for telescope for U 75 (1,450 rpm) 525.00

Surcharge for telescope for UG 75 (435 rpm) 882.00

* Since the mobile version is customizable, the desired lowering depth or device height must be indicated during ordering.

Optimix UG with trolley in standard version

AG

RA

R

14

Recordmix - for smaller to medium sized pits

Standard versionElectric motor flanged onto V2A mixing pipe (Ø 70 cm). The switch box contains a reversing star-delta switch (for bidirectional use) with a built-in motor circuit breaker and approx. 0.7 m cable. Plug is not included.

The axial forces placed on the pro-peller are supported by two taper roller bearings leading through to the agitator’s housing. Therefore the drive shaft will only experience torque when in operation.

An effective shaft seal is made on the blade side using two high quality oil seal rings. To protect the shaft the oil seal rings turn on a wearing bush-ing (no shaft wear).

The agitator pipe and propeller sup-ports are made of V2A stainless steel.

The motor handle, trolley an suspen-sion mounting frame are galvanized.

AccessoriesWe have two trolley options, 58 or 100 cm wide. Also we have a suspen-sion mounting frame EB2 with rack-and-pinion jack and pivoting latch for elevated tanks.

CAUTION:

The Recordmix L3 may only be used together with the suspension mount-ing frame EB2 or with a station-ary fixture (frame clamp for dowel fixing), that offer adequate stability against the high thrusting forces.

Accessories for RECORDMIX (galvanized)

Type Price in EUR

Standard trolley: 100 cm wide (only for Recordmix L2 / 5.5 kW) 359.00

Narrow trolley: 58 cm wide (only for Recordmix L2 / 5.5 kW) 359.00

Frame clamp for dowel fixing 182.00

Suspension mounting frame EB2 with rack-and-pinion jack for elevated tanks 1,008.00

Recordmix with trolley - optional

Recordmix in standard version with V2A piping (1.4301) and with manual control switch, without trolley or suspension mounting frame

Price in EURPIPE LENGTH

2.25 m 2.75 m 3.25 m 3.75 m 4.25 m

L2 (5.5 kW-1,450)Propeller Ø 275

1,955.00 1,975.00 2,026.00 2,046.00 2,098.00

L3 (7.5 kW-1,450)Propeller Ø 300

2,169.00 2,189.00 2,241.00 2,261.00 2,312.00

Surcharge for model: EUR

Sealing with mechanical seal SiC/SiC 429.00

Propeller in stainless steel V2A (1.4301) 185.00

Recordmix with suspension mounting frame - optional

Recordmix with trolleyRecordmix with suspension mounting frame EB2

BIO

GA

S

15

Electric Agitator for Biogas Ground Fermentors

Standard versionThe Recordmix B1 has been especially

developed for biogas lagoons with

membrane covers. Retrofitting is also

available.

The Recordmix was designed for opti-

mizing biological processes. Homoge-

neously mixing biogas substrates is

beneficial because it‘s

• preventing the formation of sink/floating layers,

• evenly distributing the temperaturein the fermentation substrate,

• distributingnutrientsforthebiologi-cal agents homogenously,

• facilitating the escape of gas fromthe substrate.

DesignRod agitator with 4 kW or 7.5 kW elec-tric motor, agitator pipe, bearing and sealing unit and propeller in low main-tenance modular design. All important components are manufactured in stain-less steel.

To protect the plastic lining on the lagoon floor, a protective ring is attached around the propeller (Ø 275 mm). A glass oil chamber is fitted to the mixer for lubrication and maintenance observation.

Included in the delivery is an agitator bracket which is used to attach the agi-tator to the concrete base. The agitator can be adjusted at any time.

The gas-tight lead-through for the agitator pipe is implemented with an EPDM60 rubber sealing membrane, which is attached to the foil with ring flanges. The agitator is thus decoupled from the foil.

The Recordmix B1 does not include a cable or a controller. The design of the lagoon must also include a mount to attach the mixer permanently.

Custom versions are available on request.

Recordmix Series B (stainless steel pipe V2A, mechanical seal SiC-SiC, coated propellers, sealing membrane, galvanized floor anchoring).

Type Price in EUR

Recordmix B1 (4.0 kW - 50 Hz - 400 V electric motor) 925 rpm - propeller Ø 300 mm - protective ring

Recordmix pipe Ø70x3 mm - 3.75 m4,274.00

Recordmix BG2 (7.5 kW - 50 Hz - 400 V drive motor) 380 rpm - propellers Ø 480 mm - scrapper

Agitator pipe Ø101.6 x 4 - 4.00 m7,014.00

Recordmix B1 in fermentation lagoon Sectional view of Recordmix B1 in fermentation lagoon

Recordmix B1 with floor mounting and sealing membrane

BIO

GA

S

16

Guide mastGuide mast 100/100/4 with floor joint

for up to 8.0 meter depth, includes

pulley unit for the hauling cable and

wall holder with gas tight cable lead-

through. Height adjustment is per-

formed by means of a Ø 8 mm V4A

hauling cable on an exterior cable

winch.

Two different versions are available:

• Gastight pivoting mast, build in ss

316 (1.4571) with a lateral adjust-

ment range ±120°, operated from

the outside and 120 cm clearance

between mast and wall

• Stationarymastwithgastightwall-

mount in ss 304 (1.4301) with lat-

eral tilt preset within a range of

±60° and 60 cm clearance

Patented designThe electrical cable guiding system is

our patented design.

The cable is guided at the rear of the

mast along a 6.0 m guide pipe, on

which cable clips are slide-mounted.

The cable clips can be inserted easily

onto the cable guide mast for flaking

of the electric cable.

Optimix and sliding mast with gastight wall lead-through, with propeller V2A, 10 m connecting cable, without controller.

Type Price in EUR

Stationary mast V2A for 6.0 m containers with gastight wall lead-through (60 cm distance), agitator height

adjustable from the exterior, lateral alignment preset4,731.00

Pivoting mast V4A for 6.0 m containers with gastight wall lead-through (120 cm distance), agitator horizontally

and laterally adjustable from outside6,611.00

OptimixUG150-380GGG40(15kWATEXZone2- propeller H620 V2A) with motor bracket in 4-roller system

6,305.00

Optimix2A135-380(13.5kWATEXZone1- propeller H620 V2A) with motor suspension in 4-roller system

7,056.00

Surcharge EUR

Surcharge for connecting cable Ø20 (7x4 +2x1 mm²), per additional meter 19.00

Additional price for shielded connecting cable Ø20 (7x4+4x1 mm²), per meter instead of standard cable

5.00 Optimix with stationary mast, gastight wall-mount (60 cm) and cable lead-through at the square pipe.

Optimix UG and 2A for biogas plants with gas-tight wall lead-through

Optimix type UG with sliding mast and pivot-ing mast with gas-tight cable lead-through .

Optimix 2A (stainless steel 1.4301)

BIO

GA

S

17

Pricing for Optimix 3G and suspension mounting frame with 150 mm glide mast

Type Price in EUR

Optimix3G250-380GGG40(25kWATEXzone2-propel-ler H850 MS galvanized) with motor bracket in 4-roller system

6,791.00

Suspension mounting frame EV5 with glide mast 150 x 150 x 5 mm V2A for 6.0 m container depth, wall bracket, pivoting gibbet with rope winch

4,426.00

Sliding mast 150 x 150 x 5 mm V4A for 6.0 m container with gastight wall lead-through (120 cm distance),

agitator horizontally and laterally adjustable from outside7,955.00

Surcharge EUR

Cable clips V4A with a carabiner for the connecting cable Ø 25 mm 24.00

Surcharge for connecting cable Ø25 (4x10+4x1 mm²) per meter 19.00

Surcharge per 0.5 m for guide mast 150x150x5 to 10 m 138.00

Optimix 3GThe new Optimix 3G is based on proven technology of previous sub-mersible models.

It has been designed for higher per-formance, continous operation and has a newer streamline design.

The mixer has 25.0 kW nominal output, during intermittent duty up to 28.7 kW (S3-40% duty cycle). The epicyclic gear (i=5.35) is designed for 30 kW and turns the propeller with about 270 rpm (50 Hz). Temperature sensors (PTC 130) have been installed to ensure safe operation.

Additional FeaturesMotor protection IP 68 - 10 m. The standard 4-pole motor has a high degree of efficiency and thereby a small nominal power input of 48 A (at 400 V, 50 Hz).

The drive shaft ø 45 mm is protected by a mechanical seal with SiC / SiC ceramic rings. Thrusting forces are transferred to the motor housing by two taper roller bearings. Due to the motor bracket with 4-roller guide that is integrated in the housing the Optimix 3G can be used for up to a 150 mm guide mast.

As a standard, the Optimix 3G is delivered with a 10 m connection cable Ø 25 mm (4x10+4x1 mm²), however without a switch.

A softstart or a frequency converter is required to turn on/off the Opti-mix 3G.

Technical data for the motor / drive:

•Operationalvoltage400V(50Hz)

•Nominaloutput25kW

•Nominalcurrent48.0A

•Powerfactorcos0.84

•Rotationspeed270rpm

•PushpropellerMSØ850mm

•Weight260kg

Different electrical specifications are available upon request.

Optimix 3G for biogas plant with gas-tight wall lead-through

Optimix 3G with gas-tight wall lead-through and adjustment (120 cm) from the outside, for closed containers

Optimix 3G with EV5 and working platform and control for open containers

BIO

GA

S

18

Giantmix FR with 30° seal plate

Price for Giantmix FR in the standard version for biogas containers (zone 2) with propeller V2A and without controller.

Price in EURO for type PropellerPipe length

3.00 m 4.00 m

FR3 -11 kW / 30° seal plateH580

9,159.00 9,447.00

FR3 - 11 kW / slewing ring ±25° 10,589.00 10,878.00

FR4 - 15 kW / 30° seal plateH620

9,317.00 9,605.00

FR4 - 15 kW / slewing ring ±25° 10,748.00 11,037.00

FR5 - 18.5 kW / 30° seal plateH660

9,832.00 10,120.00

FR5 - 18.5 kW / slewing ring ±25° 11,263.00 11,551.00

FR3 - 22 kW / 30° seal plateH700

11,024.00 11,312.00

FR6 - 22 kW / slewing ring ±25° 12,455.00 12,743.00

Surcharge for EUR

Thick-walled pipe 1.4301 V2A Ø 101.6 x 5.7, per meter of pipe length 274.00

Protective rain cover V2A for the electric motor 404.00

Second sealing membrane for double safety 297.00

Power take-off guard with safety device (for tractor-hitched operations) 304.00

Rack and pinion with winch instead of top link: on 30° plateson slewing ring design

524.00653.00

InstallationThe installation is done from the out-side through a min. opening of Ø 60 cm up to a max. of 70 x 70 cm in the container wall. (I.e. in the case of a subsequent installation the level only needs be lowered until it is below the installation opening.)

Standard versionDrivemotor(ATEX,zone2)withspurgear unit and PTO stub (equipped for tractor-hitched operations), 4.0 mm agitator pipe and propeller in ss 304 (V2A), top link for inclination adjust-ment, piping lead-through sealed by means of a technically tight rubber membrane made from EPDM60. The drive shaft is sealed by means of a mechanical seal with SiC/SiC ceramic rings; two taper roller bearings to absorb thrusting forces. The tubu-lar shaft is fitted with intermediate bearings in the agitator pipe.

Our unique “scraper” design includes a blade scraper, that takes off fibres from the propeller blade, ensureing smooth and efficient running.

A clear oil expansion reservoir serves as an indicatior for maintenance.

Different versions available:•Fixedsealingplate(98x98cm)in

ss 304 (V2A) with a fixed 30° dis-placement to the side of the pro-peller and galvanized joint device.

•Dynamic sealing frame (98 x 98cm) and cover plate in ss 304 (V2A). Joint device, slewing ring ± 25° for lateral adjustment and rotatable console are galvanized.

VersionsStandard propeller speed is about 390 rpm at mains with 50 cycles. Low-speed version with 200 rpm upon request!

Versions in ss 316 (V4A), as well as other plate sizes and lower power ratings or other pipe lengths are available upon request.

Giantmix FR with live ring ±25° and power take-off for tractor-hitched operations

GIANTMIX FR for biogas plants

Giantmix FR with 30° seal plateGiantmix FR in concrete tank

BIO

GA

S

19

Giantmix AMTDrivemotor(ATEXZone2)inpowerstages 18.5 kW (130 rpm) und 28 kW (270 rpm)

The agitator pipe Ø220 mm ss 316 (V4A) is up to 6.5 m long and has a wall strength of 8.2 mm. The high performance push propeller is made of hardened steel.

A hydraulic cylinder with manual pump is used for the height adjust-ment. The side agitating direction is already preset at about 15° left (or right) and can be modified addition-ally ±25° at the slewing ring. The gas and liquid sealing of the pipe lead-through is done with a reinforced sealing membrane, which is approved for an installation depths up to 8 m.

This membrane is attached to a seal-ing plate and screwed onto a seal-ing box 143 x 143 cm with 8 mm wall thickness (V2A). This allows the mixer to be removed for mainte-nance w/o disturbing the sealing on the tank wall.

Joint device, slewing ring and rotat-able console are galvanized. The drive shaft is sealed using a mechan-ical seal with SiC/SiC ceramic rings. The drive shaft in the agitator pipe is fitted with intermediate bearings. The oil expansion container serves for visual monitoring of the seals.

The scope of delivery does not include a cable or a controller. The use of a frequency converter is recommended.

Technical data:•Operationalvoltage400/690V•Drivepower28kWor18.5kW•Nominalcurrent52A(SL)or38A(LL)•Motorspeed1.475rpmor730rpm•Propellerspeed270rpmor130rpm•Powerfactorcos =0.85•Drivei=5.35•IngressProtectionIP55•Mixerweightsabout1,300kg

GIANTMIX AMT for biogas plants

Pricing for Giantmix AMT with reinforcing frame V2A, slewing ring ±25° galvanized, agitator pipe V4A Ø 220 x 8.2 mm, hydraulic height adjustment,

TYPE Price in EUR

AMT7(28kW/ATEXZone2)-6.0mpipelength,Push propeller MS Ø 850 mm hardened steel with 270 rpm at 50 Hz

23,090.00

AMT5(18.5kW/ATEXZone2)-6.0mpipelengthPush propeller MS Ø 1200 mm hardened steel with 130 rpm at 50 Hz

24,289.00

Giantmix AMT mounted on tank wall Giantmix AMT in tank

Giantmix AMT available with fast-speed or low-speed motor, spur gear unit (75 dB), up to 6.5 meter pipe length, pipe-Ø220 mm in V4A, with slewing ring ±25°, hydraulic inclination adjustment, usable for up to 8 m below fill level.

Giantmix AMT mounted on tank wall Giantmix AMT in tank

Different electrical specifications are available upon request.

8. Reservation of TitleThe subject of the delivery shall remain our property until all our monetary claims aris-ing out of the business relationship with the Purchaser, including ancillary claims and claims for damages, have been satisfied in full and checks and bills of exchange have been honored in full. The Purchaser shall be entitled to dispose of the goods subject to our reservation of title in the ordinary course of business, so long as he properly fulfills his obligations to us. The Purchaser hereby assigns inn advance all claims arising out of the resale of the delivered goods subject to our reservation of title, with all ancillary and security rights inncluding claims arising out of checks and bills of exchange as security for all payment obligations arising out of the business relatioonship wiith us. If the value of the securities to which we are entiitled exceeds the claims against the Purchaser to be secured by more than 20 %, then we are obligated, at the request of the Purchaser, to release these seecurities to the extent that these in total exceed the claims to be secured by more than 20 %. In the event of any breach of contract by the Purchaser, in particular default in payment, we shall be entitled to withdraw from the contract and demand that the goods be returned.

9. WarrantyIf the service we provide or the product we deliver is failing, then the purchaser shall, provided he is not responsible for the imperfection, be entitled to demand rectification or, at our option, delivery of a new product. If the rectification is not successful or if neither rectification nor delivery of a new, free from defects product is made within a reasonable period or if such is refused, then the Purchaser may, at its option, demand either a reduction of the purchase price commensurate with the imperfection, or with-draw from the contract. All claims for rectification, replacement or withdrawal from the contract or reduction of the purchase price on grounds of obvious or, within the meaning of § 377 II German Commercial Code (HGB), recognizable defects are excluded if the Purchaser does not give written notice thereof within 10 days after receipt of the goods. §§ 377, 378 German Commercial Code (right to rely on a lack of conformity of the goods is lost if the Purchaser fails to give notice within the aforesaid period) shall apply in all other cases. Any agreement made by our representatives in relation to quality must be set down in writing. The Purchaser is aware that contact with aggressive media (e.g. liquid manure or sewage) may result in signs of corrosion appearing on the product pur-chased; this shall not constitute any product defect. We shall not give any warranty or assume any liability in respect of damage resulting from the following causes: Unsuitable or improper use, natural wear, wear resulting from above-average strain, in particular on bearings and sealing elements, incorrect assembly or start-up by the Purchaser or any third party, incorrect or negligent handling and unsuitable operating resources. Claims for defects by purchasers who are business persons shall become statute-barred after the expiry of one year of the product being delivered.

10. Compensation for damagesIn the event that any duty is neglected as a result of ordinary negligence, we as well as our vicarious agents shall only be liable to the extent of immediate, foreseeable and average damage typically caused by the nature of the contract. We, as well as our vicari-ous agents, shall not be liable for any neglect of duty resulting from ordinary negligence and not essential to the contract if such neglect does not jeopardize execution of the contract. The afore-mentioned restrictions on liability shall not affect any Purchaser claims arising on the basis of product liability, fraudulent misrepresentation or warranty. Furthermore, the restrictions on liability shall not apply to damage attributable to us as a result of harm to life, physical injury or impairment to health.

11. Product observation, participation in recall activities, duty to give noticeThe purchaser shall undertake to keep the goods under observation and to assist us in carrying out any product observation duties. The purchaser shall undertake to help us as well as the enforcement authorities with any recall activities that may become neces-sary. For this purpose, it shall, in particular, be necessary to preserve and make available all documents that provide the means to retrace products to the end customer/point of installation. The purchaser shall be required to notify us immediately of any reason to assume that a product marketed or used by the Purchaser is unsafe.

12. Place of PerformanceThe place of performance for all obligations shall be Sulzberg.

13. Applicable Law and JurisdictionThe law of the Federal Republic of Germany, with exclusion of the UN Convention on the International Sale of Goods or other international conventions for the regulation of the sale of goods, shall apply to the extent that nothing different was expressly agreed. The courts of Kempten/Allgäu shall have exclusive jurisdiction for all disputes relating to this business relationship and agreement.

14. Partial InvalidityIf any individual provision of these terms and conditions shall be invalid in whole or in part, this shall not affect the validity of the remaining provisions. The parties shall replace the invalid provision by such a provision which comes closest to the economic purpose of the invalid provision and is valid.

GENERAL TERMS AND CONDITIONS OF SALE, DELIVERY, PAYMENT AND WARRANTY (Effective: 06/2008)

1. ScopeThese general terms and conditions of sale shall apply to all deliveries and services ordered from us by the purchaser. These terms and conditions of sale shall also apply for all additional and subsequent orders, contract supplements and amendments without having to be referenced in the individual case, unless otherwise agreed upon. The general terms and conditions of the purchaser are not accepted to the extent that they differ in substance from the following terms and conditions of sale and/or contain additional provisions. If one contract party relies on an agreement which is not confirmed in writing and which deviates from the following terms and conditions of sale, then such party shall bear the burden of proof in the event of dispute.

2. OffersOur offers are subject to change and are non-binding. To the extent that orders were not expressly confirmed by us, they shall be deemed to have been accepted by us as of the time of receipt if they have not been refused within 14 days after the issuance of the order. Brochures or the technical documents attached to our offer or the order confirmation, as well as illustrations, drawings, construction suggestions, etc. are general guidelines, to the extent that specific details are not expressly warranted or designated as binding. We reserve the right to make technical improvements in the construction or production methods. We retain rights of use and ownership to the documents contained in the offer (i.e. cost estimates, drawings etc.), to the extent that their preparation is not to be compensated separately by the Purchaser and this compensation has not been paid. Documents contained in the offer may not be given to third parties, published, repro-duced or used for other than the agreed purpose without our approval. If the purchaser does not accept the offer, then the documents contained in the offer and belonging to us shall be returned immediately and completely upon demand.

3. PricesThe prices given are net prices and shall apply to the delivery of unpacked goods ex-works Sulzberg or ex-warehouse from our sales agencies. The transport shall be invoiced separately as an additional service. Any necessary packing shall be invoiced at our own cost and shall not be accepted for return. If the statutory value-added tax changes between conclusion of the contract and delivery, then the net price plus the value-added tax in effect at the time of delivery shall be paid. If there is a period of more than eight weeks between conclusion of the contract and the agreed delivery date, then the Purchaser shall pay for the goods at the list price set by us and generally valid at the time of the delivery.

4. Payment Terms/Late PaymentInvoice amounts shall be due and payable at the latest within 30 days after the date of the invoice. If the invoice amount is not received by us at the latest 40 days after receipt of the invoice, to the extent that the Purchaser is responsible for the delay and payment default has not already occurred prior thereto, this shall be a payment default without requiring any notice thereof. We shall calculate interest on late payments at a rate equal to 8 5 above the basis interest referred to in § 247 of the respective, current German Civil Code (BGB). The claim of greater damages for late payment is not excluded. If the Purchaser is late in payment of an installment in the event of agreed installment payments, then the entire amount still owed shall be due and payable. All payments shall be addressed to us directly.

5. Compensation, Right of Retention and Prohibition of AssignmentThe Purchaser may only set off or assert a right of retention against our claims, where the claim intended by him to be set off or the claim which is the subject of the right of retention is undisputed, has been determined by legally binding decision or a legal proceeding conducted concerning the issue is ready for decision. To the extent that a right of retention is not permissible under the above provision, the rights of retention provided in §§ 369 and 371 German Commercial Code (right of a creditor to retain moveable assets or securities of a debtor if both creditor and debtor are business men and acting in the course of their business) shall also be excluded. The Purchaser may not assign his claims against us.

6. Delivery and Transfer of RiskThe shipment of goods ordered shall take place ex works Sulzberg or ex warehouse from our sales agencies. If the purchaser desires to have the goods transported to a destination specified by him, then he shall bear the cost and the risk of transport. The shipment of the goods shall take place at the risk of the Purchaser even if as an excep-tion we accept responsibility for the cost of the transport. Prior to the shipment of the goods, the purchaser shall bear the risk of destruction, loss of possession or damage to the purchased goods for which neither party is responsible, if upon the request of the Purchaser the delivery of the goods which are ready for shipping shall be undertaken at a later date than that originally provided. The risk shall then pass to the Purchaser upon expiration of the delivery date originally provided. Insurance shall be taken out only at the request of the purchaser and at their cost.

7. Deadlines for Deliveries and ServicesTo the extent that we are not responsible for delays in production, deliveries or services, the deadline for delivery or service shall be reasonably extended.